Method of manufacturing grain-oriented electrical steel sheets

A technology of grain orientation and electrical steel sheet, which is applied in a field related to the production of grain orientation electrical steel sheet, can solve the problems of small grain size, high production cost, and roughness of the primary recrystallized steel sheet, and achieve excellent magnetic properties , less iron loss, and high magnetic flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

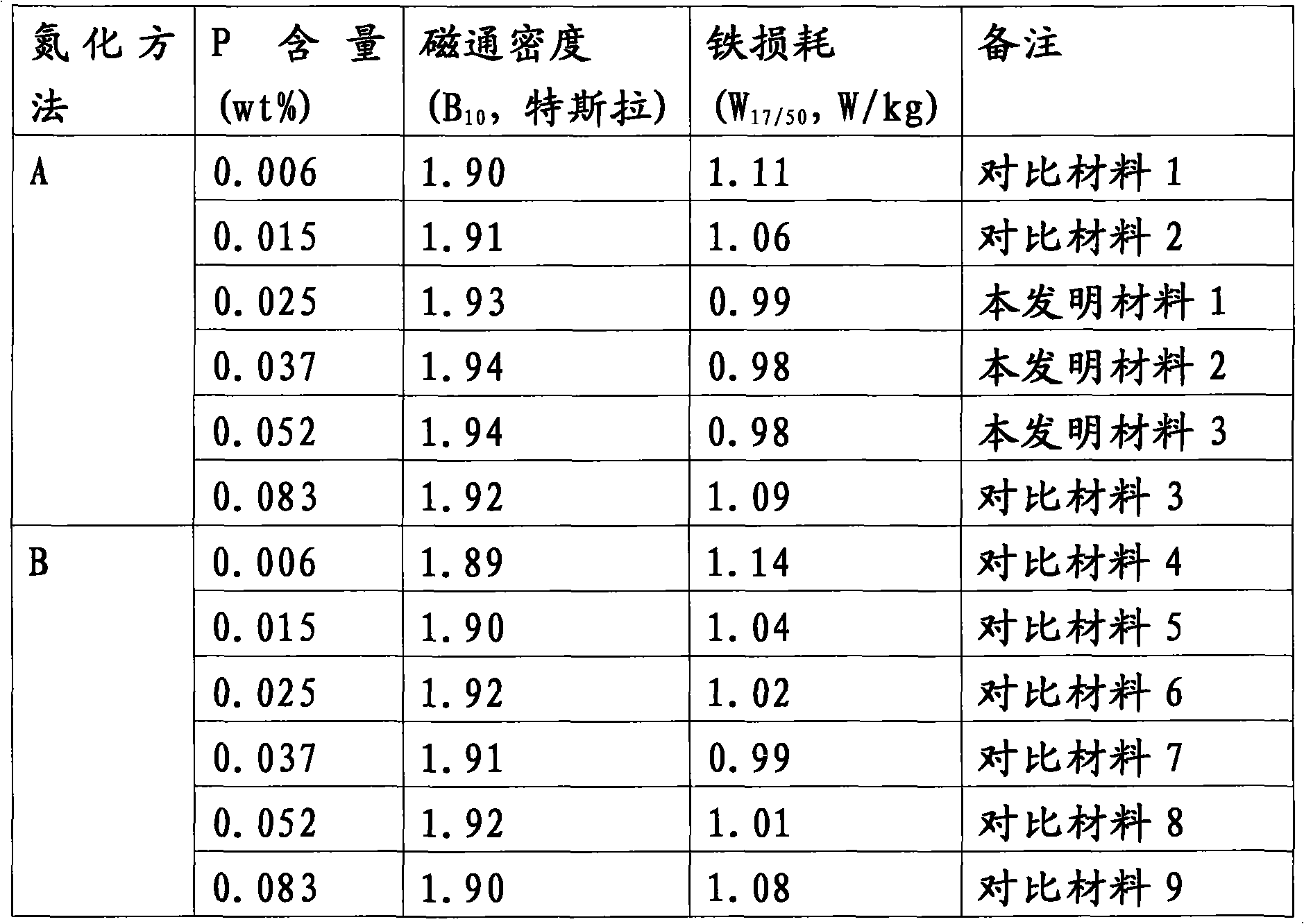

Embodiment 1

[0090] The slab used to prepare the grain oriented electrical steel sheet contains the following components in weight percent: 3.18% of Si, 0.056% of C, 0.062% of Mn, 0.0029% of S, 0.0020% of N, 0.026% of soluble Al and The balance of iron and other unavoidable impurities. The temperature at which AlN completely dissolves in the solution is 1164°C, and the temperature at which MnS completely dissolves in the solution is 1133°C. The above slabs were heated for 210 minutes at the following temperatures: 1130°C (at this temperature, both AlN and MnS are partially dissolved in the solution), 1150°C (at this temperature, MnS is completely dissolved in the solution, and AlN is partially dissolved in the solution), 1175°C and 1190°C (both temperatures are higher than 1164°C, so both AlN and MnS are completely dissolved in solution). The heated slab was then hot-rolled to produce a hot-rolled sheet having a thickness of 2.3 mm. The hot-rolled sheet is heated to above 1100°C, kept at...

Embodiment 2

[0097] The slab used to prepare the grain-oriented electrical steel sheet contains the following components in weight percentage: 3.21% of Si, 0.056% of C, 0.055% of Mn, 0.0029% of S, 0.024% of soluble Al, as shown in Table 2 below different contents of N and the balance of iron and other unavoidable impurities, the above-mentioned slab was heated for 210 minutes at a temperature higher than the temperature at which the precipitate was completely dissolved in the solution (the temperature at which MnS was completely dissolved in the solution was 1125°C, and the temperature at which AlN was completely dissolved See Table 2 for the temperature of the solution. The heated slab was hot-rolled to produce a hot-rolled sheet having a thickness of 2.3 mm. The hot-rolled sheet is heated to above 1100°C, kept at 900°C for 90 seconds, quenched in water, cleaned with acid, and then cold-rolled to a thickness of 0.30mm. Simultaneous decarburization and nitriding of cold-rolled sheets by i...

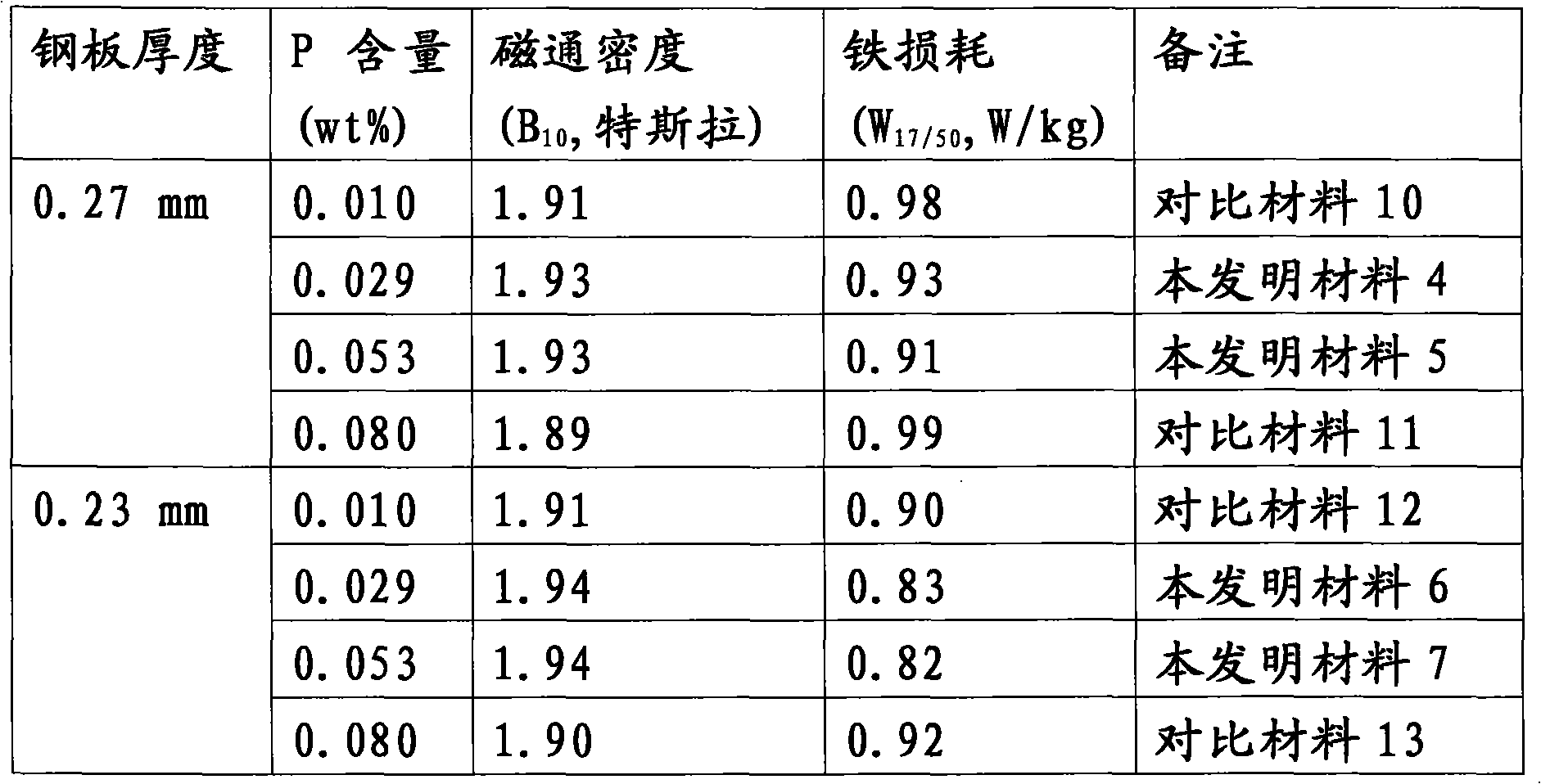

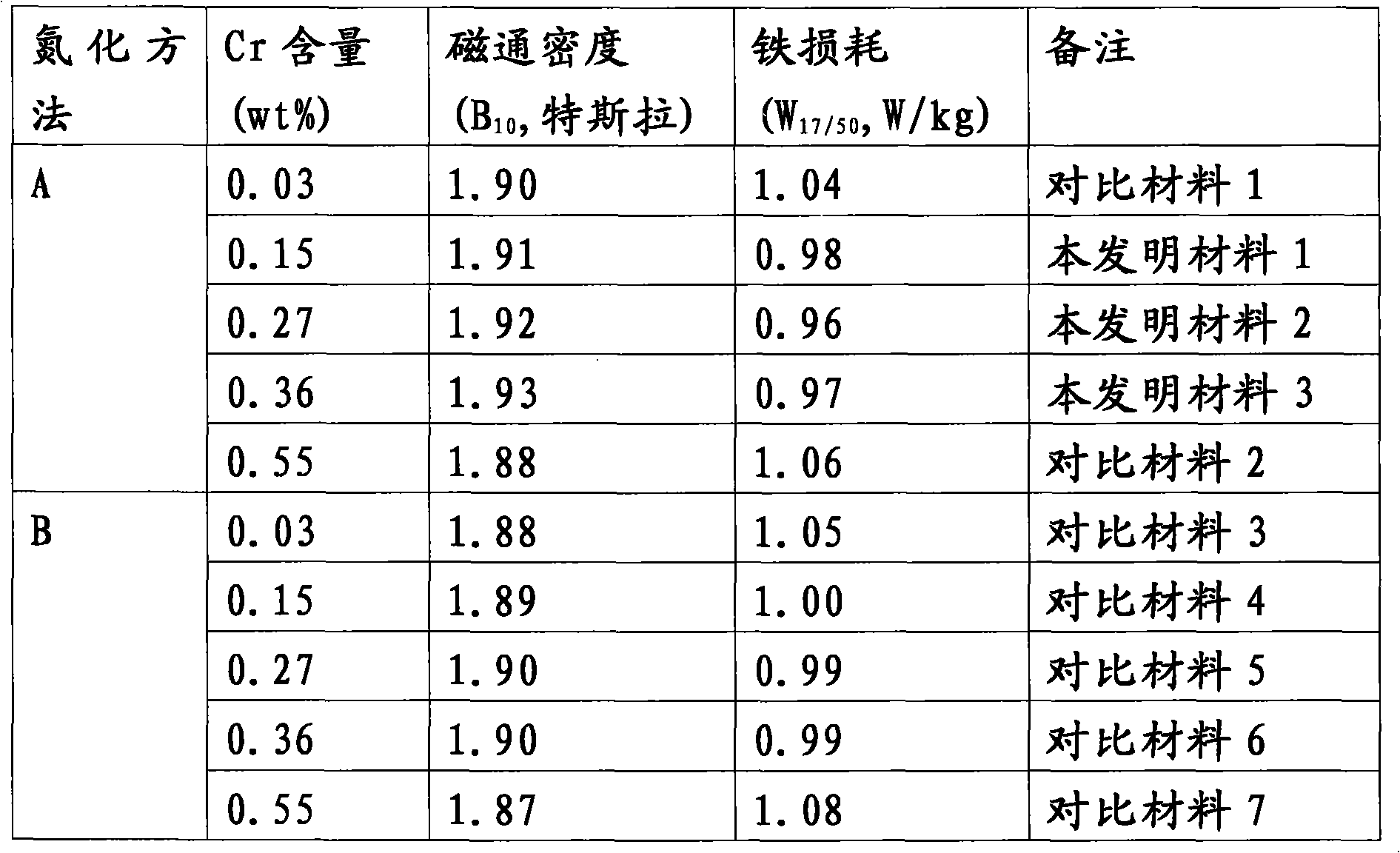

Embodiment 3

[0103] The slab used to prepare the grain-oriented electrical steel sheet contains the following components in weight percentage: 3.27% of Si, 0.045% of C, 0.064% of Mn, 0.0015% of N, 0.024% of soluble Al, as shown in Table 3 below different contents of S and the balance of iron and other unavoidable impurities, the above-mentioned slab was heated at a temperature higher than 1132° C. (this temperature is the temperature at which both MnS and AlN are completely dissolved in the solution) for 210 minutes. The heated slab was then hot-rolled to produce a hot-rolled sheet having a thickness of 2.3 mm. The hot-rolled sheet is heated to above 1100°C, kept at 900°C for 90 seconds, quenched in water, cleaned with acid, and then cold-rolled to a thickness of 0.30mm. Simultaneous decarburization and nitriding of cold-rolled sheets by introducing a mixture of 75% hydrogen and 25% nitrogen with a dew point of 65°C and 1% dry ammonia at the same time into a steelmaking furnace at a temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com