Fuse with built-in thermal-protective coating and manufacture process thereof

A manufacturing process and technology of fuses, which are applied in the manufacture of fuses, emergency protection devices, electrical components, etc., can solve the problems of high cost, low heat resistance temperature, and low arc extinguishing performance, and achieve low cost, reduced heat dissipation, and good extinguishing The effect of arc performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

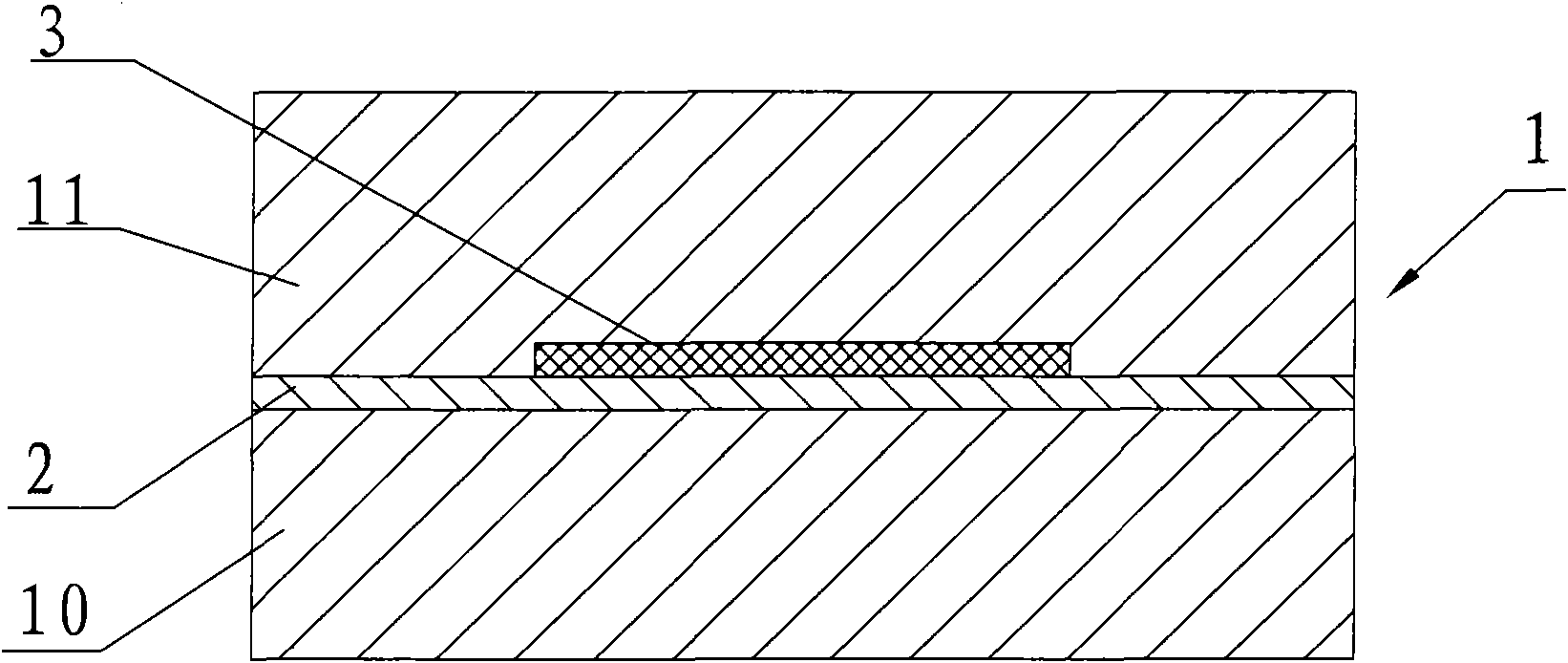

[0038] Such as figure 1 As shown, the fuse includes a glass-ceramic base 1, a fusible metal conductor 2 embedded in the glass-ceramic base 1, a heat insulating layer 3 disposed on one side of the fusible metal conductor 2, and terminal electrodes (not shown in the figure), The material used for the heat insulation layer 3 is a porous ceramic glass composite material.

[0039] The preparation method of porous ceramic glass composite material is as follows:

[0040] a. Micropowdered silica gel and low-melting glass powder (melting point lower than 600°C) are wet-milled together in a weight ratio of 9:1 to a particle size of 2-3 μm, dried and evenly sieved to obtain a mixed powder;

[0041] b. Put the mixed powder into the muffle furnace, and pre-fire it for 8 to 16 hours at 500°C to 800°C;

[0042] c. The mixed powder is wet-milled until the particle size is less than or equal to 5 μm.

[0043] The manufacturing process of the above-mentioned fuse includes the following steps...

Embodiment 2

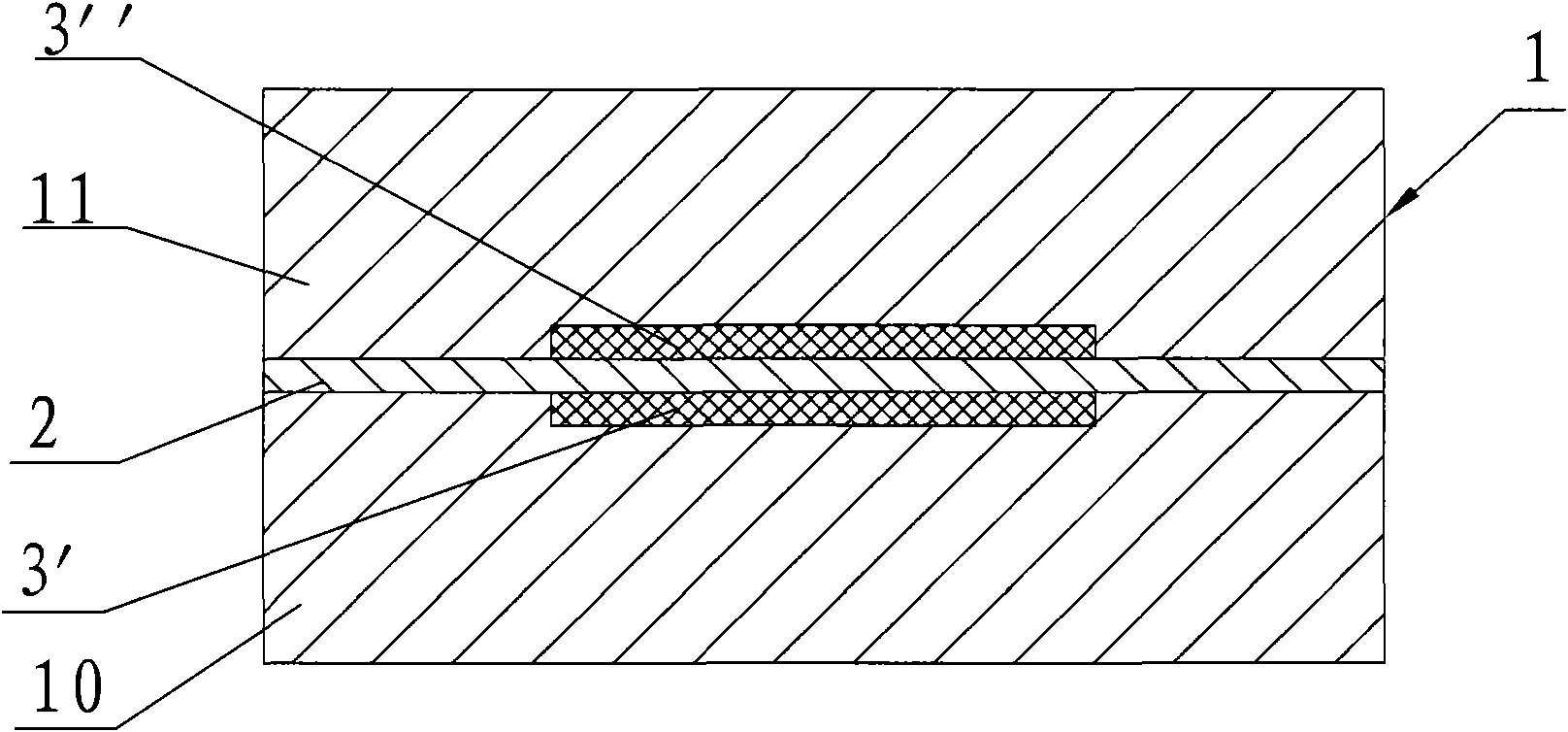

[0056] Such as figure 2 As shown, the fuse includes a glass-ceramic substrate 1, a fusible metal conductor 2 embedded in the glass-ceramic substrate 1, a thermal insulation layer 3', 3" disposed on the upper and lower surfaces of the fusible metal conductor 2, and terminal electrodes (Fig. Not shown in ), wherein the material used for the insulation layer 3', 3" is a porous ceramic glass composite material. The porous ceramic glass composite material is the same as in Example 1.

[0057] The manufacturing process of the fuse according to this embodiment includes the following steps:

[0058] (1) Obtain the green body of the fuse through the molding process of layer-by-layer addition: first coat a glass-ceramic layer with a UV-curable binder, and UV-cure the coating to form the first glass-ceramic substrate 10; Then, on the first glass-ceramic substrate 10, a slurry of porous ceramic-glass composite material with a UV-curable binder is printed by screen printing, and the slu...

Embodiment 3

[0070] The structure and manufacturing process of the fuse according to this embodiment are the same as those in Embodiment 1, except that the porous ceramic glass composite material forming the heat insulating layer 3 is prepared by the following method:

[0071] a, the hollow microspheres (mainly B 2 o 3 and Al 2 o 3 ) and low-melting point glass powder (melting point lower than 600°C) are wet-milled at a weight ratio of 9:1 to a particle size of 2-3 μm, dried and evenly sieved to obtain a mixed powder;

[0072] b. Put the mixed powder into the muffle furnace, and pre-fire it for 8-16 hours at 500℃~800℃;

[0073] c. The mixed powder is wet-milled until the particle size is less than or equal to 5 μm.

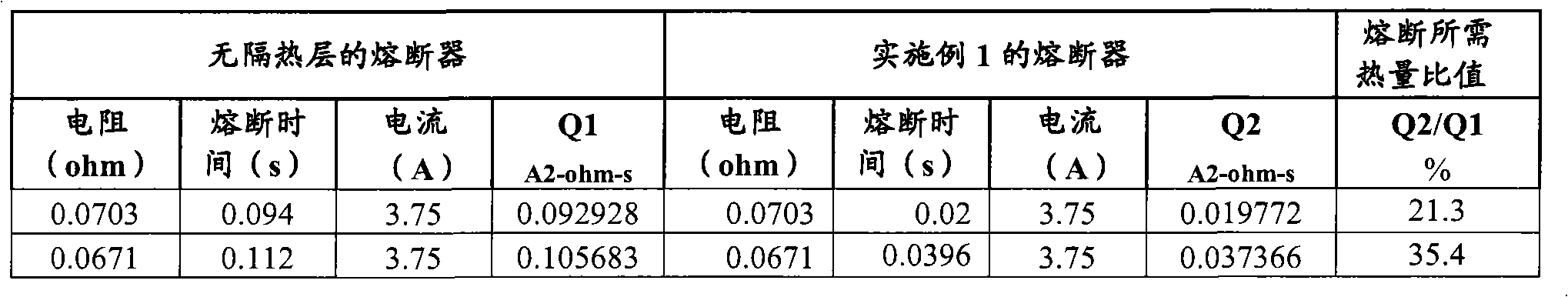

[0074] Carry out the fusing time and reliability test on the fuse of this embodiment, and the results are shown in Table 3-1 and Table 3-2 respectively.

[0075] Table 3-1 Test data of fusing time under the same overload current condition

[0076]

[0077] Table 3-2 Rel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com