Preparation method of cerium-zirconium based solid solution

A solid solution, cerium zirconium technology, which is applied in the preparation of automobile exhaust gas purification catalytic materials and the preparation of cerium zirconium-based solid solutions, can solve problems such as unfavorable industrial production and need high-pressure equipment, achieve uniform particle size, solve agglomeration, heat good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

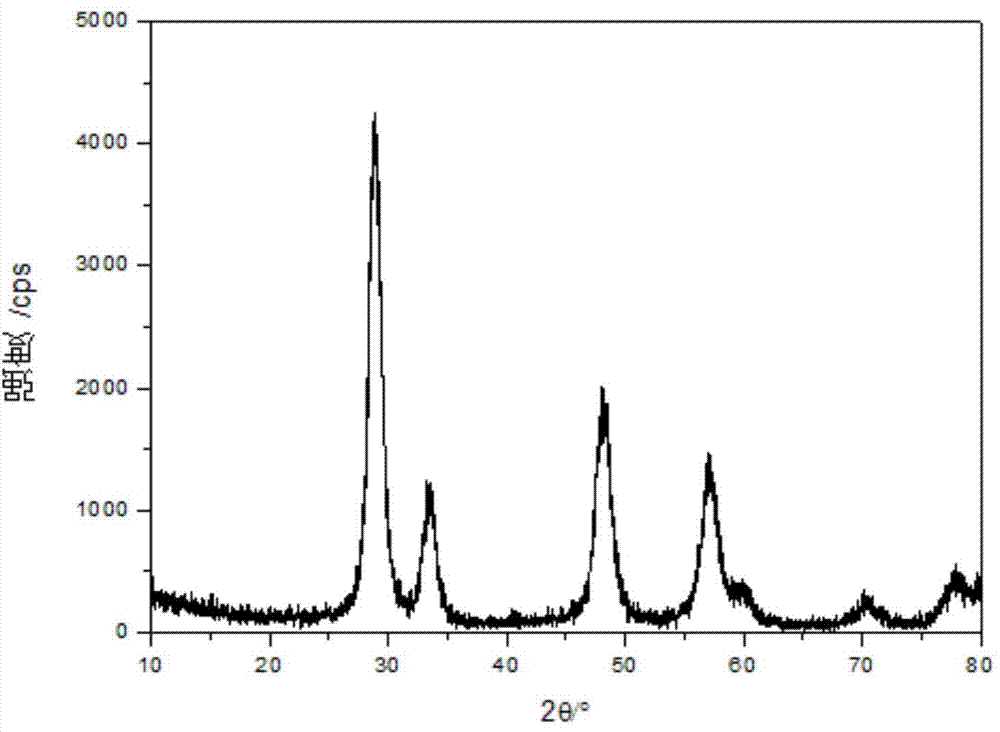

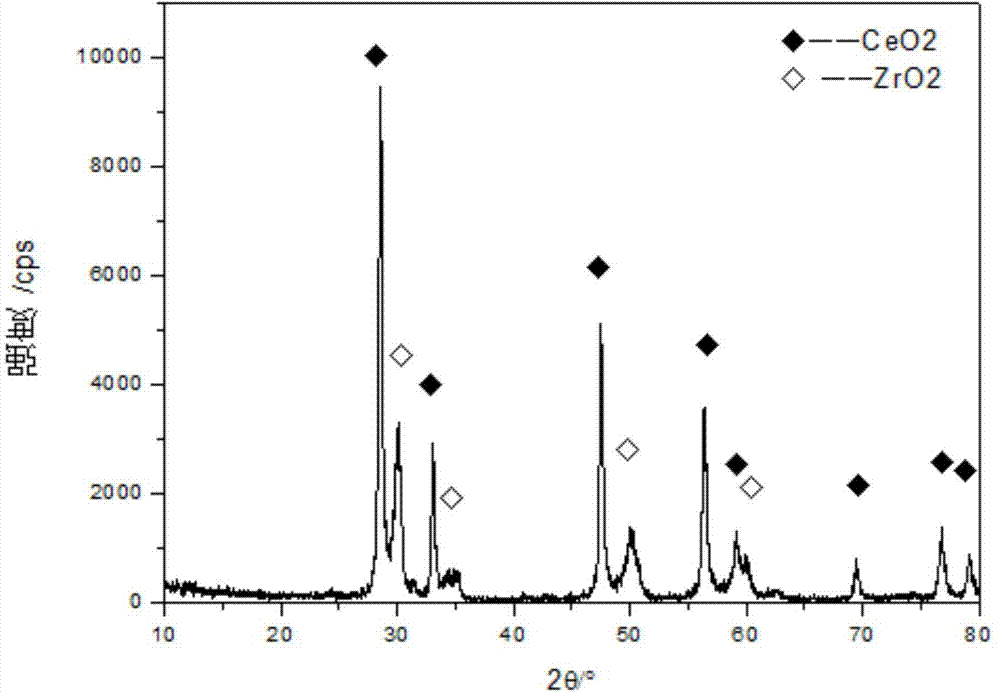

[0038] Example 1 A preparation method of cerium-zirconium-based solid solution

[0039] A preparation method of a cerium-zirconium-based solid solution, which is carried out in accordance with the following sequence of steps:

[0040] (1) Ce 4+ Preparation: Dissolve 105kg of cerium nitrate and mix it with 315kg of water, heat to 70°C, under stirring conditions, use 10% ammonia water to precipitate to pH 5, add 63kg hydrogen peroxide with a mass concentration of 30%, and then continue to use ammonia water Precipitate until the pH is 9.0, boil and keep warm for 2.0h; after plate and frame pressure filtration, 160kg of cerium hydroxide wet cake (the total amount of rare earth is 25%) is obtained; 160kg of cerium hydroxide wet cake is beaten with 800kg of pure water, and the pH is adjusted with nitric acid 1.5, after standing for 3h, vacuum filtration, Ce +4 The clarified solution A;

[0041] (2) Preparation of active component solution: in Ce 4+ Add 15.7kg lanthanum nitrate, ...

Embodiment 2-6

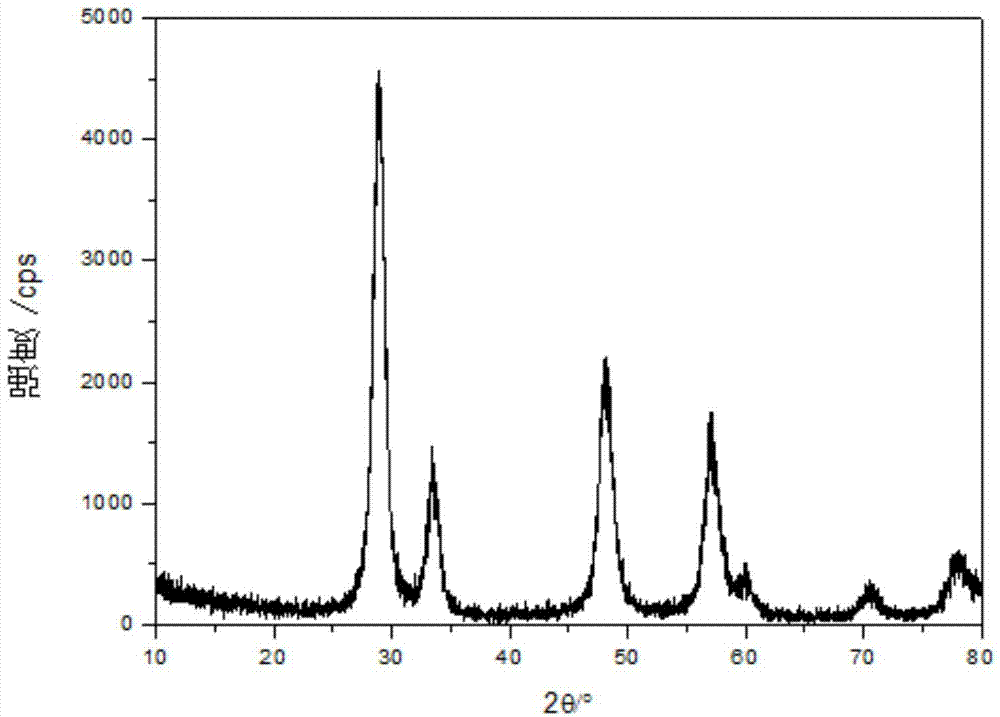

[0046] Embodiment 2-6 Preparation method of cerium-zirconium-based solid solution

[0047] Examples 2-6 are respectively a preparation method of a cerium-zirconium-based solid solution, which is similar to that of Example 1, except that the technical parameters involved are different, as shown in the following table:

[0048]

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com