High-speed numeric control automatic regulating gill

A self-leveling, needle-carding machine technology, used in deburring devices, textile and papermaking, fiber processing, etc., can solve the problems of cumbersome debugging, difficult management, limited leveling ability, etc., to reduce unfavorable factors, improve mechanical structure, Manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

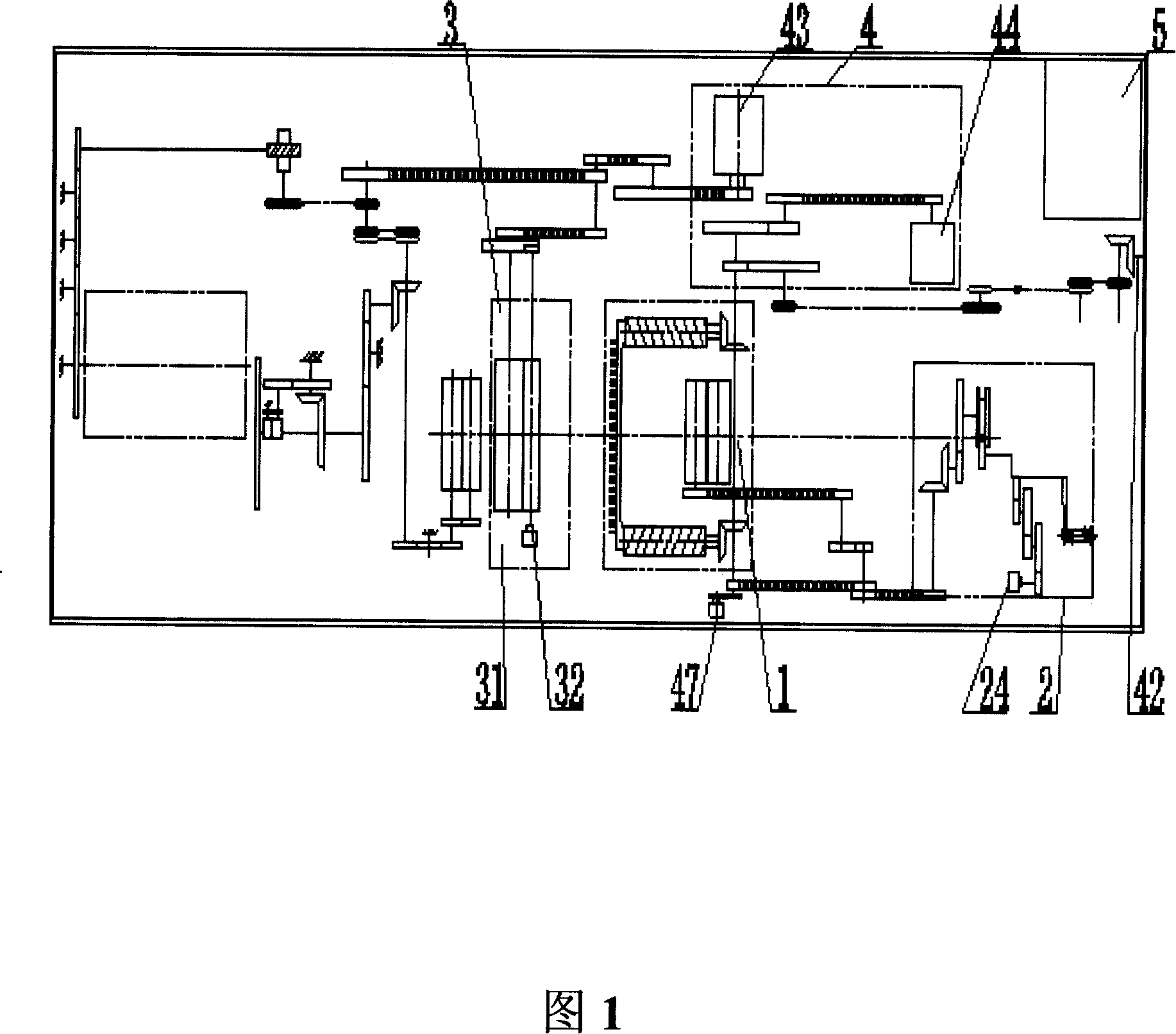

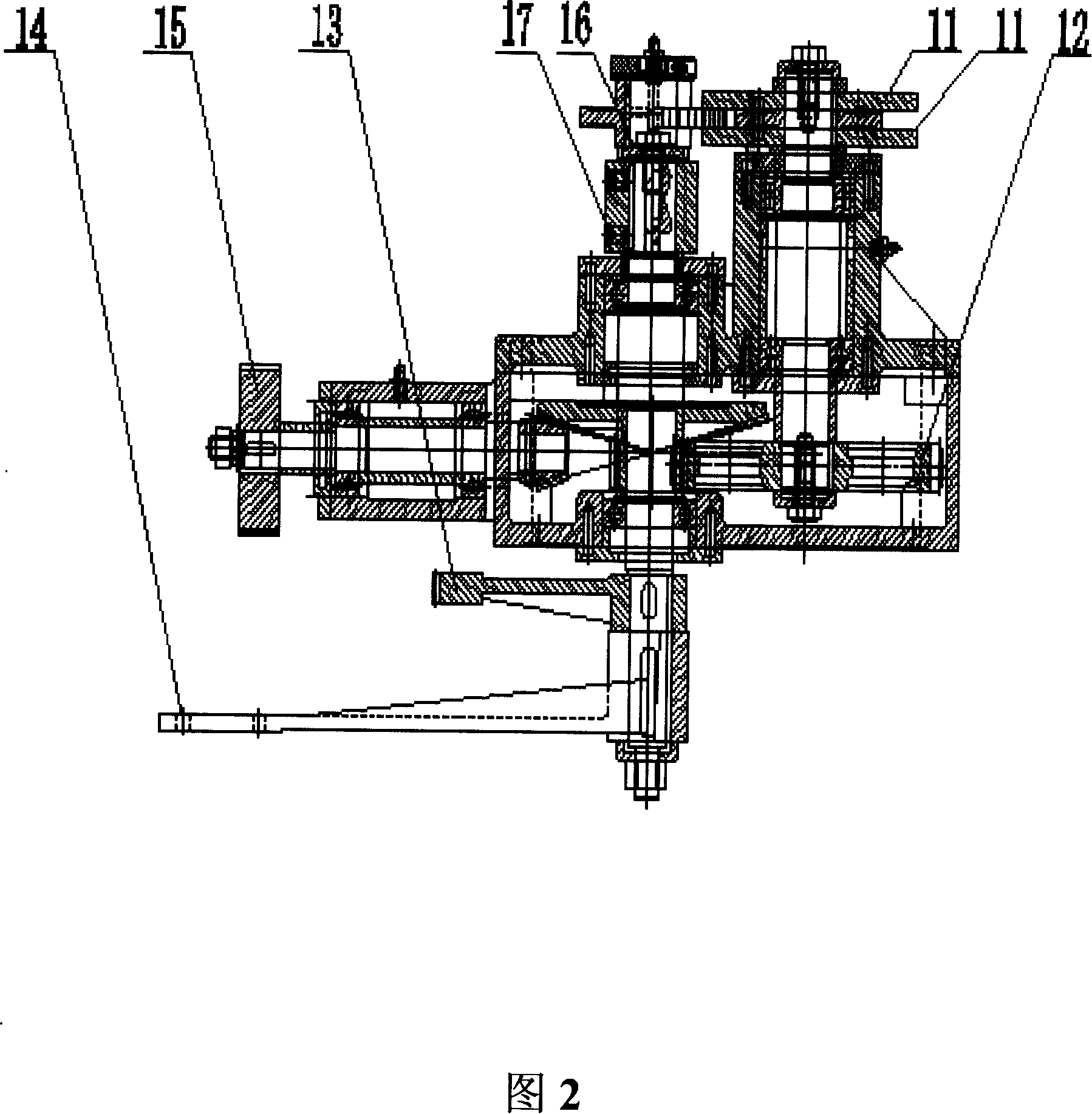

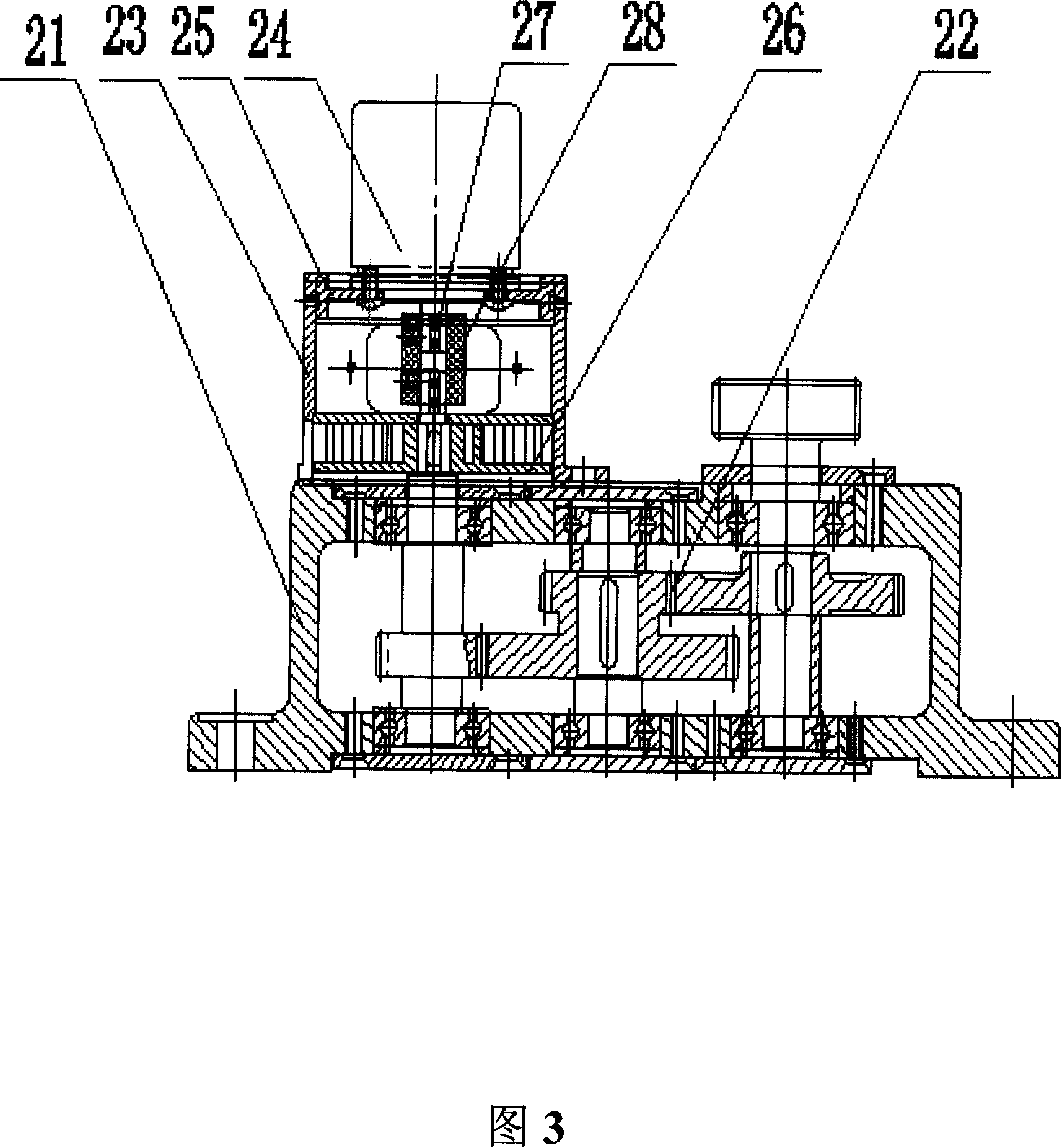

[0033]As shown in Fig. 1, a kind of high-speed numerical control self-leveling gilling machine of the present invention, it comprises feeding roller detection mechanism 1, roller displacement signal amplification detection mechanism 2, pulls out roller detection mechanism 3, driving mechanism 4 and control mechanism 5, Referring to Fig. 2, the feed roller detection mechanism 1 includes a pair of opposite front rollers 11 and a detection transmission gear set 12, the input end of the detection transmission gear set 12 is connected with the drive mechanism 4 through the input pulley 15, and the detection transmission gear The output end of the group 12 is connected with the roller displacement signal amplification detection mechanism 2; one end of the detection transmission gear group 12 is provided with a spring arm 14 and a sector gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com