Aluminum-doped spinel manganese-based material and preparation method thereof

A spar manganese-based, aluminum-doped technology, used in electrical components, battery electrodes, circuits, etc., can solve the problems of inability to achieve uniform mixing of doping elements and uneven precipitation, and achieve excellent electrochemical performance and good repeatability. , the effect of increasing the doping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

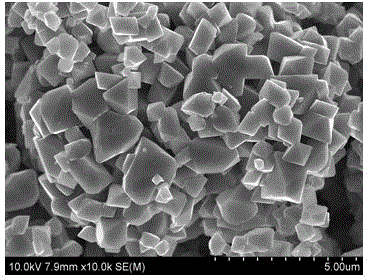

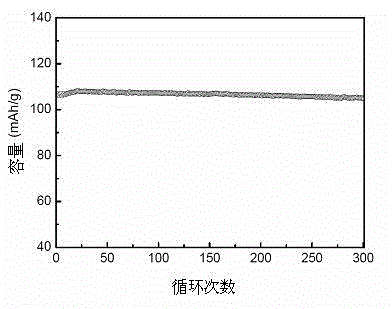

Embodiment 1

[0030] MnSO 4 ·H 2 O was dissolved in deionized water to make a 2mol / L solution. with anhydrous Na 2 CO 3 As a precipitating agent, it can be dissolved in deionized water to form a 2mol / L solution. Using a peristaltic pump, the MnSO 4 solution and Na 2 CO 3 The solution was poured into the reactor at a flow rate of 0.5mol / L. Weigh a certain amount of aluminum isopropoxide in proportion, dissolve aluminum isopropoxide and acetylacetone in ethanol according to the molar ratio of 1:1, the concentration is 0.8mol / L, and dissolve the above aluminum isopropoxide solution at a certain dropwise into the reactor. The pH of the control system is ≈8, the temperature of the system is 50°C, the stirring speed is 600r / min, and the (Mn0.925 al 0.075 )CO 3 precipitation. After the precipitate was filtered and dried, it was calcined at 850 °C for 5 h to obtain M 2 o 3 (M=Mn, Al) oxide. After fully mixing the oxide and lithium carbonate with an amount of 1.05 times the stoichiomet...

Embodiment 2

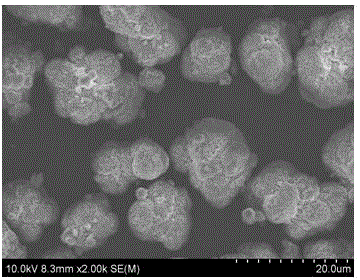

[0035] Weigh 0.1mol nickel sulfate and 0.3mol manganese sulfate according to the molar ratio of 1:3, and dissolve them in deionized water to prepare a mixed solution of 2mol / L. Weigh 0.4mol sodium carbonate and prepare a 2mol / L solution as a precipitant. The manganese sulfate solution, nickel sulfate solution and sodium carbonate solution were pumped into the reactor at a flow rate of 0.5 mol / L by a peristaltic pump. Weigh a certain amount of aluminum isopropoxide in proportion, dissolve aluminum isopropoxide and acetylacetone in ethanol according to the molar ratio of 1:1, the concentration is 0.8mol / L, and drop the aluminum salt solution at a certain speed added to the reactor. The pH value is controlled at 8.3, the temperature is 50°C, the stirring speed is 400r / min, and the reaction time is 20h. After several times of filtration, washing, and drying, a carbonate precipitate is obtained. The precipitate was heat-treated at 600°C for 5h to obtain the oxide. Fully grind th...

Embodiment 3

[0038] Dissolve manganese sulfate in deionized water to make a 1mol / L solution. Ammonium bicarbonate was used as a precipitating agent, dissolved in deionized water to form a 1mol / L solution. The manganese sulfate solution and the ammonium bicarbonate solution were pumped into the reactor at a flow rate of 0.5 mol / L by a peristaltic pump. Weigh a certain amount of aluminum isopropoxide in proportion, dissolve aluminum isopropoxide and acetylacetone in ethanol according to the molar ratio of 1:1, the concentration is 0.8mol / L, and drop the aluminum salt solution at a certain speed added to the reactor. The pH of the control system is ≈7.5, the temperature of the system is 50°C, the stirring speed is 600r / min, and the (Mn 0.925 al 0.075 )CO 3 precipitation. After the precipitate was filtered and dried, it was calcined at 800 °C for 5 h to obtain M 2 o 3 (M=Mn, Al) oxide. After fully mixing the oxide and lithium carbonate with an amount of 1.01 times the stoichiometric ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com