Special clamp structure for large-power brake drum

A special fixture and brake drum technology, applied in the direction of manufacturing tools, clamping, support, etc., can solve the problems of poor control of workpiece clamping deformation, poor clamping consistency, poor precision retention, etc., to achieve reliable clamping Good tonality, uniform distribution of clamping force, and enhanced market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

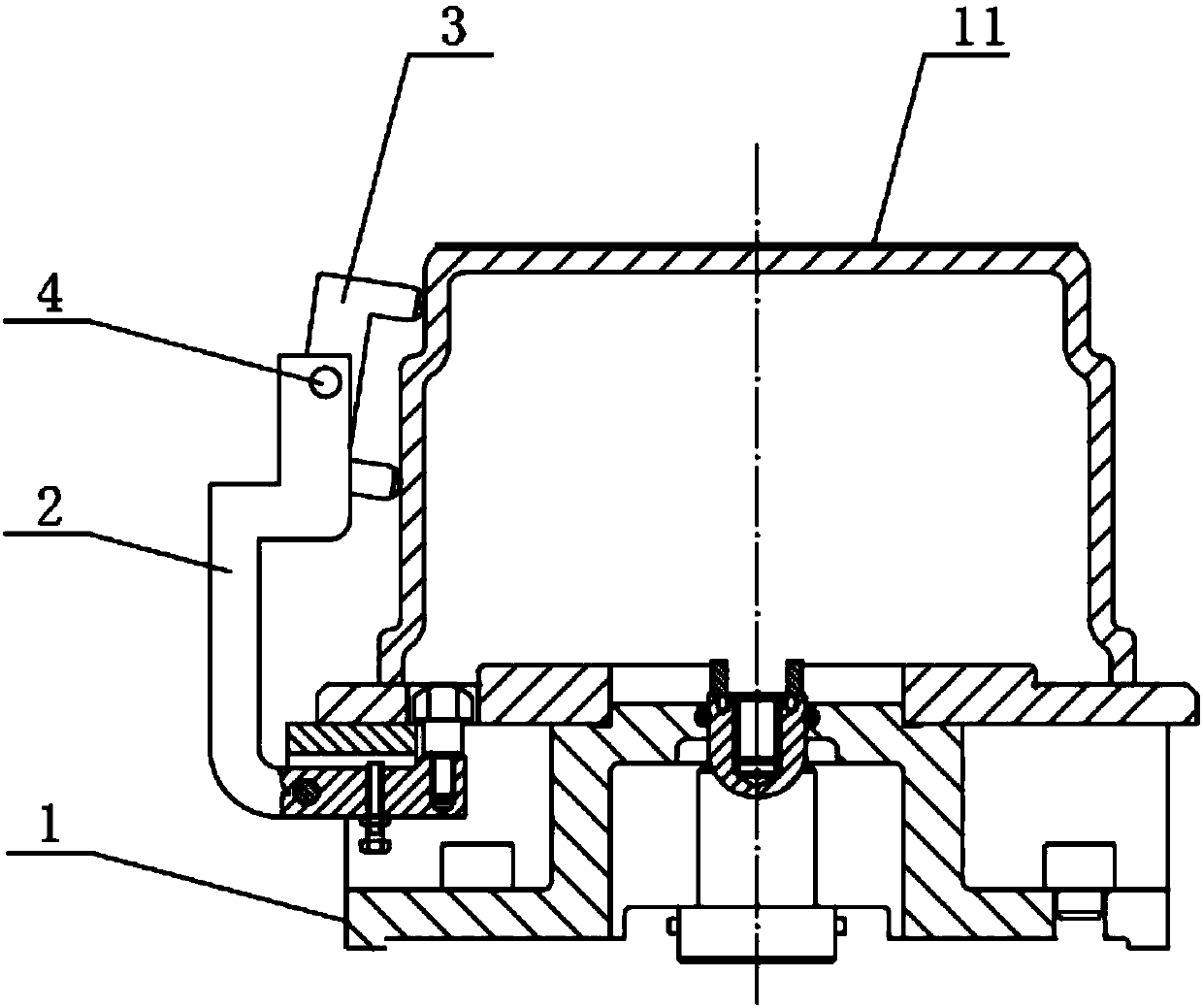

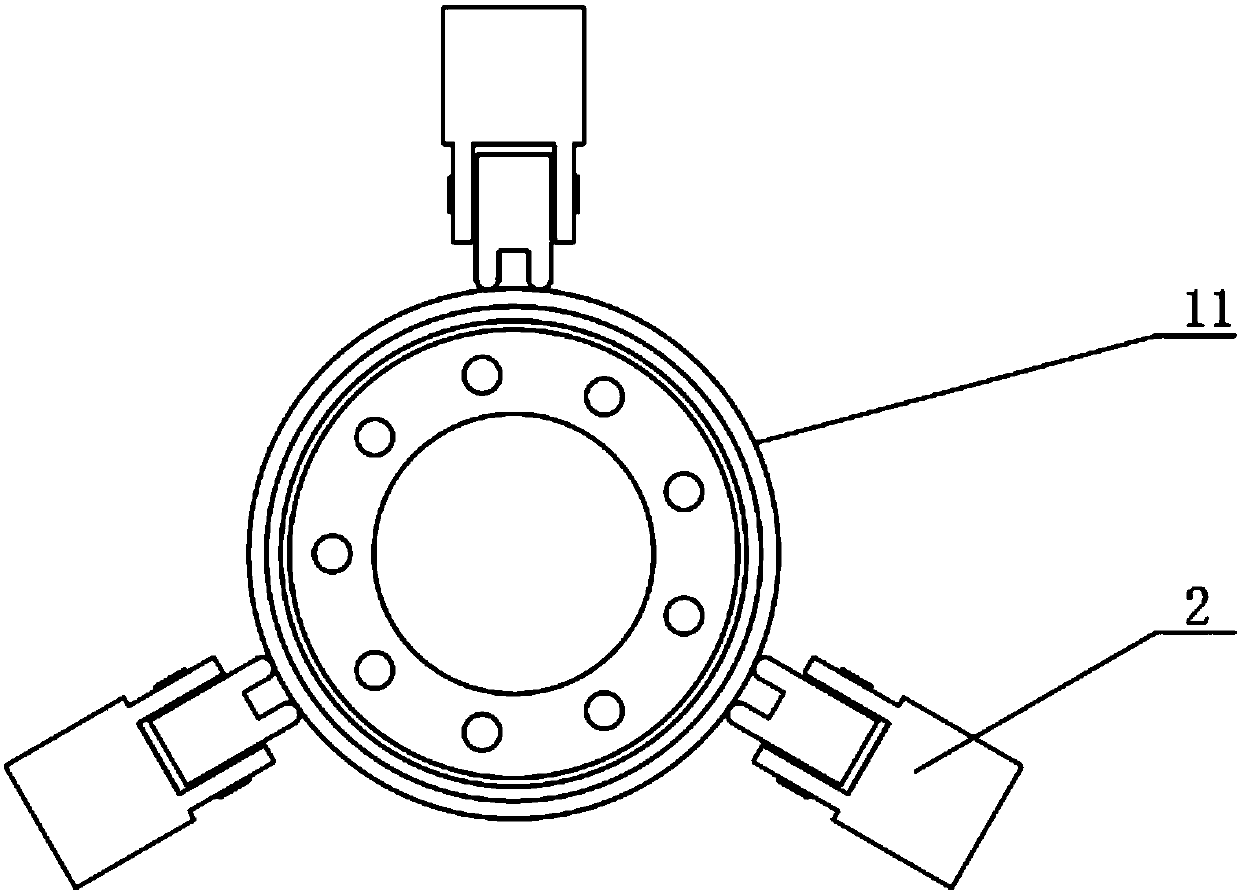

[0025] as attached figure 1 to attach Figure 5 Shown:

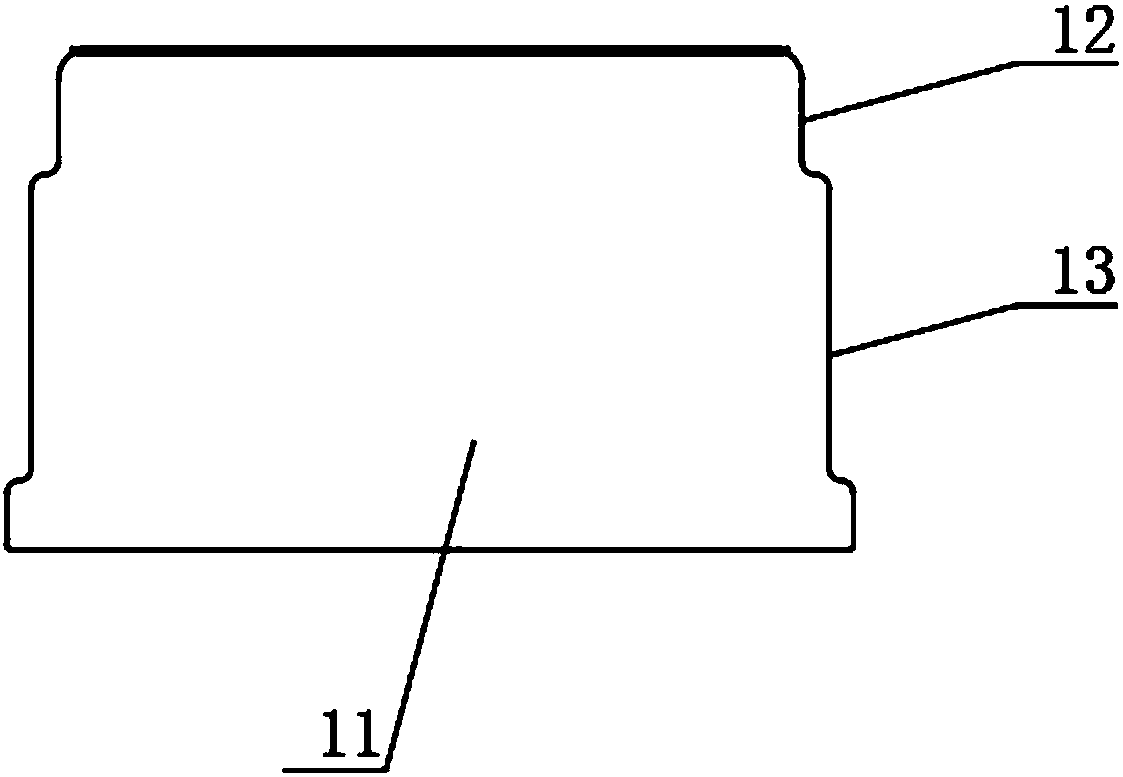

[0026] The present invention provides a special fixture structure for a large power brake drum, which includes a brake drum 11, an upper cylindrical surface 12, a lower cylindrical surface 13, a chuck seat 1, a claw bracket 2, a claw 3, a claw seat 31, a Claw body 32, rubber contact 321 and hinge shaft 4; the brake drum 11 includes an upper cylindrical surface 12 and a lower cylindrical surface 13; the bottom of the jaw bracket 2 is connected to the chuck seat 1; the jaw 3 is hinged on the claw bracket 2 through a hinge shaft 4; the claw 3 includes a claw seat 31 and a claw body 32.

[0027] Wherein, the rotation angle of the claw 3 on the claw bracket 2 is 0-30°, and the limitation of the rotation angle of the claw 3 avoids excessive rotation of the claw 3 and affects the efficiency of the next clamping.

[0028] Wherein, the claw 3 is a hoof-shaped structure, and the claw body 32 is provided with four places on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com