Method for reducing osmium secondary absorption liquid

A technology of secondary absorption and ethanol solution, which is applied in the field of reduction of absorption liquid and reduction of osmium secondary absorption liquid, which can solve problems such as potential safety hazards, difficulty in grasping the end point, and difficulty in controlling the amount of hydrazine hydrate added, so as to reduce safety risks and improve The effect of reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

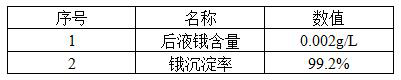

[0013] Take 3L of secondary osmium absorption solution, containing about 25g / L of osmium, and add 75% ethanol solution by volume, in which ethanol is 12.5mol. Then, the solution was heated to 55°C, kept at a constant temperature for 1 h, stood for 30 min, cooled, filtered and washed to obtain metallic osmium.

[0014]

Embodiment 2

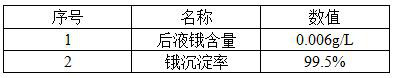

[0016] Take 2L of secondary osmium absorption solution, containing about 30g / L of osmium, and add a volume fraction of 75% ethanol solution, in which ethanol is 15mol. Then, the solution was heated to 55°C, kept at a constant temperature for 1 h, stood for 30 min, cooled, filtered and washed to obtain metallic osmium.

[0017]

Embodiment 3

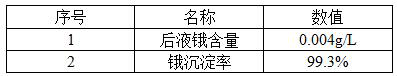

[0019] Take 2L of osmium secondary absorption solution, containing 30g / L of osmium, add ethanol solution with a volume fraction of 75%, in which ethanol is 30mol. Then, the solution was heated to 55°C, kept at a constant temperature for 1 h, stood for 30 min, cooled, filtered and washed to obtain metallic osmium.

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com