Al-Fe-Cu-Zr series aluminum alloy for cables for coal mines and aluminum alloy cable

An al-fe-cu-zr, aluminum alloy technology, applied in the field of Al-Fe-Cu-Zr aluminum alloy and aluminum alloy cables for coal mine cables, can solve the problem of high electrical conductivity and mechanical strength of cable conductors, common aluminum cores The mechanical properties and corrosion resistance of the cables are poor, and they cannot meet the bending properties of the cables used in coal mines, so as to improve the mechanical strength and tensile properties, improve the high temperature creep performance and fatigue resistance, and improve the high temperature creep resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

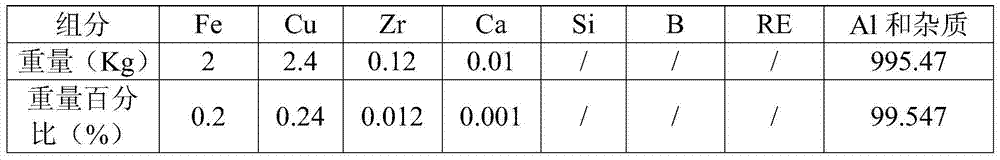

[0050] An Al-Fe-Cu-Zr series aluminum alloy for coal mine cables, the components and the weight percentages of each component are as follows (total weight: 1T):

[0051]

[0052] A certain amount of Ca is added to the above aluminum alloy material to form CaAl with Al 4 Compounds, Ca can strengthen the high-temperature performance of aluminum alloys, and cooperate with metal elements such as Fe to improve the creep resistance of aluminum alloys. At the same time, trace amounts of Ca are beneficial to the removal of hydrogen in aluminum liquid.

[0053] The method for preparing an aluminum alloy wire core by using the above-mentioned aluminum alloy material, the specific steps are as follows:

[0054] a. Casting molten aluminum alloys to obtain casting materials: adding the above-mentioned aluminum alloy components according to the above ratios, performing a melting process at 700°C, and then casting at 650°C to obtain ingots;

Embodiment 2

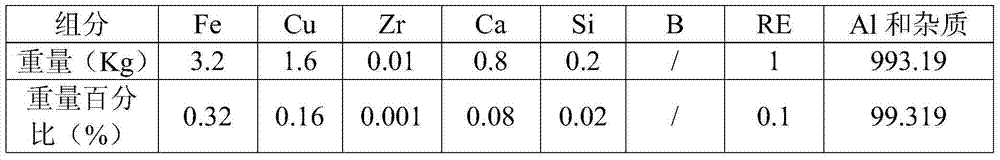

[0065] An aluminum alloy for coal mine cables, the components and the weight percentages of each component are as follows (total weight: 1T):

[0066]

[0067] A certain amount of Si and Ca are added to the above-mentioned aluminum alloy material, and the existence of a small amount of Si makes the aluminum-silicon alloy have excellent casting performance and corrosion resistance. Ca and Si form CaSi, which is insoluble in aluminum, reduces the solid solution amount of Si, and can slightly improve the conductivity of industrial pure aluminum.

[0068] The method for preparing an aluminum alloy wire core by using the above-mentioned aluminum alloy material, the specific steps are as follows:

[0069] a. Casting molten aluminum alloys to obtain casting materials: adding the above-mentioned aluminum alloy components according to the above ratios, performing a melting process at 780°C, and then casting at 660°C to obtain ingots;

Embodiment 3

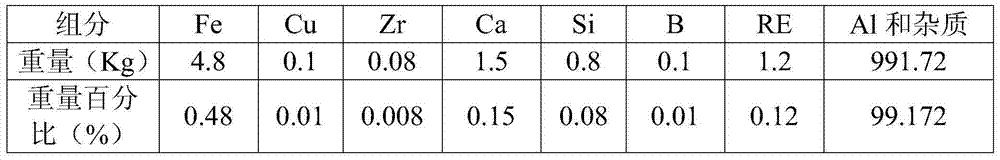

[0078] An aluminum alloy for coal mine cables, the components and the weight percentages of each component are as follows (total weight: 1T):

[0079]

[0080] In the above-mentioned aluminum alloy materials, it is preferable to add a certain amount of B and rare earth elements. B, as an aluminum alloy component, can improve the properties of the alloy, especially the electrical properties and elongation properties, and ensure the performance of the alloy through a reasonable ratio of each component. .

[0081] Rare earth elements can not only significantly improve the electrical properties of the alloy, but also have the effect of improving the fatigue resistance and bending performance of the alloy, prolonging the service life of the cable. Wherein, the rare earth element RE includes Ce, La and Pr, wherein the content of Ce and La accounts for 50% of the total content of the rare earth element.

[0082] The method for preparing an aluminum alloy wire core by using the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com