Iron nitride magnetic powder and method of producing the powder

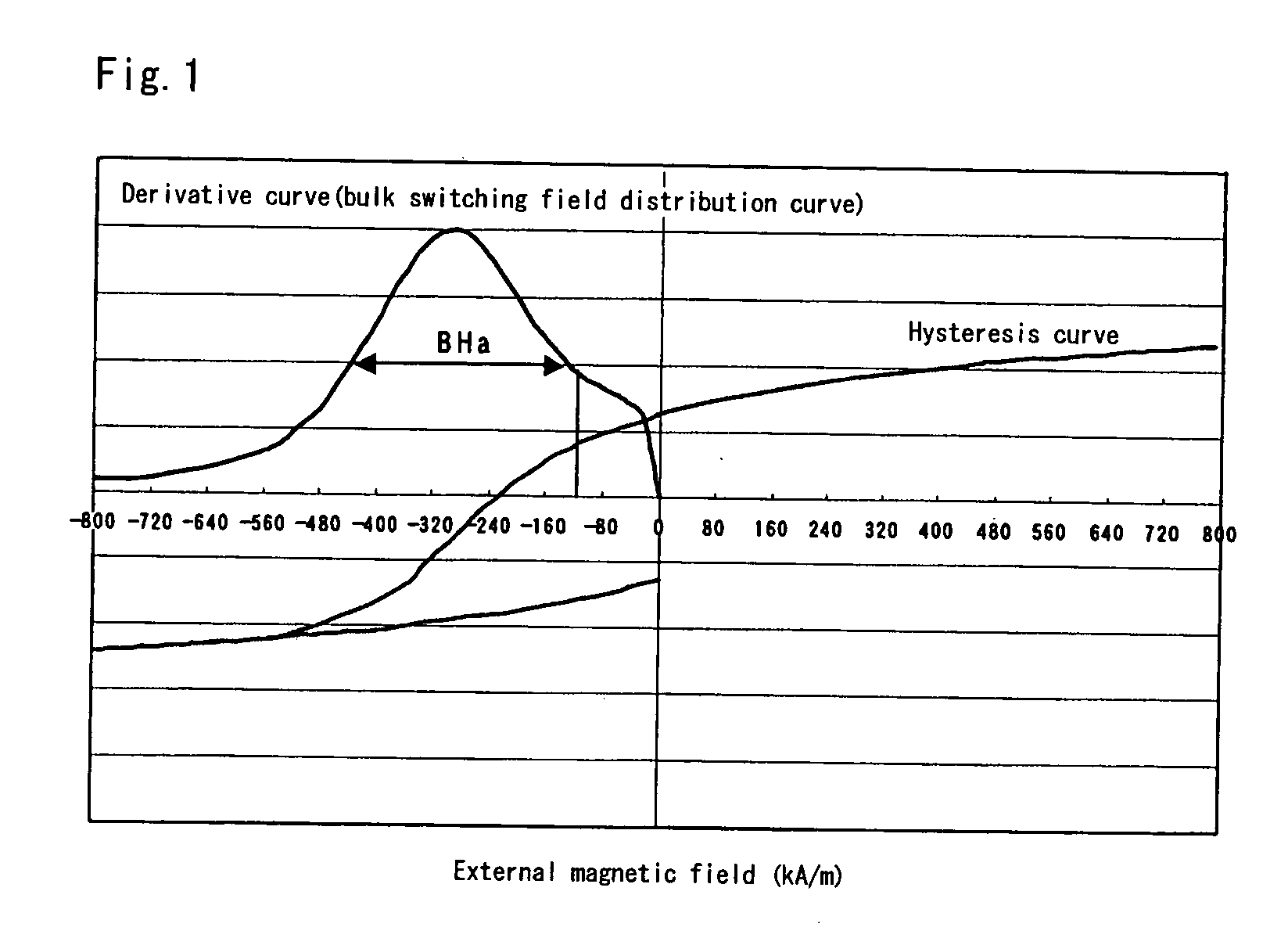

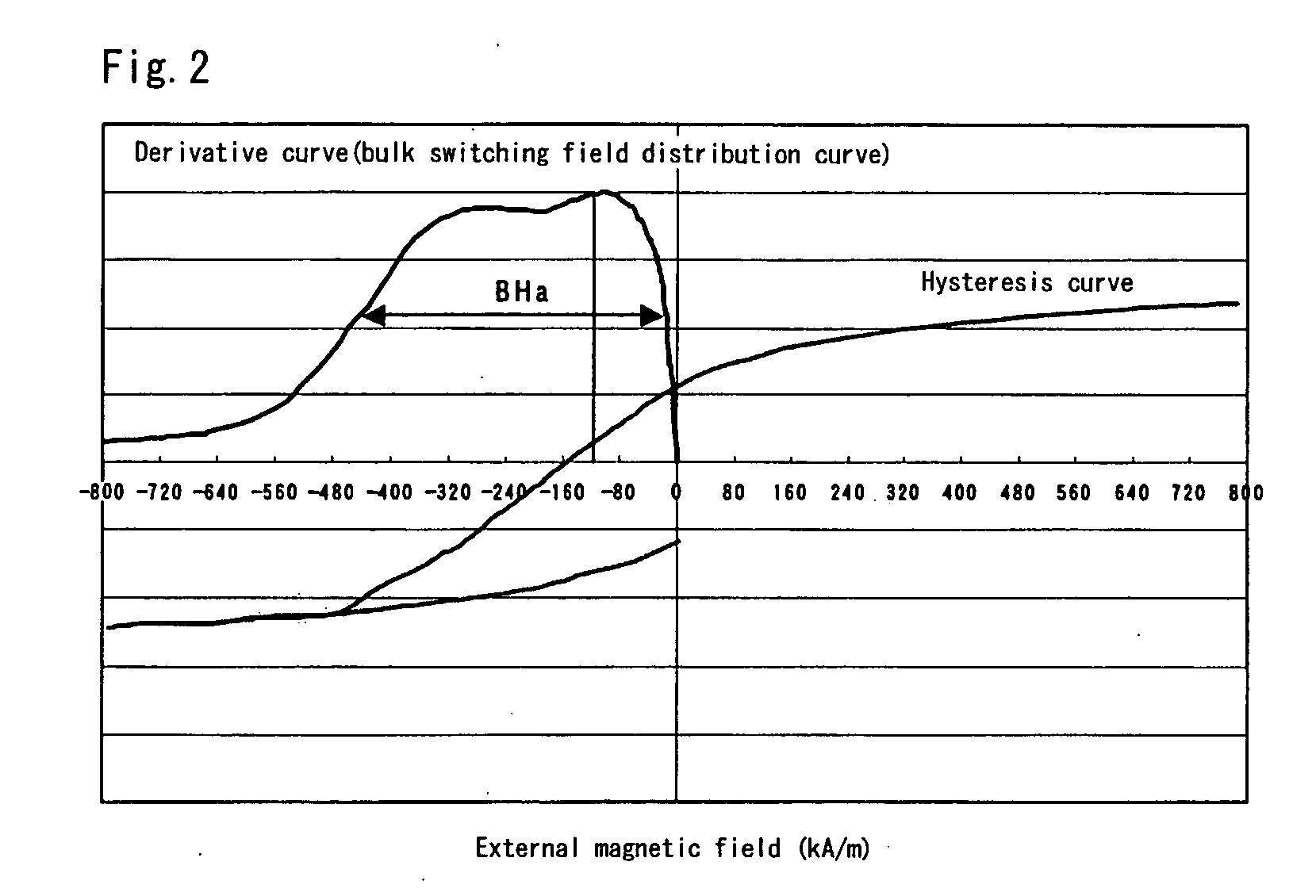

a technology of iron nitride and magnetic powder, which is applied in the field of iron nitride magnetic powder and method of producing powder, can solve the problems of inability to realize sufficient resolution, inability to record, and phenomena cannot be eliminated, and achieve excellent magnetic properties, good oxidation resistance, and high hc and low bsfd.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0043] As starting material was used a powder composed of 27 nm average diameter magnetite particles having a surface layer of Si and Y oxides (Si and Y content expressed as atomic percent based on Fe of 4.7 at. % and 1.0 at. %, respectively). The powder was placed in a furnace, heated, and reduced in a stream of hydrogen gas at 500° C. for one hour. It was then cooled to 100° C., at which temperature the gas of the gas stream was changed from hydrogen to ammonia, and thereafter heated to 165° C. At this temperature, the outlet pressure of the discharge gas was regulated to put the furnace under a controlled pressurized condition of 0.1 MPa. Nitriding was conducted for 11 hours under this pressurized condition.

[0044] After the nitriding treatment, the outlet pressure of the discharge gas was returned to atmospheric pressure to discontinue the pressurization, whereafter the temperature was lowered to 80° C. and the gas of the gas stream was changed to nitrogen gas to which was added...

example 2

[0047] Example 1 was repeated except that the outlet pressure of the discharge gas was regulated to put the furnace under a controlled pressurized condition of 0.3 MPa.

[0048] The powder obtained had an average particle diameter of 25 nm and a BET specific surface area of 44 m2 / g. The results of magnetic property evaluation were: Hc=239 KA / m, σs=97 AM2 / Kg, and BSFD=1.31. The powder oxidation resistance Δσs was 23.7% and the ratio below Hc 120 KAm in the BSFD was 9.3%. The evaluated tape properties were: Hcx=265 KA / m, SFDx=0.56, SQx=0.75, and tape oxidation resistance ΔBm of 11.8%.

example 3

[0049] Example 1 was repeated except that the starting material used was 20 nm average diameter goethite particles containing Al and Y as sinter preventing agents at atomic percents based on Fe of 9.4 at. % and 1.9 at. %, respectively.

[0050] The powder obtained had an average particle diameter of 15 nm and a BET specific surface area of 69 m2 / g. The results of magnetic property evaluation were: Hc=214 KA / m, σs=67 Am2 / Kg, and BSFD=1.77. The powder oxidation resistance Δσs was 35.3% and the ratio below Hc 120 KAm in the BSFD was 13.2%. The evaluated tape properties were: Hcx=233 KA / m, SFDx=0.71, SQx=0.70, and tape oxidation resistance ΔBm of 16.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com