Preparation method for porous titanium-ceramic composite biological material

A porous material and biological technology, applied in the field of porous composite materials and medical metal materials, can solve the problems of poor biocompatibility, insufficient mechanical properties of porous titanium alloy system, etc., to improve biological activity, biocompatibility and biological activity , the effect of improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

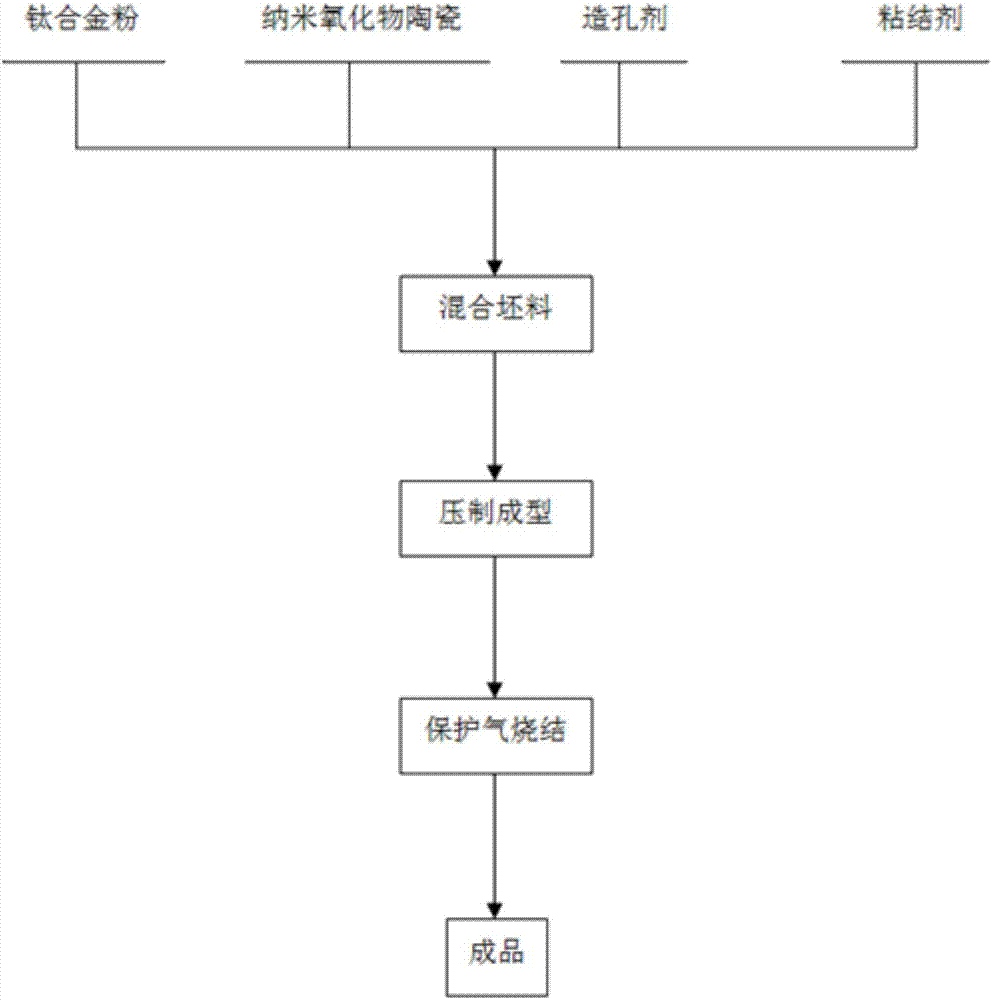

Method used

Image

Examples

Embodiment 1

[0024] (1) Ti2448 (Ti-24Nb-4Zr-8Sn, purchased from Institute of Metals, Chinese Academy of Sciences) and nano ZrO 2 Mix the ingredients according to the mass ratio of 95:5, then add the mixed material and zirconia grinding balls into the ball milling jar according to the mass ratio of 1:2, and add alcohol to two-thirds of the ball milling jar. Mixed material in planetary ball mill 300r·min -1 Under the ball milling for 10h, stop for 1h when the ball mill reaches 5h. The ball-milled raw materials are dried in a 120°C drying oven at a constant temperature, and 10wt.% NH is added after drying 4 HCO 3 Pore-forming agent and 4wt.% polyethylene glycol binder, and fully hand-grinded in an agate mortar for 30min;

[0025] (2) Pour the raw material powder mixed uniformly through hand grinding into a stainless steel mold for compaction, and then hold it under a pressure of 200MPa for 5min to form it;

[0026] (3) Put the pressed sample into a tube-type resistance furnace, use a vacu...

Embodiment 2

[0028] (1) Ti2448 (Ti-24Nb-4Zr-8Sn, purchased from Institute of Metals, Chinese Academy of Sciences) and nano ZrO 2 Mix the ingredients according to the mass ratio of 95:5, then put the mixed material and zirconia grinding balls into the ball milling jar according to the mass ratio of 1:2, and add alcohol to two-thirds of the ball milling jar. Mixed material in planetary ball mill 300r·min -1 Under the ball milling for 10h, stop for 1h when the ball mill reaches 5h. The ball-milled raw materials are dried in a 120°C drying oven at a constant temperature, and 30wt.% NH is added after drying 4 HCO 3 Pore-forming agent and 3wt.% polyethylene glycol binder, and fully hand-grinded in an agate mortar for 30min;

[0029] (2) Pour the raw material powder mixed uniformly through hand grinding into a stainless steel mold for compaction, and then hold it under a pressure of 250MPa for 5min to form it;

[0030] (3) Put the pressed sample into a tubular muffle furnace, use a vacuum pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com