Resistance card for direct-current lightning arrester and production process thereof

A technology for resistors and lightning arresters, applied in varistors, varistor cores, etc., can solve the problems of poor electrical properties of zinc oxide resistors, square wave current capacity, complicated manufacturing process, and increased manufacturing costs. , to achieve uniform and stable internal structure, excellent aging performance, and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

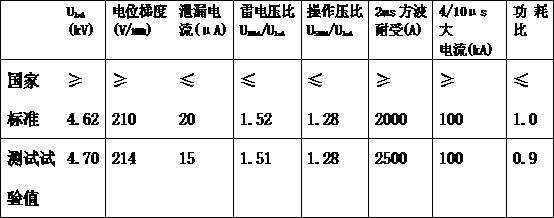

Embodiment 1

[0029] The resistor sheet for the DC arrester of the present embodiment is made of the following raw materials in weight percent: Bi 2 o 3 : 4.0%; Sb 2 o 3 : 4.0%; 2 o 3 : 1.0%; MnCO 3 : 0.50%; NiO: 0.80%; ZrO 2 : 0.1%; Al(NO 3 ) 3 : 0.03%; B 2 o 3 : 0.10%; binder 0.6%; dispersant 0.3% and defoamer 0.1%; the balance is mainly ZnO.

[0030] Its production process is to carry out according to the following steps:

[0031] The first step, material preparation: weigh Bi respectively according to the proportion 2 o 3 , Sb 2 o 3 、 Co 2 o 3 , MnCO 3 , NiO, ZrO 2 , Al(NO 3 ) 3 , B 2 o 3 , binder, dispersant, defoamer and ZnO, the Bi 2 o 3 , Sb 2 o 3 、 Co 2 o 3 , MnCO 3 , NiO, ZrO 2 and B 2 o 3 After mixing and calcining in a calciner, send it into a ball mill and grind it to a particle size of ≤1 μm to make a mixed powder. The calcining temperature is 750°C and the calcining time is 0.5 hours; at the same time, Al(NO3)3 is added with water Al(NO 3 ) ...

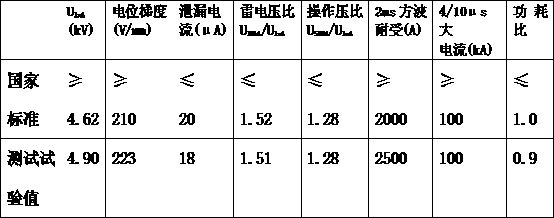

Embodiment 2

[0043] The resistor sheet for the DC arrester of the present embodiment is made of the following raw materials in weight percent: Bi 2 o 3 : 5.0%; Sb 2 o 3 : 5.0%; 2 o 3 : 1.5%; MnCO 3 : 1.0%; NiO: 1.60%; ZrO 2 : 0.5%; Al(NO 3 ) 3 : 0.05%; B 2 o 3 : 0.16%; binder 0.9%; dispersant 0.6% and defoamer 0.3%; the balance is mainly ZnO.

[0044] Its production process is basically the same as Example 1, the difference is only in:

[0045] In the first step, the calcination temperature is 800°C, and the calcination time is 0.8 hours;

[0046] In the second step, in the granulation process, the weight percentage of the mixed powder contained in the prepared slurry is controlled at 67%, and the particle size of the granulated material is 90 μm;

[0047] In the third step, the control value of the moisture content by weight in the wet material is 1.25%, and the aging time is 18 hours;

[0048] In the fourth step, the debinding temperature is 450°C, the debinding time is 3 ho...

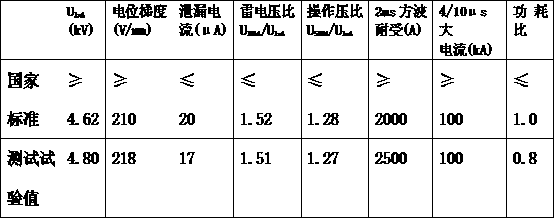

Embodiment 3

[0055] The resistor sheet for the DC arrester of the present embodiment is made of the following raw materials in weight percent: Bi 2 o 3 : 6.0%; Sb 2 o 3 : 6.0%; 2 o3 : 2.0%; MnCO 3 : 1.50%; NiO: 2.00%; ZrO 2 : 1.0%; Al(NO 3 ) 3 : 0.06%; B 2 o 3 : 0.20%; binder 1.2%; dispersant 0.9% and defoamer 0.4%; the balance is mainly ZnO.

[0056] Its production process is basically the same as Example 1, the difference is only in:

[0057] In the first step, the calcination temperature is 850°C, and the calcination time is 1 hour;

[0058] In the second step, in the granulation process, the weight percentage of the mixed powder in the prepared slurry is controlled at 70%, and the particle size of the granulated material is 120 μm;

[0059] In the third step, the control value of the moisture content by weight in the wet material is 1.5%, and the aging time is 24 hours;

[0060] In the fourth step, the debinding temperature is 500°C, the debinding time is 4 hours, the pre-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com