High-coercivity neodymium-iron-boron magnet preparation method and neodymium-iron-boron magnet thereof

A high coercive force, NdFeB technology, applied in the direction of magnetic objects, inductors/transformers/magnet manufacturing, magnetic materials, etc., can solve the problems of small coercive force improvement of NdFeB magnet materials, poor effect of heavy rare earth elements, etc. , to achieve good grain boundary diffusion effect, high coercive force enhancement effect, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of high coercivity NdFeB magnet preparation method, it comprises the following steps:

[0045] S1: NdFeB powder with a particle size of 2.0-2.5 μm is obtained by distributing ingredients according to the design, casting and smelting, hydrogen crushing, and jet milling;

[0046] S2: Mix NdFeB powder and binder at a mass ratio of 1:0.08-0.09, and perform oriented static pressure molding on the mixture in a 1.5T magnetic field to obtain a compacted NdFeB rough billet;

[0047] S3: Mix the material containing heavy rare earth elements with NdFeB powder and heat it to the immersion temperature and keep it in a molten state. The immersion temperature is 1100-1300°C to obtain a heavy rare earth source melt;

[0048] S4: Put the NdFeB rough blank in a cage or basket and heat it under a protective atmosphere. The heating temperature is gradually increased until the heating temperature is 200-250°C higher than the melting point of the adhesive. Melt flows out from the surf...

Embodiment 2

[0087] A high coercive force NdFeB magnet preparation method, based on the first embodiment, the difference is:

[0088] S1: Dosing according to the design composition, casting smelting, hydrogen crushing, and jet milling to obtain coarse NdFeB powder with a particle size of 3.0-3.5 μm and fine NdFeB powder with a particle size of 2-2.5 μm;

[0089] S2: Mix the fine NdFeB powder and the coarse NdFeB powder at a mass ratio of 0.2-0.3:1, and then add a binder according to the mass ratio of the NdFeB powder and the binder at a mass ratio of 1:0.08-0.09 for mixing, Perform oriented static pressure molding on the mixture in a 1.5T magnetic field to obtain a compacted NdFeB rough billet;

[0090] Steps S3-S6 are the same as those in Embodiment 1.

[0091] The shape of the finished NdFeB magnet can be determined according to the actual situation, and its thickness is greater than 5mm. Here, a disc with a diameter of 25mm is used as a sample. The element composition of finished NdFe...

Embodiment 3

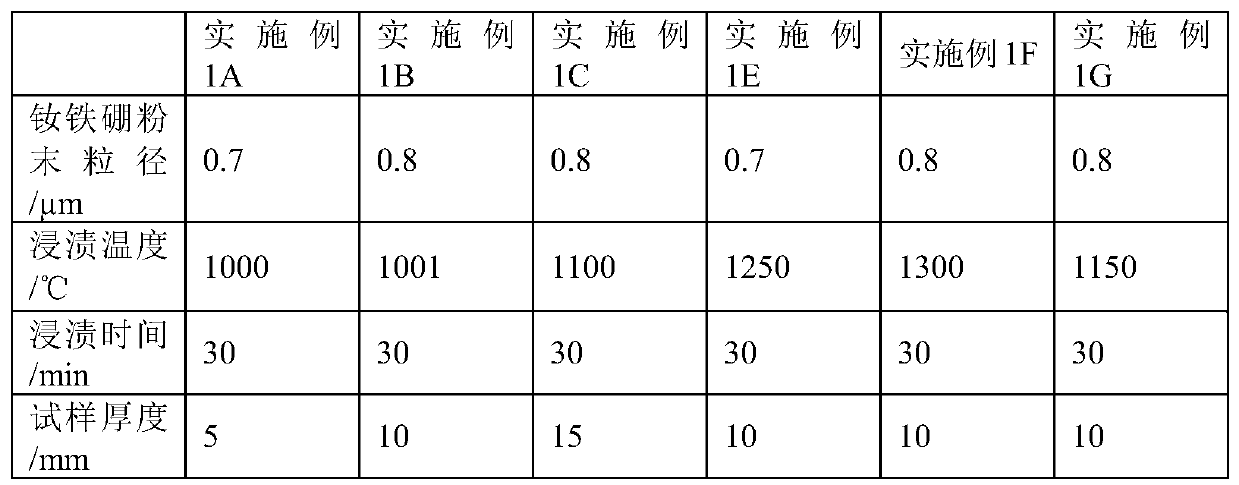

[0104] A high-coercivity NdFeB magnet preparation method, based on Example 2F, the difference is that the particle size of the binder powder is different, and Example 3A-3C is set, and the specific parameters are as follows.

[0105]

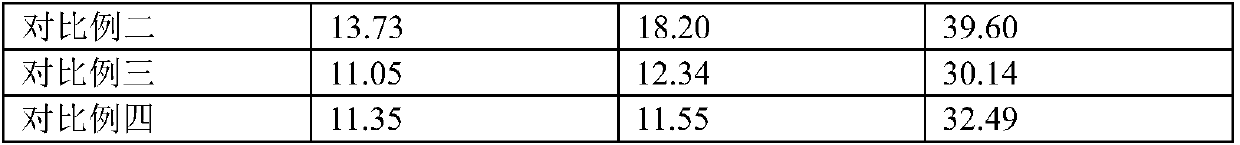

[0106] The grain boundary diffused heavy rare earth NdFeB magnet obtained in Example 3 was tested, and the test results are as follows.

[0107] Remanence / kGs Intrinsic coercive force / kOe Maximum energy product / MGOe Example 3A 12.85 17.70 40.04 Example 3B 13.54 22.77 44.52 Example 3C 14.14 24.65 48.60 Example 3E 14.22 23.46 49.14

[0108] By comparing Example 2 and Example 3, it can be seen that the closer the particle size of the binder powder is to the particle size of the coarse NdFeB powder, the smaller the possibility of deformation and collapse of the NdFeB rough blank during the heating process of S4 and S5, At the same time, the better the effect of solid solution and penetration betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com