Method for sorting quartz sand

A quartz sand and sorting technology, applied in the field of sorting quartz sand, can solve the problems of decreased durability of sieve plates, shortened production process of quartz sand, different mesh sizes, etc., and achieves the effect of improving efficiency and shortening production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 10

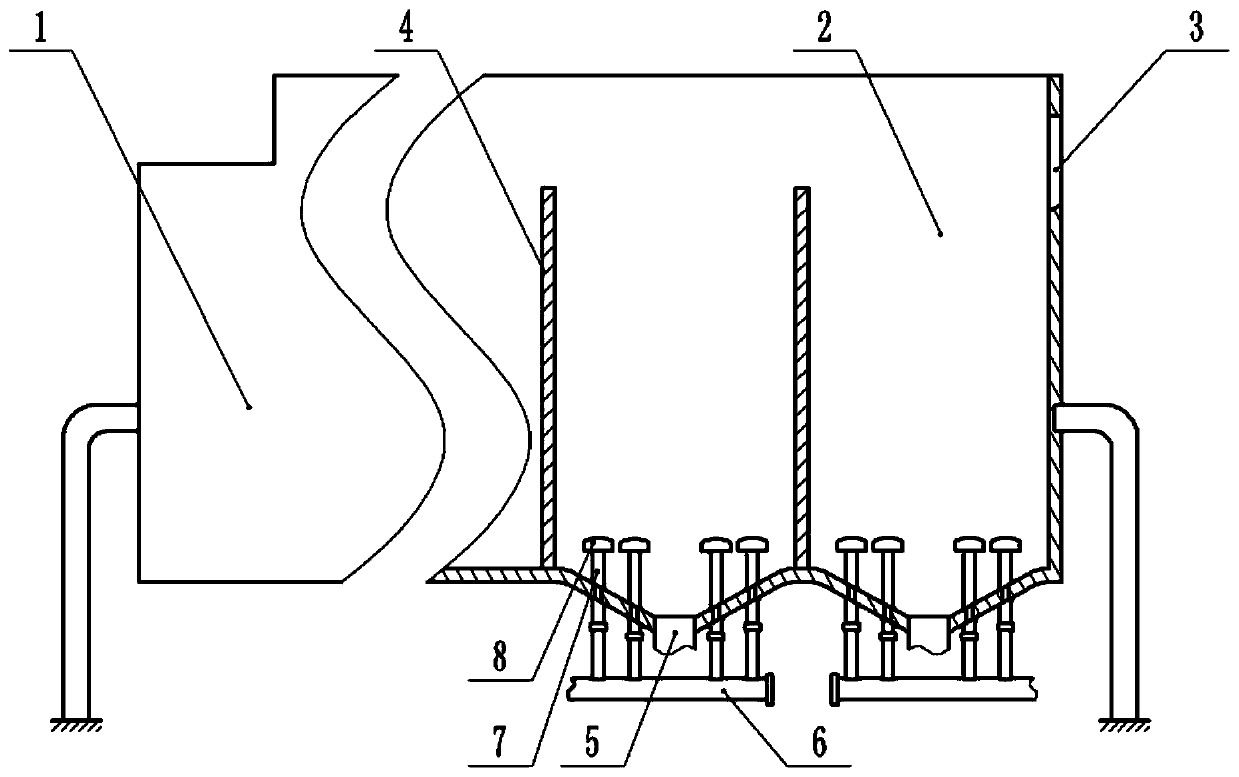

[0057] like figure 1 Shown: a method for sorting quartz sand, comprising the following steps:

[0058] A. Prepare equipment

[0059] Prepare a sorting box 1 with a length of 6.4m, a width of 1.5m, and a height of 1.5m. A sand inlet 3 is provided on the right side of the sorting box 1, and a sand outlet is opened on the left side of the sorting box 1. Prepare a plurality of dividing plates 4 with different heights to meet the requirements of different heights of dividing plates 4 in the present application. In this embodiment, a plurality of dividing plates 4 with a height of 1 m are installed in the sorting box 1 along the horizontal direction, i.e. dividing plates The height of 4 is 2 / 3 of the height of the sorting box 1, and the partition plate 4 is detachable and replaceable. Specifically, in this embodiment, a vertical slot is arranged in the sorting box 1, and the partition plate 4 is snapped into the slot Inside, it is convenient to replace the partition 4. The separa...

Embodiment 13

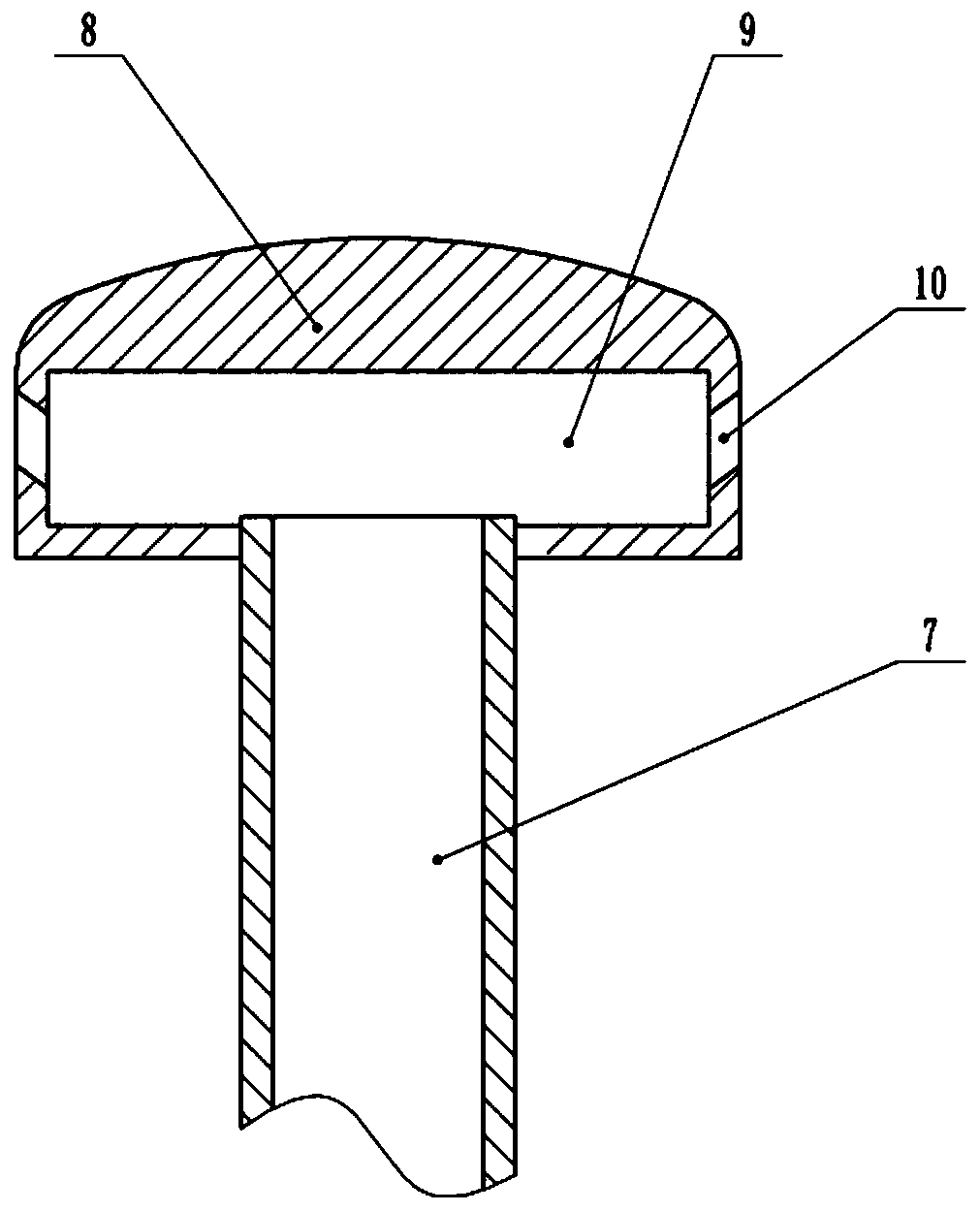

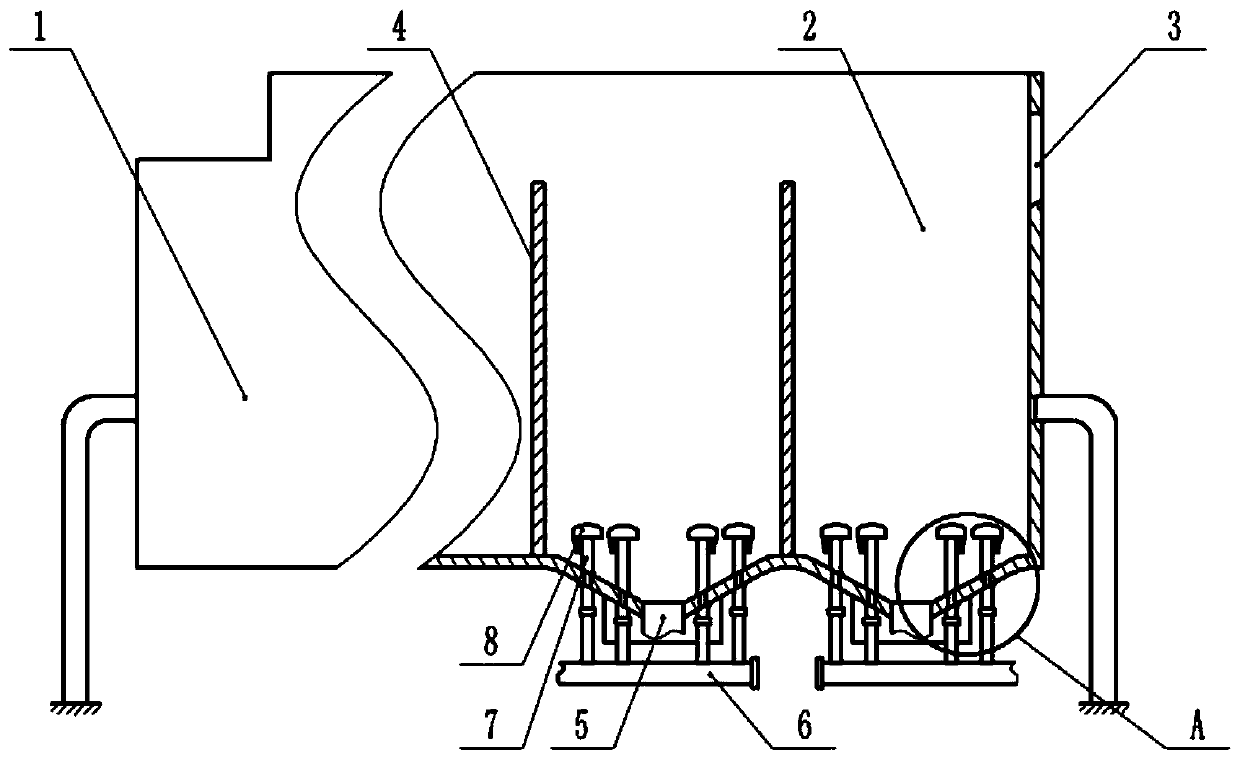

[0073] The parameters used in this embodiment are exactly the same as those in Embodiment 10. The difference between this embodiment and Embodiment 10 lies in the structure of the water spray plate used in step B. Specifically, such as image 3 and Figure 4 As shown, the water spray tray 8 is rotatably connected to the water supply pipe 7, and the water spray holes 10 on the same water spray tray 8 are all arranged obliquely along the same direction of the circumference of the water chamber 9, and the water flows from each water spray hole through the water chamber 9. While 10 is discharged, the water spray plate 8 is subjected to the counterclockwise (or anticlockwise) thrust of the water flow, thereby rotating. A sand cleaning hole is provided at the bottom of the water spray tray 8. In order to reduce the diversion of the sand cleaning hole, only one sand cleaning hole is provided in this embodiment, and a sand cleaning pipe 11 is bonded at the sand cleaning hole. The sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com