Quick-change aluminum alloy anodic oxidation hanging tool

A technology of anodizing hangers and aluminum alloys, applied in the direction of anodizing, electrolysis process, electrolysis components, etc., can solve the problems of uneven clamping points around the circumference, adjustment of support inner holes, deformation of parts, etc., to solve the problems of cost and cycle. effect, avoid clamping deformation, overcome uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

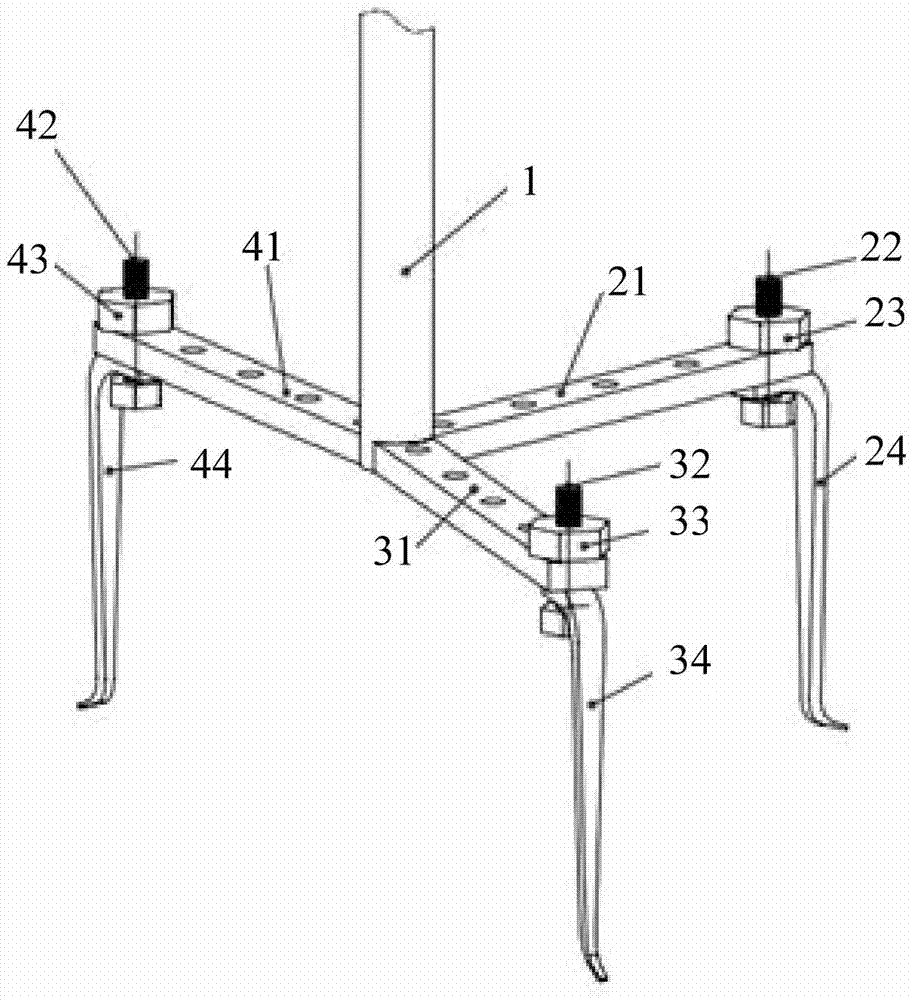

[0013] Such as figure 1 As shown, the quick-change aluminum alloy anodized hanger includes a hanger body 1 and three adjustment support bars, that is, the bottom end of the vertically set hanger body 1 is horizontally welded and fixed to the first adjustment support bar 21 and the second adjustment support bar 31 and the third adjustment support bar 41, the shape and size of the three adjustment support bars are the same, the first adjustment support bar 21, the second adjustment support bar 31 and the third adjustment support bar 41 are evenly distributed with respect to the circumference of the hanger body 1, Vertical through holes are distributed at intervals on each adjustment support bar. The first spring foot 24 is fixed on the first adjustment support bar 21 by the first compression bolt 22 and locked by the first lock nut 23. The second spring foot 34 Fixed on the second adjustment support bar 31 by the second compression bolt 32 and locked by the second lock nut 33, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com