Strengthening and toughening heat treatment method of in-situ titanium boride particle reinforced aluminum matrix composite

An aluminum-based composite material and particle-reinforced aluminum technology are applied in the field of heat treatment of in-situ titanium boride particle-reinforced aluminum-based composite materials for strengthening and toughening, which can solve problems such as difficulty in solid solution, uneven precipitation, and the like, and achieve a simple process method. Easy to operate, promote diffusion, improve the effect of insufficient solid solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

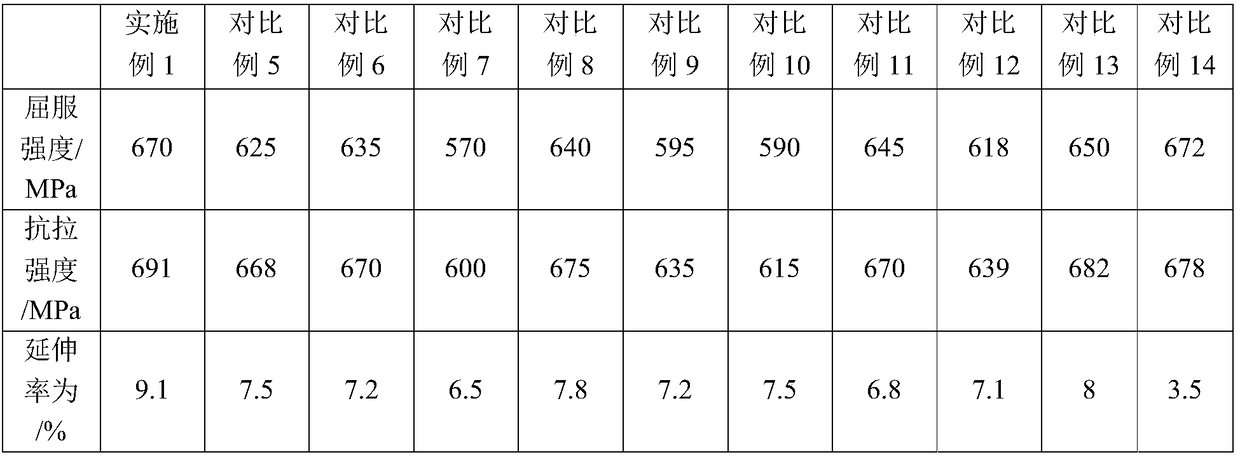

Embodiment 1

[0028] This embodiment relates to an in-situ TiB 2 A heat treatment method for strengthening and toughening the nanoparticle-reinforced aluminum-based composite material, comprising the following steps:

[0029] First to 3wt.%TiB 2 / 7050 aluminum matrix composite ingot (TiB 2 The particle size is 20-500nm) for homogenization treatment, the homogenization temperature is 470°C, the holding time is 24h, and then air-cooled.

[0030] After homogenization, high-temperature pretreatment is carried out, that is, at a solution temperature of 480 ° C, heat preservation for 2 hours, quickly remove the water quenching, and then add 3wt.% TiB 2 / 7050 aluminum-based composite material is hot-extruded at 420°C, and then rapidly water-quenched, and the transfer time is less than 15s.

[0031] 3wt.%TiB after hot extrusion 2 / 7050 aluminum matrix composite material, annealing treatment, the annealing temperature is 360 ℃, the time is 4h, and then rapid water quenching, the transfer time is...

Embodiment 2

[0036] This embodiment relates to an in-situ TiB 2 A heat treatment method for strengthening and toughening the nanoparticle-reinforced aluminum-based composite material, comprising the following steps:

[0037] First to 8wt.%TiB 2 / 2024 aluminum matrix composite ingot (TiB 2 The particle size is 20-500nm) for homogenization treatment, the homogenization temperature is 490°C, the holding time is 48h, and then air-cooled.

[0038] After homogenization, carry out high-temperature pretreatment at 505°C for 3 hours, quickly remove the water quenching, and then add 8wt.%TiB 2 / 2024 aluminum matrix composite material is hot extruded at 420°C, and then rapidly water quenched, and the transfer time is less than 15s.

[0039] 8wt.%TiB after hot extrusion 2 / 2024 aluminum matrix composite material, annealing treatment, the annealing temperature is 380 ℃, the holding time is 5h, and then rapid water quenching, the transfer time is less than 15s.

[0040] The annealed 8wt.%TiB 2 / 20...

Embodiment 3

[0045] This embodiment relates to an in-situ TiB 2 A heat treatment method for strengthening and toughening the nanoparticle-reinforced aluminum-based composite material, comprising the following steps:

[0046] First to 10wt.%TiB 2 / 6061 aluminum matrix composite ingot (TiB 2 The particle size is 20-500nm) for homogenization treatment, the homogenization temperature is 550°C, the time is 48h, and then air-cooled.

[0047] After homogenization, high temperature pretreatment was carried out at 565°C for 4 hours, water quenching was taken out quickly, and then 10wt.%TiB 2 / 6061 aluminum-based composite material is hot-extruded at 420°C, and then rapidly water-quenched, and the transfer time is less than 15s.

[0048] 10wt.%TiB after hot extrusion 2 / 6061 aluminum matrix composite material, annealing treatment, the annealing temperature is 380 ℃, the holding time is 8h, and then rapid water quenching, the transfer time is less than 15s.

[0049] The annealed 10wt.%TiB 2 / 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com