Two-phase region heat treatment process for ferritic stainless steel hot rolled strip

A technology of hot-rolled strip steel and ferrite, which is applied in the field of stainless steel heat treatment, can solve the problems of no obvious improvement in stamping formability and wrinkle resistance, and achieve the suppression of the formation of cluster-like aggregation structures, developed texture, and improved plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

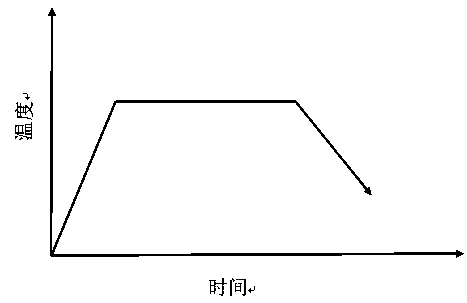

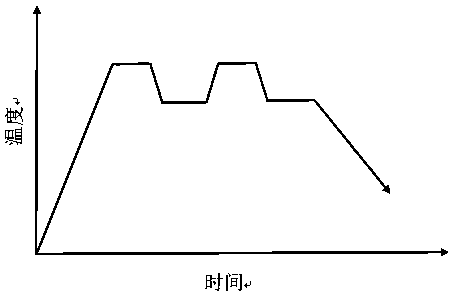

[0023] Example: Put the above-mentioned hot-rolled coils into a high-temperature box furnace to raise the temperature to 980°C, keep warm for 3 hours, then cool to 850°C with the furnace, keep warm for 5 hours, and recirculate once according to this cycle, then cool with the furnace to below 250°C and leave the furnace Air cooling, process such as figure 2 shown.

[0024] The mechanical properties of 430 ferritic stainless steel hot-rolled strip treated by two methods are shown in Table 1.

[0025] Table 1 Mechanical properties of 430 ferritic stainless steel hot-rolled strip after treatment

[0026]

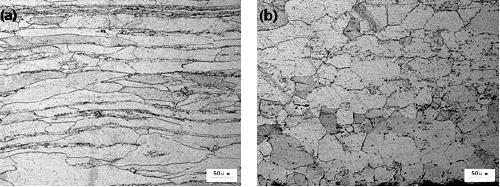

[0027] 430 ferritic stainless steel hot-rolled strip has the following mechanical properties after annealing: Rp 0.2 ≥205MPa, Rm≥420MPa, A≥22%, HV value≤200. It can be seen from Table 1 that the embodiment has lower strength, hardness and higher elongation, which is beneficial to the forming process of the plate and strip. The typical metallographic structure of comparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com