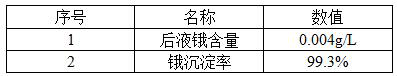

Patents

Literature

31results about How to "Control sedimentation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

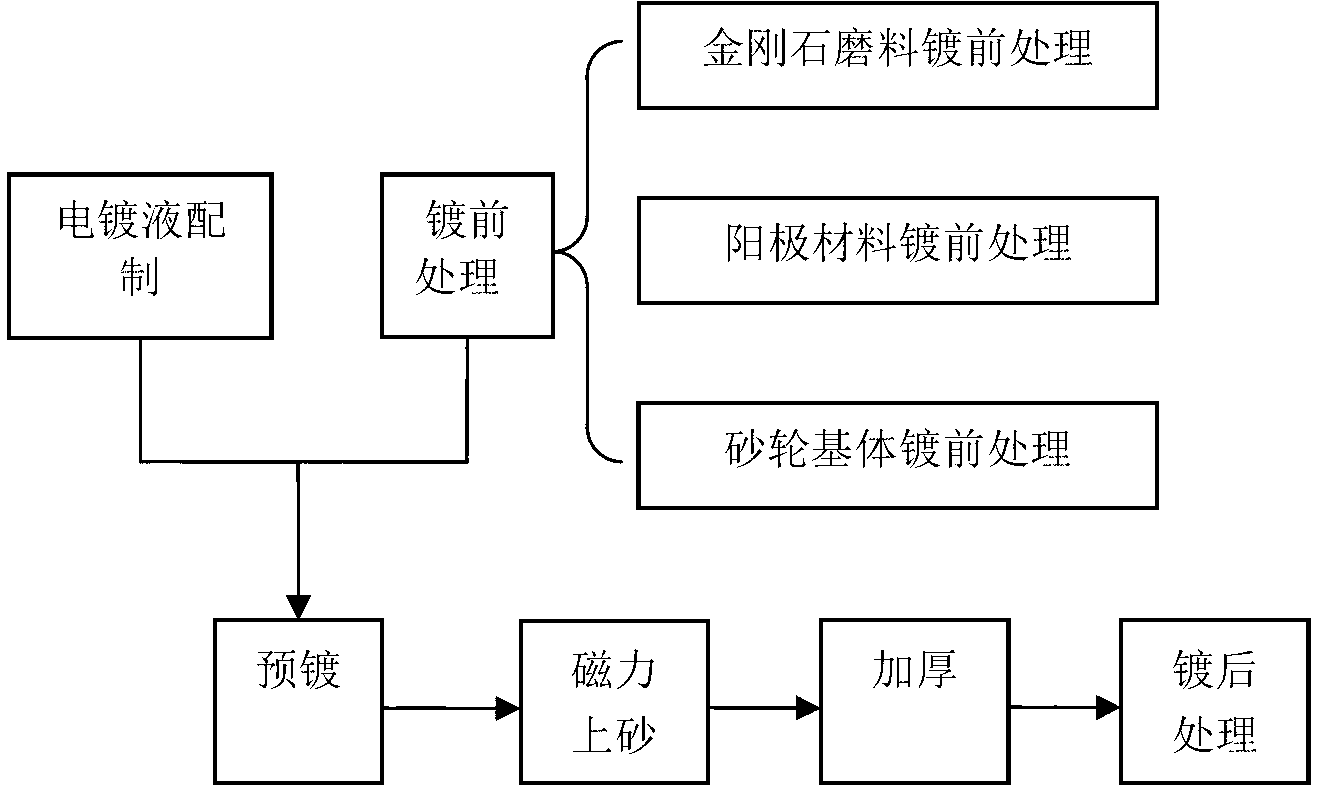

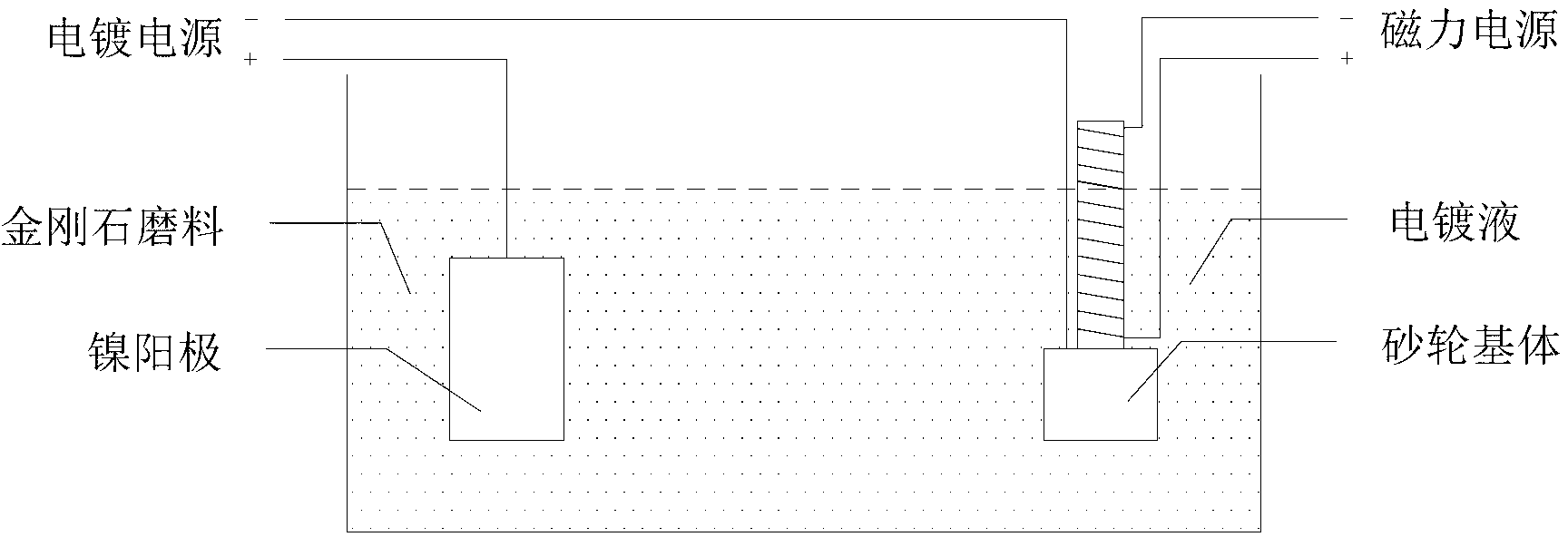

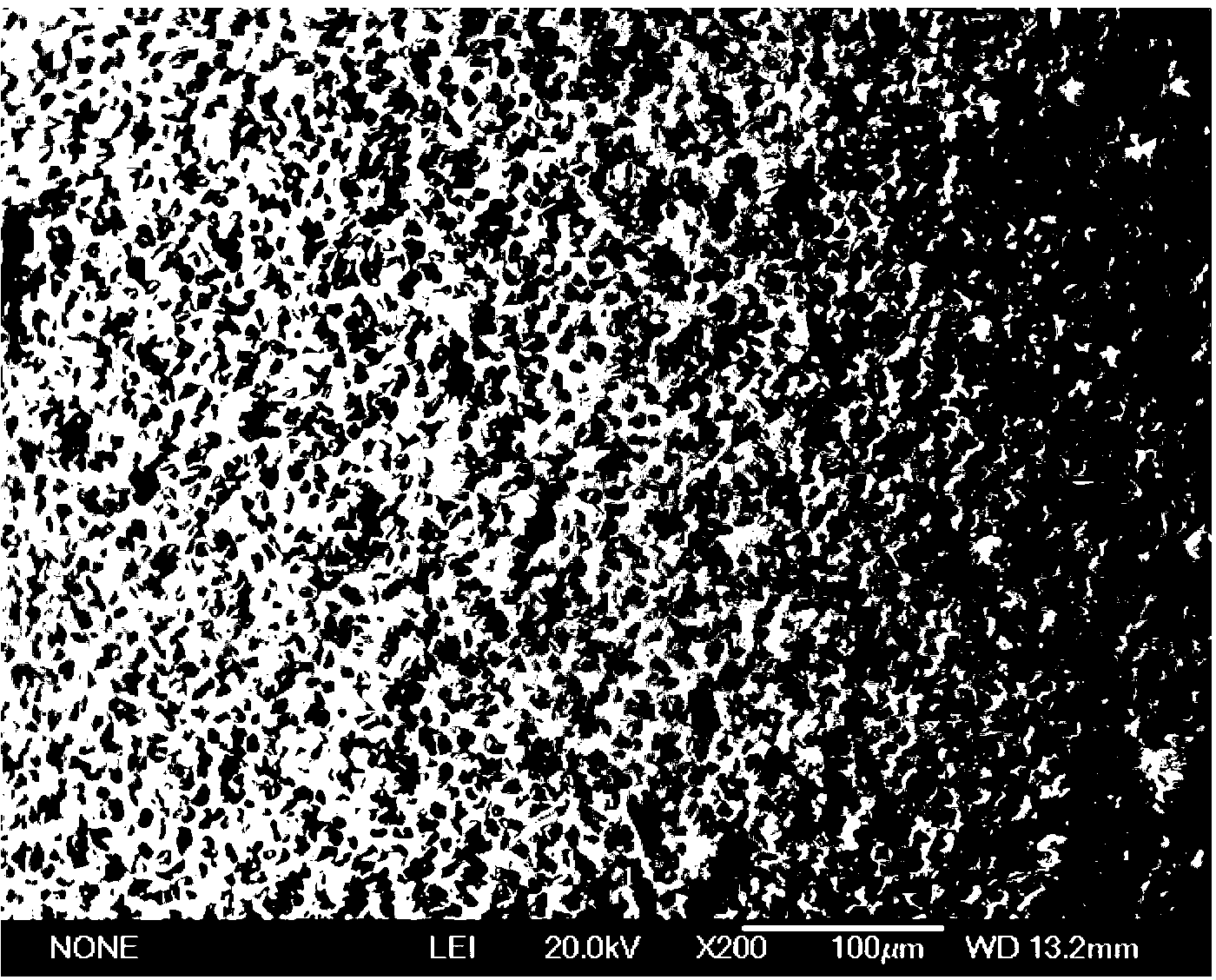

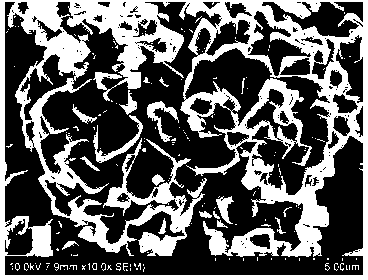

Method for producing grinding electroplated diamond wheel

ActiveCN103173840AControl sedimentation rateEvenly distributedCellsElectrolytic coatingsGranularityGrinding wheel

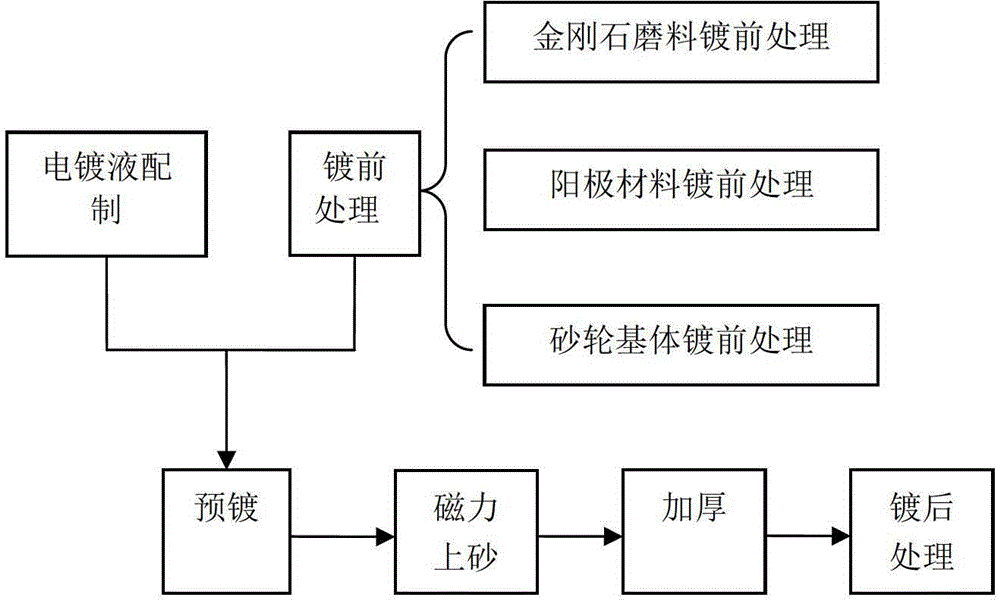

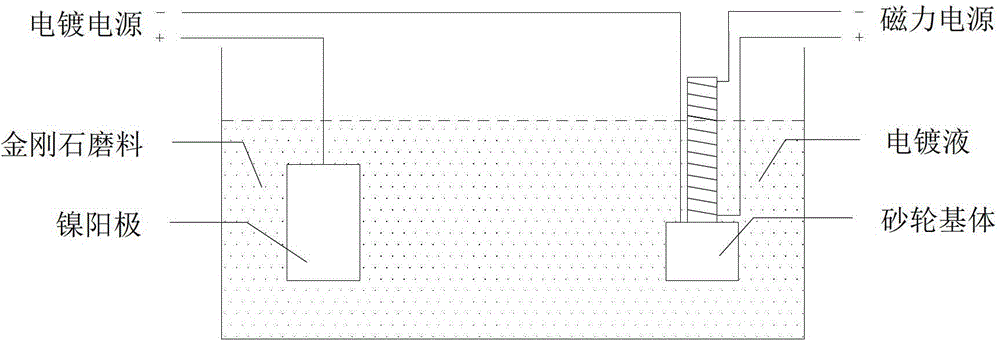

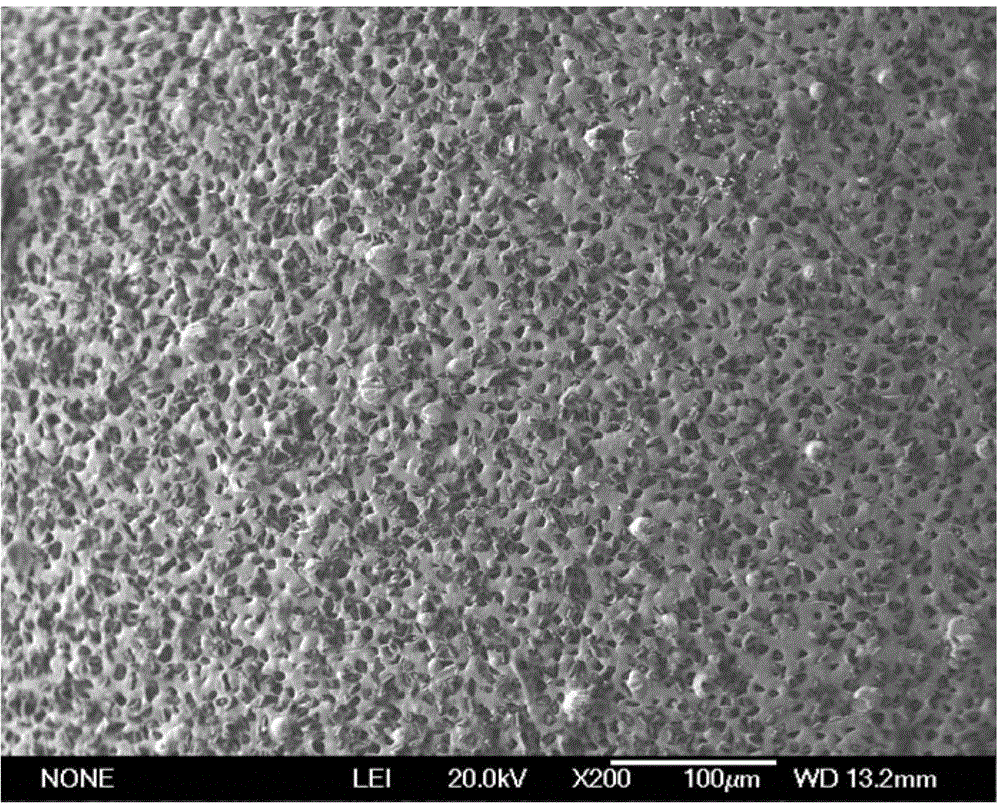

The invention discloses a method for producing a grinding electroplated diamond wheel. The method comprises the steps of: 1, preparing an electroplating bath; 2, pre-treating before plating; 3, pre-plating, wherein the current density is 1.2-1.8A / dm<2>, and the thickness of a pre-plating layer is 7-10micrometers; 4, magnetically sand feeding, namely applying magnetic induction intensity of 400-1000mT on a plating surface of a grinding wheel base body so as to absorb a diamond abrasive through the plating surface of the grinding wheel base body, and depositing an electroplating layer through electrifying, wherein the sand feeding current density is 0.5-0.8A / dm<2>, and the thickness of the plating layer is 15% of the average particle size of the diamond abrasive; 5, thickening, wherein the current density is 1.6-2.0A / dm<2>, and the thickness of the thickened plating layer is 65% of the average particle size of the diamond abrasive; and 6, treating after the plating so as to obtain the grinding electroplated diamond wheel. By utilizing the method for producing the grinding electroplated diamond wheel, the abrasive with fine granularity can be uniformly solidified on the plating surface, and the produced grinding wheel has good shape retention performance and satisfies grinding requirements on high precision and high efficiency.

Owner:白鸽磨料磨具有限公司

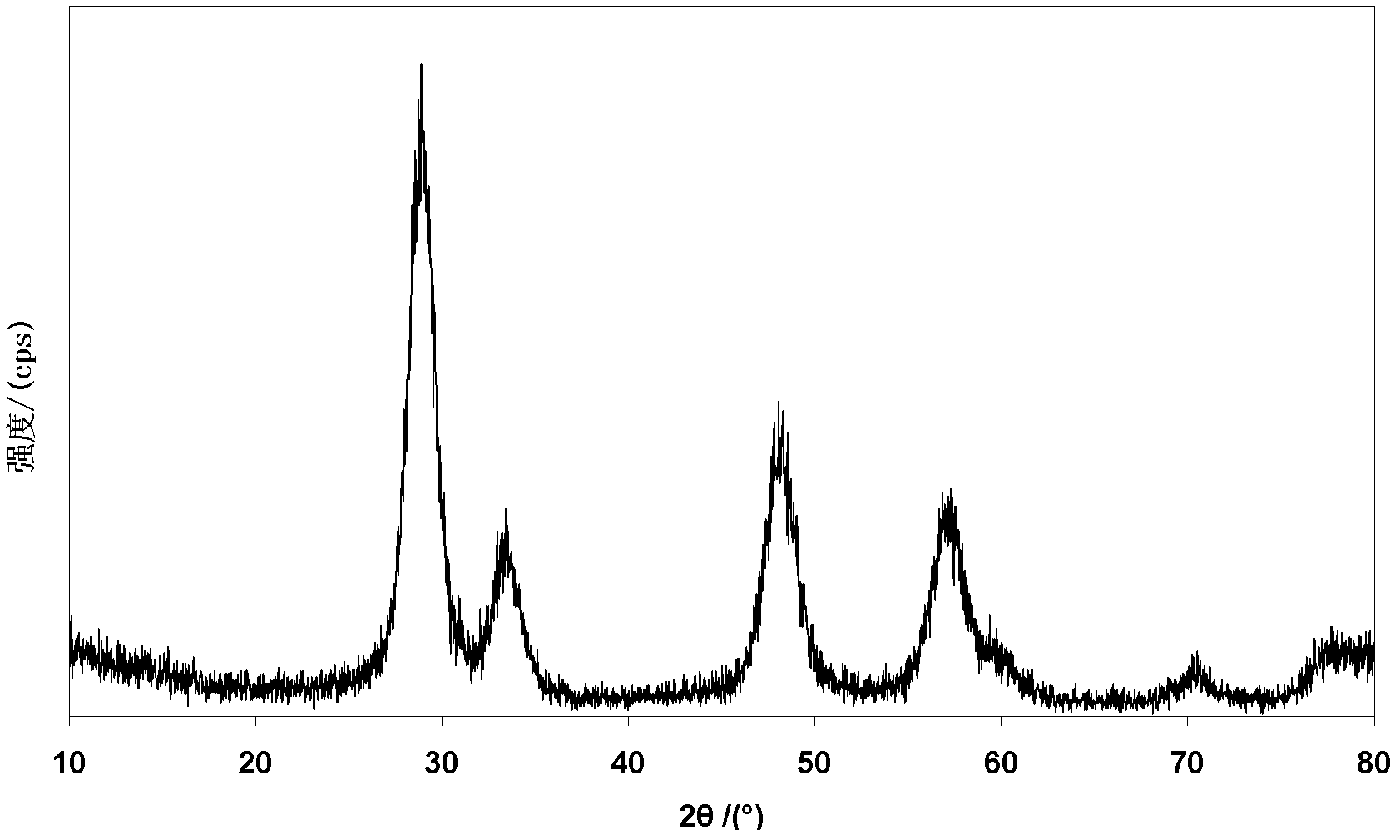

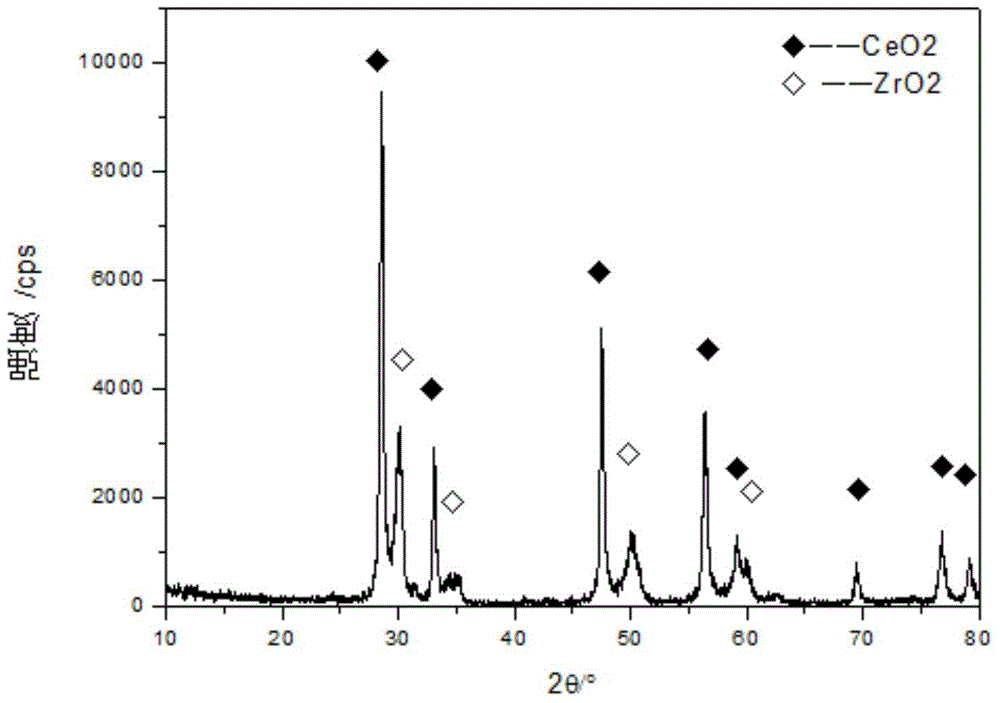

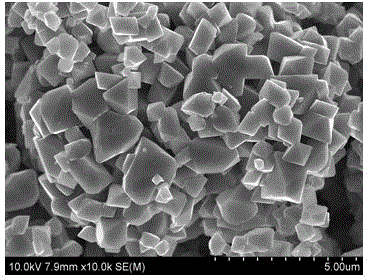

Cerium-zirconium-based solid solution rare earth oxygen-storage material and preparation method thereof

ActiveCN103127925ASmall particlesLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsReaction rateHeat stability

The invention discloses a cerium-zirconium-based solid solution rare earth oxygen-storage material and a preparation method thereof. The cerium-zirconium-based solid solution rare earth oxygen-storage material has a specific surface area equal to or greater than 90m<2>.g<-1>, has a specific surface area equal to or greater than 30m<2>.g<-1> after being calcined at a temperature of 1000 DEG C for 4 hours, and has a specific surface area equal to or greater than 20m<2>.g<-1> after being calcined at a temperature of 1050 DEG C for 12 hours. Compared with the prior art, the preparation method has the advantages that before precipitation, a mixed metal salt solution is added with a certain amount of an organic acid so that acidity of the mixed metal salt solution is improved or the mixed metal salt solution forms sol; a reaction rate is inhibited and a precipitation rate is controlled so that a stable precursor having the uniform grain size is obtained; and the precipitate precursor surface treatment is carried out by a surfactant so that the aperture size and the aperture volume of a calcination product are improved and the cerium-zirconium-based solid solution rare earth oxygen-storage material having good heat stability is prepared. The cerium-zirconium-based solid solution rare earth oxygen-storage material has the advantages of small granule size, large specific surface area, high temperature aging resistance and high activity.

Owner:上海华明高纳稀土新材料有限公司

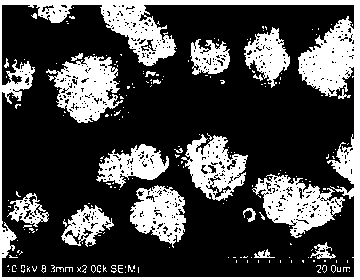

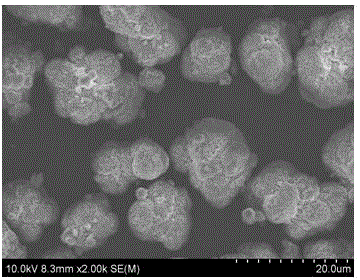

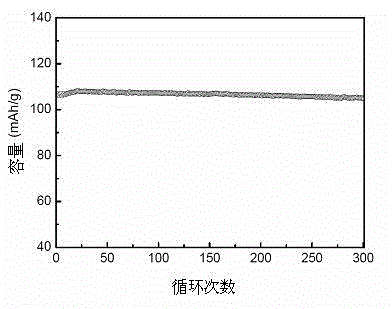

Aluminum-doped spinel manganese-based material and preparation method thereof

ActiveCN102938460AImprove uniformityExcellent electrochemical performanceCell electrodesAluminiumOxide

The invention discloses an aluminum-doped spinel manganese-based material and a preparation method thereof. The method comprises the steps of respectively putting configured manganese source compound solution, or a nickel source compound, aluminum salt compound solution and a precipitator solution into a reactor according to the flow rate being 0.5-2L / h, stirring to control the pH value of a system to be 7-8.5 and the heating temperature of the system to be 30 DEG C-60 DEG C, heating and then curing for 10h-20h to obtain a spherical precipitate precursor, washing and drying the spherical precipitate precursor; forging the dried precipitate for 5-20h under the temperature being 600-900 DEG C; and sufficiently mixing oxidizing materials and a lithium source compound according to a proportion that the stoichiometric ratio exceeds the lithium source compound by 1-10%, and forging for 5-20h under the temperature being 600-900 DEG C to obtain the modified spinel manganese-based material. According to the method disclosed by the invention, the feature of the precursor and the distribution uniformity of an Al element can be improved effectively; due to the reasonable high forging temperature and doping proportion, the structure stability of the aluminum-doped spinel manganese-based material can be improved greatly, and the circulation performance and high-temperature and low-temperature performances of the material can be improved; and the process is simple, and the repeatability is good.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

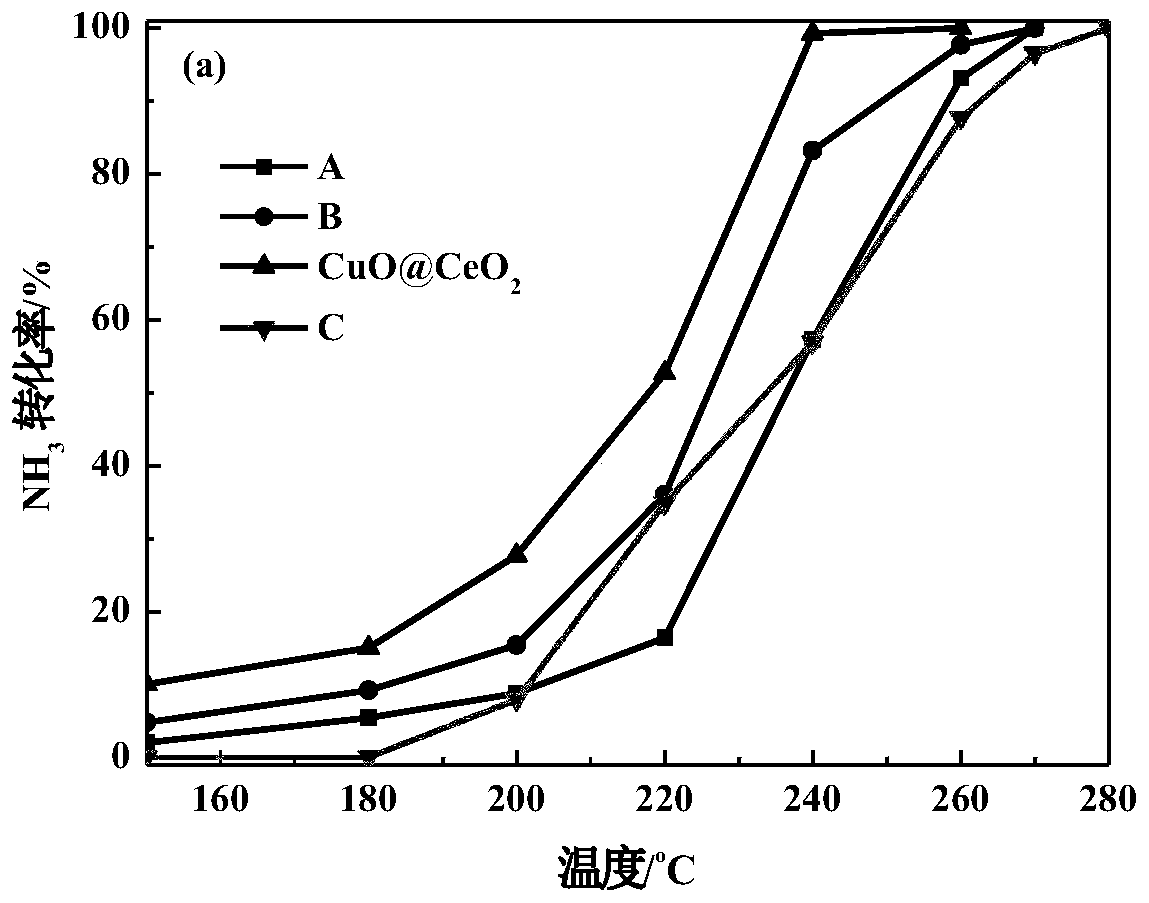

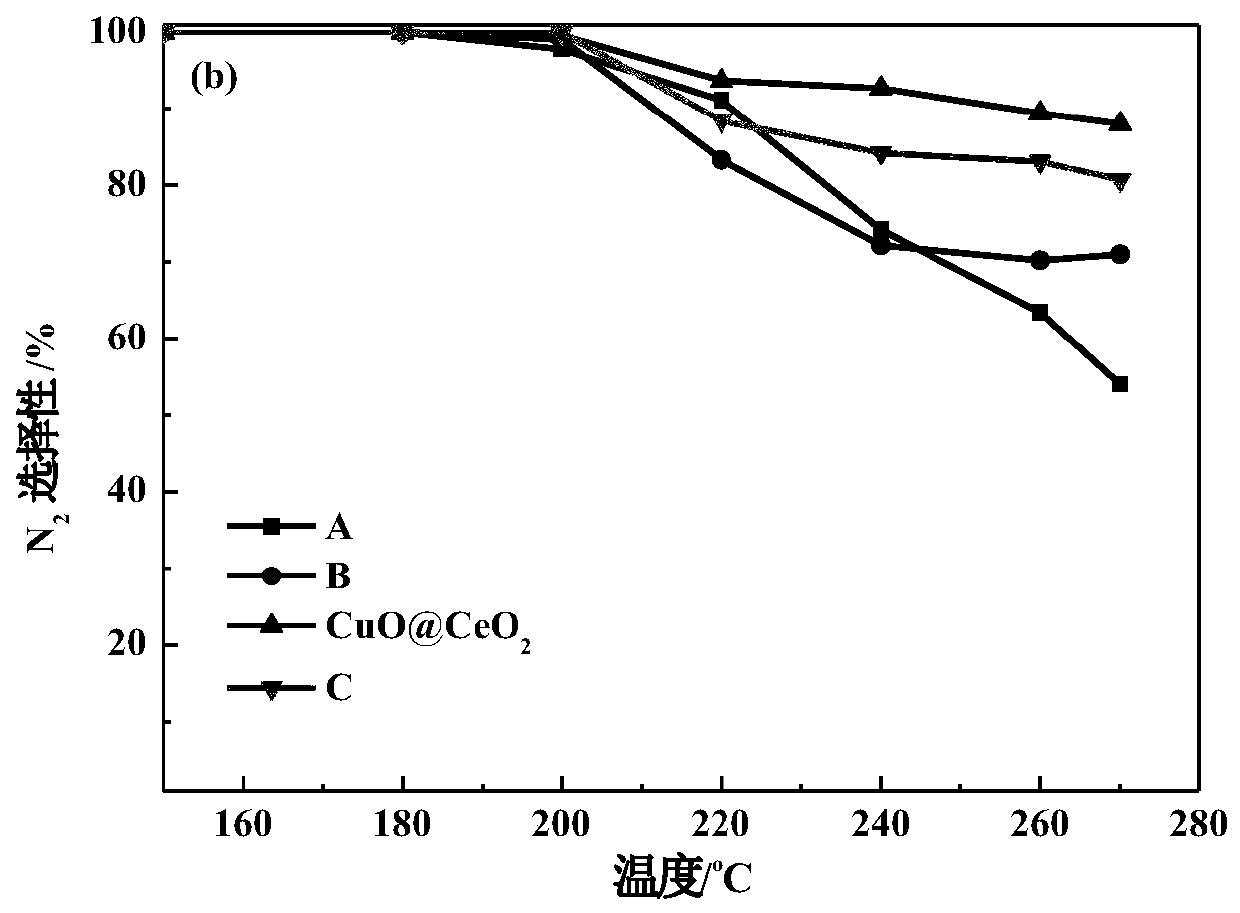

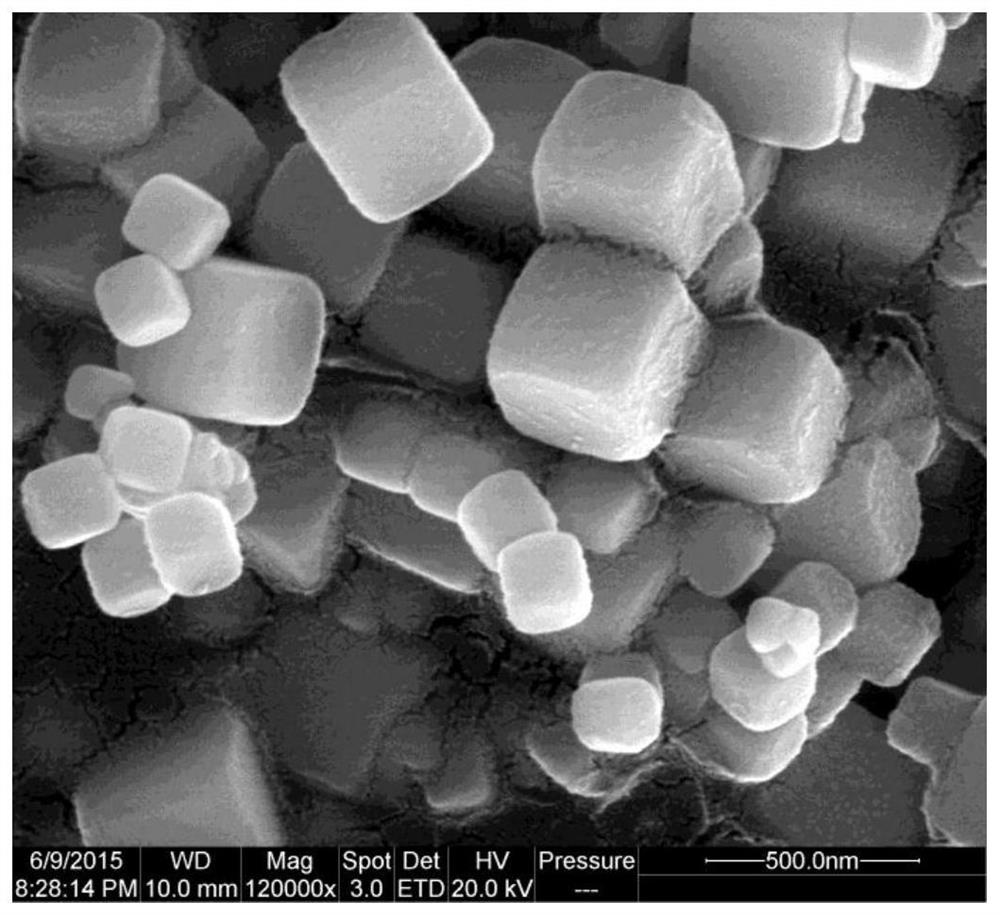

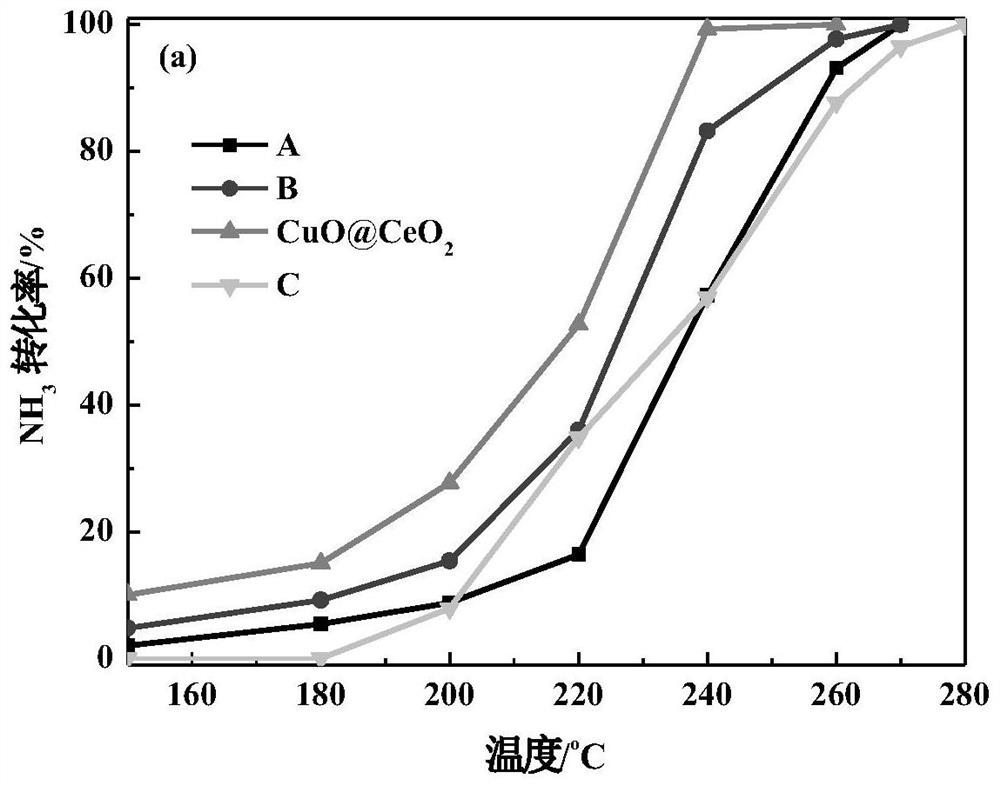

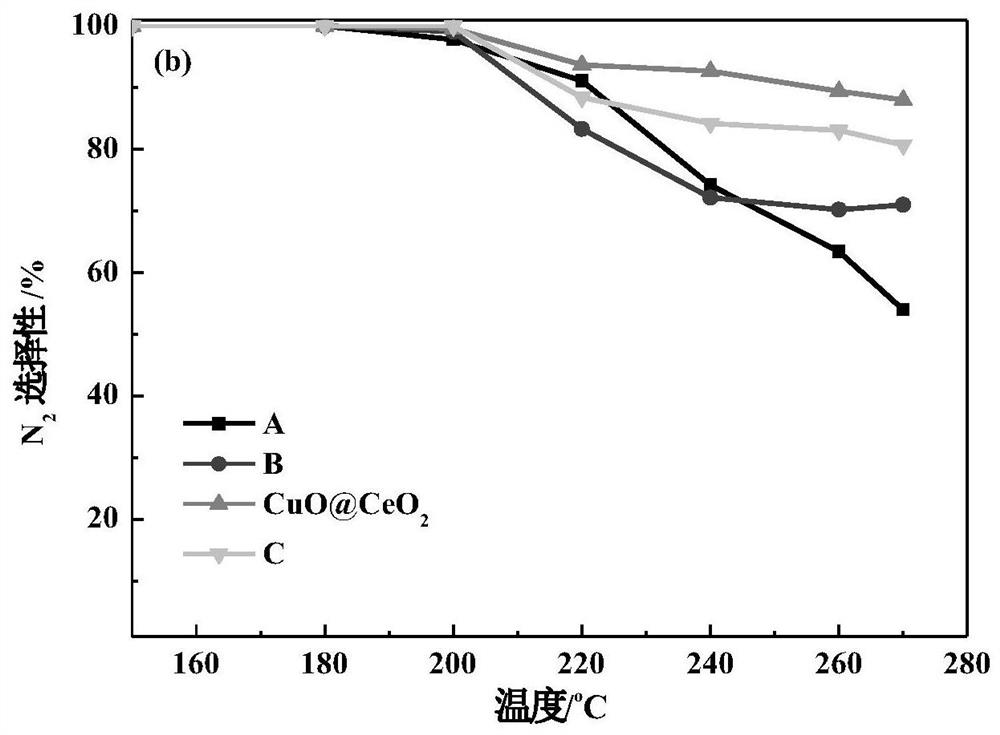

Core-shell structure nanometer copper cerium composite oxide catalyst, and preparation method and applications thereof

ActiveCN109926060AGood ammonia oxidation activityRealize the packageDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumCopper oxide

The invention belongs to the technical field of catalytic material, and discloses a core-shell structure nanometer copper cerium composite oxide catalyst, and a preparation method and applications thereof. The core-shell structure nanometer copper cerium composite oxide catalyst can be used for ammonia selective catalytic oxidation reaction. Catalyst synthetic conditions are adjusted, so that control on copper oxide particle surface local hydrolysis reaction is realized, regulation and control on cerium oxide outer wall generation and copper oxide particle etching degree are realized, and at last, the CuO@CeO2 core-shell structure composite material taking mesoporous structure CeO2 as the shell is obtained. The catalyst possesses excellent ammoxidation activity and N2 selectivity, and highreaction stability; the preparation method is simple, reliable, and high in efficiency; the raw materials are easily available; and the preparation method is convenient for large scale preparation.

Owner:DALIAN UNIV OF TECH

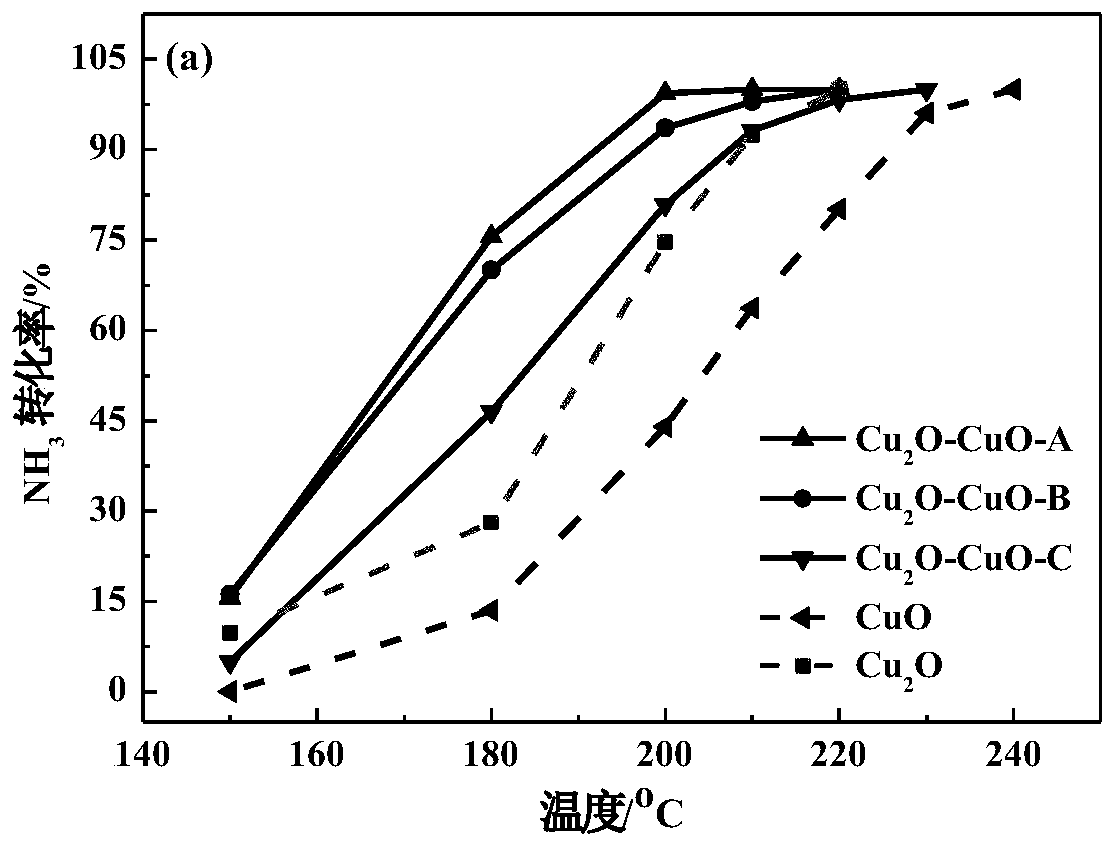

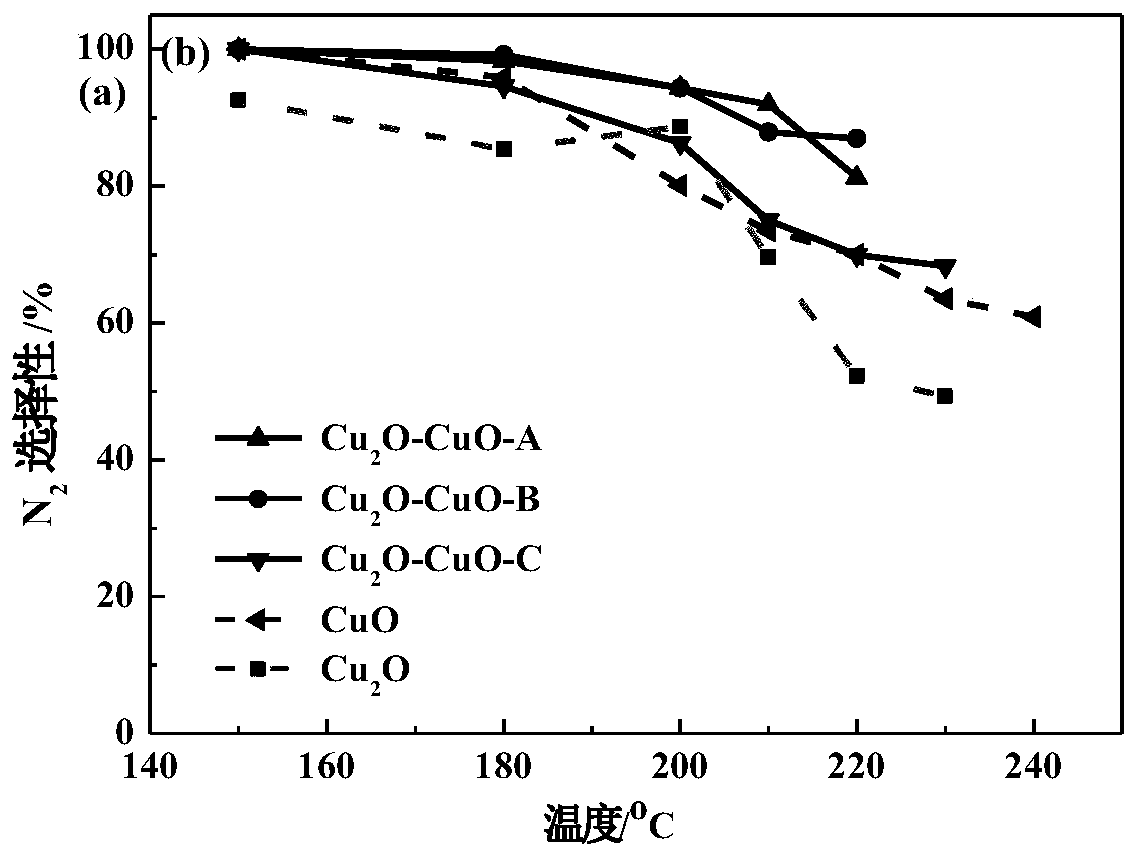

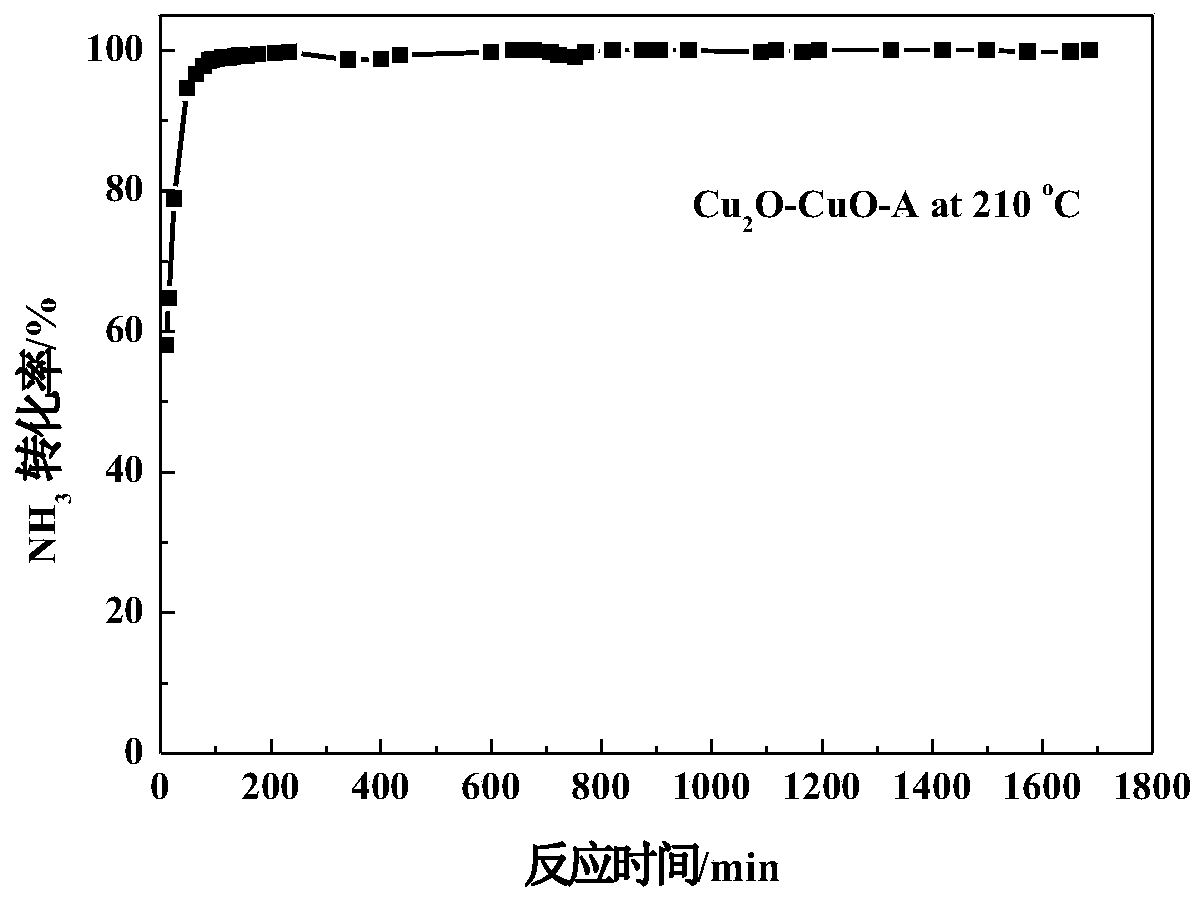

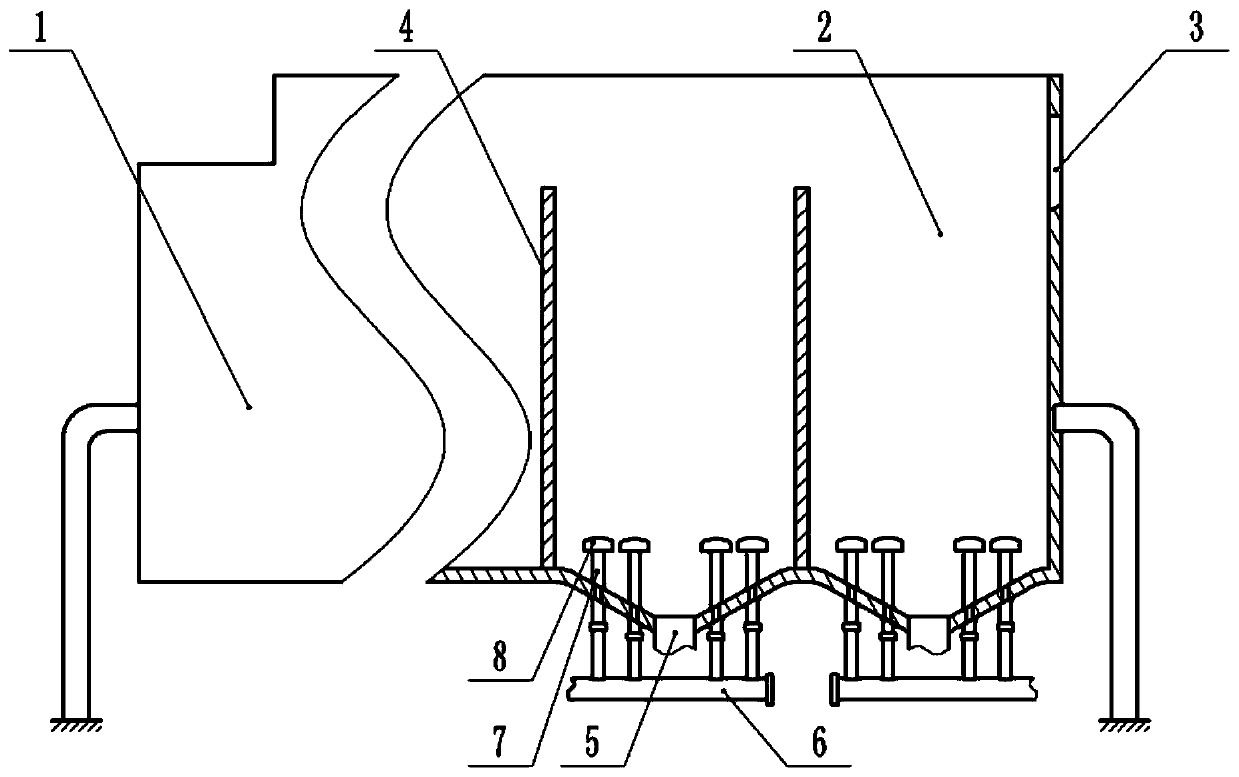

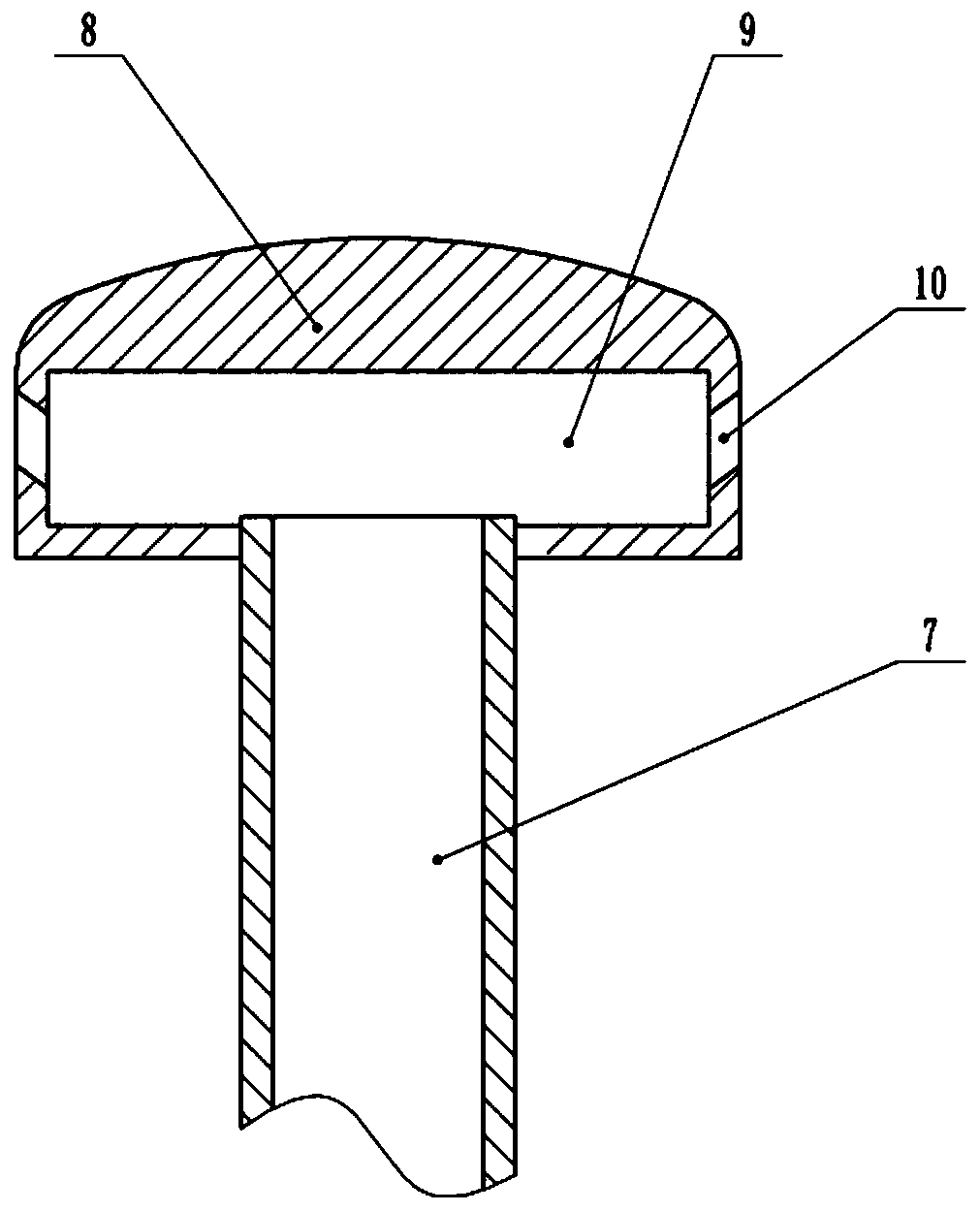

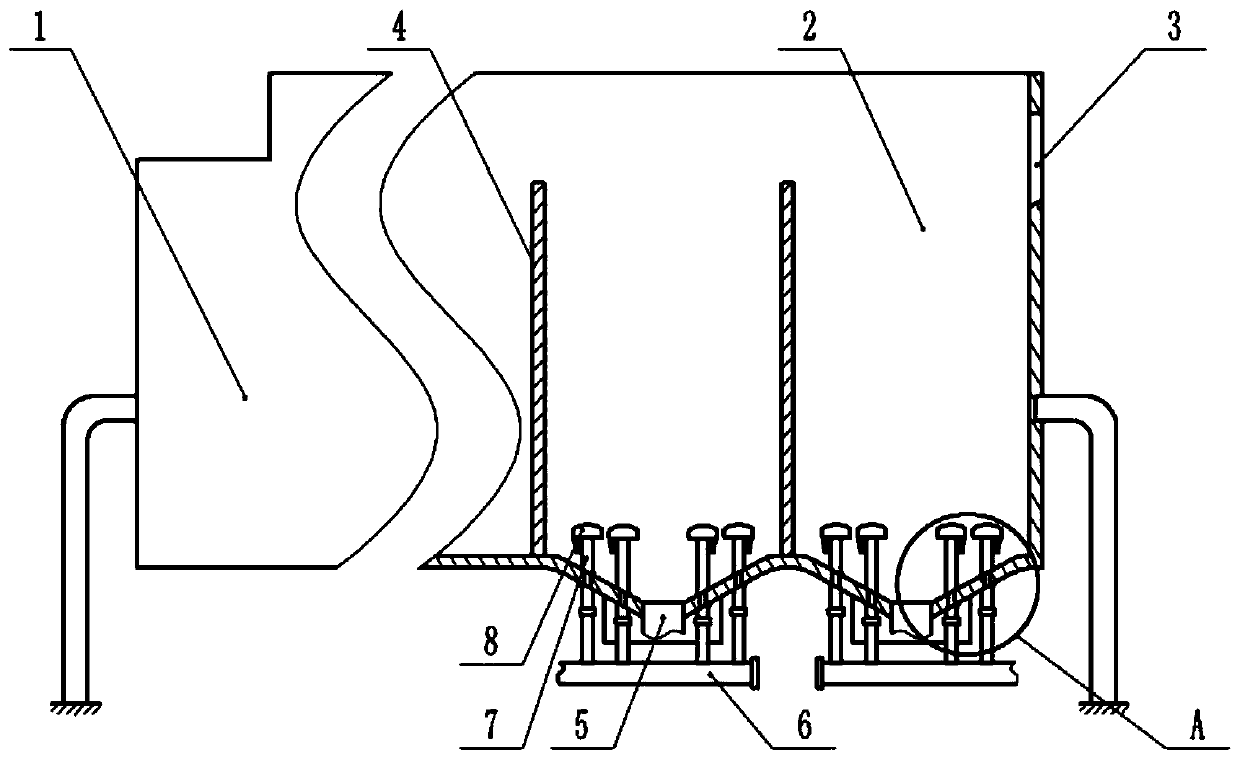

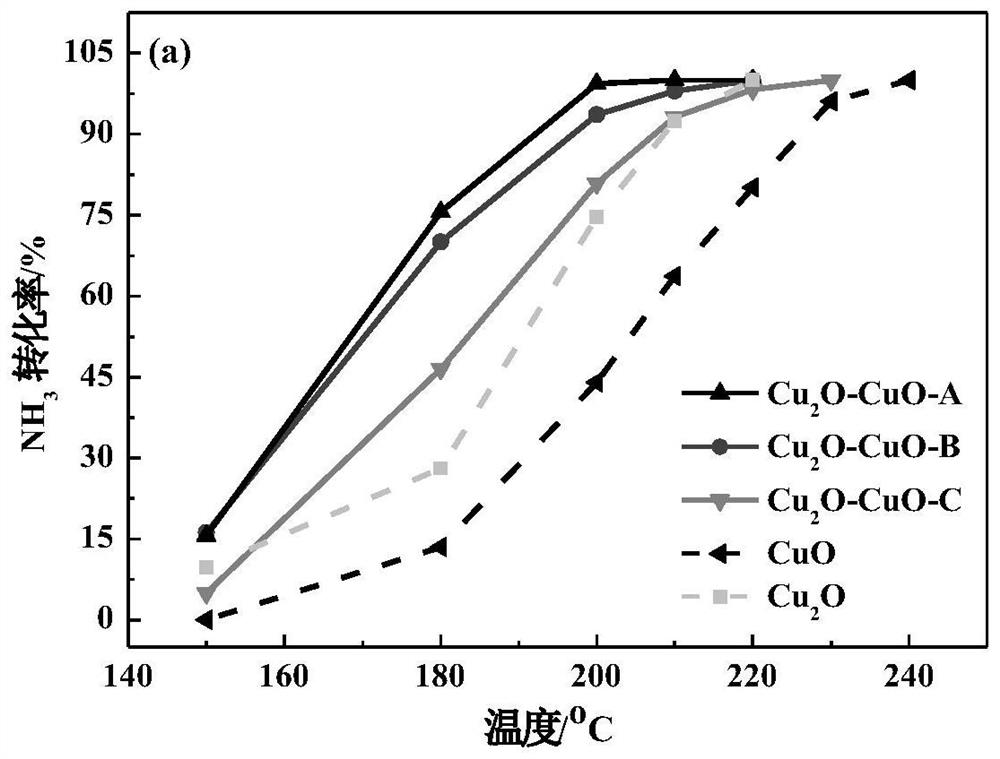

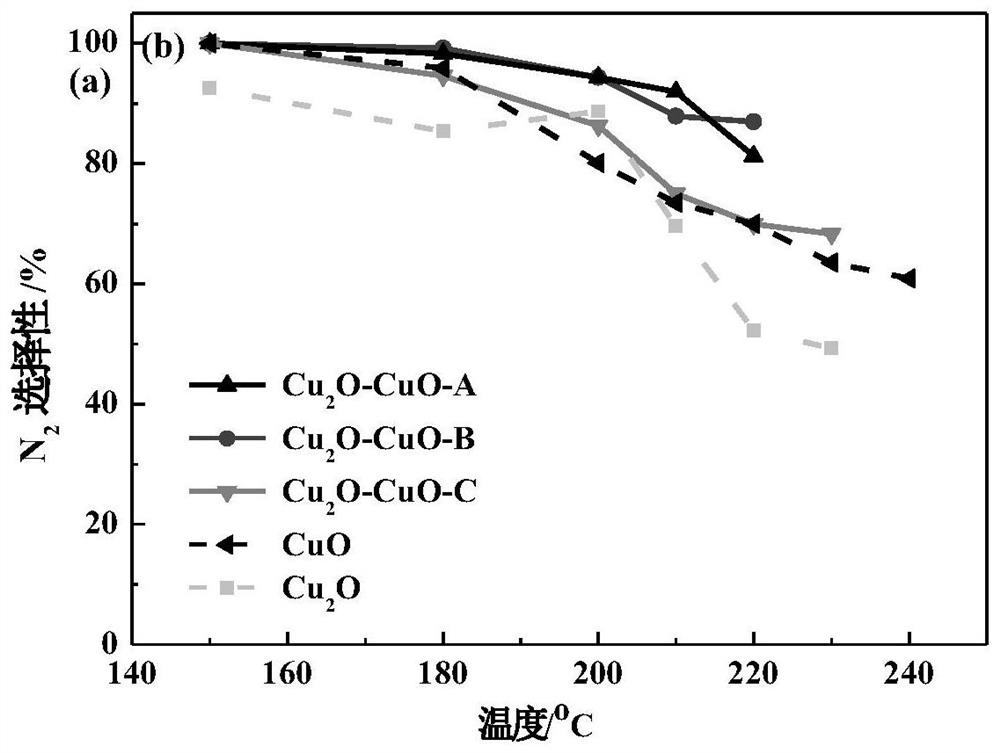

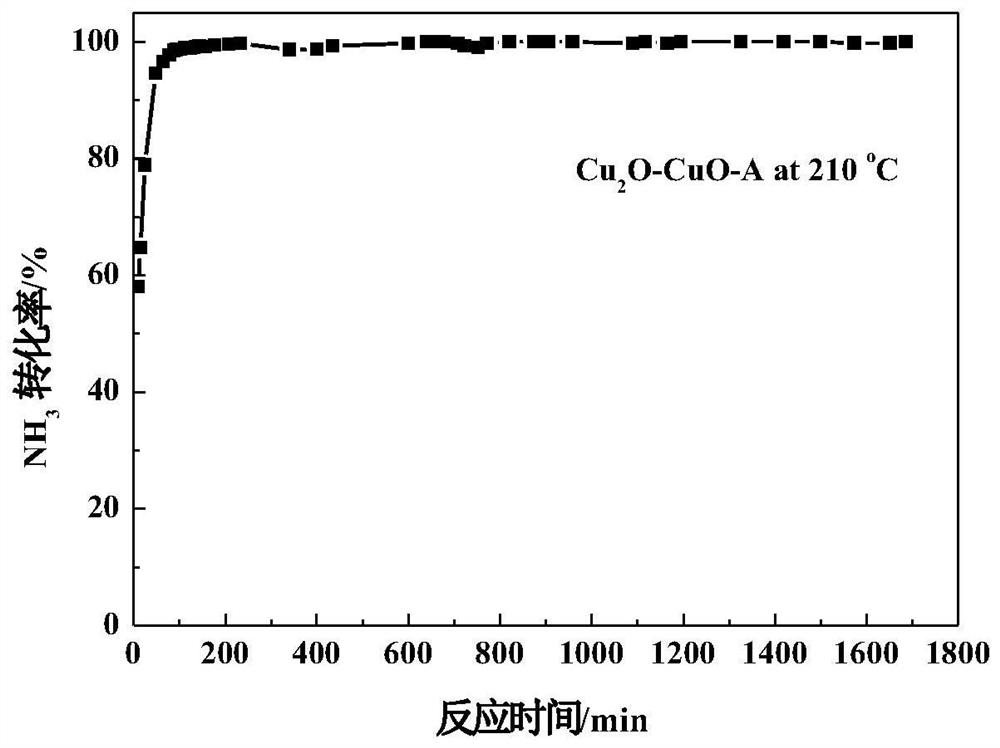

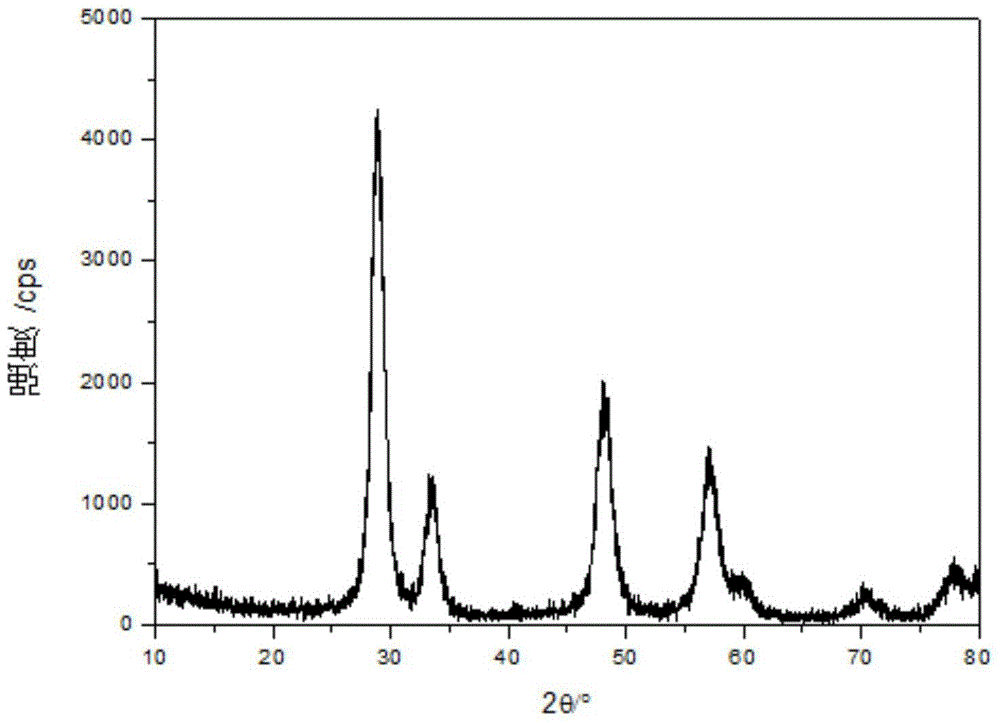

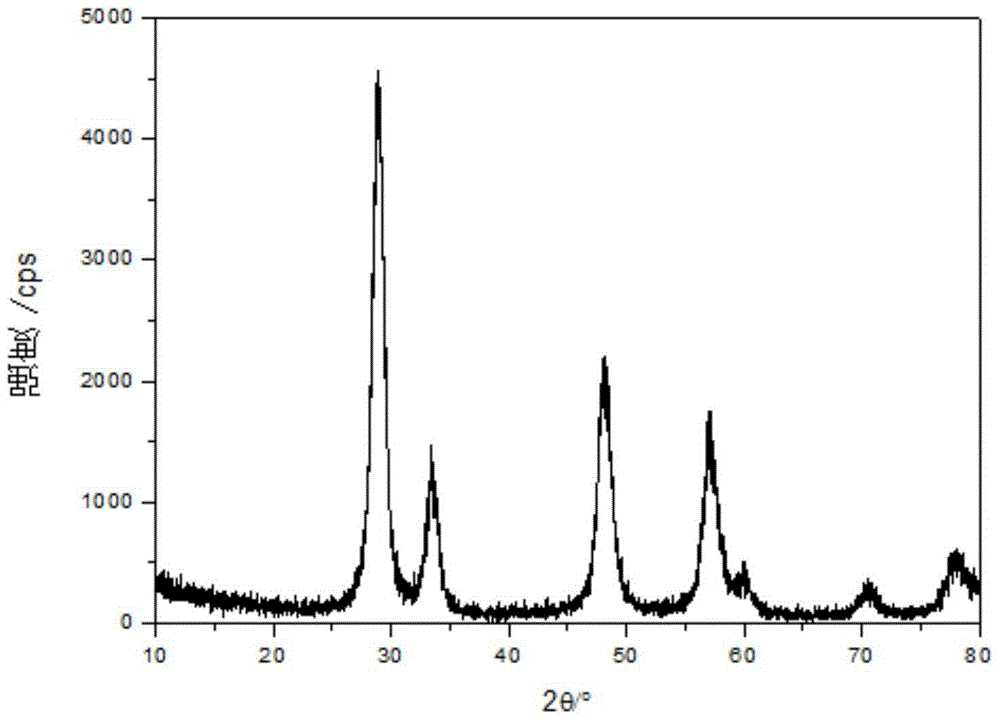

Single-component double-active-site Cu2O-CuO nanometer mixed phase structure copper oxide catalyst, and preparation method and applications thereof

ActiveCN109926048AGood choiceHigh selectivityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationCopper oxide

The invention belongs to the technical field of catalytic material, and provides a single-component double-active-site Cu2O-CuO nanometer mixed phase structure copper oxide catalyst, and a preparationmethod and applications thereof. The single-component double-active-site Cu2O-CuO nanometer mixed phase structure copper oxide catalyst can be used for ammonia selectivity catalytic oxidation. Control on cuprous particle surface reconstruction process is realized through adjusting catalyst pretreatment conditions, so that regulation and control on surface copper oxide outer wall formation is realized; and at last, the Cu2O-CuO nanometer mixed phase structure composite copper oxide material taking Cu2O nanometer particles as cores is obtained, wherein the Cu2O nanometer particle cores are coated with CuO housings. The catalyst is excellent in ammoxidation activity and N2 selectivity, and reaction stability; the preparation method is simple and reliable, and high in efficiency; the raw materials are easily available; and the preparation method is convenient for large amount preparation.

Owner:DALIAN UNIV OF TECH

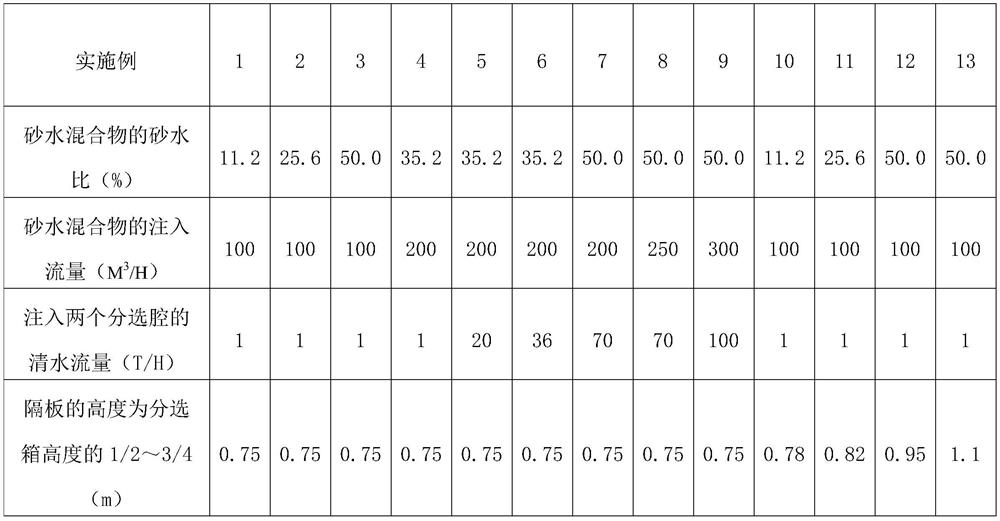

Method for sorting quartz sand

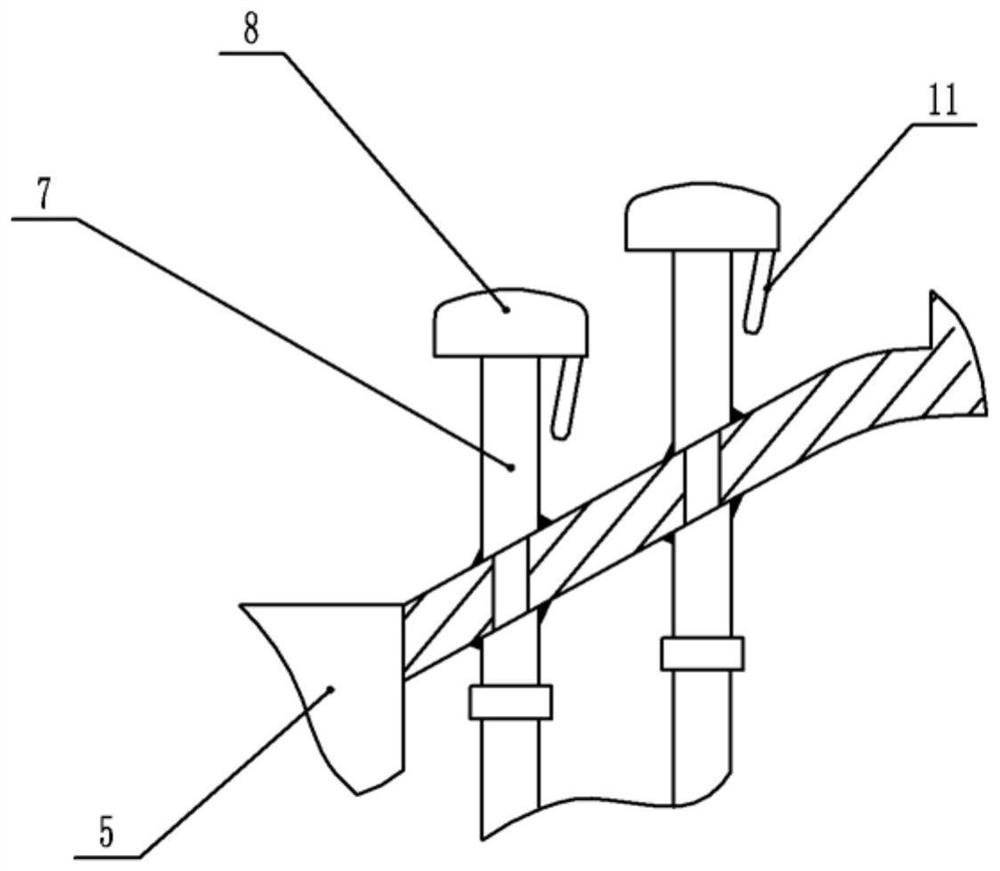

ActiveCN110064500AShort production processImprove efficiencyCleaning using liquidsWet separationUltrasonic generatorMineralogy

The invention belongs to the technical field of quartz sand processing, and specifically discloses a method for sorting quartz sand. The method comprises the following steps that clear water is continuously fed into a sorting box, and clear water flows upwards; quartz sand particles and clear water are mixed into a sand-water mixture, and the sand-water mixture is introduced into the sorting box from the side wall of the sorting box at a flow rate of 100 M<3> / H to 300 M<3> / H; ultrasonic force is applied to the quartz sand particles in the sorting box through an ultrasonic generator, and the frequency of the ultrasonic generator is 28 KHz to 42 KHz; and the quartz sand particles in the sorting box are discharged and collected after sorting is completed. By adopting the process, the quartz sand can be cleaned while being sorted, and the production process of quartz sand is shortened.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Preparation method of 1,3-propane sultone

InactiveCN108997303AControl sedimentation rateLattice stabilizationOrganic chemistryDistillationPrecipitation

The invention discloses a preparation method of 1,3-propane sultone. The preparation method comprises the steps as follows: firstly, preparing a calcium chloride solution, adding citric acid to prepare a mixed solution A, mixing the mixed solution A with a sodium polyacrylate to prepare a mixed solution B, then, quickly adding the mixed solution B to a sodium carbonate solution for precipitation to prepare porous calcium carbonate, and soaking the porous calcium carbonate in a peroxybenzoic acid solution to prepare a catalyst; mixing sodium allylsulfonate and a sulfuric acid solution, adding the catalyst for a reaction, adding an ethanol solution of sodium hydroxide for a reaction, and finally, adding hydrochloric acid for acidization to prepare 3-hydroxypropanesulfonic acid; mixing prepared 3-hydroxypropanesulfonic acid and n-hexane, adding the mixture to a three-neck flask to be stirred to react, cooling a product to the room temperature after the reaction, and performing reduced pressure distillation to prepare the target product 1,3-propane sultone. The method is simple to operate, low in energy consumption and high in product yield.

Owner:SUZHOU GAIDE FINE MATERIALS CO LTD

Method for preparing finishing liquid for improving anti-electrostatic property of fabric

The invention discloses a method for preparing a finishing liquid for improving the anti-electrostatic property of a fabric and relates to the field of fabric finishing. The method specifically comprises the following steps: firstly, dissolving manganese nitrate and zirconium acetate into ethanol, adding sodium chloride and citric acid, precipitating with an alkali liquid, and mixing with porous silica gel and carbon nanotubes so as to obtain mixed powder; dispersing the mixed powder into deionized water so as to obtain a dispersion liquid, further putting into a sticky liquid prepared after sodium alginate is dissolved into an alkali liquid, finally reacting with butyl acrylate and potassium peroxodisulfate, further adding a thickening agent, a defoaming agent and a leveling agent, and uniformly stirring and mixing, thereby obtaining the finishing liquid. The finishing liquid prepared by using the method is high in stability, high in wettability with a fabric, and capable of effectively improving the anti-electrostatic property and the weather resistance of the fabric.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

Fluorescent glue capable of packaging white light LEDs

The invention discloses fluorescent glue capable of packaging white light LEDs. The fluorescent glue is prepared by mixing the following components in parts by weight: 50-60 parts of allochroic silicagel, 45-50 parts of water-proof silica gel, 30-40 parts of super light clay, 20-25 parts of epoxy resin glue, 5-10 parts of colorful flashlight powder, 10-12 parts of blue fluorescent powder, 10-12 parts of red fluorescent powder, 10-12 parts of green fluorescent powder, 3-5 parts of diffusion powder, 5-8 parts of light dispersing agent, 5-8 parts of electron powder and 5-10 parts of nanometer negative ion powder. The fluorescent glue capable of packaging the white light LEDs can improve the yield of the white light LEDs; compared with traditional fluorescent glue, the sedimentation rate of the fluorescent glue can be effectively controlled, the brightness of the LEDs is improved, and thus the product quality is improved.

Owner:广东赛铭照明科技有限公司

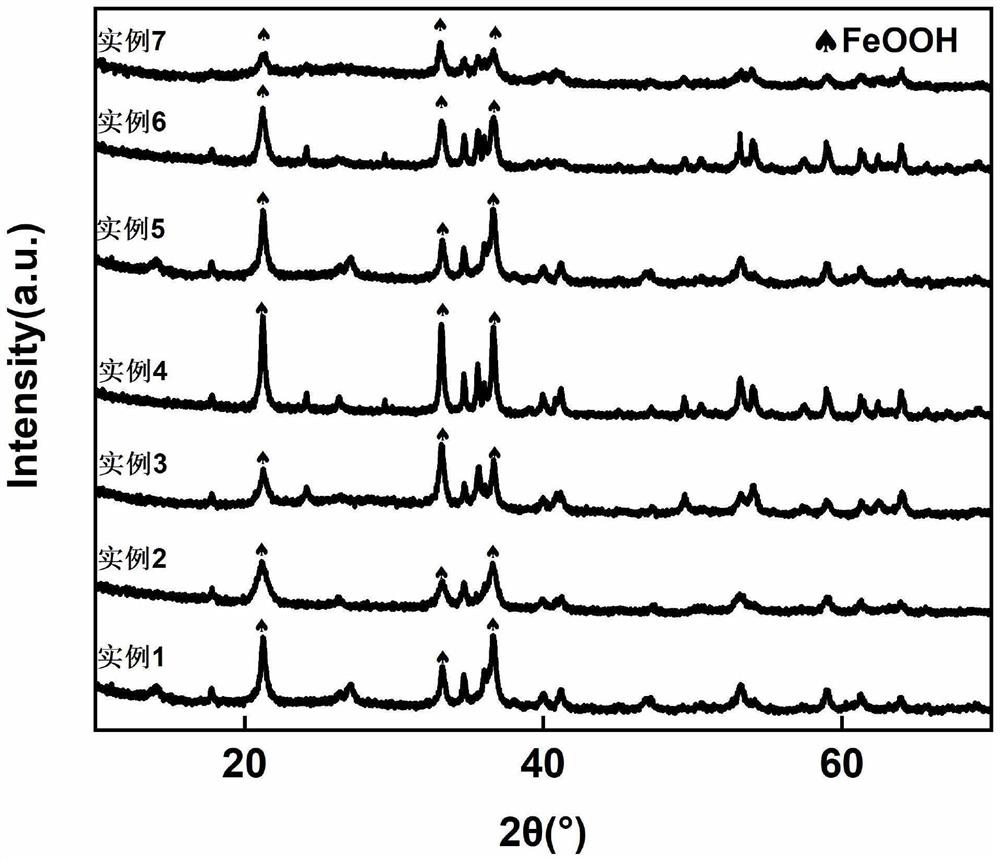

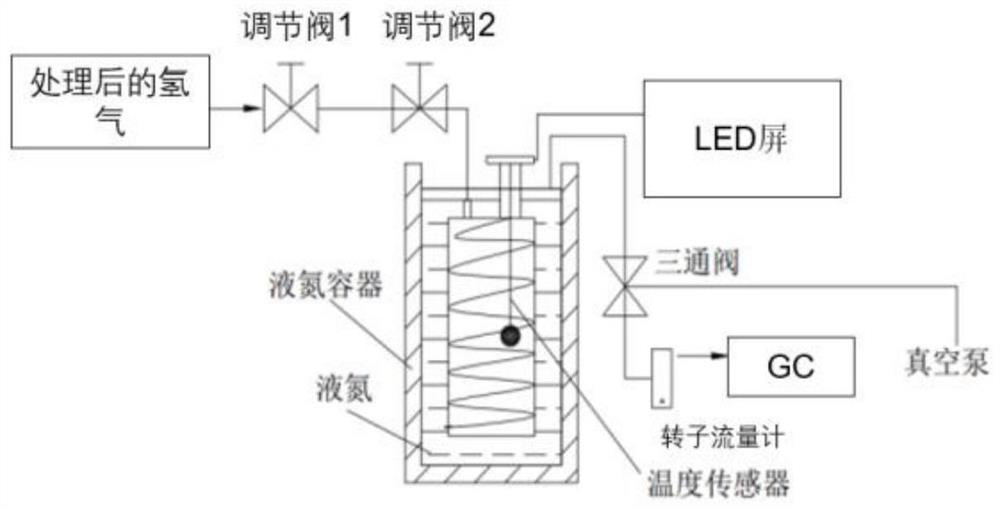

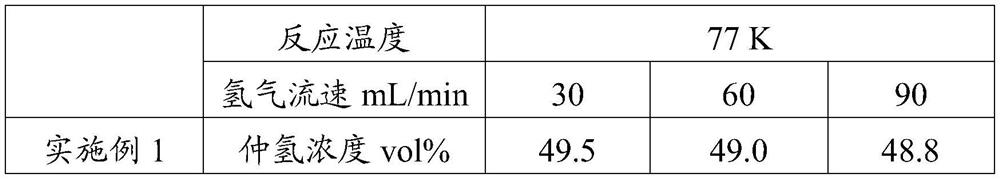

Nano hydrated iron oxide as well as preparation method and application thereof

PendingCN114314677ASmall particlesGuaranteed uniformityMaterial nanotechnologyCatalyst activation/preparationNano catalystHydration reaction

The invention belongs to the technical field of catalysts, and provides a preparation method of nano hydrated iron oxide. According to the preparation method, the mixed solution containing the water-soluble ferric salt and the precipitant is firstly prepared, then the mixed solution containing the precipitant is dropwise added into the mixed solution containing the water-soluble ferric salt for the hydrothermal precipitation reaction, nanoscale ferric oxide hydrate FeOOH is obtained, the particle size uniformity and catalytic activity of the catalyst are guaranteed, the preparation process is simple, and the cost is low; citric acid and ethanol are respectively added as dispersing agents in the process of preparing two mixed solutions and are used for dispersing particles in the hydrothermal reaction process, so that the precipitation speed is controlled, rapid growth of the particles is avoided, and the nano-catalyst with smaller particles is obtained. The result of the embodiment shows that the particle size of the hydrated iron oxide prepared by the preparation method provided by the invention is 15-25nm; when the catalyst is used for catalytic conversion of ortho-parahydrogen, the concentration of parahydrogen is 49.7%, and the conversion rate is 99.3%.

Owner:NINGBO UNIV

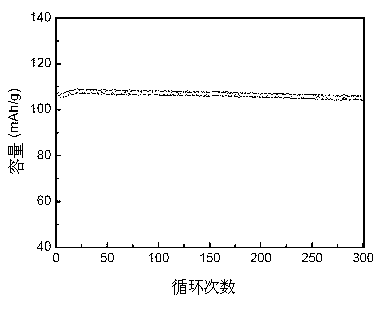

Preparation method of high-capacity secondary alkaline zinc-nickel battery

InactiveCN107895818AImprove conductivityIncrease profitFinal product manufactureCell electrodesNickel saltCarbonization

The invention discloses a preparation method of a high-capacity secondary alkaline zinc-nickel battery. The method comprises the following steps that firstly, a Ni3(BTC)2 DMF precursor is prepared with nickel salt and BTC as raw materials; secondly, the precursor is subjected to pre-carbonization to obtain a pre-carbonized Ni3(BTC)2 DMF precursor; thirdly, pre-carbonized powder and sulfur powder are mixed and sulfurized to prepare a Ni3S2 / C composite material; a positive plate is prepared; fourthly, zinc oxide is prepared through a co-precipitation method; fifthly, zinc oxide, zinc powder andsodium phytate are mixed and ground and then mixed with polytetrafluoroethylene emulsion to prepare negative slurry, then the surface of a collector material is coated with the negative electrode slurry, drying and rolling are conducted, and a negative plate is prepared; the positive plate, a diaphragm and the negative plate are laminated together and wound into a core to be placed into a batteryshell, then an electrolyte is injected, tabs are subjected to spot welding, sealing and formation are conducted, and the secondary alkaline zinc-nickel battery is prepared. The battery prepared through the method is good in cycling stability and large in capacity.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

A kind of preparation method of tin oxide coated cobalt magnesium lithium material

ActiveCN105006567BLattice stabilizationCoated evenlyCell electrodesSecondary cellsLithiumMagnesium salt

The invention discloses a method for preparing a stannic-oxide-wrapped cobalt magnesium lithium material. The method includes the following steps: cobalt salt and magnesium salt are dissolved into water, stabilizers are added to be mixed, a solution A is obtained, the solution A and precipitators are added into a reaction container at the same time for carrying out co-precipitation, purifying processing, heat nature determining processing and sub-high temperature processing are carried out on sediment to obtain cobalt magnesium oxide; the cobalt magnesium oxide is mixed with LiOH.H2O, absolute ethyl alcohol is added, ball milling is carried out in a planetary ball mill, filtering and drying are carried out, the obtained powder material is loaded into a porcelain boat, the porcelain boat with the powder material is pushed into a resistance furnace to be sintered, and a cobalt magnesium lithium material is obtained after cooling is carried out; the obtained cobalt magnesium lithium material is mixed with SnCl2.2H2O and deionized water, the mixture is evenly stirred, ultrasonic processing, filtering and drying are carried out, and the stannic-oxide-wrapped cobalt magnesium lithium material is obtained after roasting is carried out in a muffle furnace. The prepared stannic-oxide-wrapped cobalt magnesium lithium material is stable in electrochemical performance, stable in crystal lattice, large in tap density and good in cycle performance and rate performance.

Owner:玉环市星光眼镜厂

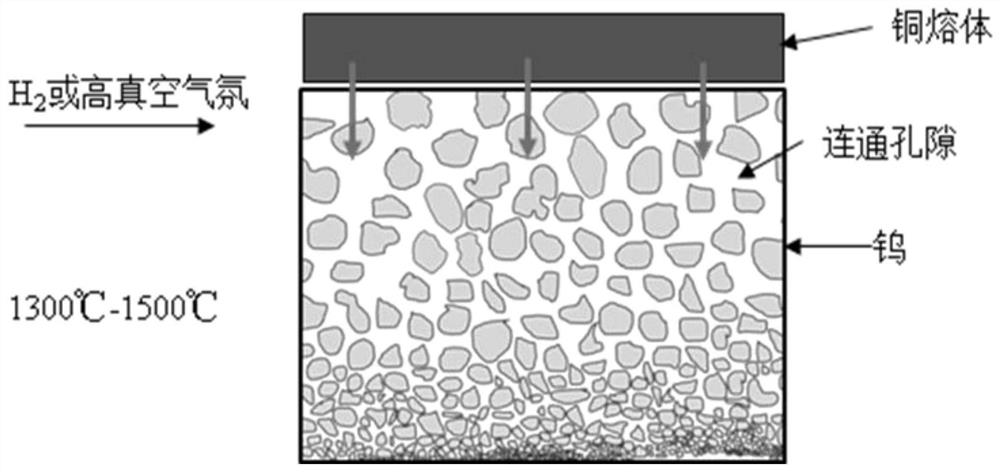

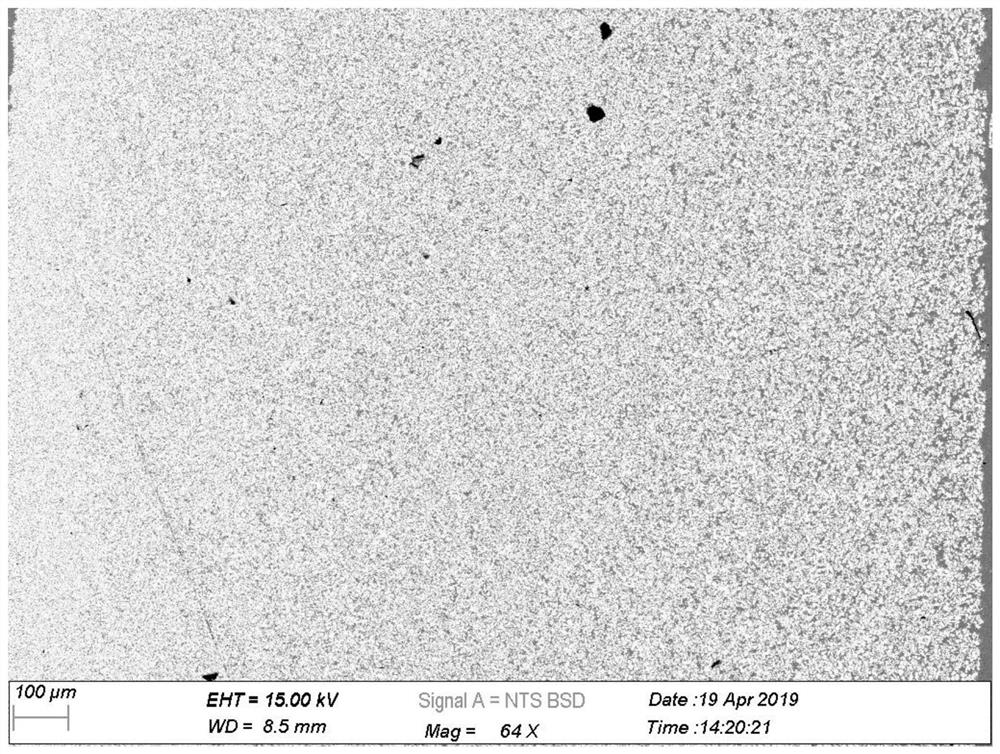

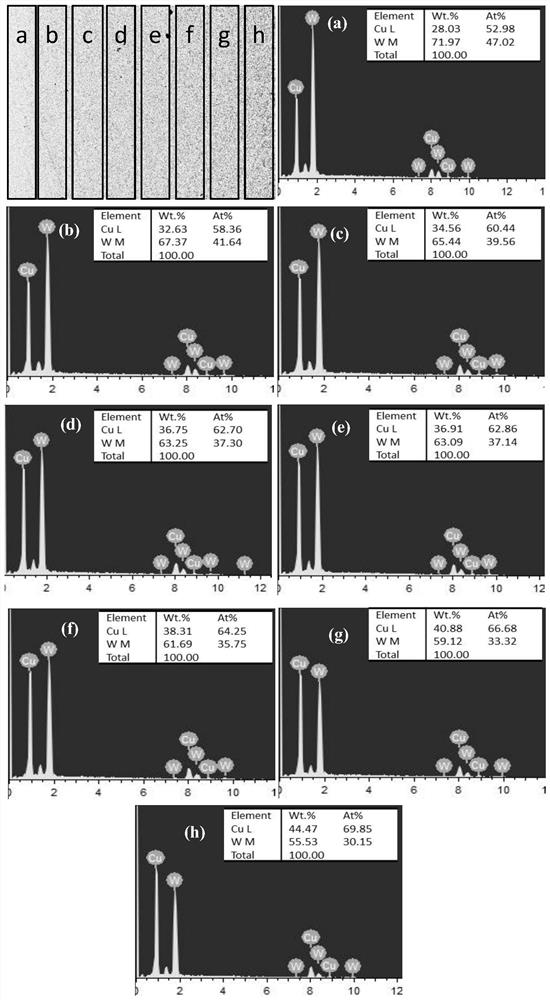

A kind of preparation method of w-cu continuous gradient composite material

The invention discloses a preparation method of a W-Cu continuous gradient composite material, which uses W powders of different particle sizes as raw materials, adds binders, dispersants, plasticizers, etc., mixes them through ball milling to obtain suspension slurry, and then settles and dries to obtain The green body is debinding and sintered to obtain a W skeleton with a continuous gradient distribution of pores, and then infiltrated with Cu at a certain temperature, and finally a W-Cu continuous gradient composite material with W and Cu components continuously changing along the cross section is obtained. The invention can realize the continuous change of W and Cu components along the cross section, and further realize the continuous change of material properties along the cross section; the raw materials used in the method of the invention are easy to obtain, the process flow is short, and the cost is low, which is suitable for large-scale production.

Owner:HEFEI UNIV OF TECH

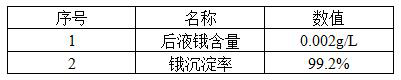

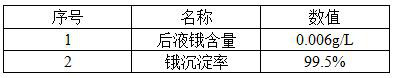

Method for reducing osmium secondary absorption liquid

The invention discloses a method for reducing secondary osmium absorption liquid, which comprises the following steps: adjusting the pH value of the secondary osmium absorption liquid to 5-7, and controlling the concentration of the secondary osmium absorption liquid to be 25-30g / L; and heating the secondary osmium absorption liquid to 55-65 DEG C, adding an ethanol solution, reacting for 1-2 hours at the constant temperature of 55-65 DEG C, filtering and washing to obtain the metal osmium. The ethanol solution is used for replacing hydrazine hydrate reduction osmium secondary absorption liquid, so that the cost is reduced. According to the method, the pH of the osmium secondary absorption liquid is adjusted before the ethanol solution is added, so that the osmium precipitation rate of the osmium absorption liquid can be effectively controlled; hydrazine hydrate is replaced with an ethanol solution, and due to the fact that hydrazine hydrate is a strong reducing agent and has certain dangerousness, the safety risk is reduced; according to the method, the osmium absorption liquid is heated to 55-65 DEG C before the ethanol solution is added for reduction, the reduction efficiency is effectively improved, the osmium reduction rate is larger than or equal to 99%, and the content of osmium in the liquid after reaction is smaller than or equal to 0.01 g / L.

Owner:JINCHUAN GROUP LIMITED

A kind of preparation method of lithium ion battery

ActiveCN106997965BHigh tap densityImprove conductivityMaterial nanotechnologyFinal product manufactureCarbon layerAluminium-ion battery

The invention discloses a preparation method of a lithium ion battery. The specific process is as follows: firstly, a carbon-coated lithium iron phosphate positive plate is prepared by using a co-precipitation method and using foamed nickel as a substrate; then, using the foamed nickel as a substrate, growing Co 3 o 4 Nanowire arrays, and using the method of constant voltage electrodeposition on Co 3 o 4 A silicon layer is deposited on the surface of the nanowire array, and a carbon layer is sprayed on the surface of the silicon layer to obtain a negative electrode sheet. Finally, the positive electrode sheet, separator, and negative electrode sheet are stacked in sequence to make a roll core, which is sealed in the battery case and injected with electrolyte. charging, aging, and formation to produce a lithium-ion battery. The lithium-ion battery produced by the method has high energy density, high power, good cycle performance, and low preparation cost.

Owner:安徽力源新能源有限公司

A kind of preparation method of electroplated diamond grinding wheel for grinding

ActiveCN103173840BControl sedimentation rateEvenly distributedCellsElectrolytic coatingsGranularityElectroplating

Owner:白鸽磨料磨具有限公司

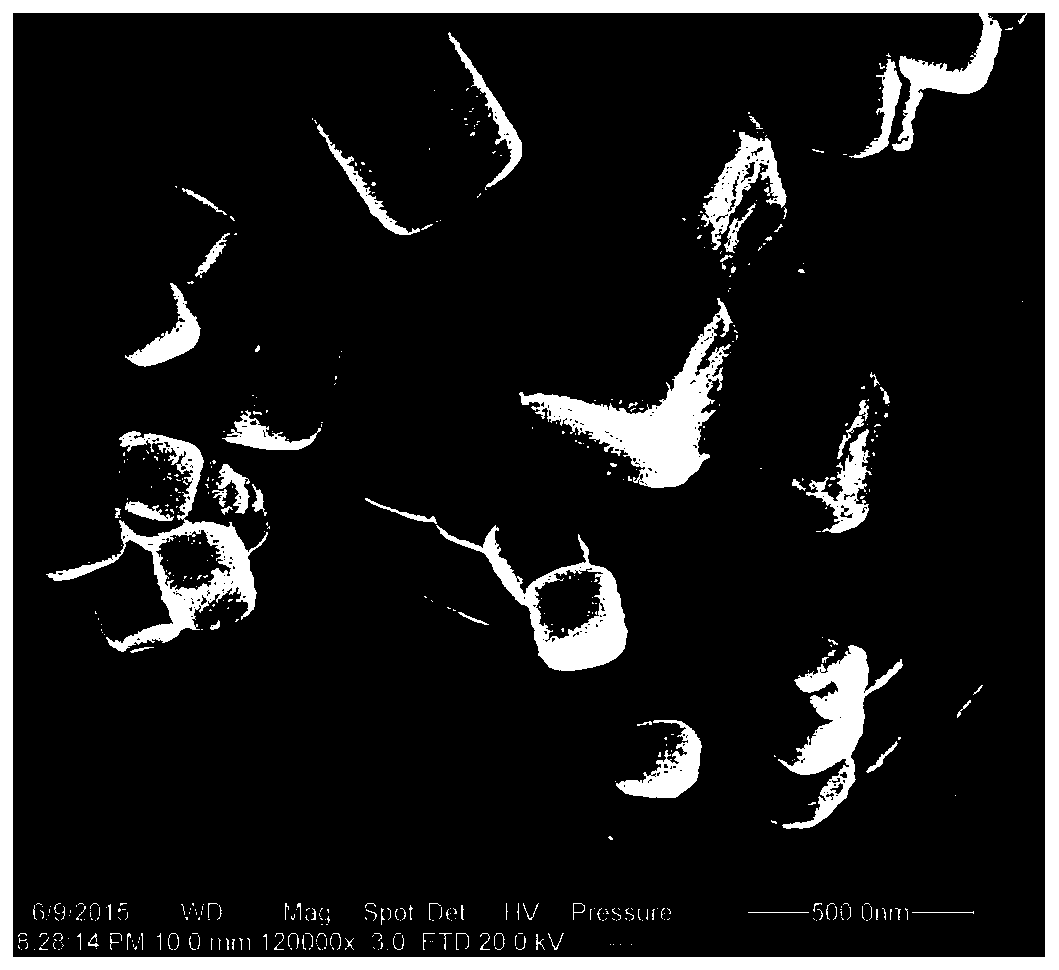

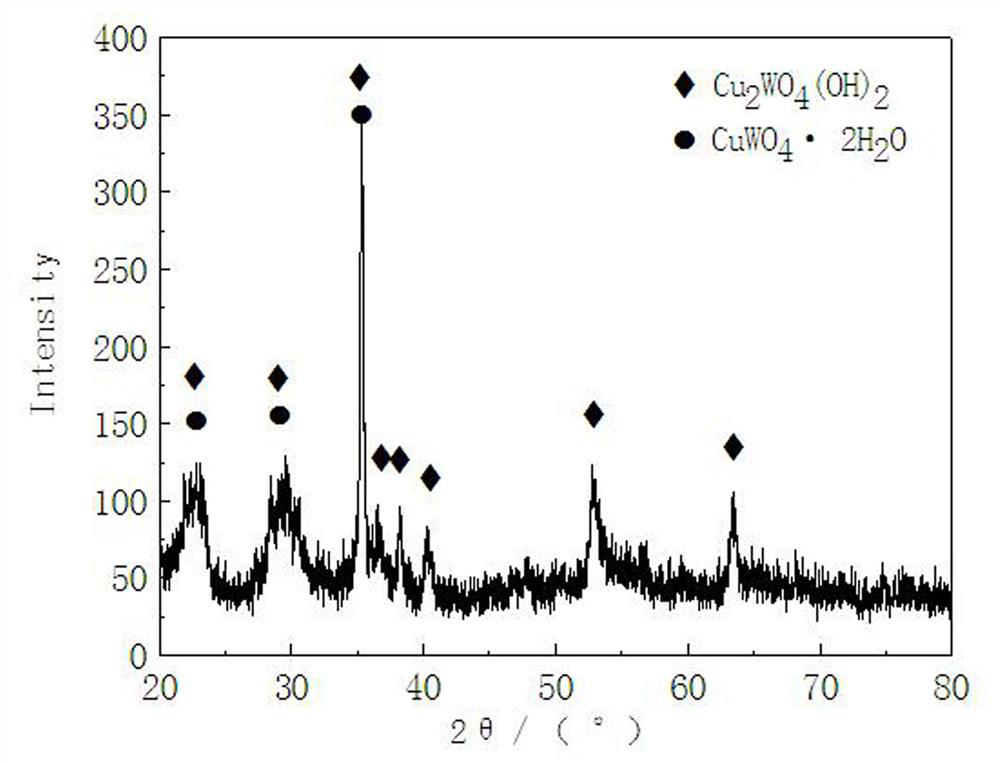

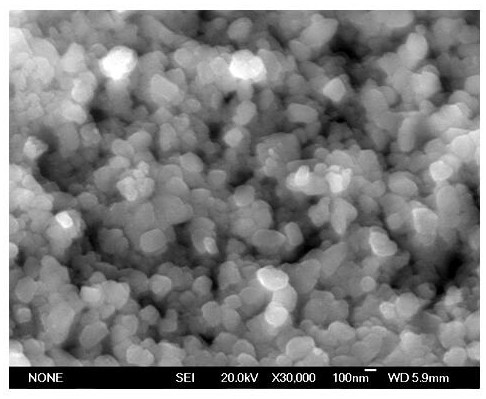

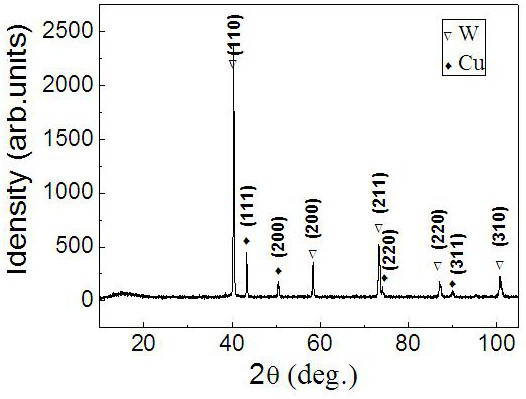

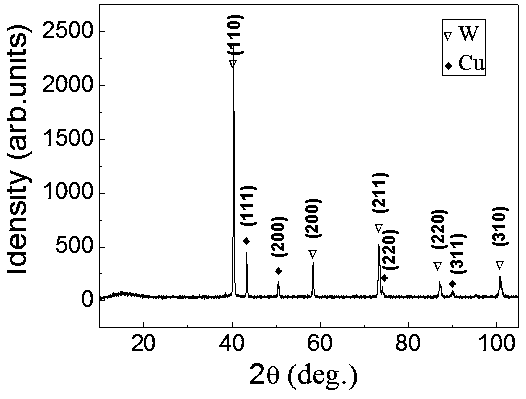

A simple preparation method of nanoscale tungsten copper precursor powder

ActiveCN108339989BOptimizing the Hydrothermal Reaction ProcessShorten the production cycleNanotechnologyCopper nitratePhysical chemistry

A simple preparation method of nano-scale tungsten-copper precursor powder, the corresponding solution is prepared by using sodium tungstate dihydrate and copper nitrate trihydrate as raw materials, and then the sodium tungstate solution is dropped into the containing The pH value of the mixed solution is adjusted by using ammonia water or nitric acid in the copper nitrate solution of copper complex ions, and then the mixed solution is directly placed in a vacuum drying oven to undergo a thermochemical reaction, thereby preparing a nano-scale tungsten-copper precursor powder. The method of the present invention can prepare tungsten-copper precursor powder with uniform mixing, fine particles and high purity. Compared with the hydrothermal method, the present invention is characterized by short production cycle, no need of reaction kettle, and reduced preparation cost.

Owner:HENAN UNIV OF SCI & TECH

A kind of fluorescent glue and the technology of using fluorescent glue to encapsulate white light LED

The invention relates to fluorescent glue and a process of packaging a white light LED (light-emitting diode) by the same. The fluorescent glue comprises silica gel, fluorescent powder and nano anti-precipitating powder. The silica gel includes agent A and agent B. The weight ratio among the agent A, the agent B, the fluorescent powder and the nano anti-precipitating powder is 1: 0.5: (0.075-0.3): (0.045-0.15). Since the nano anti-precipitating powder is added into the fluorescent powder, precipitation speed of the fluorescent powder can be effectively controlled, output of white light of an LED can be increased, luminance of the LED can be improved, and product quality of the LED can be improved, as compared with those of traditional fluorescent glue.

Owner:SHANGHAI ADVANCED SILICON TECH CO LTD

A single component dual active site cu 2 O-cuo nano-mixed structure copper oxide catalyst, preparation method and application

ActiveCN109926048BGood choiceHigh selectivityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystNanoparticle

The invention belongs to the technical field of catalytic materials and provides a single-component dual-active-site Cu 2 O-CuO nano-mixed structure copper oxide catalyst, preparation method and application. The catalyst can be used in selective catalytic oxidation of ammonia. By adjusting the pretreatment conditions of the catalyst, the control of the surface reconstruction process of the cuprous particles is realized, so as to achieve the purpose of regulating the formation of the outer wall of copper oxide on the surface. Finally get Cu 2 The O nanoparticles are the core, and the Cu with a CuO shell on the outside 2 O‑CuO nano-mixed phase structure composite copper oxide material. The catalyst has excellent ammonia oxidation activity and N 2 Selectivity, and good reaction stability. The preparation method is simple, efficient and reliable, the raw materials are readily available, and the preparation is easy in large quantities.

Owner:DALIAN UNIV OF TECH

Method for preparing composite reinforcement by taking plant fibers as template and application of composite reinforcement in metal-based composite material

InactiveCN111020413AControl sedimentation rateSmall sizeLiquid/solution decomposition chemical coatingSodium acetateMeth-

The invention discloses a method for preparing a composite reinforcement by taking plant fibers as a template. The method specifically comprises the following steps: modifying the surfaces of plant fibers by adopting 2-acrylamide-2-methylpropanesulfonic acid; mixing the plant fibers with a metal salt solution; adding sodium ethylene diamine tetracetate and an ammonia water solution for reaction; after the reaction is finished, mixing the prepared solid with a mixed solution of magnesium nitrate, strontium acetate and aluminum nitrate, adding a sodium hydroxide solution for reaction, drying theprepared solid after the reaction is finished, performing carbonization treatment in a muffle furnace to prepare a composite reinforcement, and mixing the composite reinforcement with a metal matrixto prepare the composite material. The method is simple to operate, the prepared composite material is high in strength and good in toughness, and sound interface bonding is achieved between the reinforcement and the metal matrix.

Owner:南京环达新材料有限公司

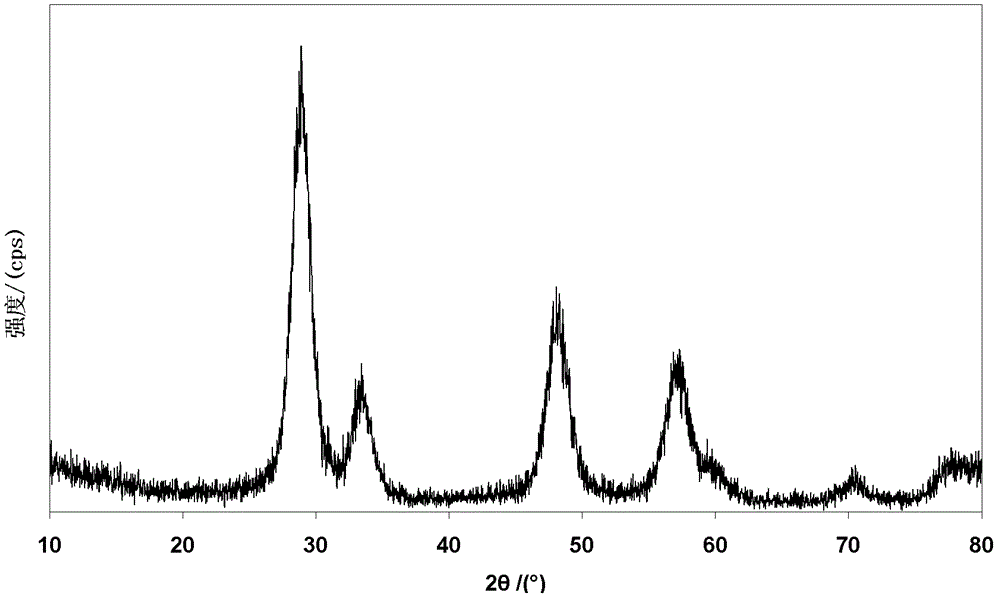

Preparation method of cerium-zirconium based solid solution

ActiveCN104492414BUniform particle sizeLarge particle sizeMetal/metal-oxides/metal-hydroxide catalystsCeriumBULK ACTIVE INGREDIENT

The invention discloses a preparation method of a cerium-zirconium based solid solution. The preparation method comprises the following sequential steps: (1) preparation of Ce<4+>; (2) preparation of active ingredient solution; (3) precipitation reaction; (4) surface modification; (5) roasting. The Ce<4+> is prepared firstly and then mixed with other rare earth ions and positively quadrivalent zirconium ions to obtain a mixed metal nitrate solution; as the mixed metal nitrate solution contains an organic complexing agent, the precipitation speed in the precipitation reaction process is controlled by virtue of complexing coordination of the organic complexing agent and the rare earth and zirconium ions, so that a precursor uniform and stable in particle size is obtained; the surface treatment is performed on the precipitate precursor by use of polyacrylic acid, and therefore, the agglomeration problem of particles in the roasting process is solved, and the pore diameter and the pore volume of the roasted product are increased, and consequently, the cerium-zirconium based solid solution catalytic material excellent in heat stability is obtained. The preparation method is suitable for the preparation of the solid solutions.

Owner:方复(上海)新材料科技有限公司

A core-shell structure nano-copper cerium composite oxide catalyst, preparation method and application

ActiveCN109926060BGood ammonia oxidation activityRealize the packageDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCerium

The invention belongs to the technical field of catalytic materials, and discloses a core-shell structure nano-copper-cerium composite oxide catalyst, a preparation method and an application. The catalyst can be used in selective catalytic oxidation of ammonia. By adjusting the synthesis conditions of the catalyst, the local hydrolysis reaction on the surface of the copper oxide particles can be controlled, so as to achieve the purpose of regulating the formation of the outer wall of cerium oxide and the etching degree of the copper oxide particles. Finally, with CuO nanoparticles as the core, mesoporous CeO 2 CuO@CeO for the shell 2 Composite materials with core-shell structure. The catalyst has excellent ammonia oxidation activity and N 2 Selectivity, and good reaction stability. The preparation method is simple, efficient and reliable, the raw materials are readily available, and the preparation is easy in large quantities.

Owner:DALIAN UNIV OF TECH

Simple preparation method for nano-grade tungsten-copper precursor powder

The invention discloses a simple preparation method for nano-grade tungsten-copper precursor powder. The method comprises the steps that a corresponding solution is prepared by taking tungstic acid sodium salt dihydrate and copper nitrate hydrate as raw materials, then a sodium tungstate solution is dropped into a copper nitrate solution containing copper complexing ions with the speed of 1-10 drops per second, then the pH value of the mixed solution is adjusted by using ammonia water or nitric acid, and then the mixed solution is directly put into a vacuum drying oven to generate thermochemical reaction, so that the nano-grade tungsten-copper precursor powder is prepared. By utilizing the method, the tungsten-copper precursor powder which is uniform in mixing, fine in particle and high inpurity can be prepared, and compared with a hydrothermal method, the method has the significant characteristics that the production period is short, a reaction kettle is not needed, and the preparation cost is reduced.

Owner:HENAN UNIV OF SCI & TECH

Cerium-zirconium-based solid solution rare earth oxygen-storage material and preparation method thereof

ActiveCN103127925BSmall particlesLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsReaction rateHeat stability

The invention discloses a cerium-zirconium-based solid solution rare earth oxygen-storage material and a preparation method thereof. The cerium-zirconium-based solid solution rare earth oxygen-storage material has a specific surface area equal to or greater than 90m<2>.g<-1>, has a specific surface area equal to or greater than 30m<2>.g<-1> after being calcined at a temperature of 1000 DEG C for 4 hours, and has a specific surface area equal to or greater than 20m<2>.g<-1> after being calcined at a temperature of 1050 DEG C for 12 hours. Compared with the prior art, the preparation method has the advantages that before precipitation, a mixed metal salt solution is added with a certain amount of an organic acid so that acidity of the mixed metal salt solution is improved or the mixed metal salt solution forms sol; a reaction rate is inhibited and a precipitation rate is controlled so that a stable precursor having the uniform grain size is obtained; and the precipitate precursor surface treatment is carried out by a surfactant so that the aperture size and the aperture volume of a calcination product are improved and the cerium-zirconium-based solid solution rare earth oxygen-storage material having good heat stability is prepared. The cerium-zirconium-based solid solution rare earth oxygen-storage material has the advantages of small granule size, large specific surface area, high temperature aging resistance and high activity.

Owner:上海华明高纳稀土新材料有限公司

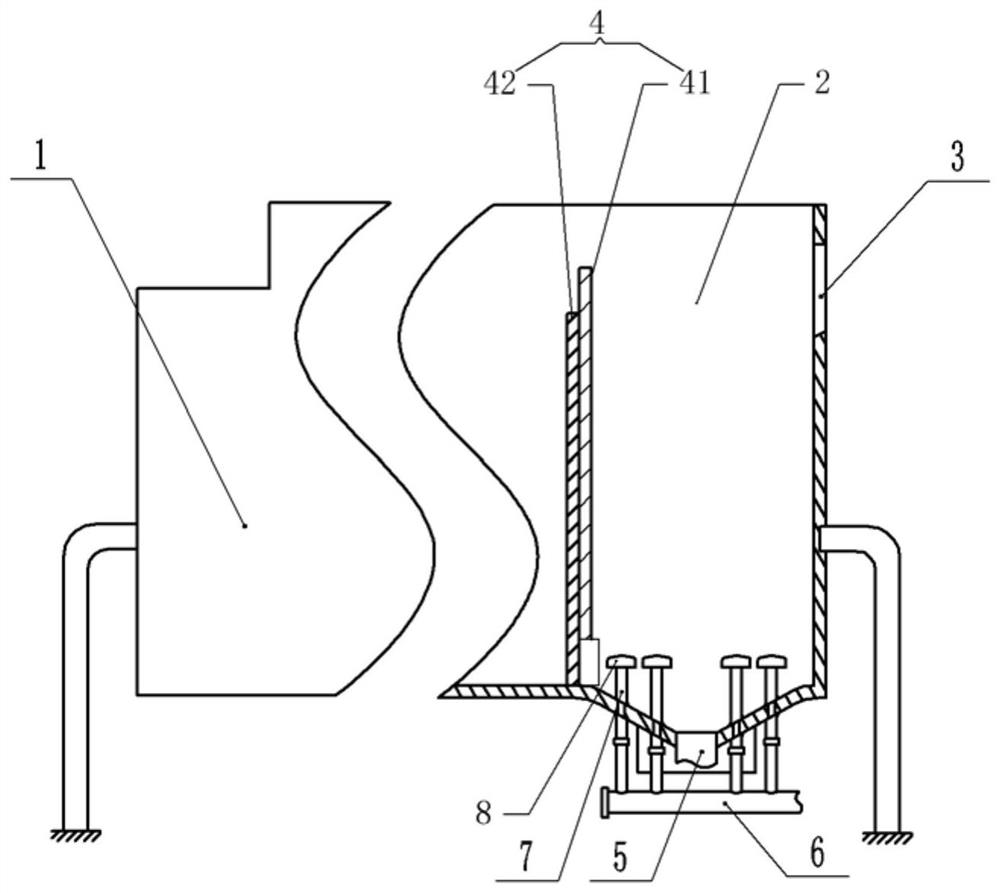

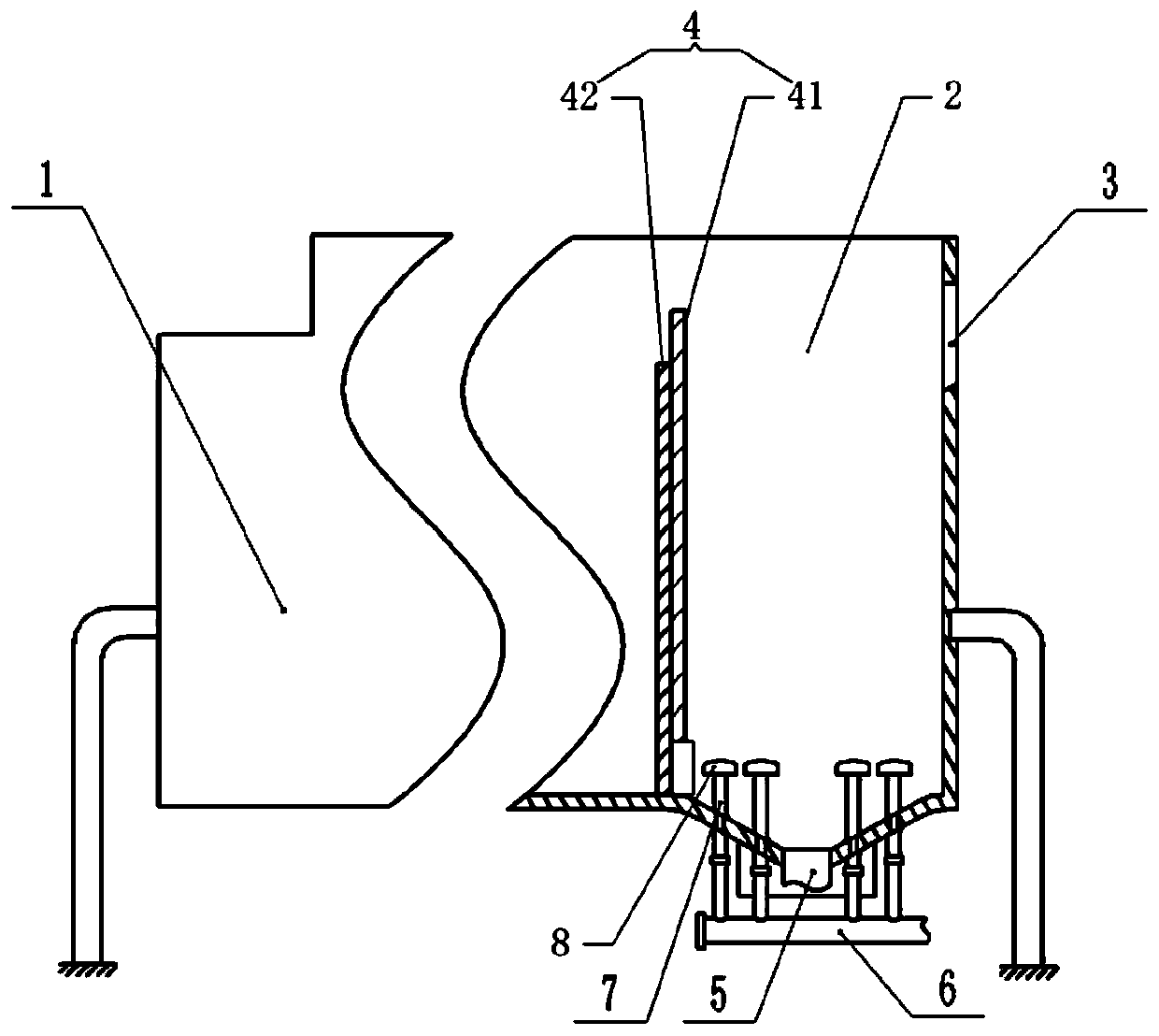

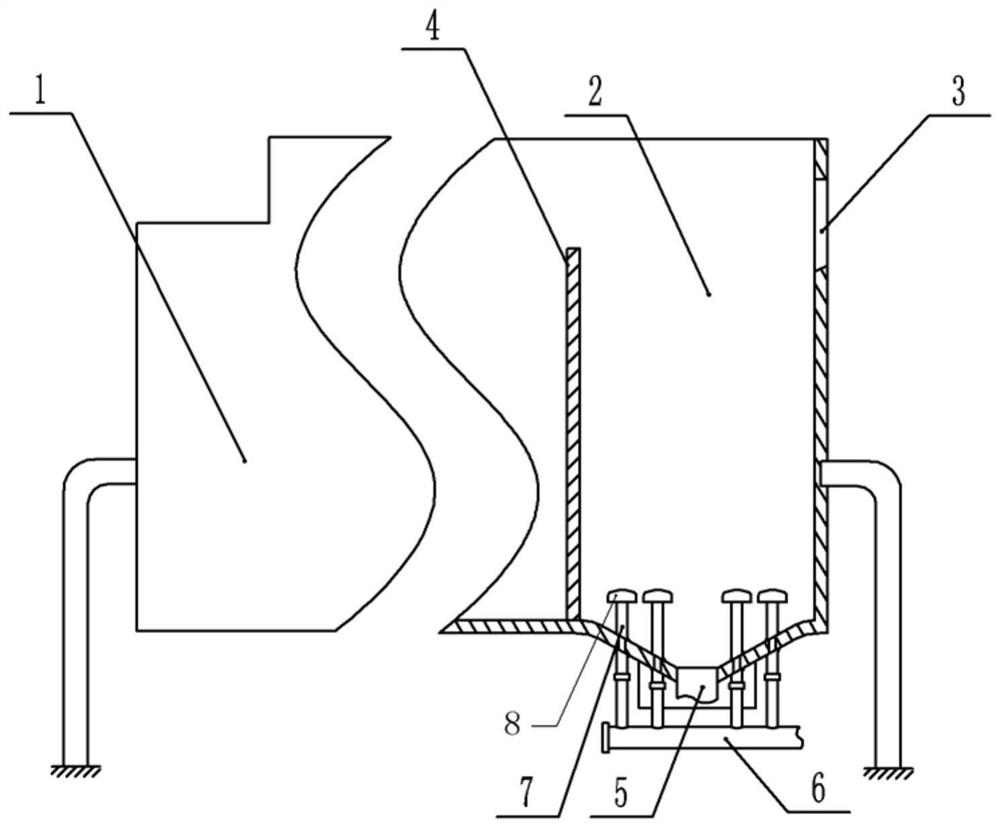

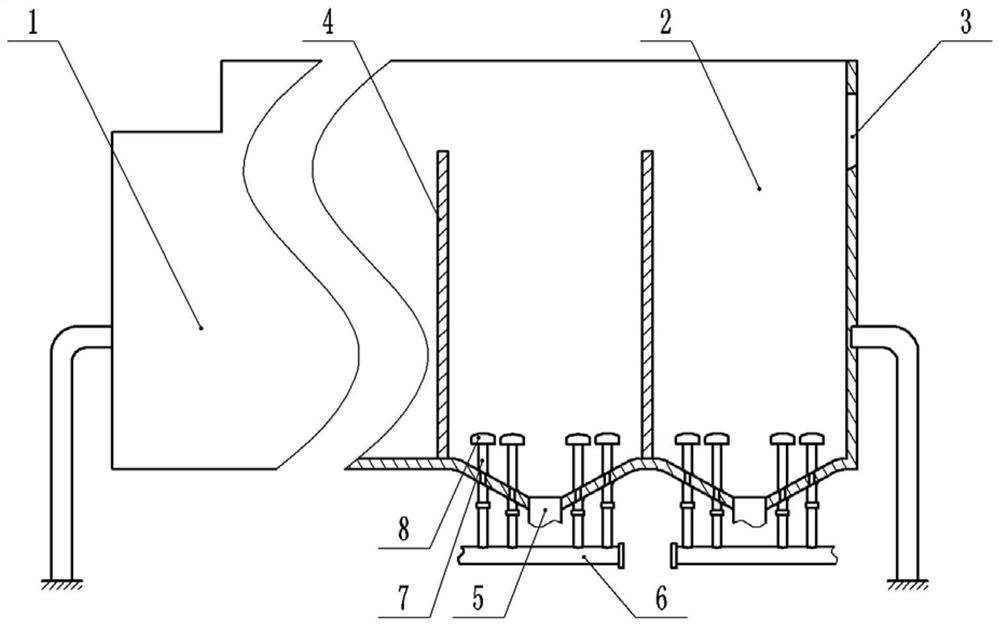

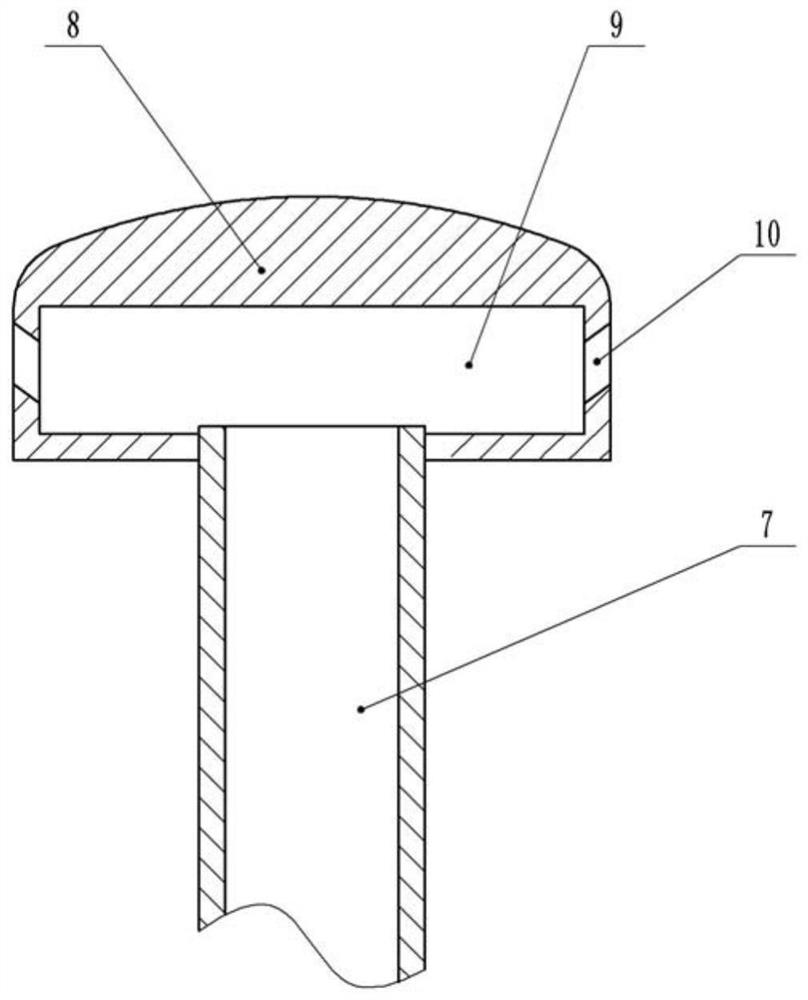

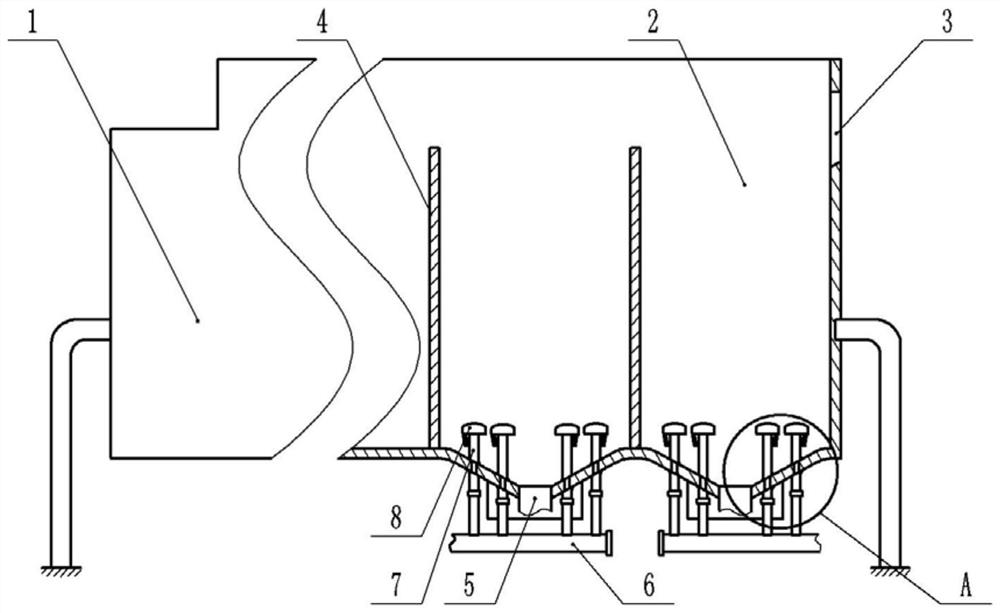

An air-injection quartz sand hydraulic separation method

ActiveCN110064504BControl sedimentation ratePrevent fallingCleaning using liquidsWet separationPhysical chemistryGas mixing

The invention relates to the technical field of quartz sand processing, and discloses a gas-injection type quartz sand hydraulic separation method. The separation is carried out in a sorting box, which includes the following steps: step A, feeding gas into the sorting box The air flow direction of the gas is directed upward; step B, the sand-water mixture is introduced, and the quartz sand particles and the gas are mixed to form a sand-water mixture; the sand-water mixture is 100M 3 / H~300M 3 The flow rate of / H is passed into the sorting box from the side wall of the sorting box; step C, completing the sorting, after the sorting is completed, the quartz sand particles in the sorting chamber are discharged and collected. In the present invention, quartz sand is screened at multiple stages through gas-liquid mixing.

Owner:长江造型材料(集团)科左后旗有限公司

Abrasion-resistant glass based on micro-nano array structure coating and preparation method thereof

The invention relates to the field of multifunctional glass preparation, and provides abrasion-resistance glass based on a micro-nano array structure coating. A plasma spraying technology is adopted for preparing a silicon nitride coating with the thickness of 100-200 nm on the surface of the abrasion-resistance glass; a zinc fluoride micro-nano array layer with the thickness of 80-150 nm grows onthe surface of the silicon nitride coating, and zinc fluoride is hollowed and grows perpendicularly on the surface of the silicon nitride coating; polymer macromolecular chains are grafted on the surface of the zinc fluoride micro-nano array and are carboxymethyl chitosan. The invention further discloses a preparation method of the abrasion-resistant glass. According to the prepared abrasion-resistance glass, a membrane layer and a glass substrate are good in bonding performance, the abrasion resistance of the glass can be improved effectively, and mechanical properties are excellent.

Owner:BEIJING BOMINGTANG GLASS

Gas injection type quartz sand hydraulic separation method

ActiveCN110064504AControl sedimentation ratePrevent fallingCleaning using liquidsWet separationProduct gasQuartz

The invention relates to the technical field of quartz sand processing, and discloses a gas injection type quartz sand hydraulic separation method. The separation is carried out in a separation box, and the separation method comprises the following steps of A introducing gas, continuously introducing the gas into the separation box, wherein the gas flow direction of the gas faces upwards; B, introducing a sand-water mixture, and mixing quartz sand particles and gas to form a sand-water mixture; and introducing the sand-water mixture into the separation box from the side wall of the separationbox at a flow rate of 100 M<3> / H-300 M<3> / H; and C, finishing the separation, specifically, after sorting is finished, quartz sand particles in the separation cavity are discharged and collected. According to the gas injection type quartz sand hydraulic separation method, the quartz sand is subjected to multi-stage screening in a gas-liquid mixing mode.

Owner:长江造型材料(集团)科左后旗有限公司

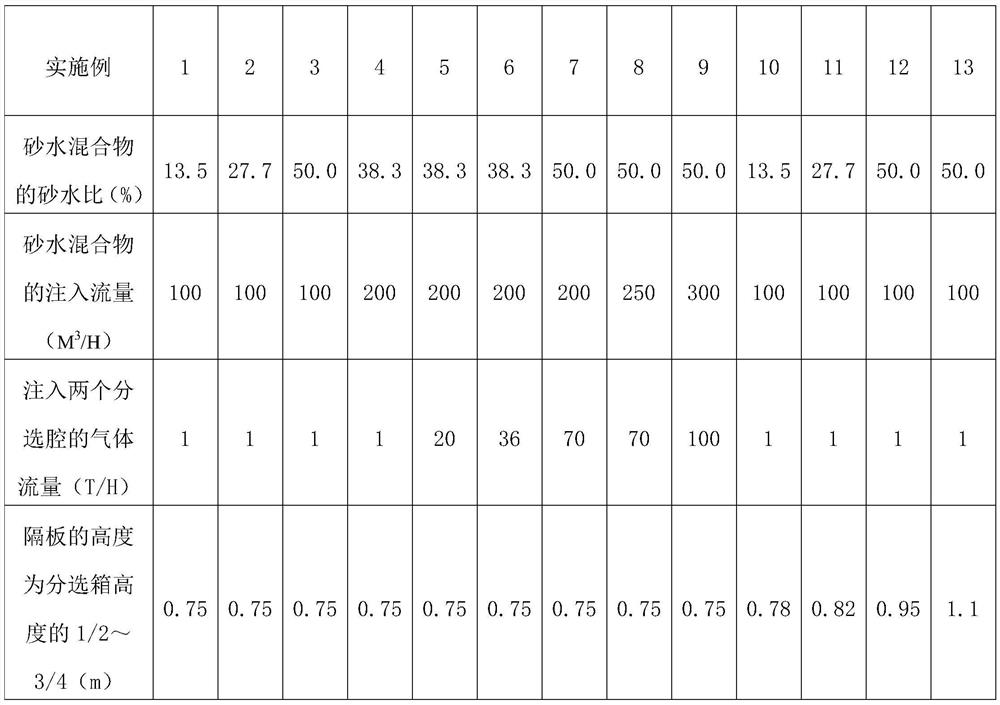

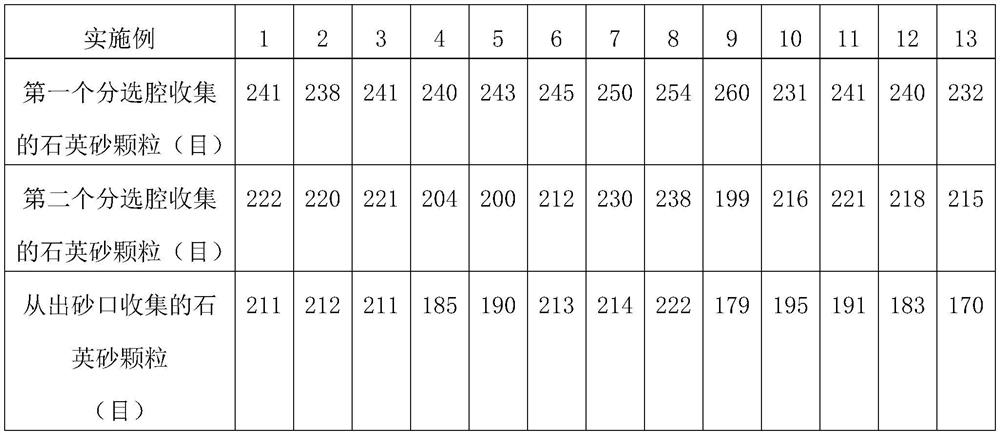

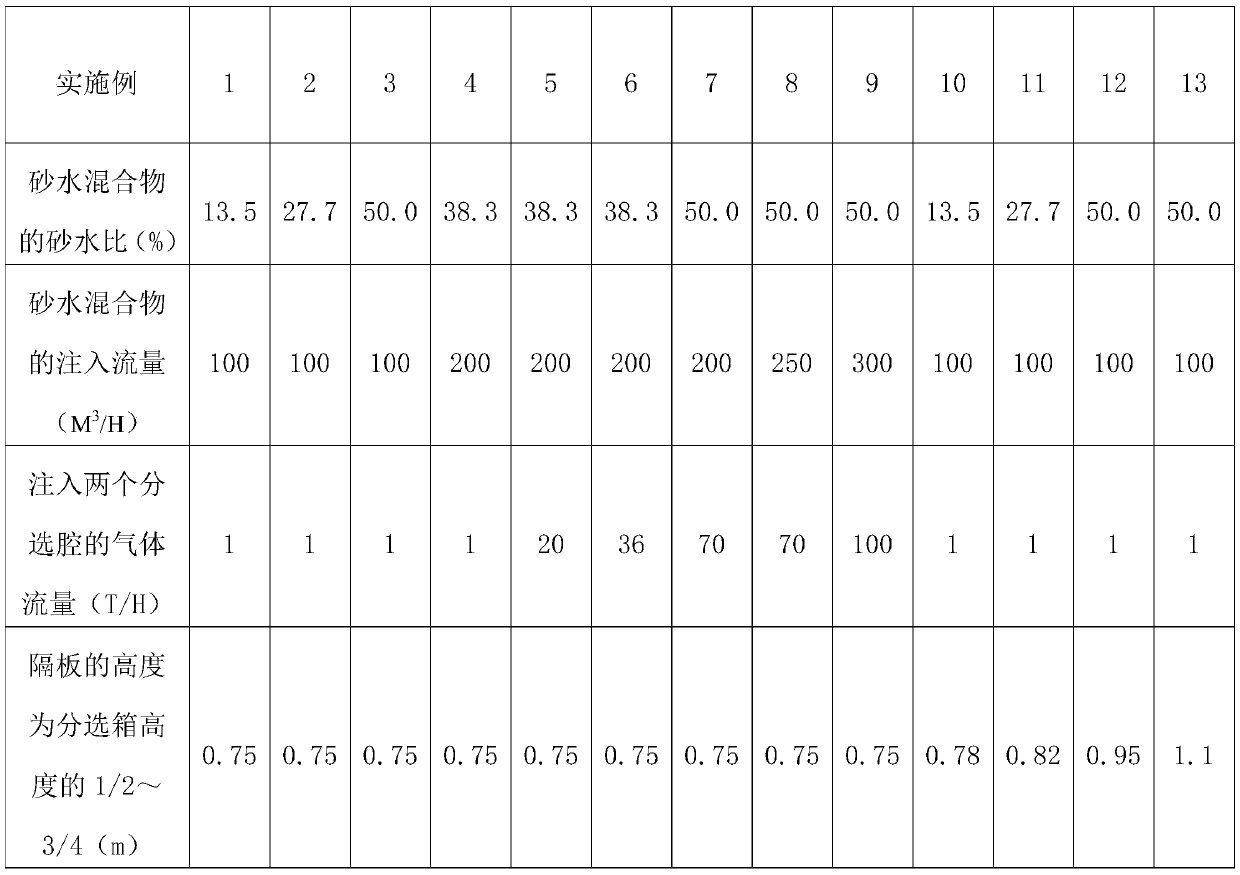

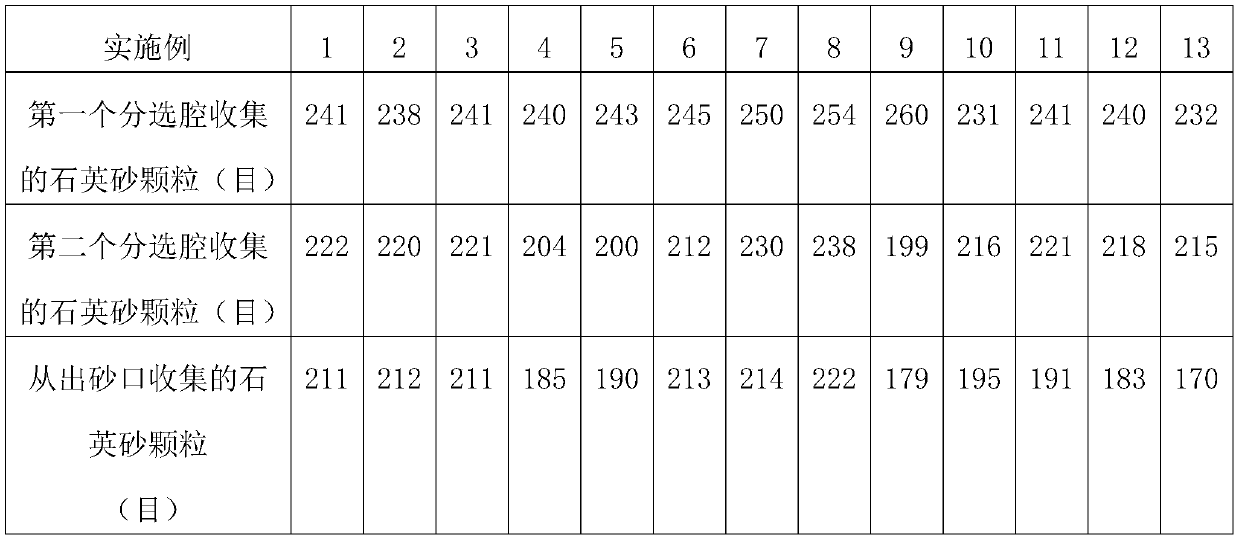

A kind of multistage quartz sand sorting method

ActiveCN110064502BReduce flow rateControl sedimentation rateCleaning using liquidsWet separationPhysical chemistryWater flow

The invention relates to the technical field of quartz sand processing, and discloses a multi-stage quartz sand sorting method, step A, preparing equipment, preparing a sorting box, and installing a partition in the sorting box, and the partition divides the sorting box Divided into at least two sorting chambers arranged side by side, the height of the partition is 1 / 2 to 3 / 4 of the height of the sorting box; step B, pouring clean water into each sorting chamber at the same time, clear water The direction of the water flow in the sorting box is facing upward; step C, pass in the sand-water mixture, mix the quartz sand particles and clean water to form a sand-water mixture; 3 / H~300M 3 The flow rate of / H is passed into the sorting box from the side wall of the sorting box; step D, completing the sorting, after the sorting is completed, the quartz sand particles in the sorting chamber are discharged and collected. The invention can carry out multi-stage separation to the quartz sand.

Owner:长江造型材料(集团)科左后旗有限公司

Aluminum-doped spinel manganese-based material and preparation method thereof

Owner:SHANGHAI INST OF SPACE POWER SOURCES

A method for sorting quartz sand

ActiveCN110064500BReduce flow rateControl sedimentation rateCleaning using liquidsWet separationPhysical chemistryWater flow

The invention belongs to the technical field of quartz sand processing, and specifically discloses a method for sorting quartz sand. Sand-water mixture, make the sand-water mixture 100M 3 / H-300M 3 The flow rate of / H passes into the sorting box from the side wall of the sorting box; the ultrasonic force is given to the quartz sand particles in the sorting box through the ultrasonic generator, and the frequency of the ultrasonic generator is 28KHz-42KHz; after the sorting is completed , discharge and collect the quartz sand particles in the sorting box. By adopting the process of the invention, cleaning can be completed when the quartz sand is sorted, and the production process of the quartz sand is shortened.

Owner:长江造型材料(集团)科左后旗有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com