Continuous semi-solid slurry preparing device and method capable of inhibiting segregation of Sn element in ZCuSn10P1 alloy

A semi-solid slurry and alloy technology, applied in the field of material science, can solve the problems of high production cost, difficult temperature control, easy oxidation during processing, etc., and achieve the effect of less intergranular segregation and reduced concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

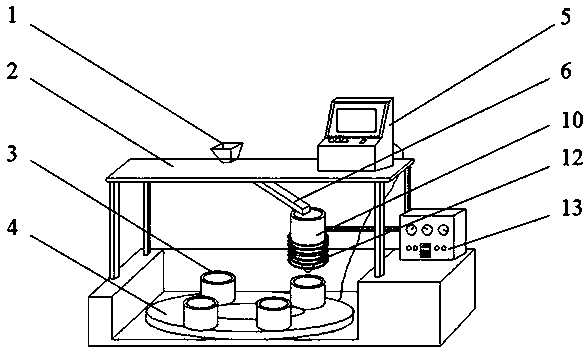

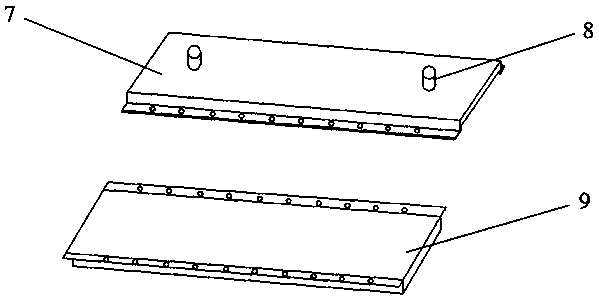

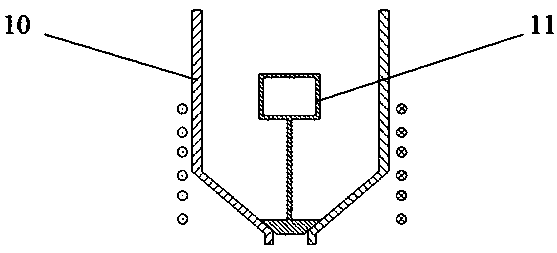

[0030] Such as Figures 1 to 5 As shown, the device for continuously preparing semi-solid slurry that suppresses the segregation of ZCuSn10P1 alloy tin elements includes a control cooling device, a quasi-isothermal device and a pouring turntable device;

[0031] The control cooling device includes a sprue cup 1, an operating table 2 and an inclined plate 6, and the similar isothermal device includes a reaction kettle 10, a floating block 11, an induction heater 12, an induction heater control device 13 and a floating block 11, and a pouring turntable device Including a graphite crucible 3, a rotary table 4, a rotary control device 5 and a rotary power mechanism;

[0032]The sprue cup 1 is inserted into the operation table 2, the bottom of the sprue cup 1 is connected to the inclined plate 6, the outlet at the bottom of the inclined plate 6 is connected to the upper end of the top of the reaction kettle 10, and the reaction kettle 10 is uniformly equipped with induction heaters...

Embodiment 2

[0041] Such as Figures 1 to 5 As shown, the device for continuously preparing semi-solid slurry that suppresses the segregation of tin elements in the ZCuSn10P1 alloy includes a control cooling device, a quasi-isothermal device and a pouring turntable device;

[0042] The control cooling device includes a sprue cup 1, an operating table 2 and an inclined plate 6, and the isothermal device includes a reaction kettle 10, a floating block 11, an induction heater 12, an induction heater control device 13 and a floating block 11, and a pouring turntable device Including a graphite crucible 3, a rotary table 4, a rotary control device 5 and a rotary power mechanism;

[0043] The sprue cup 1 is inserted into the operation table 2, the bottom of the sprue cup 1 is connected to the inclined plate 6, the outlet at the bottom of the inclined plate 6 is connected to the upper end of the top of the reaction kettle 10, and the reaction kettle 10 is uniformly equipped with induction heaters...

Embodiment 3

[0047] Such as Figures 1 to 5 As shown, the device for continuously preparing semi-solid slurry that suppresses the segregation of tin elements in the ZCuSn10P1 alloy includes a control cooling device, a quasi-isothermal device and a pouring turntable device;

[0048] The control cooling device includes a sprue cup 1, an operating table 2 and an inclined plate 6, and the isothermal device includes a reaction kettle 10, a floating block 11, an induction heater 12, an induction heater control device 13 and a floating block 11, and a pouring turntable device Including a graphite crucible 3, a rotary table 4, a rotary control device 5 and a rotary power mechanism;

[0049] The sprue cup 1 is inserted into the operation table 2, the bottom of the sprue cup 1 is connected to the inclined plate 6, the outlet at the bottom of the inclined plate 6 is connected to the upper end of the top of the reaction kettle 10, and the reaction kettle 10 is uniformly equipped with induction heaters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com