Light wear-resistant composite environment-friendly material and preparation method thereof

An environmentally friendly material and lightweight technology, applied in the field of lightweight wear-resistant composite environmental protection materials and their preparation, can solve the problems of low technical content, waste of resources, poor wear resistance and tensile resistance, etc., and achieve broad application prospects , Improve the application level, the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

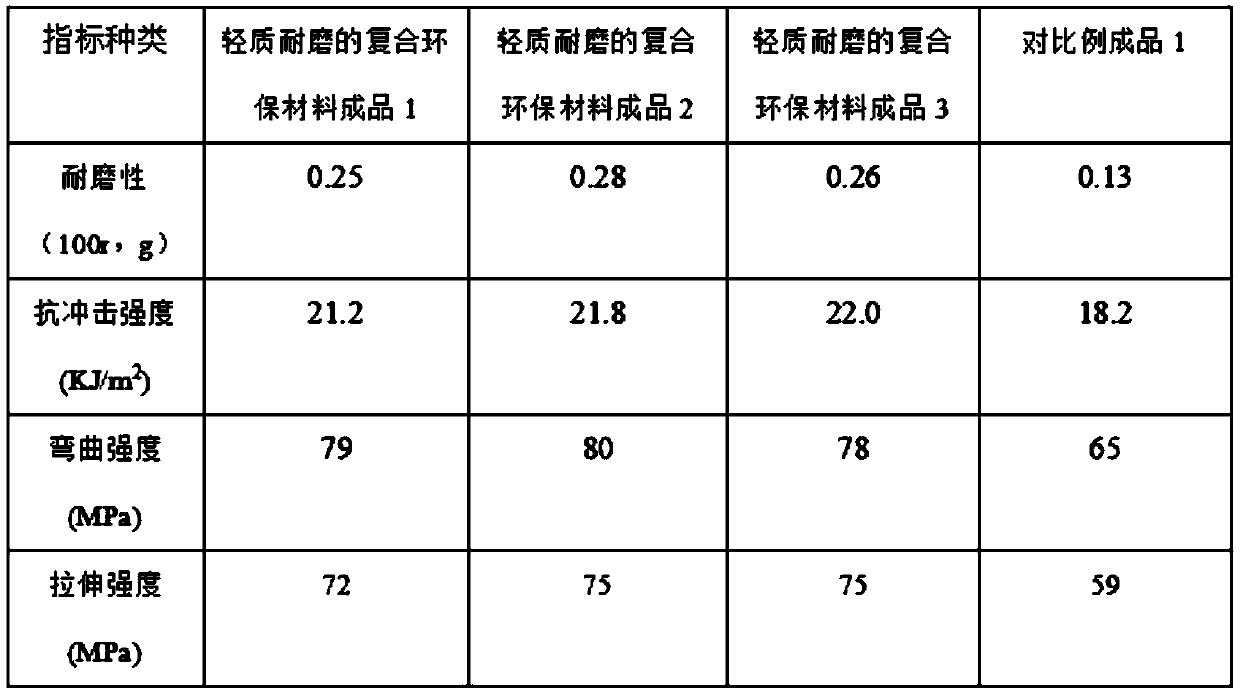

Examples

Embodiment 1

[0023] A lightweight wear-resistant composite environmental protection material, comprising: 75 parts of recycled plastic materials, 20 parts of crop straw, 15 parts of lauric acid diethanolamide, 20 parts of wear-resistant additives, 15 parts of dimethyl phthalate 8 parts of hydrogenated castor oil, 12 parts of dioctyl adipate, 15 parts of sulfate, 6 parts of polytetrafluoroethylene, 1 part of glass beads, 1 part of calcium carbonate, 4 parts of zinc stearate, silane coupling agent 1 part, 3 parts of light additives, 1 part of antioxidant.

[0024] A preparation method of a lightweight wear-resistant composite environmental protection material, comprising the steps of:

[0025] 1) Weigh the raw materials according to the above formula and set aside;

[0026] 2) Putting the crop straw into a pulverizer to pulverize it, transporting it to a dryer, and drying it at 70° C. until the moisture content is 5-7%, to obtain crop straw powder;

[0027] 3) Plastic recycled materials, l...

Embodiment 2

[0030] A lightweight wear-resistant composite environmental protection material, comprising: 85 parts of recycled plastic materials, 80 parts of crop straw, 50 parts of lauric acid diethanolamide, 30 parts of wear-resistant additives, 25 parts of dimethyl phthalate 12 parts of hydrogenated castor oil, 18 parts of dioctyl adipate, 25 parts of sulfate, 15 parts of polytetrafluoroethylene, 3 parts of glass beads, 10 parts of calcium carbonate, 6 parts of zinc stearate, silane coupling agent 8 parts, 7 parts of light additives, 5 parts of antioxidant.

[0031] A preparation method of a lightweight wear-resistant composite environmental protection material, comprising the steps of:

[0032] 1) Weigh the raw materials according to the above formula and set aside;

[0033] 2) Putting crop straw into a pulverizer to pulverize it, transporting it to a dryer, and drying it at 80° C. until the moisture content is 5-7%, to obtain crop straw powder;

[0034] 3) Plastic recycled materials...

Embodiment 3

[0037] A lightweight wear-resistant composite environmental protection material, comprising: 80 parts by weight of recycled plastic materials, 50 parts of crop straw, 30 parts of lauric acid diethanolamide, 25 parts of wear-resistant additives, 20 parts of dimethyl phthalate 10 parts of hydrogenated castor oil, 15 parts of dioctyl adipate, 20 parts of sulfate, 12 parts of polytetrafluoroethylene, 2 parts of glass beads, 5 parts of calcium carbonate, 5 parts of zinc stearate, silane coupling agent 4 parts, 5 parts of light additives, 3 parts of antioxidant.

[0038] A preparation method of a lightweight wear-resistant composite environmental protection material, comprising the steps of:

[0039] 1) Weigh the raw materials according to the above formula and set aside;

[0040] 2) Putting the crop straw into a pulverizer to pulverize it, transporting it to a dryer, and drying it at 75° C. until the moisture content is 5-7%, to obtain crop straw powder;

[0041] 3) Plastic recyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com