Method for preparing high-temperature resisting organic adhesive by utilizing liquid silicon carbide precursor

A technology of silicon carbide and high temperature resistance, applied in the direction of adhesives, etc., can solve the problems of polysiloxane molecular structure change, lower use temperature, low bonding strength, etc., and achieve low surface energy, reliable source, and good bonding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] To a 250ml three-necked flask equipped with condensation reflux and mechanical stirring, add 20g of liquid polymethylsilane (self-made), 20ml of toluene, and 5g of tetramethyltetravinylcyclotetrasiloxane, heated to 180°C for reaction for 5h, and then cooled to 150 ℃, under reduced pressure distillation for 0.5h to remove the solvent and small molecules to obtain a light yellow viscous liquid, the entire reaction process is under nitrogen protection.

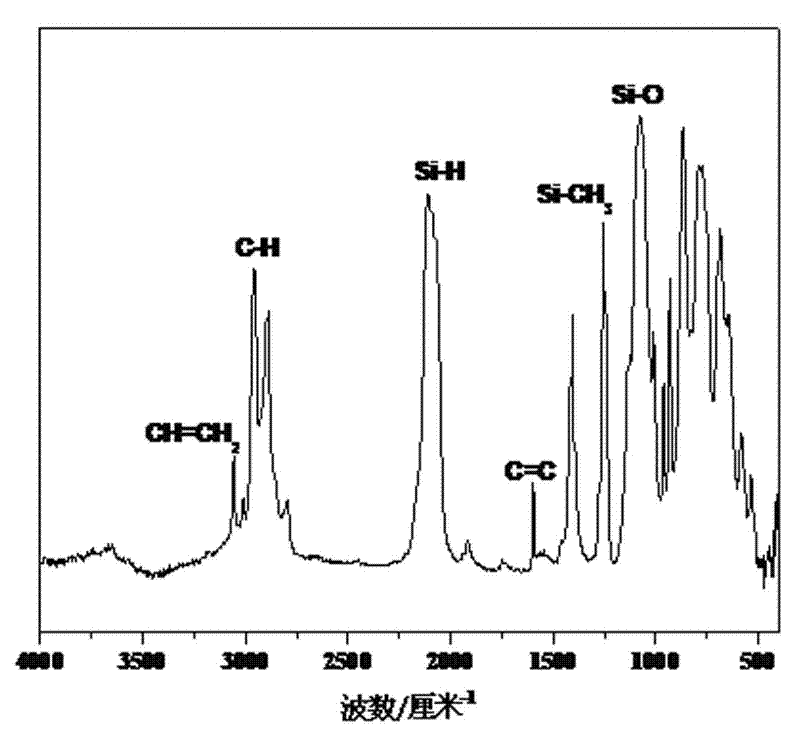

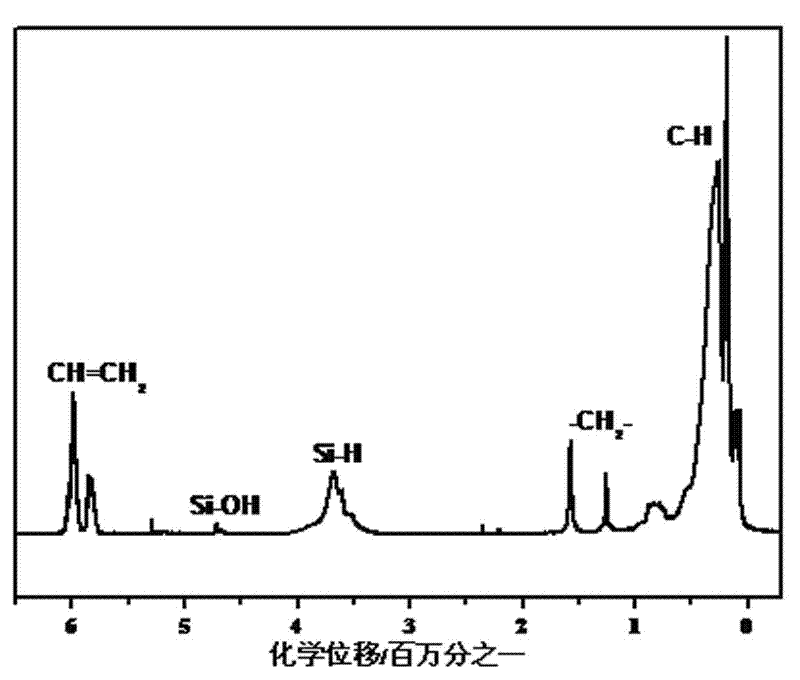

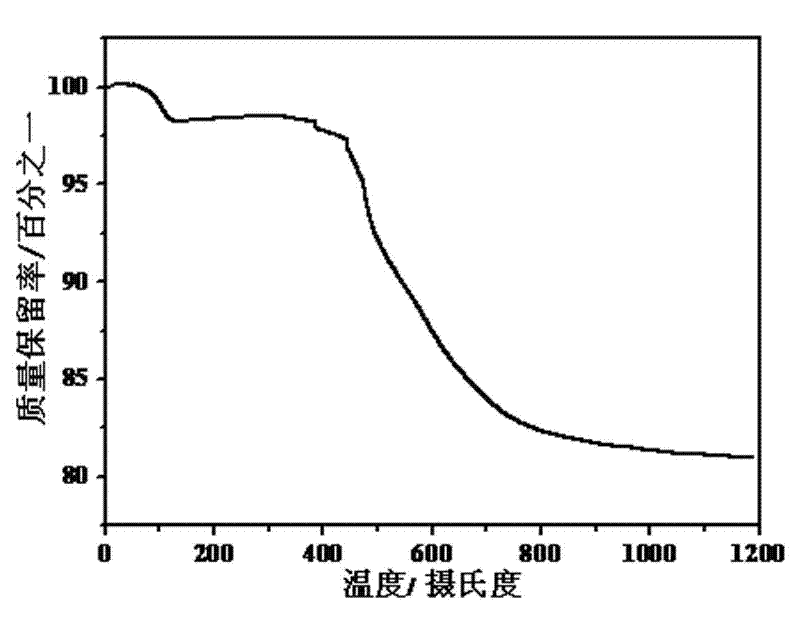

[0022] see figure 1 and figure 2 : by IR, 1 H-NMR analysis showed that the polymer contained Si-H, Si-OH, Si-CH 3 , Si-O-Si, CH=CH 2 chemical bonds. The polymer has excellent high temperature resistance, N 2 The weight loss at 1200 ℃ in the atmosphere is only 18.8%, and the weight loss at 1200 ℃ in the air atmosphere is only 8.6%.

Embodiment 2

[0024] Add 20g liquid polycarbosilane, 20ml tetrahydrofuran, 20g tetramethyltetraenyl cyclotetrasiloxane to the 250ml three-necked flask equipped with condensation reflux and mechanical stirring, add 1.7ppm of platinum-containing catalyst, heat to 100 ° C with mechanical stirring After 1.5h, the temperature was lowered to 80°C, and the solution was distilled under reduced pressure for 0.25h to remove the solvent and small molecules, and a pale yellow viscous liquid was obtained. The whole reaction process was under nitrogen protection. The resulting polymer N 2 The weight loss at 1200 ℃ in the atmosphere is 20.4%, and the weight loss at 1200 ℃ in the air atmosphere is 14.5%.

Embodiment 3

[0026] Into a 250ml three-necked flask equipped with condensation reflux and mechanical stirring, add 20g of liquid polysilane, 10g of tetramethyltetravinylcyclotetrasiloxane, add 2.1ppm of chloroplatinic acid, heat to 150°C and mechanically stir for 1.5h, then The temperature was lowered to 80° C., and distilled under reduced pressure for 0.25 h to remove small molecules to obtain a white viscous liquid. The whole reaction process was under nitrogen protection. The resulting polymer N 2 The weight loss at 1200 ℃ in the atmosphere is 21.5%, and the weight loss at 1200 ℃ in the air atmosphere is 17.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com