Preparation method for synthesizing nucleocapsid TiO2/Al2O3 nano powder by one-step hydrothermal process

A technology of nano-powder and hydrothermal method, which is applied in the field of preparation of core-shell TiO2/Al2O3 nano-powder by one-step hydrothermal method, which can solve the problems of high manufacturing cost, complicated process, long production cycle, etc., and achieve reduction The effect of production time, shortened process flow, and light degree of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

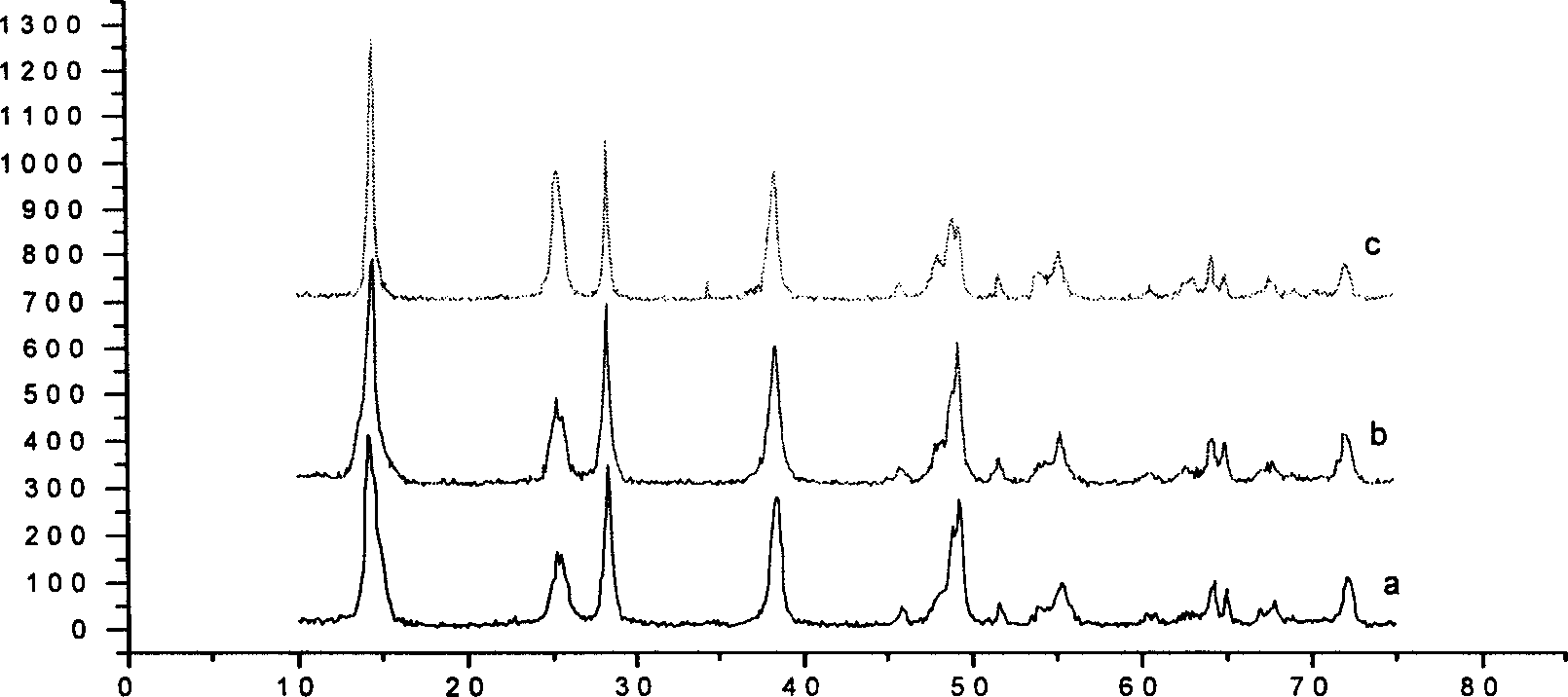

Image

Examples

Embodiment 1

[0021] Weigh 9 grams of titanium tetrachloride, add deionized water to make a 0.2M solution, add 15% ammonia water dropwise at a rate of 1-2 drops / second at a stirring speed of 150r / min, and control the pH value to 8.5 Ti in solution 4+ The precipitation is complete, and Ti(OH) is obtained 4 Precipitate and age for 0.5h; weigh 6 grams of AlCl 3 .6H 2 O into the beaker, add deionized water to make a solution with a certain concentration, and then add it dropwise to the uniformly dispersed Ti(OH) at a rate of 1-2 drops / second 4 In the cloudy solution, continue to stir, and at the same time, drop 15% ammonia water into the cloudy solution at a rate of 2-3 drops / second, adjust the pH value to 8.8, and after aging for a certain period of time, filter it with deionization Washed several times with water until AgNO 3 Test the filtrate until no precipitation occurs, and the precipitate obtained by suction filtration at this time is core-shell type Ti(OH) 4 / Al(OH) 3 Precursor. ...

Embodiment 2

[0023] Weigh 12 grams of titanium tetrachloride, add deionized water to make a 0.25M solution, add 15% ammonia water dropwise at a rate of 1-2 drops / second at a stirring speed of 150r / min, and control the pH value to 8.8 Ti in solution 4+ The precipitation is complete, and Ti(OH) is obtained 4 Precipitate and age for 0.5h; weigh 7.5g of AlCl 3 .6H 2 O into the beaker, add deionized water to make a solution with a certain concentration, and then add it dropwise to the uniformly dispersed Ti(OH) at a rate of 1-2 drops / second 4 In the cloudy solution, continue to stir, and at the same time, drop 15% ammonia water into the cloudy solution at a rate of 2-3 drops / second, adjust the pH value to 9.2, and after aging for a certain period of time, filter it with deionization washed several times with water until AgNO 3 Test the filtrate until no precipitation occurs, and the precipitate obtained by suction filtration at this time is core-shell type Ti(OH) 4 / Al(OH) 3 Precursor. A...

Embodiment 3

[0025] Weigh 6 grams of titanium tetrachloride, add deionized water to make a 0.3M solution, add 15% ammonia water dropwise at a rate of 1-2 drops / second at a stirring speed of 150r / min, and control the pH value to 9.0 Ti in solution 4+ The precipitation is complete, and Ti(OH) is obtained 4 Precipitate and age for 0.5h; weigh 5.1g of AlCl 3 .6H 2 O into the beaker, add deionized water to make a solution with a certain concentration, and then add it dropwise to the uniformly dispersed Ti(OH) at a rate of 1-2 drops / second 4 In the cloudy solution, continue to stir, and at the same time, drop 15% ammonia water into the cloudy solution at a rate of 2-3 drops / second, adjust the pH value to 9.5, and after aging for a certain period of time, filter it with deionization washed several times with water until AgNO 3 Test the filtrate until no precipitation occurs, and the precipitate obtained by suction filtration at this time is core-shell type Ti(OH) 4 / Al(OH) 3 Precursor. Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com