Preparation method of zinc oxide thin film photocatalyst

A technology of zinc oxide thin film and photocatalyst, which is applied in the fields of environmental protection, inorganic materials and photocatalysis, can solve the problems of a large number of surfactant operation steps, and achieve the effect of facilitating recovery and reuse, improving sample purity and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

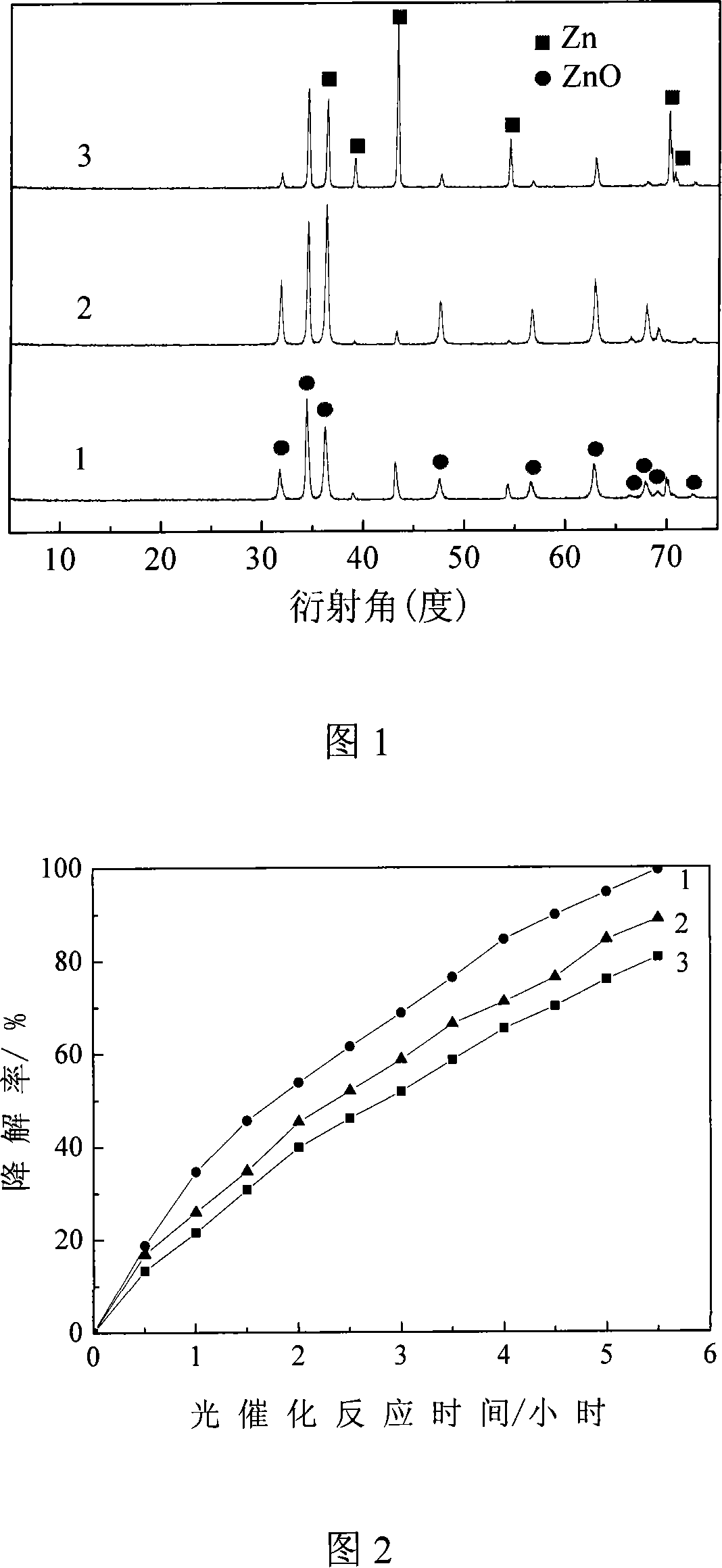

[0021] Clean a commercially available metal zinc sheet with a purity greater than 99.9%, a thickness of 0.1cm, and an area of 1cm×1cm in ultrasonic waves with distilled water, absolute ethanol and acetone, and put the cleaned zinc sheet into 20ml polytetrafluoroethylene Add 4ml of distilled water into the lined autoclave, seal the container and put it in a 100°C incubator to react for 48 hours. After cooling, take out the zinc flakes and dry them to obtain the zinc oxide film. Curve 1 in accompanying drawing 1 is the X-ray diffractogram of obtained product, can find out from the figure, obtained product diffraction peak is the diffraction peak of zinc oxide except the diffraction peak of substrate zinc plate, and no unnecessary impurity peak occurs. In this patent, the activity of zinc oxide is evaluated by the degradation rate of zinc oxide film photocatalytically degrading methyl orange under ultraviolet light. Curve 1 in accompanying drawing 2 is the degradation rate diag...

Embodiment 2

[0023] Clean a commercially available metal zinc sheet with a purity greater than 99.9%, a thickness of 0.1cm, and an area of 1cm×1cm in ultrasonic waves with distilled water, absolute ethanol and acetone, and put the cleaned zinc sheet into 20ml polytetrafluoroethylene Add 4ml of distilled water into the lined autoclave, seal the container and put it in a thermostat at 140°C to react for 24 hours. After cooling, take out the zinc flakes and dry them to obtain the zinc oxide film. Curve 2 in accompanying drawing 1 is the X-ray diffractogram of obtained product, as can be seen from the figure, obtained product diffraction peak except the diffraction peak of substrate zinc flake, is the diffraction peak of zinc oxide, and no unnecessary impurity peak occurs. In this patent, the activity of zinc oxide is evaluated by the degradation rate of zinc oxide film photocatalytically degrading methyl orange under ultraviolet light. Curve 2 in accompanying drawing 2 is the degradation ra...

Embodiment 3

[0025] Clean a commercially available metal zinc sheet with a purity greater than 99.9%, a thickness of 0.1cm, and an area of 1cm×1cm in ultrasonic waves with distilled water, absolute ethanol and acetone, and put the cleaned zinc sheet into 20ml polytetrafluoroethylene Add 4ml of distilled water to the lined autoclave, seal the container and put it in a 180°C incubator to react for 4 hours. After cooling, take out the zinc flakes and dry them to obtain the zinc oxide film. Curve 3 in accompanying drawing 1 is the X-ray diffractogram of obtained product, can find out from the figure, obtained product diffraction peak is the diffraction peak of zinc oxide except the diffraction peak of substrate zinc plate, and no unnecessary impurity peak occurs. In this patent, the activity of zinc oxide is evaluated by the degradation rate of zinc oxide film photocatalytically degrading methyl orange under ultraviolet light. Curve 3 in accompanying drawing 2 is the degradation rate figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com