Multi-nut-seat assembled uplift pile

A nut seat and pull-resistant pile technology is applied in the field of multi-nut seat-assembled pull-resistant piles, which can solve the problems of failing to meet architectural design requirements, large groundwater buoyancy, and strong destructive welding surface, so as to prevent damage, improve performance, The effect of improving tensile strength and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

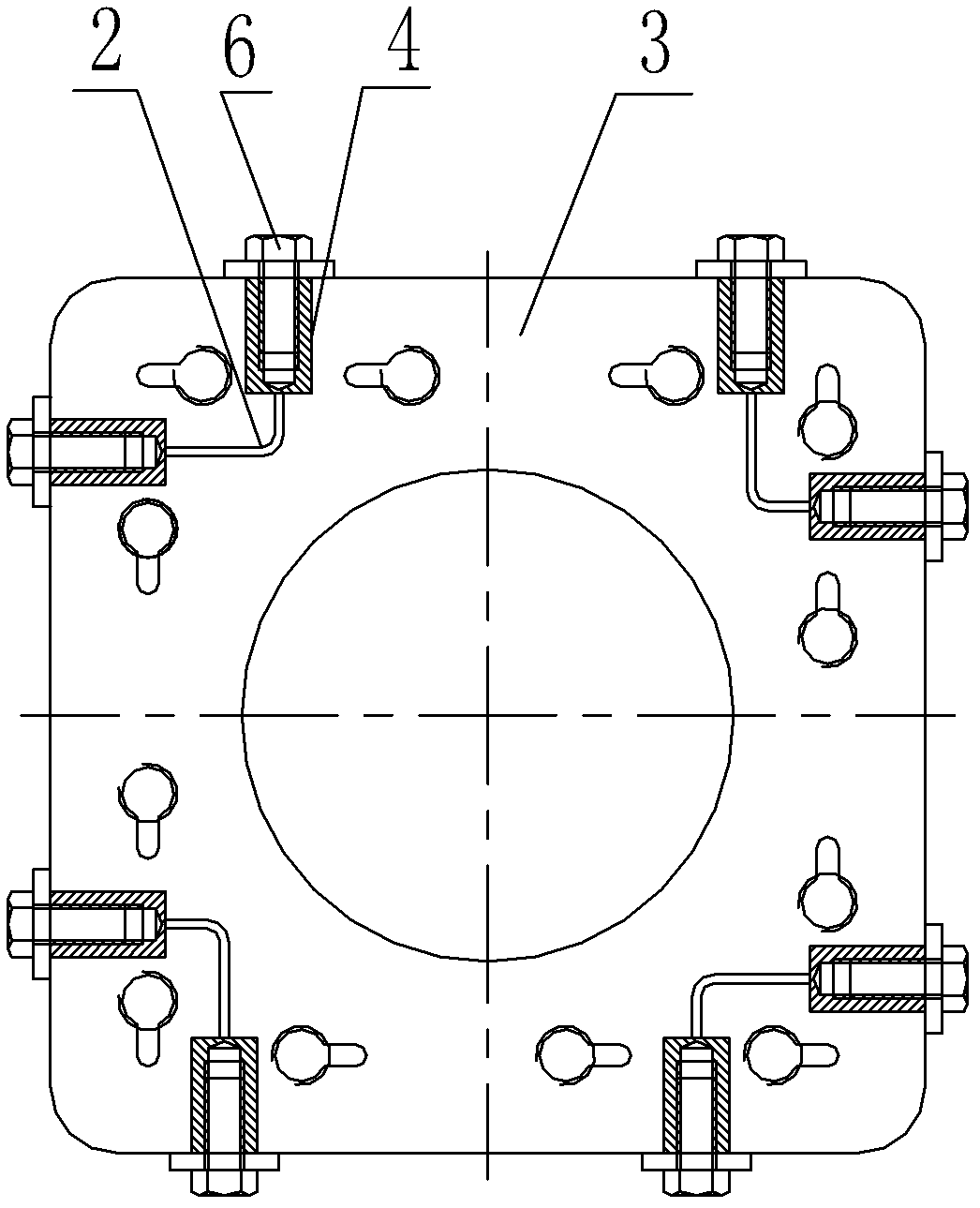

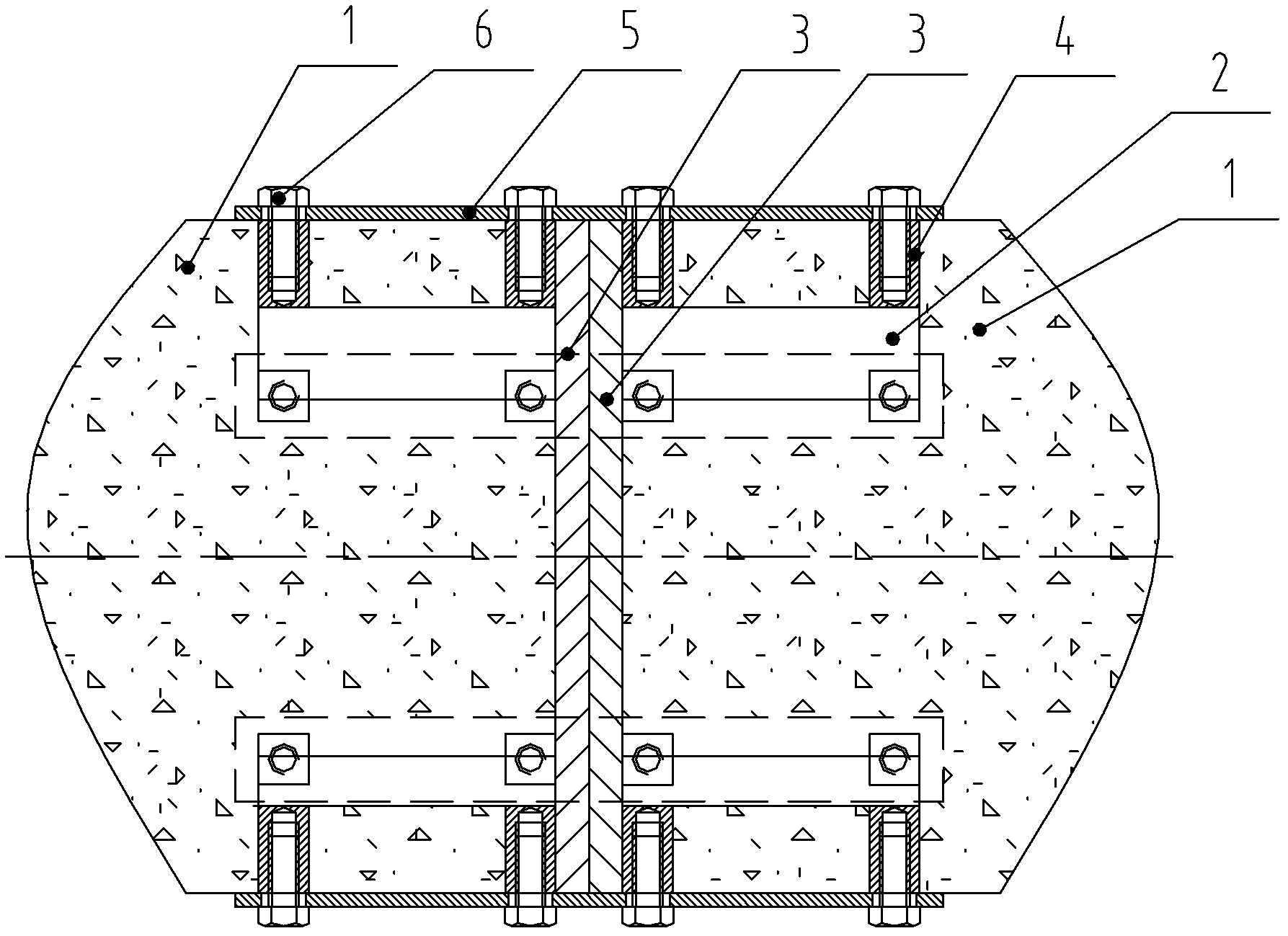

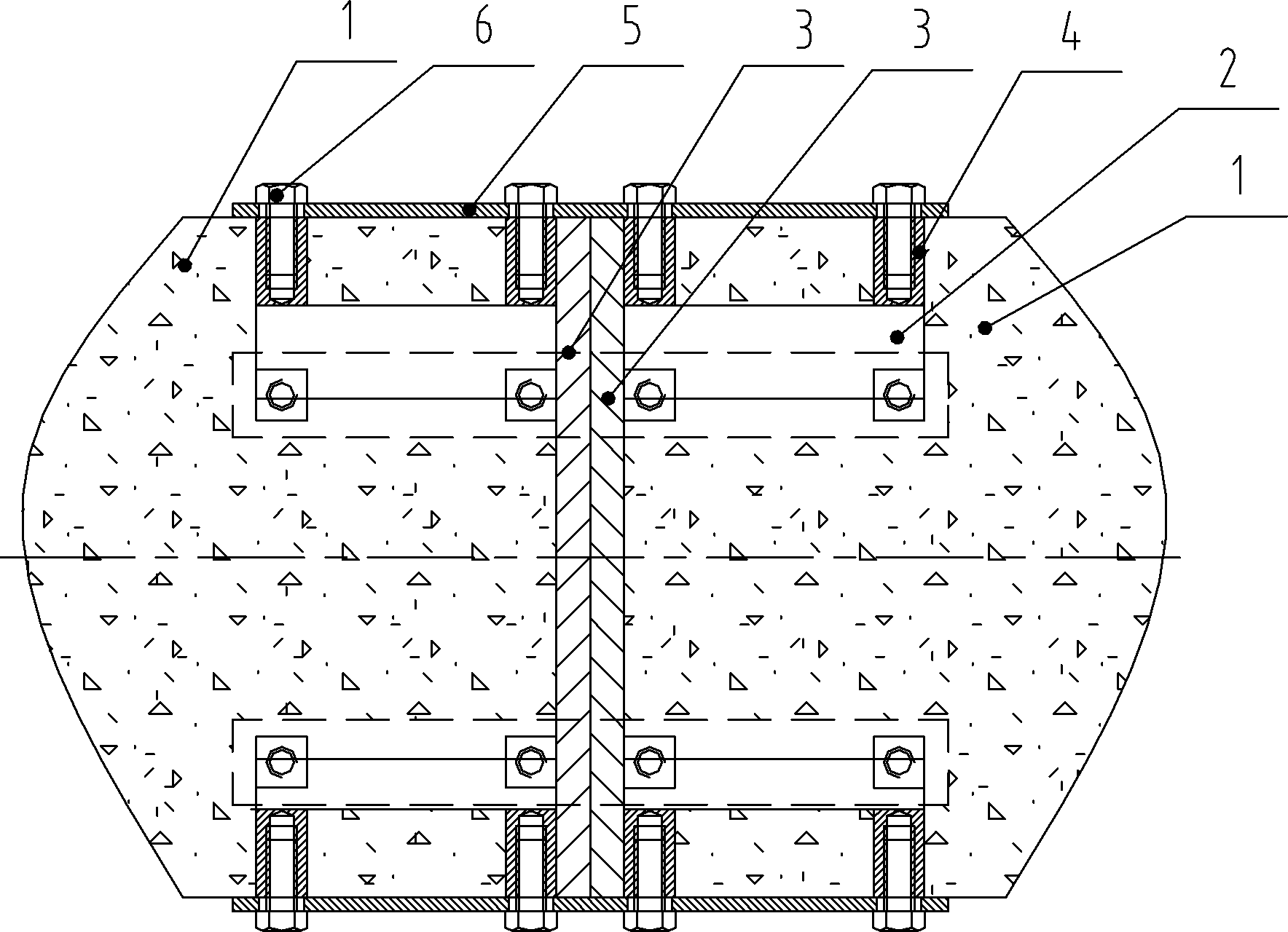

[0013] Such as figure 1 As shown, a multi-nut seat assembled uplift pile includes a pile body 1 and a plurality of L-shaped anti-rotation connecting plates 2, and a square end plate 3 is provided at the end of the pile body 1, inside the pile body 1 and along the Next to the end plate 3, there are at least two large groups of nut seats in the direction of the middle of the pile body 1. There is a gap between two adjacent large groups of nut seats. Each large group of nut seats is divided into four groups, and each group has two The four sides of the nut seat 4 and the end plate 3 respectively correspond to a nut seat group; the two nut seats 4 arranged in two adjacent groups and adjacent to each other are respectively connected to the two ends of an L-shaped anti-rotation connecting plate 2 At the same time, the two ends of the anti-rotation connecting plate 2 extend ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com