Coating structure and surface treating method

A construction and coating technology, applied in the direction of coating, combustion method, metal material coating process, etc., can solve problems such as difficulty in ensuring long-term heat resistance of high-temperature components - water vapor corrosion resistance, and the intermediate layer is prone to cracking and peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Reference Figure 1 ~ Figure 6 The embodiment of the present invention will be described in detail.

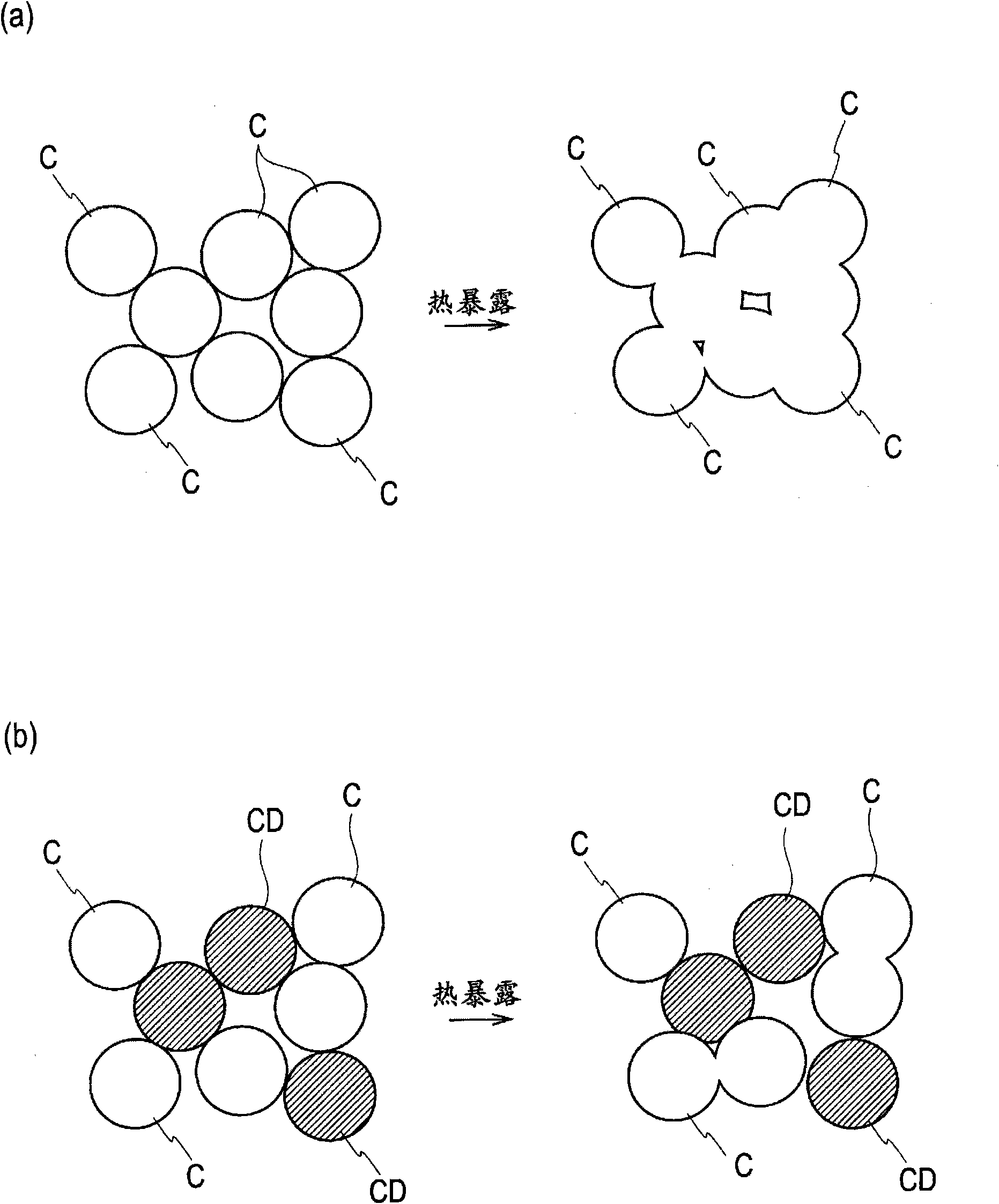

[0025] [1] First, refer to figure 2 The new knowledge that is the premise of the coating structure and the surface treatment method according to an embodiment of the present invention will be described.

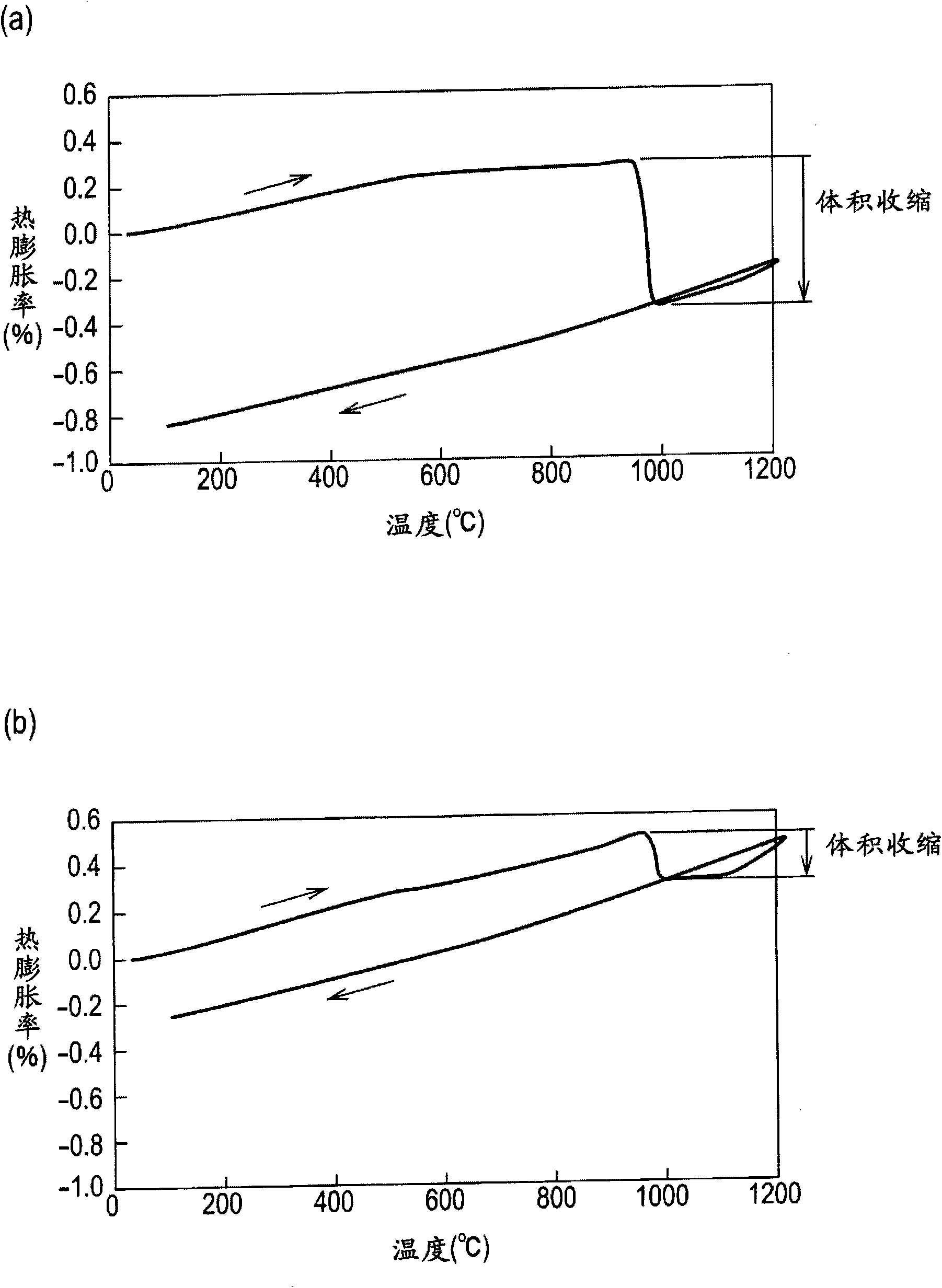

[0026] in figure 2 The results of thermal expansion tests respectively performed on test piece A (a comparative example: not shown) and test piece B (one example: not shown) that simulated the intermediate layer are shown in FIG.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com