Aluminum alloy plate for molding

A technology of aluminum alloy plate and compound, which is applied in the field of Al-Mg-Si aluminum alloy plate for forming, can solve the problems of lower BH property and difficulty in improving yield strength, and achieve the effect of improving BH property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

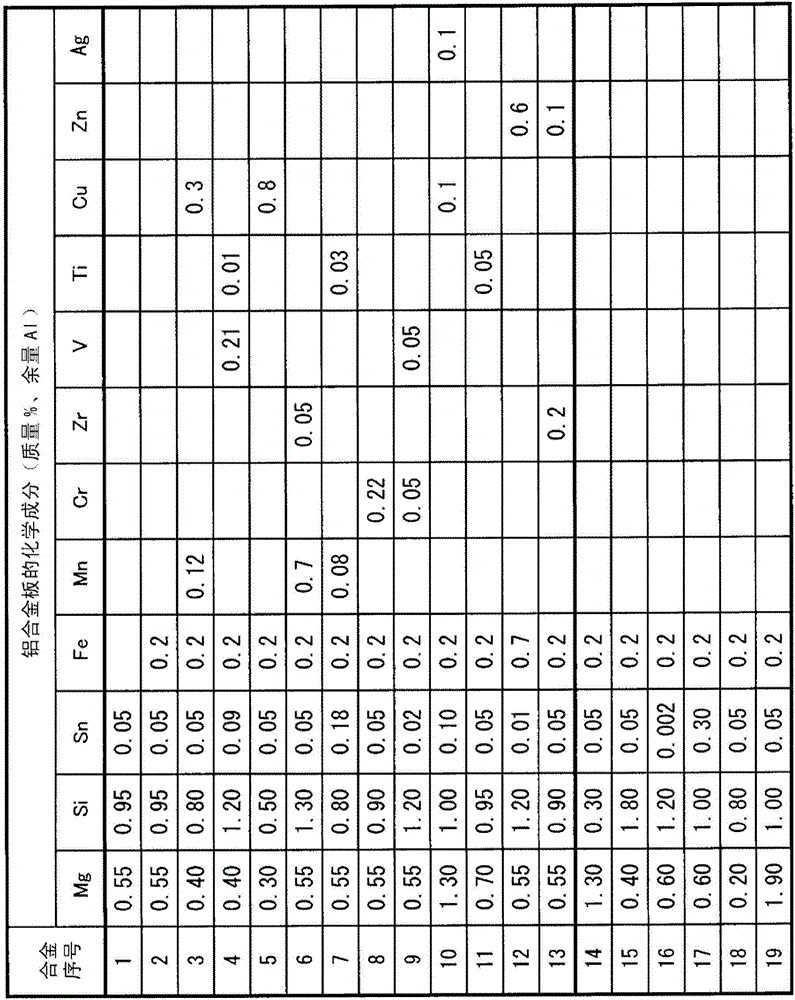

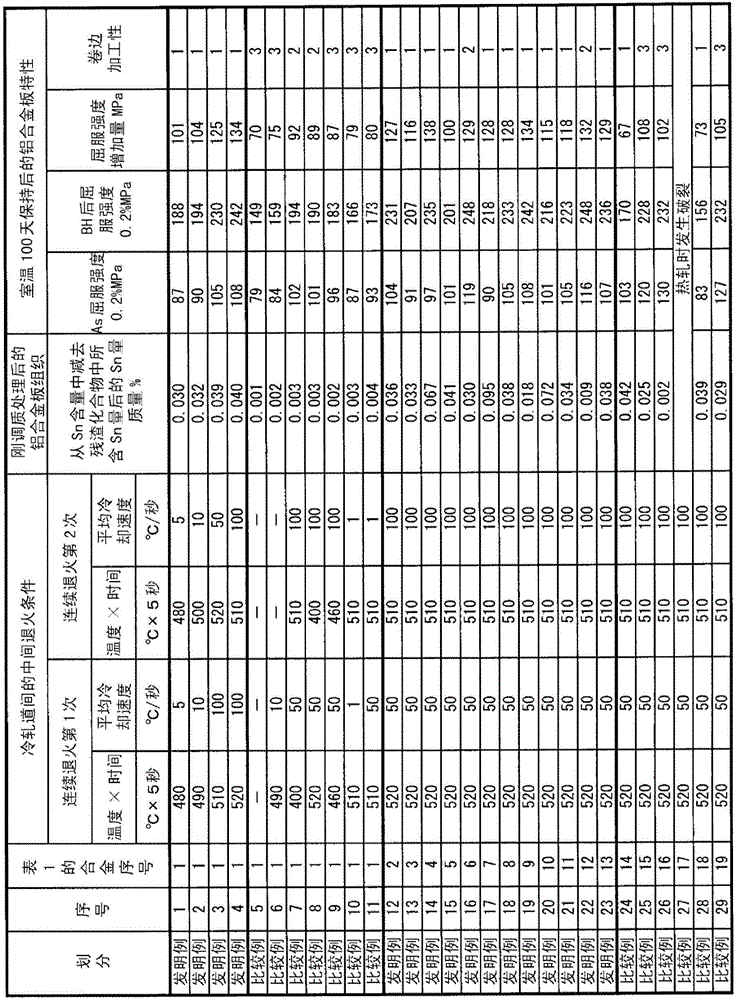

[0091] Next, examples of the present invention will be described. 6000-series aluminum alloy plates having different solid-solution amounts of Sn were produced separately according to the above-mentioned intermediate annealing conditions, and the solid-solution amounts of Sn specified in the present invention were investigated. Furthermore, the BH property (coating bake hardenability) and hemming workability of this board after maintaining it at room temperature for 100 days were also evaluated. The results are shown in Table 2.

[0092] The specific production conditions of these aluminum alloy plates are as follows. Aluminum alloy ingots having the respective compositions shown in Table 1 were melted together by the DC casting method. At this time, the average cooling rate at the time of casting was common to each example, and the liquidus temperature to the solidus temperature was 50° C. / min. It should be noted that, in the display of the content of each element in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com