A kind of insulating coating method and metal powder core prepared according to the method

A technology of insulation coating and metal powder core, applied in the field of metal powder core, can solve the problem of low annealing temperature, achieve the effect of improving strength, heat treatment temperature and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

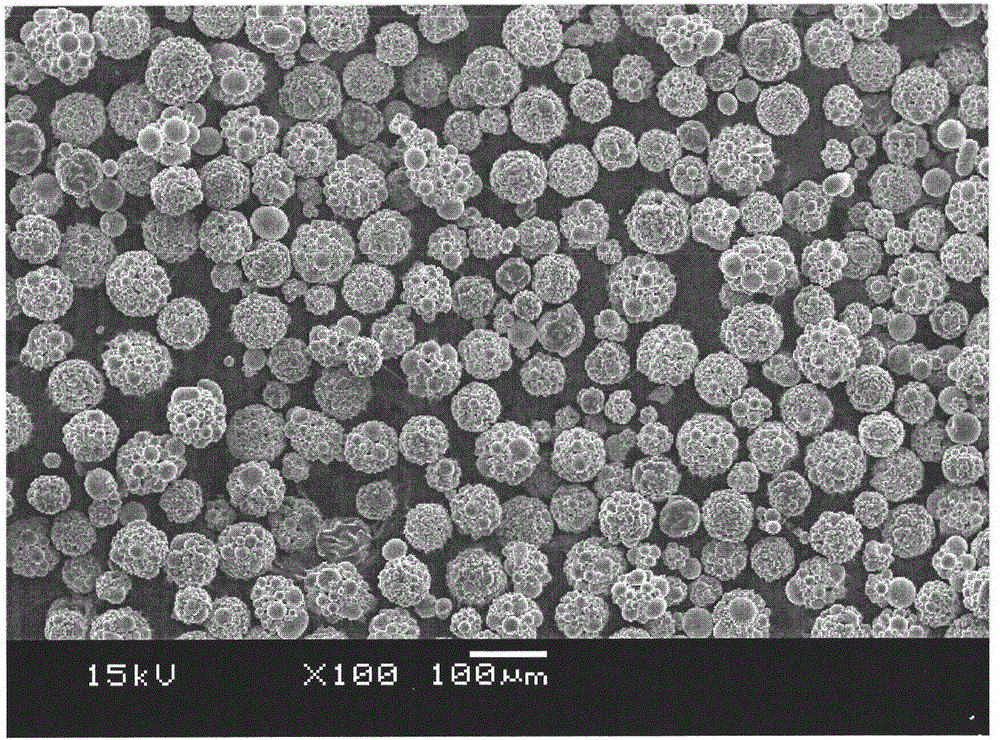

Image

Examples

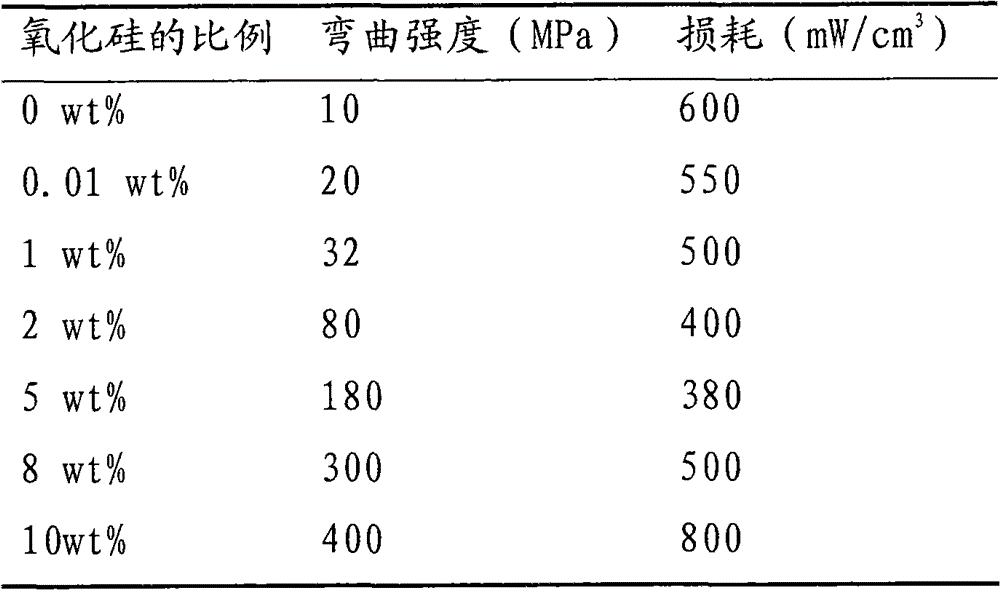

Embodiment 1

[0015] The powder of this embodiment is the composition that adopts atomization method preparation to be Fe 80 Si 16 B 4 Iron-based amorphous soft magnetic powder, bismaleimide and silicon oxide are selected as the insulating coating agent, and the mixing ratio of silicon oxide is 0wt%, 0.01wt%, 1wt%, 2wt%, and 5wt%, 10wt%, the particle size is below 50nm, the overall insulating coating agent accounts for 3% of the amorphous powder, and the pressing pressure is 1800MPa. The subsequent metal powder cores are annealed in vacuum at 450°C. The loss is tested with a BH AC impedance analyzer, and the bending strength is tested with a three-point bending method of a universal tensile testing machine.

[0016] Table 1 Improvement of metal powder core strength and loss by different oxide mixing ratios

[0017]

[0018] It can be seen from the above table that the strength of the metal powder core increases significantly when the nano-oxide is mixed in, and the greater the ratio,...

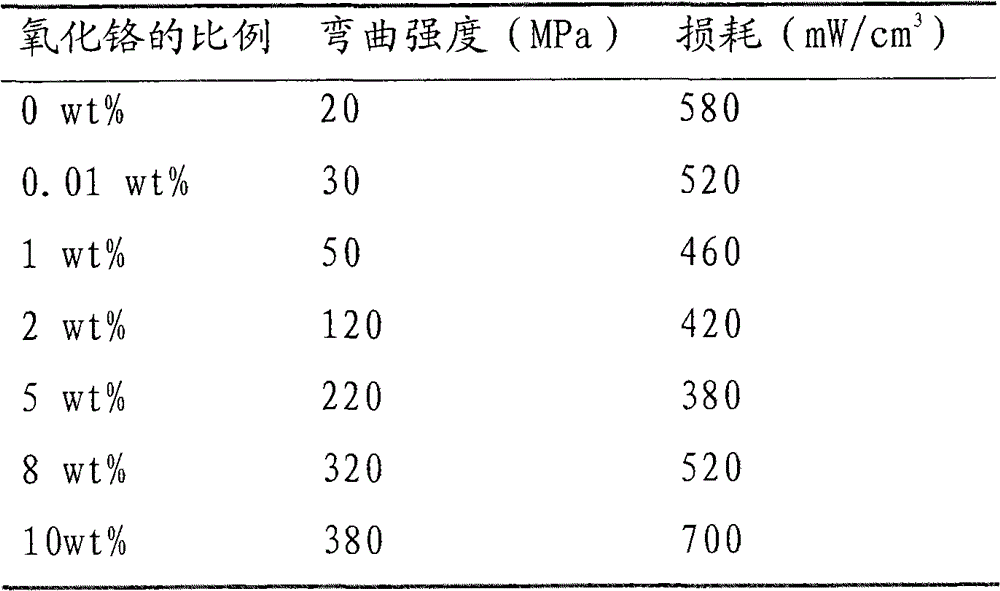

Embodiment 2

[0020] The powder of this embodiment is the composition that adopts atomization method preparation to be Fe 80 Si 16 B 4 The iron-based amorphous soft magnetic powder, the insulating coating agent selects cyanate and chromium oxide, and the mixing ratio of chromium oxide is 0wt%, 0.01wt%, 1wt%, 2wt%, 5wt%, 10wt% of cyanate, The particle size is below 50nm, the overall insulating coating agent accounts for 3% of the amorphous powder, and the pressing pressure is 1800MPa. The subsequent metal powder cores are annealed in vacuum at 450°C. The loss is tested with a BH AC impedance analyzer, and the bending strength is tested with a three-point bending method of a universal tensile testing machine.

[0021] Table 2 Improvement of metal powder core strength and loss by different oxide mixing ratios

[0022]

[0023] It can be seen from the above table that the strength of the metal powder core increases significantly when the nano-oxide is mixed in, and the greater the ratio,...

Embodiment 3

[0025] The powder of this embodiment is the composition that adopts atomization method preparation to be Fe 80 Si 16 B 4 The iron-based amorphous soft magnetic powder, the insulating coating agent is polyimide and alumina, and the mixing ratio of alumina is 0wt%, 0.01wt%, 1wt%, 2wt%, 5wt%, 10wt% of polyimide %, the particle size is below 50nm, the overall insulating coating agent accounts for 3% of the amorphous powder, and the pressing pressure is 1800MPa. The subsequent metal powder cores are annealed in vacuum at 450°C. The loss is tested with a BH AC impedance analyzer, and the bending strength is tested with a three-point bending method of a universal tensile testing machine.

[0026] Table 3 Improvement of metal powder core strength and loss by different oxide mixing ratios

[0027]

[0028] It can be seen from the above table that the strength of the metal powder core increases significantly when the nano-oxide is mixed in, and the greater the ratio, the higher t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com