Ceramic base/NAO composite friction material and preparation method thereof

A composite friction material and friction material technology, applied in the direction of friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problem of lack of material core design technology, advanced technology, product performance and quality that cannot meet the host, safety and stability adhesion issues such as large differences in sex, rust, and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0064] Raw Material Raw Material Example 1 Example 2 Example 3

[0065] 1 Phenolic Resin 4 6 8

[0066] 2 Kevlar aramid fiber 3 2.5 0.5

[0067] 3 Ceramic Fiber Ceramic fiber 4 7 10

[0068] 4 Potassium Titanate Potassium titanate fiber 12 8 5

[0069] 5 Zirconia Zirconia 15.8 11 5

[0070] 6 Copper Copper or copper fiber 15.2 8 16

[0071] 7 Sodium carbonate light 0.8 0.8 0.8

[0072] 8 Barium Sulfate 21 28 16

[0073] 9 Reinforcing fibers 5 0 9

[0074] 10 Wear resistant material 11 12 16.2

[0075] 11 Functional filler 9.5 14.2 10.5

[0076] 12 Toughening filler 3.5 5 2.6

[0077] 13 Balance margin 0.2 0.5 0.4

[0078] ∑ 100 100 100

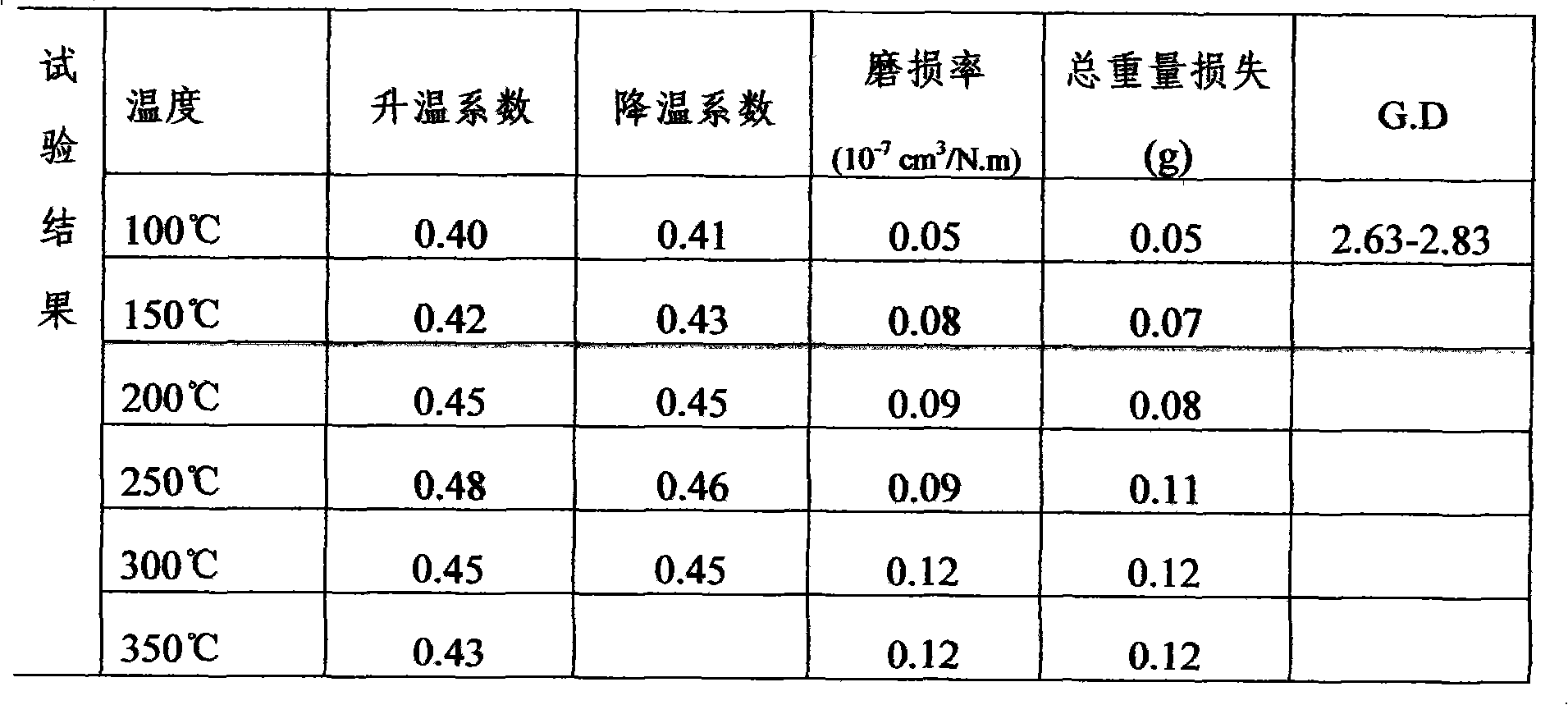

[0079] According to the national standard GB5763-98 test results:

example 1

[0081]

[0082]

[0083] Example 2:

[0084]

example 3

[0086]

[0087] It can be seen from the above table that the wear of the material does not increase much at the high temperature stage of 300-350°C, but the wear of the friction material usually increases sharply at the high temperature stage of 300-350°C.

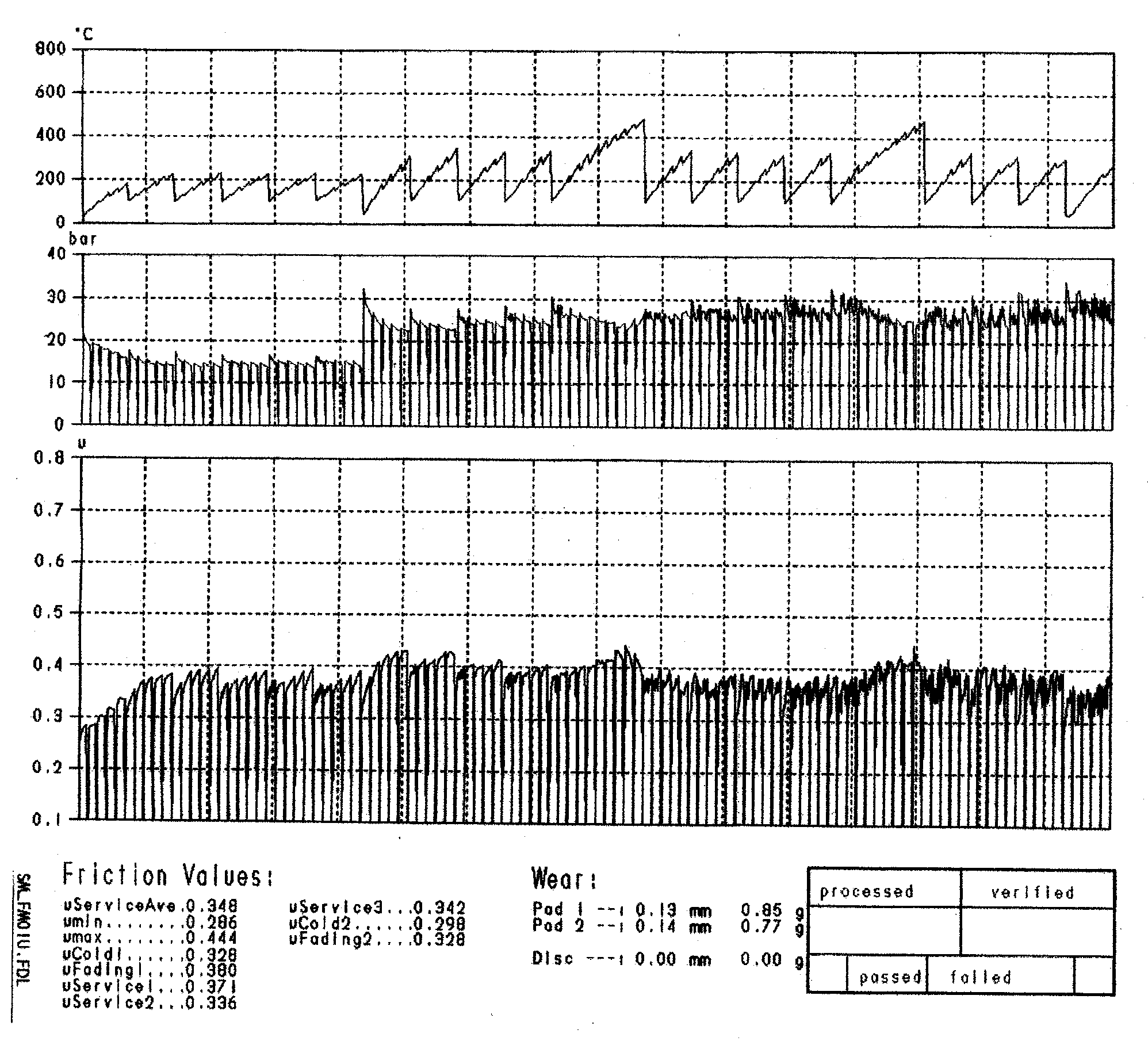

[0088] Example KRAUSS test report of Example 2: see the attached manual for details figure 1

[0089] From attached figure 1 It can be seen that the friction coefficient of the material rises above 400°C, and the outstanding heat resistance and stability performance is consistent, the fluctuation is extremely small, and the recovery performance is excellent; while the friction coefficient of friction materials generally decreases at 350°C.

[0090] The feature of the present invention is that the ceramic-based / NAO friction material has a stable dual friction coefficient of the friction pair, excellent heat resistance and stability, good braking inertia, high compression ratio, and extremely low wear (can be used for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com