Iron nitride-based magnetic powder, process for producing the same, and magnetic recording medium

An iron nitride-based, powder-based technology, applied in magnetic recording, chemical instruments and methods, magnetic objects, etc., can solve the problems of poor weather resistance, etc., and achieve improved aging degradation, improved durability and reliability, and excellent The effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

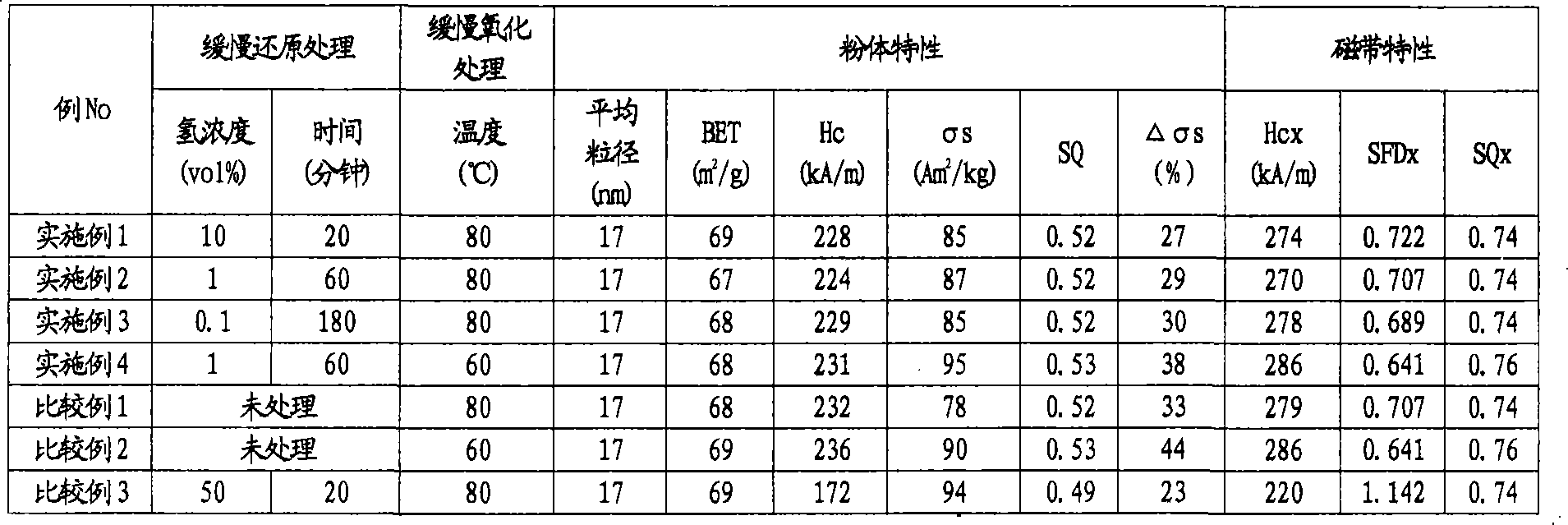

Embodiment 1

[0071] FeSO at 0.2mol / L (L means liter) 4 After adding 0.5 L of 12 mol / L NaOH aqueous solution and sodium aluminate in an amount of Al / Fe=20 atomic % to 4 L of the aqueous solution, while maintaining a liquid temperature of 40° C., air was blown in at a flow rate of 300 mL / min for 2.5 hours, thereby Precipitates the ferric hydroxide which solid-solutes Al. After this oxidation treatment, the precipitated ferric basic hydroxide was filtered, washed with water, and dispersed in water again. Yttrium nitrate in an amount of Y / Fe=1.0 atomic % was added to the dispersion, and a 12 mol / L NaOH aqueous solution was adjusted to pH=7 to 8 at 40° C. to coat the particle surface with yttrium. Thereafter, filtration and water washing were performed. Dry in air at 110°C.

[0072] As a result of compositional analysis of the obtained powder, the atomic ratios of Al and Y to Fe were Al / Fe=9.6 atomic % and Y / Fe=2.3 atomic %.

[0073] The obtained powder mainly composed of ferric basic hydro...

Embodiment 2

[0079] Except that in the "slow reduction treatment" of Example 1, the hydrogen concentration in the hydrogen-nitrogen mixed gas was changed to 1.0 vol%, and the treatment time was changed to 60 minutes, the magnetic powder was produced under the same conditions as in Example 1, And the same measurement as in Example 1 was performed.

Embodiment 3

[0081] Except that in the "slow reduction treatment" of Example 1, the hydrogen concentration in the hydrogen-nitrogen mixed gas was changed to 0.1 vol%, and the treatment time was changed to 180 minutes, the magnetic powder was produced under the same conditions as in Example 1, And the same measurement as in Example 1 was performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com