Tetragonal zirconia based composite ceramic ultrathin cover plate and preparation process thereof

A composite ceramic and zirconia-based technology, which is applied in the field of square zirconia-based composite ceramic ultra-thin cover plates and its preparation, can solve the problems of high sintering temperature, low solid content, and easy deformation of thin plates, and achieve excellent mechanical properties and flatness The effect of high precision and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

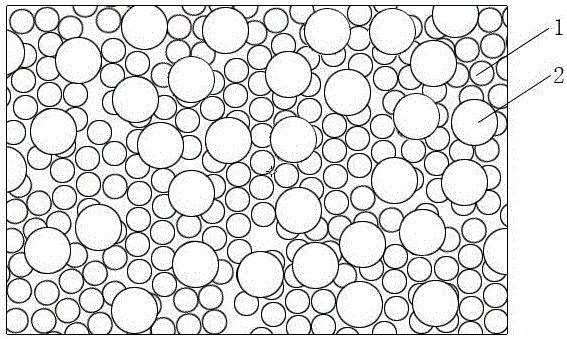

Image

Examples

Embodiment 1

[0020] According to the total amount of 63g ceramic material, calculate the dosage of 0.08μm square zirconia powder with a particle size of 0.08μm and pure alumina powder with a particle size of 1μm in a volume ratio of 70:30, and weigh them separately; add 26.75g of methyl ethyl ketone and ethanol mixed solvent and 2g of triolein dispersant, ball mill and mix for 24 hours. After ball milling, 5g of styrene-acrylic emulsion binder and 3.25g of glycerol plasticizer were added, and ball milling was continued for 6 hours. Then add 0.05g of defoaming agent and defoam in a vacuum stirred tank for 20 minutes to obtain a ceramic slurry with a solid content of 63%. The resulting ceramic slurry was cast on a casting machine and dried for 15 minutes in the main drying zone of the casting machine at 120°C to obtain a ceramic green tape. Finally, the ceramic green tape was cut and put into a sintering bowl box at 1300°C After sintering for 3 hours, the tetragonal zirconia-based composite ...

Embodiment 2

[0022] According to the total amount of 65g ceramic material, calculate the amount of 0.4μm square zirconia powder and 3μm square zirconia powder with a volume ratio of 50:50, and weigh them separately; add 25.75g methyl ethyl ketone and ethanol mixed solvent and 2g triolein dispersant, ball mill and mix for 15h. After ball milling, 4.25 g of styrene-acrylic emulsion binder and 3 g of glycerin plasticizer were added, and ball milling was continued for 5 hours. Then add 0.05g of defoaming agent and defoam in a vacuum stirred tank for 20 minutes to obtain a ceramic slurry with a solid content of 65%. The resulting ceramic slurry was cast on a casting machine and dried in the main drying zone of the casting machine at 120°C for 15 minutes to obtain a ceramic green tape. Finally, the ceramic green tape was cut and put into a sintering bowl box at 1500°C After sintering for 2 hours, the ultra-thin zirconia-based composite ceramic cover plate with cross-scale structure according to ...

Embodiment 3

[0024] According to the total amount of ceramic material 70g, calculate the dosage of 0.5μm square zirconia powder with a particle size of 0.5μm and pure aluminum nitride powder with a particle size of 3μm in a 40:60 volume ratio; add 22.6g methyl ethyl ketone and ethanol mixed solvent And 2g triolein dispersant, ball mill and mix for 12h. After ball milling, 3g of styrene-acrylic emulsion binder and 2.4g of glycerol plasticizer were added, and ball milling was continued for 2h. Then add 0.05g of defoaming agent, and defoam in a vacuum stirred tank for 30 minutes to obtain a ceramic slurry with a solid content of 70%. The resulting ceramic slurry was cast on a casting machine and dried in the main drying zone of the casting machine at 120°C for 15 minutes to obtain a ceramic green tape. Finally, the ceramic green tape was cut and put into a sintering bowl box at 1500°C After sintering for 3 hours, the tetragonal zirconia-based composite ceramic ultra-thin cover plate with cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com