High-nitrogen composite alloy and preparation method thereof

A composite alloy, high nitrogen technology, applied in the field of metallurgy, can solve the problems of low nitrogen content and unstable quality of high nitrogen steel bars, and achieve the effect of increasing nitrogen content, avoiding cracking and spalling, and providing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

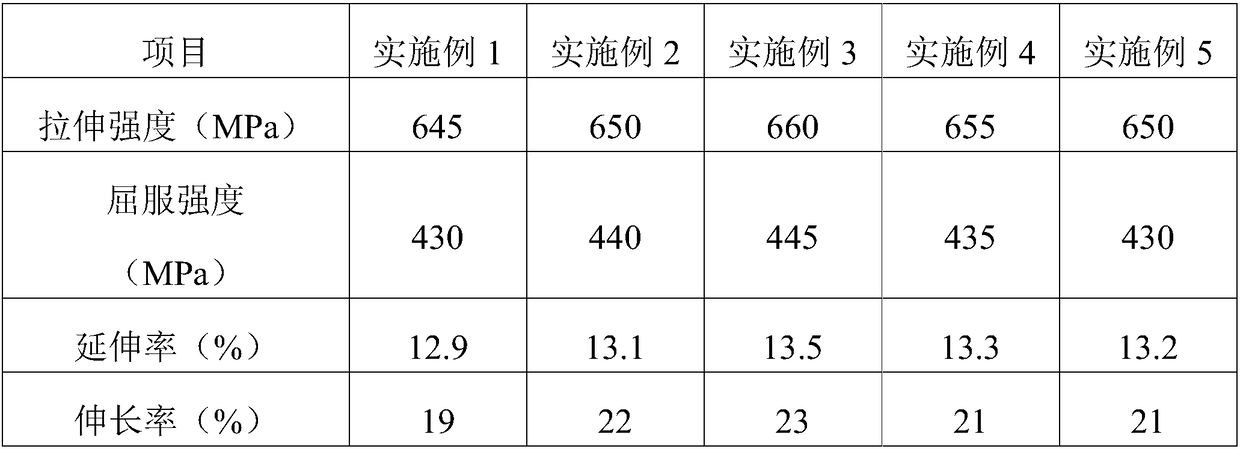

Examples

Embodiment 1

[0029] A method for preparing a high-nitrogen composite alloy, comprising the following steps:

[0030] S1. Material preparation: Weigh 55 parts of ferrotitanium powder, 23 parts of ferroniobium powder, 10 parts of ferrosilicon nitride, 10 parts of chromium nitride, 1 part of silicon manganese nitride, 1 part of rare earth lanthanum, 3.5 parts of vinyl acetate, 1.5 parts of dicyclohexyl dicarboxylate, 5 parts of ethanol, 0.05 parts of Span-60, set aside;

[0031] Among them, the titanium content in ferro-titanium powder is 35-75%, the niobium content in ferroniobium powder is 50-70%, the nitrogen content in ferrosilicon nitride is 25-32%, and the nitrogen content in silicon-manganese nitride is 20-25%. %, the nitrogen content in chromium nitride is 5-10%;

[0032] S2. Premix 1: add ferro-titanium powder, ferroniobium powder, ferrosilicon nitride, chromium nitride, silicon-manganese nitride, and rare earth lanthanum into a high-speed ball mill and mix for 40 minutes until even...

Embodiment 2

[0039] A method for preparing a high-nitrogen composite alloy, comprising the following steps:

[0040]S1. Material preparation: Weigh 25 parts of ferrotitanium powder, 55 parts of ferroniobium powder, 16 parts of ferrosilicon nitride, 16 parts of chromium nitride, 6 parts of silicon manganese nitride, 2 parts of rare earth lanthanum, 4.5 parts of vinyl acetate, 1.7 parts of dicyclohexyl dicarboxylate, 6 parts of ethanol, 0.06 parts of Span-60, set aside;

[0041] Among them, the titanium content in ferro-titanium powder is 35-75%, the niobium content in ferroniobium powder is 50-70%, the nitrogen content in ferrosilicon nitride is 25-32%, and the nitrogen content in silicon-manganese nitride is 20-25%. %, the nitrogen content in chromium nitride is 5-10%.

[0042] S2. Premix 1: add ferro-titanium powder, ferroniobium powder, ferrosilicon nitride, chromium nitride, silicon-manganese nitride, and rare earth lanthanum into a high-speed ball mill and mix for 45 minutes until uni...

Embodiment 3

[0049] A method for preparing a high-nitrogen composite alloy, comprising the following steps:

[0050] S1. Material preparation: Weigh 40 parts of ferrotitanium powder, 40 parts of ferroniobium powder, 15 parts of ferrosilicon nitride, 13 parts of chromium nitride, 5 parts of silicon manganese nitride, 3 parts of rare earth lanthanum, 5 parts of vinyl acetate, 2 parts of dicyclohexyl dicarboxylate, 7 parts of ethanol, 0.07 part of Span-60, set aside;

[0051] Among them, the titanium content in ferro-titanium powder is 35-75%, the niobium content in ferroniobium powder is 50-70%, the nitrogen content in ferrosilicon nitride is 25-32%, and the nitrogen content in silicon-manganese nitride is 20-25%. %, the nitrogen content in chromium nitride is 5-10%.

[0052] S2. Premix 1: Add ferrotitanium powder, ferroniobium powder, ferrosilicon nitride, chromium nitride, silicon manganese nitride, and rare earth lanthanum into a high-speed ball mill and mix for 50 minutes until uniforml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com