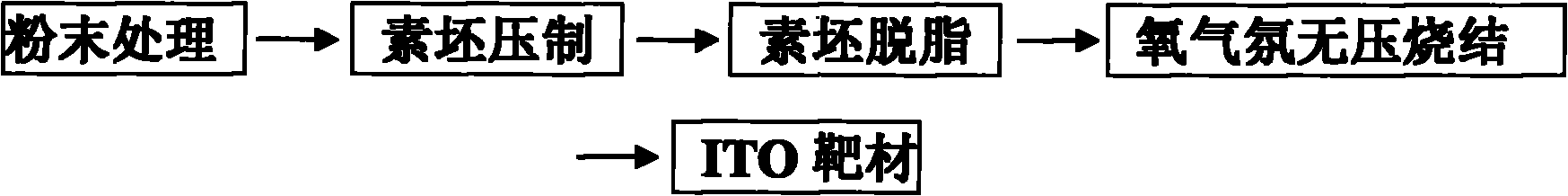

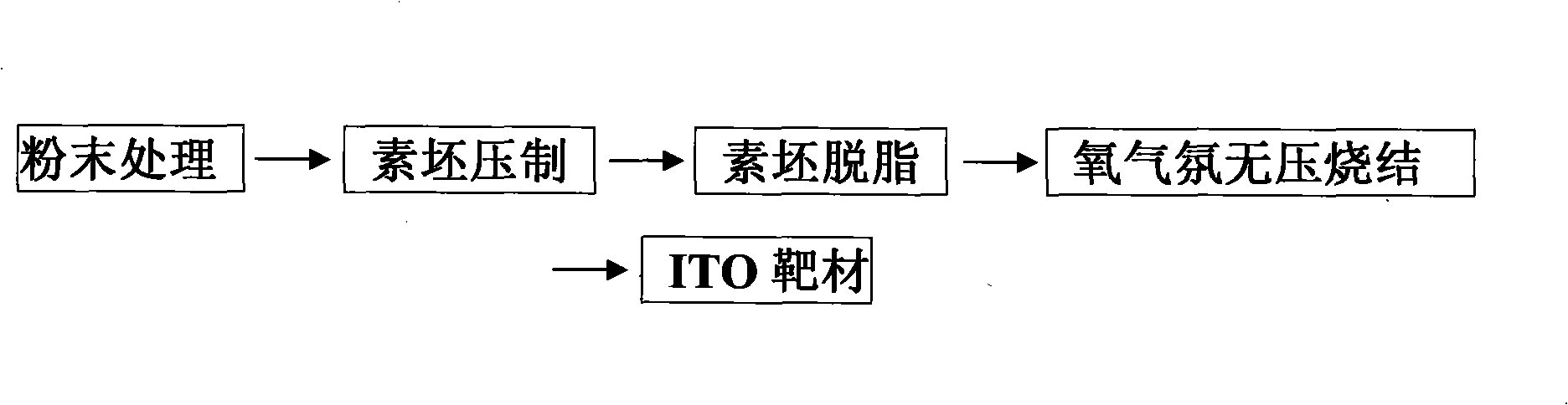

Method of preparing ITO target material by oxygen atmosphere pressureless sintering process

A sintering method and oxygen atmosphere technology, applied in the field of ITO target preparation, can solve the problems of difficult process control, extremely high requirements for sintering equipment, danger, etc., and achieve the effects of low cost, good electrical conductivity and safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] After degreasing the pressed green body, put it into the sintering furnace for sintering. Raise the furnace temperature to 1600°C at 400°C / hr, keep it warm for 60 hours, and the oxygen flow rate is 20L / min. The density of the sample obtained by sintering is 6.03g / cm 3 , the density is 84.2%.

Embodiment 2

[0039] After degreasing the pressed green body, put it into the sintering furnace for sintering. Raise the furnace temperature to 1000°C at 400°C / hr, keep it warm for 10 hours, and the oxygen flow rate is 8L / min; ℃ / hr Raise the furnace temperature to 1600 ℃, keep it warm for 60 hours, the oxygen flow rate is 20L / min, and the density of the sample obtained by sintering is 6.75g / cm 3 , the density is 94.3%.

Embodiment 3

[0041]After degreasing the pressed green body, put it into the sintering furnace for sintering. Raise the furnace temperature to 1000°C at 400°C / hr, keep it warm for 10 hours, and the oxygen flow rate is 8L / min; ℃ / hr Raise the furnace temperature to 1600℃, keep it warm for 60 hours, the oxygen flow rate is 20L / min, and the density of the sample obtained by sintering is 7.01g / cm 3 , the density is 97.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com