Processing method for restoring all-ceramic substrate material

A technology of base material and processing method, which is applied in the field of preparation and processing of all-ceramic base materials for restoration, and can solve problems such as cracking of outer layer porcelain, low thermal conductivity, failure of bridge repair, etc., and achieve the effect of solving poor bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

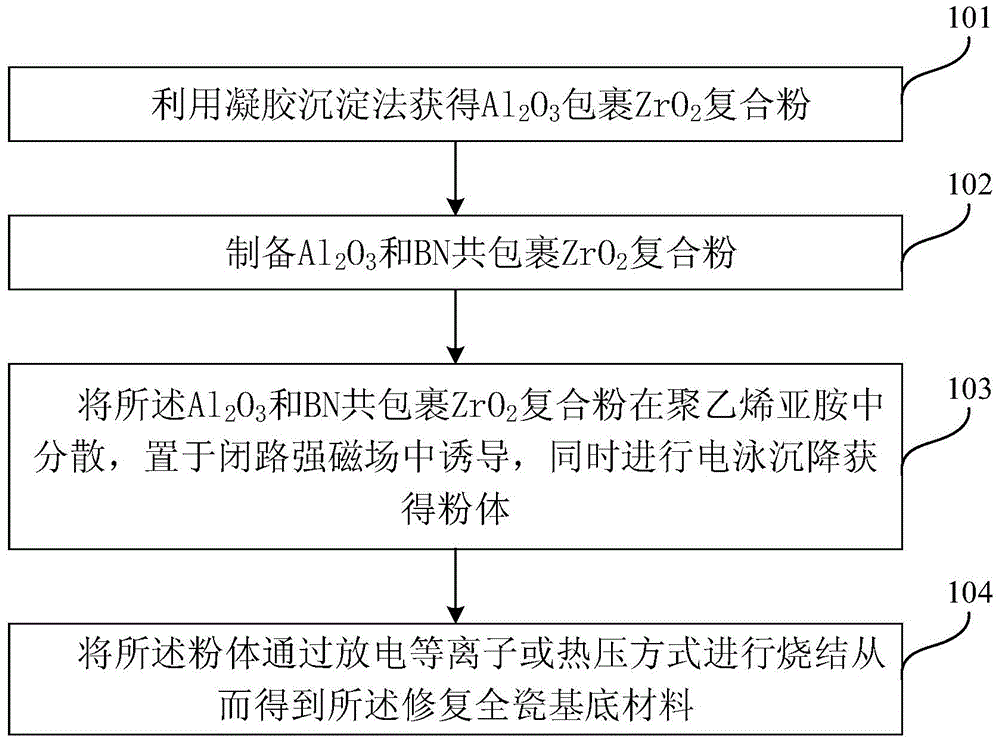

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

[0025] The machinable ceramics in the processing method for repairing all-ceramic base materials of the present invention can unify the strength and machinability, because the machinability index M=K IC / H V , Good processability requires high K IC And low hardness. Low hardness means that the internal bonding of the material is weak, which leads to a decrease in material strength. But the strength of the material can pass K IC To improve. K as one of the basic properties of materials IC It is the tissue sensitivity factor, which is the resistance encountered when cracks in the material develop instability. The toughening of ceramic materials has been developed relatively well, which provides a possibility to apply some advanced toughening mechanisms to machinable ceramics, and it is possible to obtain both strength and wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Theoretical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com