Adjustable hydraulic frock

A tooling and hydraulic technology, applied in the mechanical field, can solve problems such as unsatisfactory clamping and positioning, insufficient rigidity, etc., and achieve the effects of improving clamping accuracy and reliability, preventing parts from deforming, and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

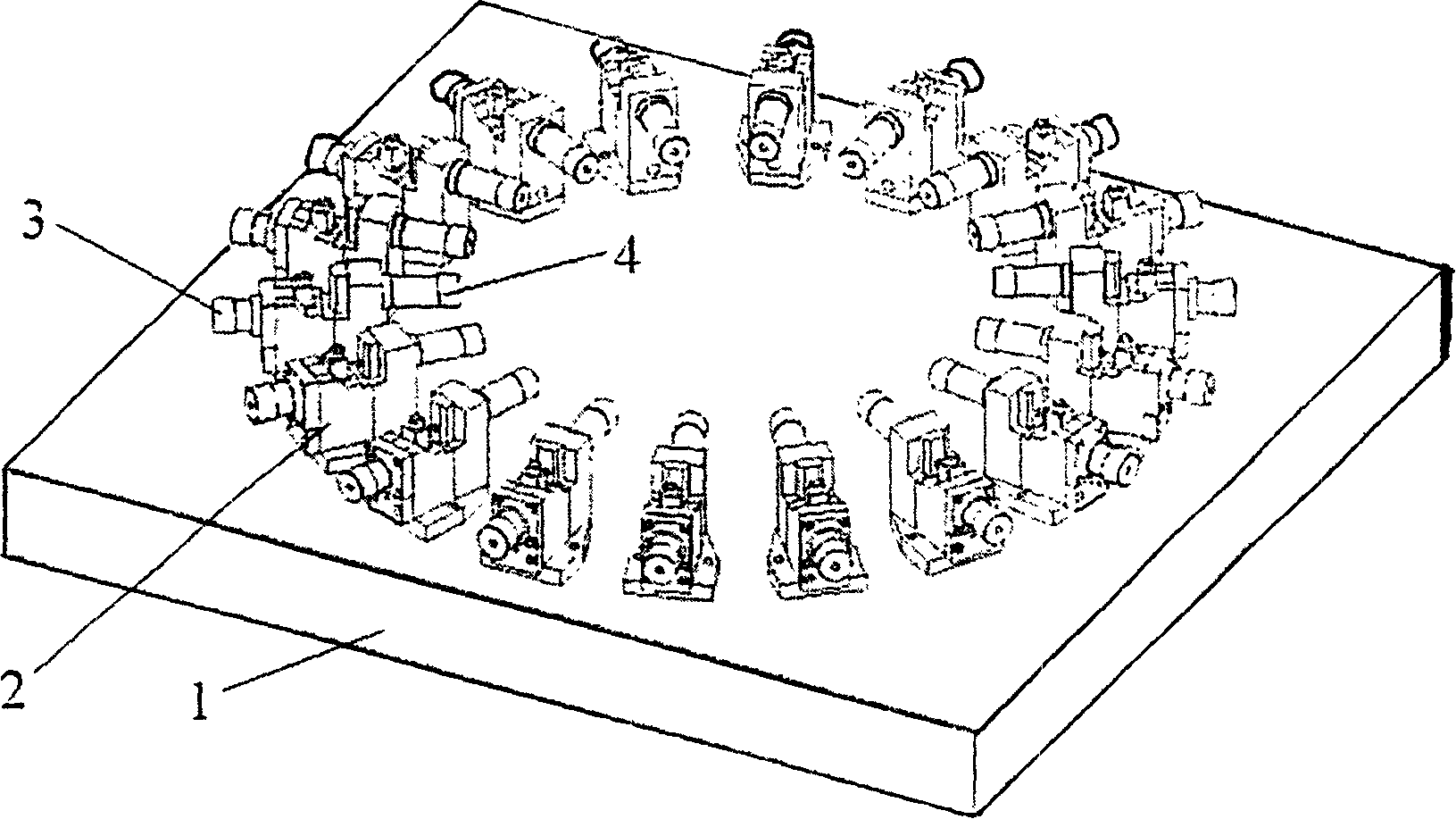

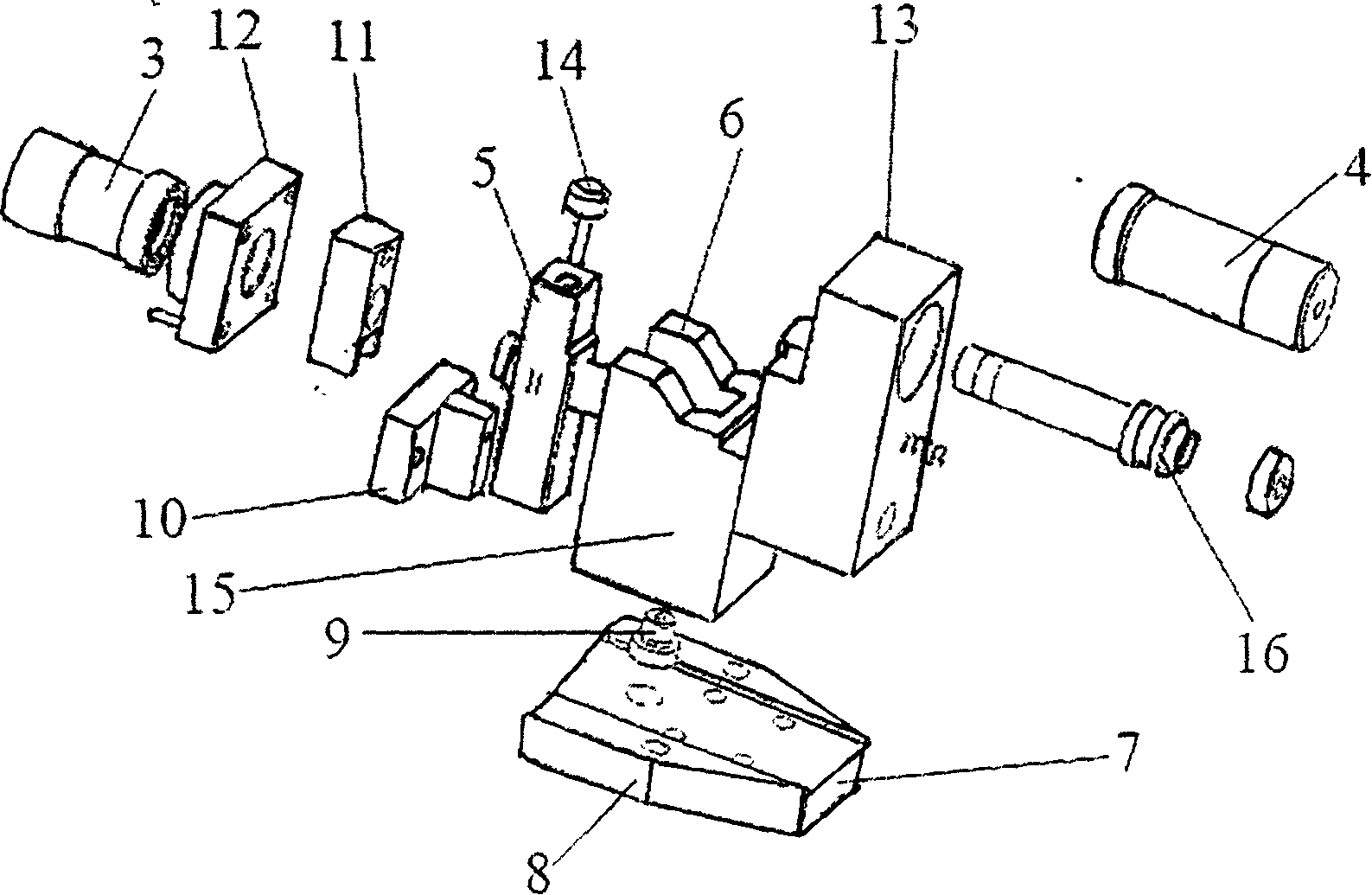

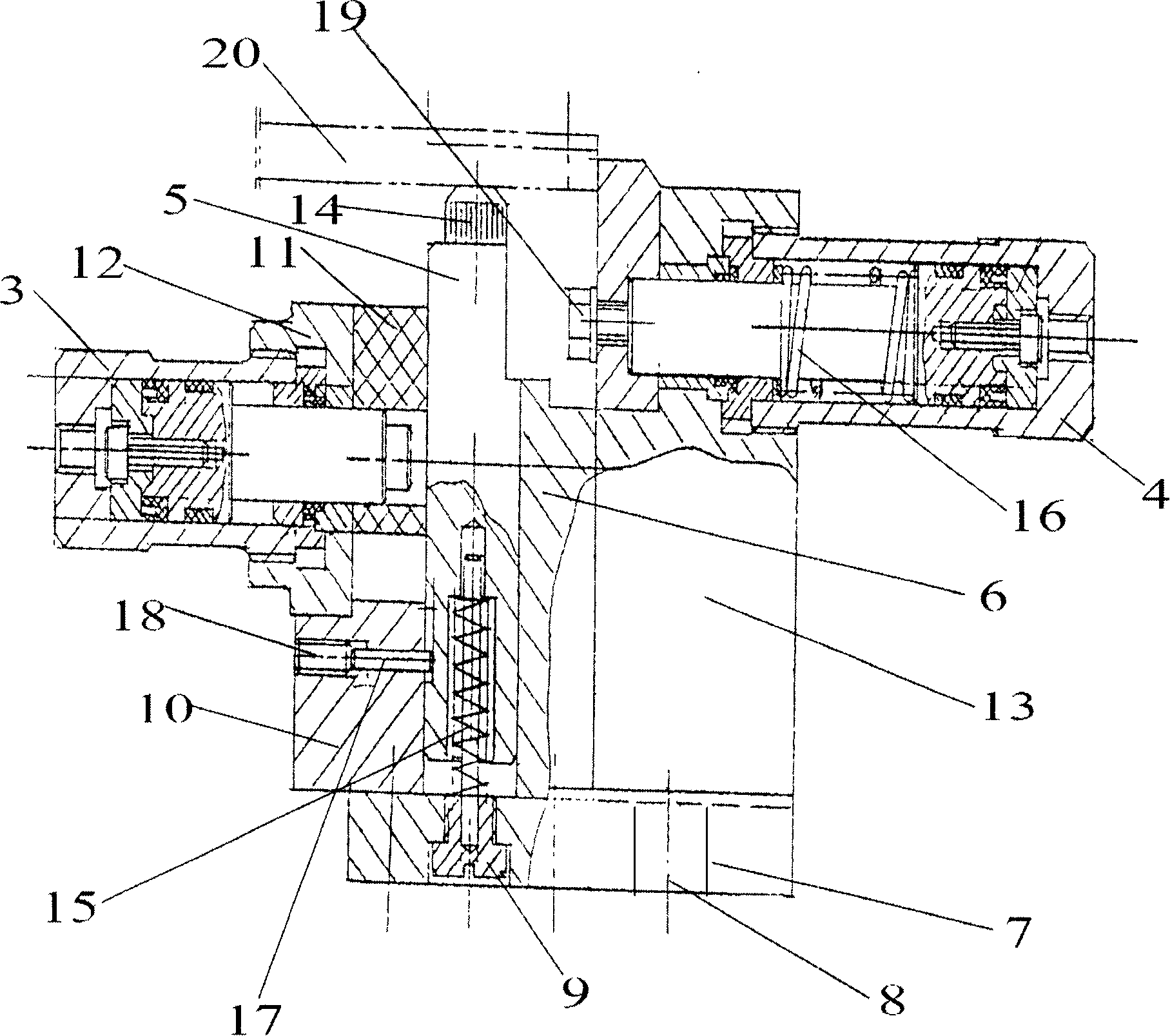

[0013] Such as figure 1 , figure 2 and image 3 As shown, the adjustable hydraulic tooling of the present invention is composed of an installation platform 1 and a plurality of support devices 2, wherein the number of the support devices 2 is 18, and any support device 2 is fixedly arranged on the installation platform 1, the support devices 2 are arranged in equal circles along the circumferential direction, and any support device 2 is formed by a support seat 7, and the support seat 7 is fixedly connected with the installation platform 1 through fasteners, and the upper side of the support seat 7 A lifting base 6 is provided, and a vertical through hole is arranged in the lifting base 6, and a lifting rod 5 is arranged in the vertical through hole, the lower end of the lifting rod 5 is connected with the support base 7, and one side of the lifting base 6 is connected with a Tightening oil cylinder mounting seat 13, tensioning oil cylinder mounting seat 13 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com