Zirconia ceramic matrix composite and preparation method thereof

A technology for zirconia ceramics and composite materials, which is applied in the field of zirconia ceramic matrix composites and their preparation, can solve the problems of reducing the high temperature performance and chemical stability of ceramics, high cost, and low toughness of ceramic materials, and achieves low oxidation resistance. , Wide application prospects, excellent high temperature mechanical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

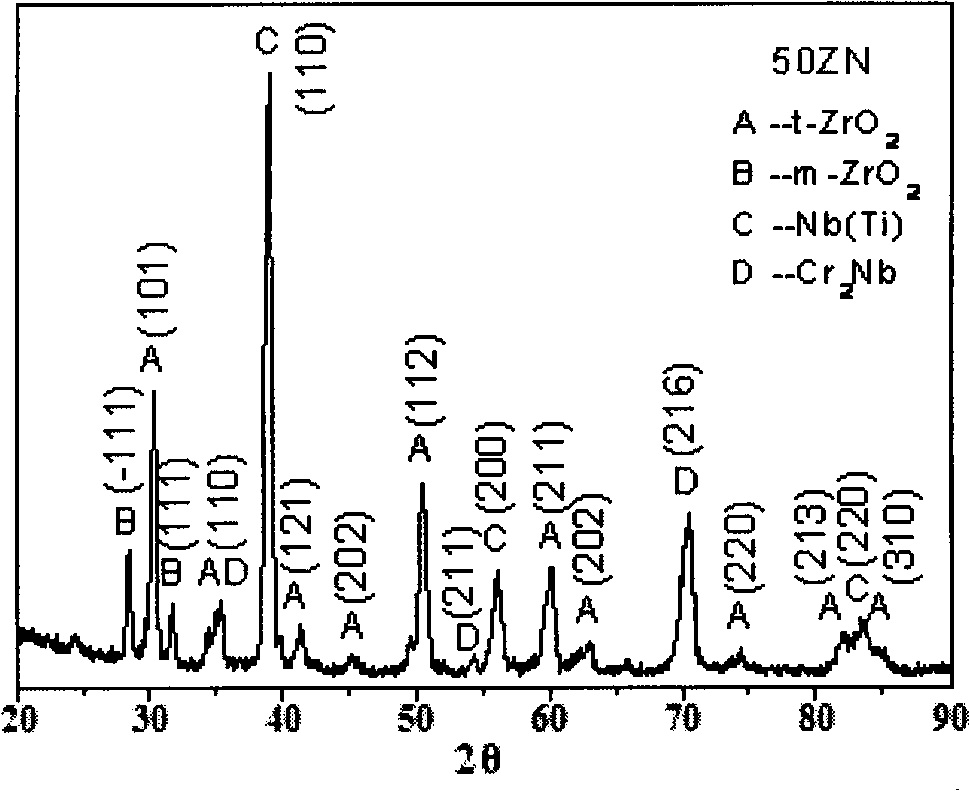

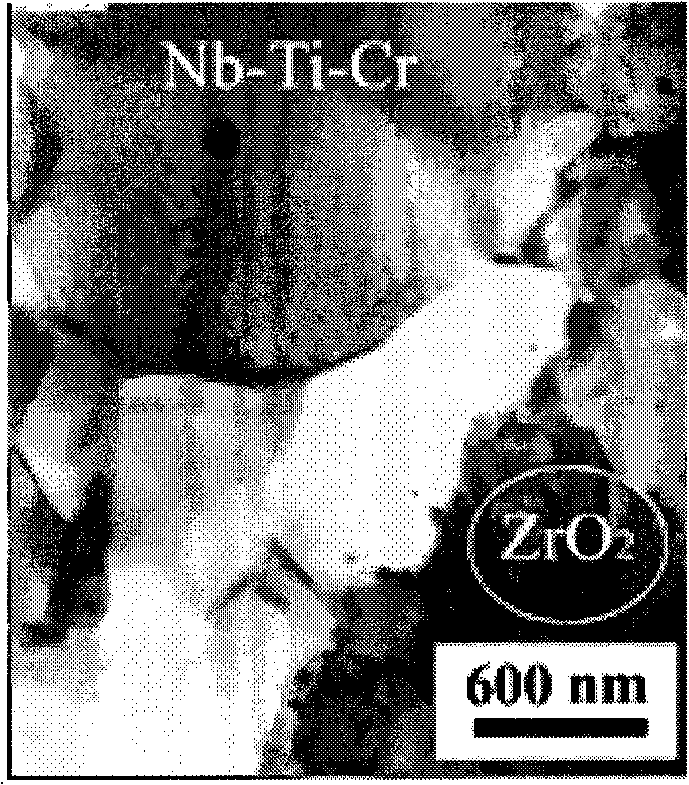

[0030] (1) Nb powder, Ti powder, and Cr powder with a particle size of 2000 to 8000nm and a purity of ≥99.0% are mixed according to the ratio of Nb:Ti:Cr=50:37:23, and ball milled under a nitrogen atmosphere. The ball milling time is 20 ~60h, the mill speed is 360r / min, after ball milling, the toughening phase powder with a particle size of 200~500nm is obtained;

[0031] (2) ZrO with a particle size of 10-40nm 2 (3Y) powder and toughening phase powder are mixed according to the volume ratio of 30:70, using QM-1SP2 planetary high-energy ball mill, nickel-chromium stainless steel vacuum ball milling tank and carbide balls, and ball milling under nitrogen atmosphere , the ball milling time is 1h, and the mill speed is 100r / min;

[0032] (3) The mixed powder is hot-pressed and sintered in a multifunctional sintering furnace with a heating rate of 50°C / min and a vacuum degree of 3×10 -3 Pa. The sample was degassed at 500°C for 30 minutes. The sintering temperature is 1250-1450...

Embodiment 2

[0034] (1) Nb powder, Ti powder, and Cr powder with a particle size of 2000 to 8000nm and a purity of ≥99.0% are mixed according to the ratio of Nb:Ti:Cr=50:37:23, and ball milled under a nitrogen atmosphere. The ball milling time is 20 ~60h, the mill speed is 360r / min, after ball milling, the toughening phase powder with a particle size of 200~500nm is obtained;

[0035] (2) ZrO 2 (3Y) powder and toughening phase powder are mixed according to the volume ratio of 40:60, using QM-1SP2 planetary high-energy ball mill, nickel-chromium stainless steel vacuum ball milling tank and carbide balls, and ball milling under nitrogen atmosphere , the ball milling time is 0.5h, and the mill speed is 100r / min;

[0036] (3) The mixed powder is hot-pressed and sintered in a multifunctional sintering furnace with a heating rate of 25°C / min and a vacuum of 3×10 -3 Pa. The sample was degassed at 500°C for 30 minutes. The sintering temperature is 1250-1450° C., the holding time is 60 minutes,...

Embodiment 3

[0038] ZrO 2 (3Y) The powder is mixed with the toughening phase powder at a volume ratio of 50:50, and the other operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com