Cuprous oxide film with high photoelectrochemical performance and preparation method thereof

A cuprous oxide and photoelectrochemical technology, applied in electrolytic inorganic material coating, etc., can solve the problems of poor film uniformity and high cost, and achieve the effects of reduced defects, less environmental pollution, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

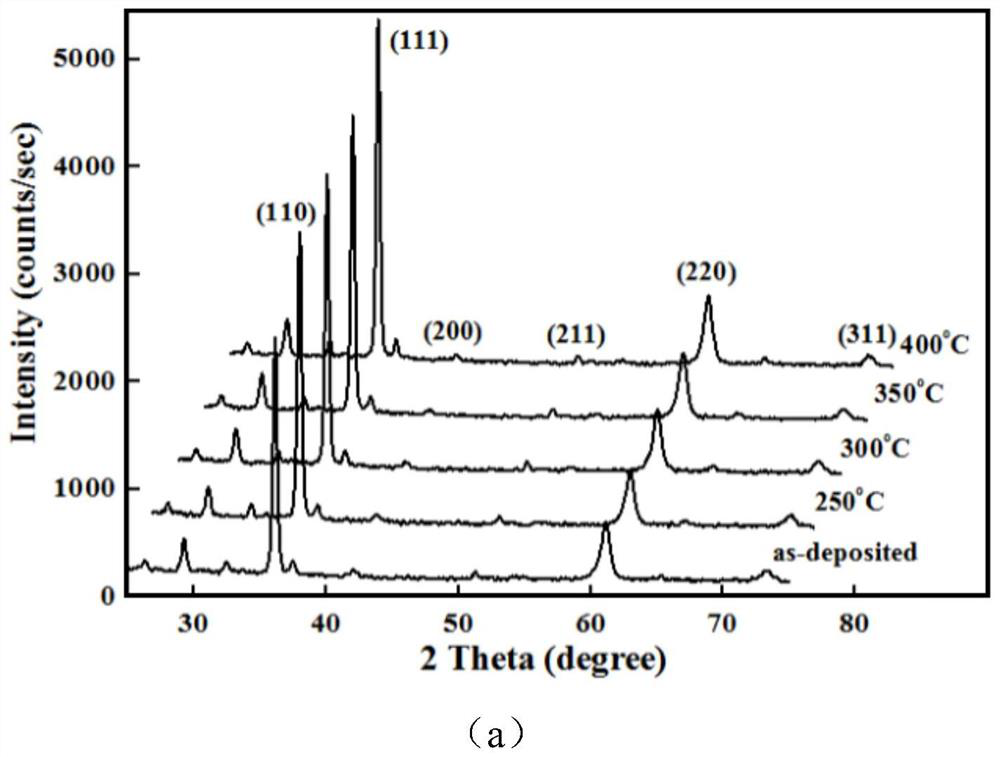

[0039] A cuprous oxide film with high photoelectrochemical performance, 25g of copper sulfate pentahydrate is dissolved in 250mL of deionized water, stirred, and made into a copper sulfate solution with a molar concentration of 0.4mol / L. Dissolve 50ml of sodium lactate in 250mL of deionized water and stir to prepare a sodium lactate solution with a molar concentration of 1.4mol / L. Take 10 mL of the above-mentioned copper sulfate and 10 mL of sodium lactate solution, mix and stir it, and add 1 mol / L sodium hydroxide solution dropwise thereto to adjust the pH to 10. Control the solution temperature at 60° C. by means of a constant temperature water bath. Deposition of cuprous oxide thin films was carried out using a three-electrode electrochemical cell. The working electrode is conductive glass. The counter electrode is a high-purity platinum electrode. The reference electrode is Ag / AgCl / KCl saturated solution electrode. Insert the three electrodes into the prepared electrode...

Embodiment 2

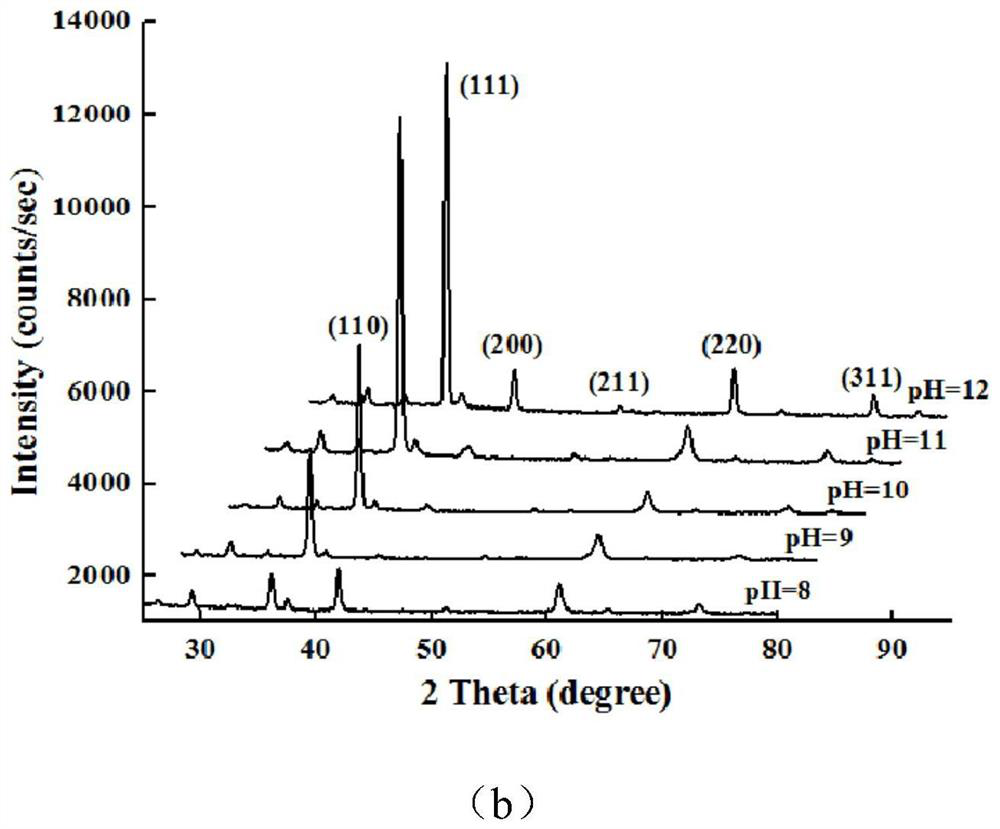

[0048] A cuprous oxide film with high photoelectrochemical performance, 25g of copper sulfate pentahydrate is dissolved in 250mL of deionized water, stirred, and made into a copper sulfate solution with a molar concentration of 0.4mol / L. Dissolve 50ml of sodium lactate in 250mL of deionized water and stir to prepare a sodium lactate solution with a molar concentration of 1.4mol / L. Take 10mL of the above-mentioned copper sulfate and 10ml of sodium lactate solution, mix and stir, add dropwise 1mol / L sodium hydroxide solution to adjust the pH to 12.0, and control the solution temperature at 60°C by means of a constant temperature water bath. Deposition of cuprous oxide thin films was carried out using a three-electrode electrochemical cell. The working electrode is conductive glass. The counter electrode is a high-purity platinum electrode. The reference electrode is Ag / AgCl / KCl saturated solution electrode. Insert the three electrodes into the prepared electrodeposition solut...

Embodiment 3

[0050] A cuprous oxide thin film with high photoelectrochemical performance, 7.5g copper sulfate pentahydrate is dissolved in 250mL deionized water, stirred, and made into a copper sulfate solution with a molar concentration of 0.2mol / L. Dissolve 25ml of sodium lactate in 250mL of deionized water and stir to prepare a sodium lactate solution with a molar concentration of 0.7mol / L. Take 10mL of the above-mentioned copper sulfate and 10ml of sodium lactate solution, mix and stir, add dropwise 1mol / L sodium hydroxide solution to adjust the pH to 12.0, and control the temperature of the solution at 70°C by means of a constant temperature water bath. Deposition of cuprous oxide thin films was carried out using a three-electrode electrochemical cell. The working electrode is conductive glass. The counter electrode is a high-purity platinum electrode. The reference electrode is Ag / AgCl / KCl saturated solution electrode. Insert the three electrodes into the prepared electrodepositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com