Preparation method of non-magnetic high-strength texture Ni-W alloy baseband

A high-strength, non-magnetic technology, applied in the field of preparation of non-magnetic, high-strength textured Ni-W alloy base strips, to avoid strip breakage, increase costs, and eliminate edge cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

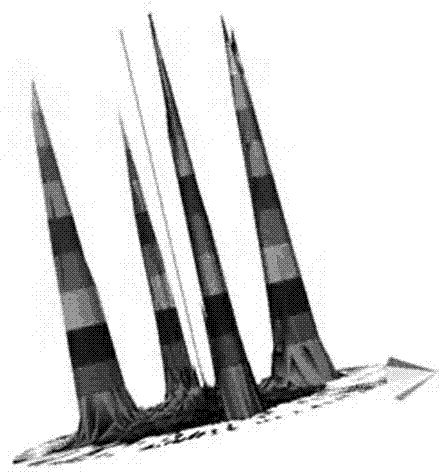

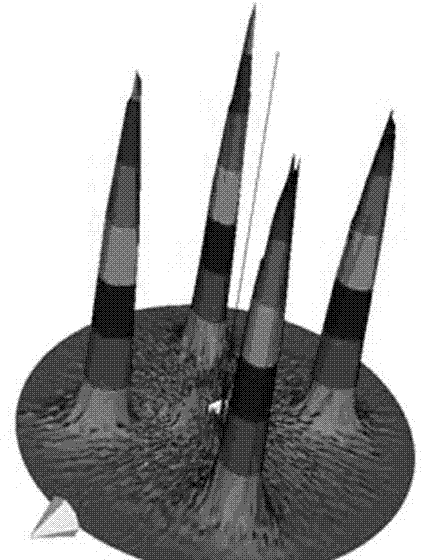

Image

Examples

Embodiment 1

[0023] The nickel block and tungsten block with a purity of 99.99% are mixed according to the molar percentage of tungsten at 9.6%, and the mixed material after mixing is melted in a vacuum induction melting furnace to obtain a nickel-tungsten alloy ingot. Heat the nickel-tungsten alloy ingot at 1200°C for 2.5 hours, then heat-forge it into a billet with a length×width×thickness of 400mm×25mm×25mm. Afterwards, hot-rolling treatment is carried out, and the deformation amount of each pass is 15%-18%, and a hot-rolled billet with a thickness of 12mm is obtained; the hot-rolled nickel-tungsten alloy is subjected to one-pass cold rolling, and the deformation amount is 15%, and then Shot blasting treatment to remove the oxide scale on the surface; warm rolling the above-mentioned nickel-tungsten alloy after removing the oxide scale. A nickel-tungsten alloy with a thickness of 5mm is produced; the Ni-9.6at.%W alloy obtained by the above-mentioned warm rolling is cold-rolled with a wo...

Embodiment 2

[0025] The nickel block and tungsten block with a purity of 99.99% are mixed according to the molar percentage of tungsten at 9.6%, and the mixed material after mixing is melted in a vacuum induction melting furnace to obtain a nickel-tungsten alloy ingot. Heat the nickel-tungsten alloy ingot at 1200°C for 2.5 hours, then heat-forge it into a billet with a length×width×thickness of 400mm×25mm×25mm. Afterwards, hot-rolling treatment is carried out, and the deformation amount of each pass is 15%-18%, and a hot-rolled billet with a thickness of 14mm is obtained; the hot-rolled nickel-tungsten alloy is subjected to one-pass cold rolling, and the deformation amount is 15%, and then Shot blasting treatment to remove the oxide scale on the surface; warm rolling the above-mentioned nickel-tungsten alloy after removing the oxide scale. A nickel-tungsten alloy with a thickness of 5mm is produced; the Ni-9.6at.%W alloy obtained by the above-mentioned warm rolling is cold-rolled with a wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com