Flexible locating and combined locking type rough turning clamp of large thin-wall flange

A flexible positioning and flange technology, used in the field of vehicle fixtures, can solve the problems of poor positioning reference, trouble, flange roundness and flatness out of tolerance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

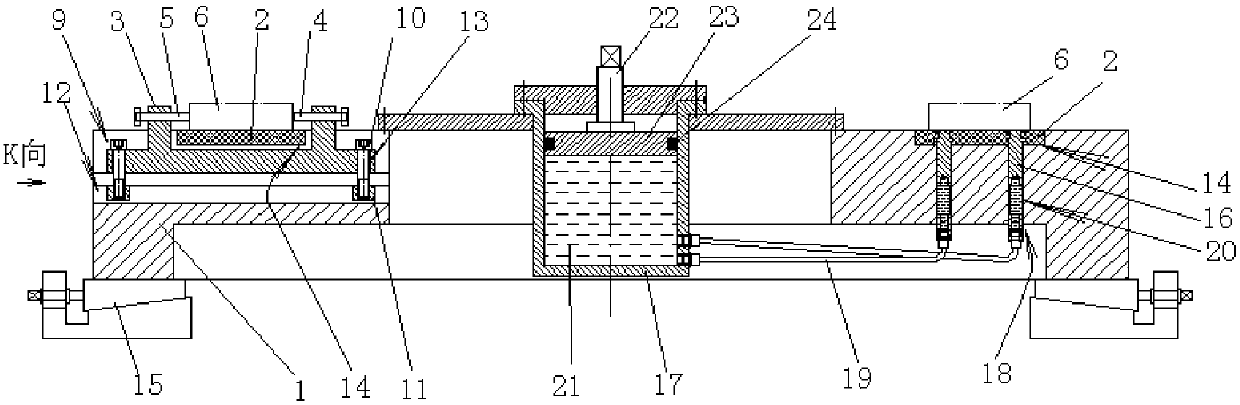

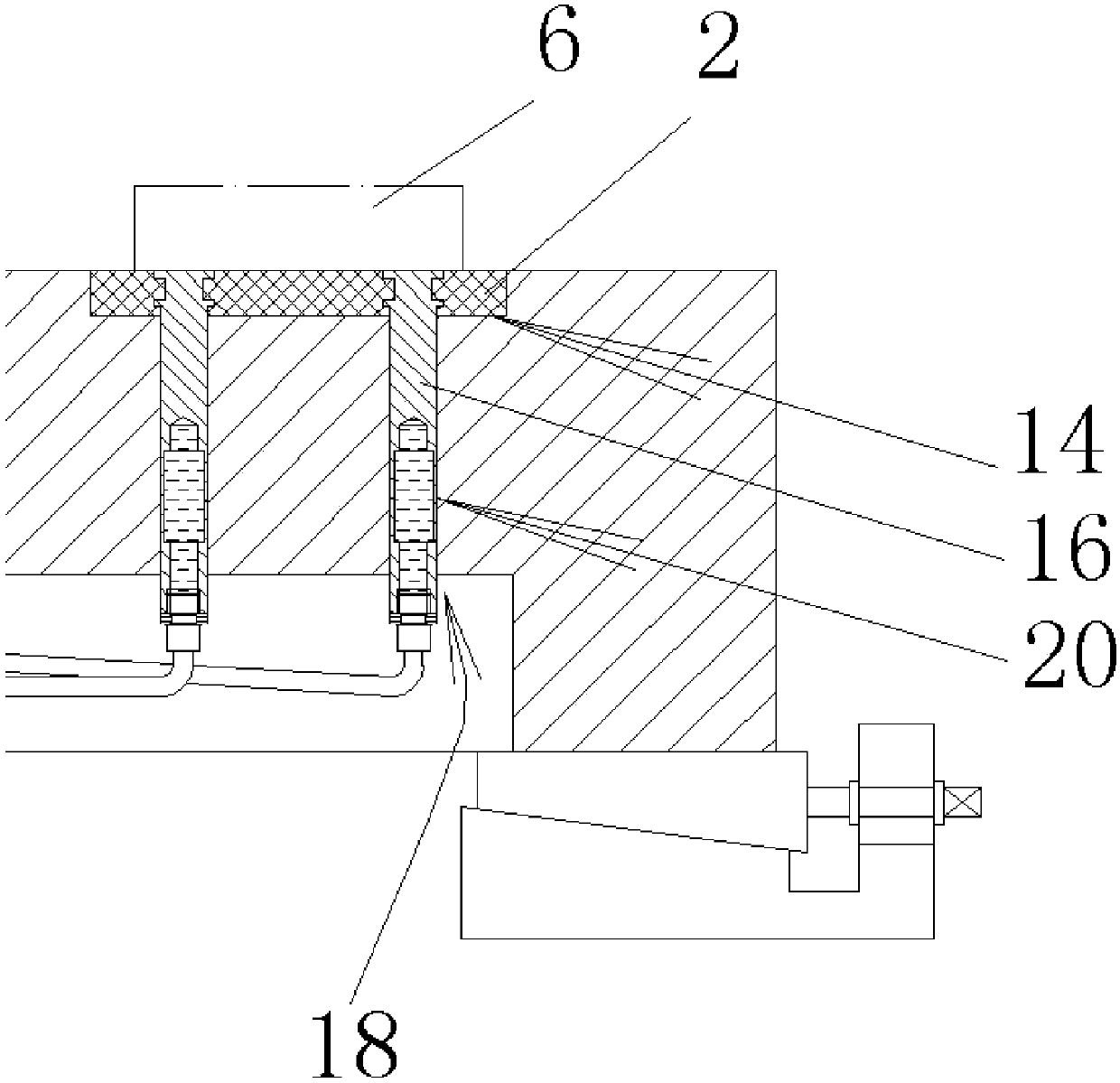

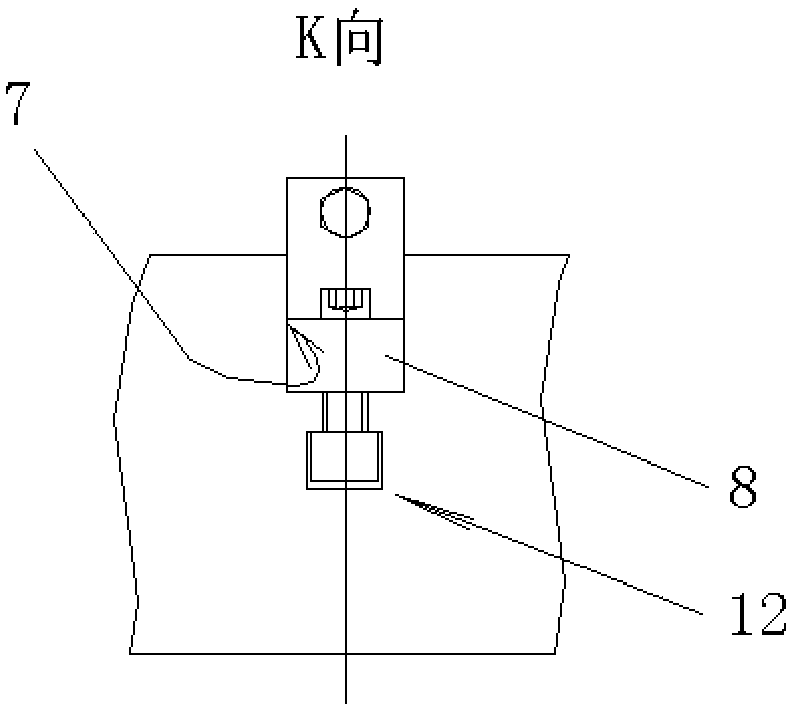

[0030] Such as Figures 1 to 4Shown is an embodiment of the flexible positioning and joint locking type roughing fixture of a large thin-walled flange of the present invention, including a chassis 1 and a flexible positioning device for positioning the end face of the flange blank, and is used for simultaneously clamping the inner surface of the flange. The floating clamping device of the hole and the outer circle, the combined locking device for fixing the flexible positioning plane of the flexible positioning device; the flexible positioning device includes a soft rubber positioning plate 2 installed on the chassis 1 and several A rigid guide post 16 per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com