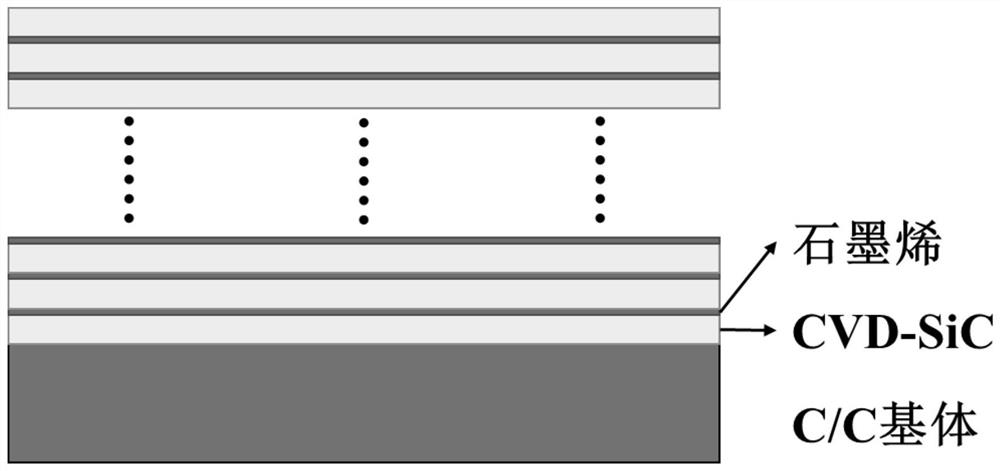

Silicon carbide/graphene bionic laminated coating and preparation method thereof

A silicon carbide layer and graphene layer technology, applied in the field of silicon carbide/graphene bionic laminated coating and preparation, can solve the problems of unfavorable coating oxidation resistance, accelerated coating failure process, insufficient dense coating, etc. Excellent anti-oxidation performance, increased fracture work, uniform and dense coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) The density is 1.7g / cm 3 The two-dimensional C / C composite material is used as the matrix, and a sample with a size of 10mm×10mm×10mm is cut from the C / C composite material, polished with 400 mesh SiC sandpaper, then ultrasonically cleaned with ethanol, and placed in a temperature of 70 Dry in an oven at ℃ for 4 h.

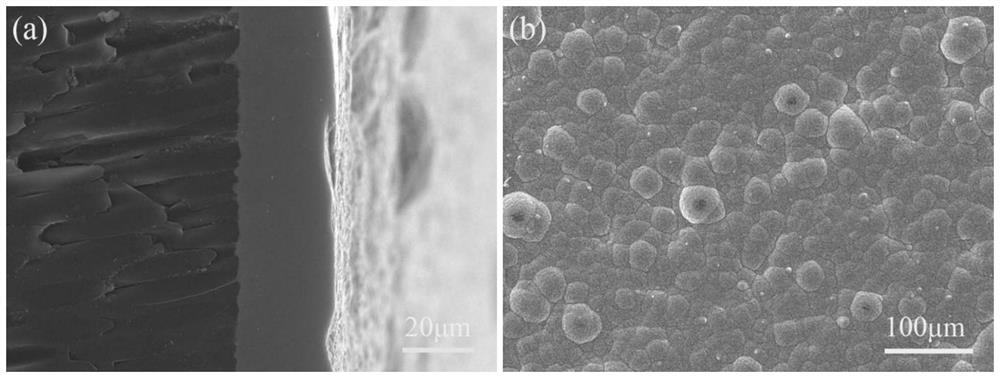

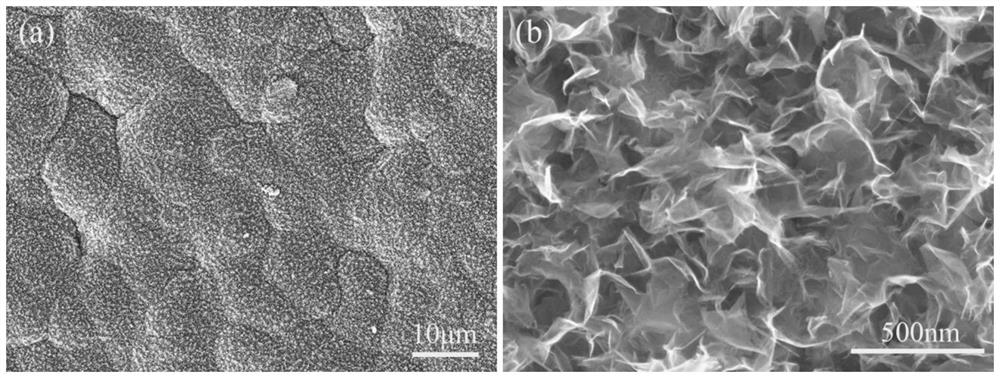

[0029] 2) Hang the C / C substrate in the deposition area of the vertical resistance furnace, vacuumize to -0.095Mpa, pass Ar as the protective gas, and raise the furnace temperature to 1000°C at a heating rate of 5°C / min. When the temperature reaches the deposition temperature, dilute Ar and react H 2 , and then open the carrier gas H 2 Methyltrichlorosilane (MTS) is brought into the reaction zone for deposition, and the gas flow control range during this process is: dilute Ar: 300 sccm, react H 2 : 2L / min, carrier gas H 2 : 30sccm; the deposition time is 2h, after the deposition is completed, stop feeding the reaction gas, turn off the heating powe...

Embodiment 2

[0033] 1) The density is 1.7g / cm 3 The two-dimensional C / C composite material is used as the matrix, and a sample with a size of 10mm×10mm×10mm is cut from the C / C composite material, polished with 400 mesh SiC sandpaper, then ultrasonically cleaned with ethanol, and placed in a temperature of 70 Dry in an oven at ℃ for 4 h.

[0034] 2) Hang the C / C substrate in the deposition area of the vertical resistance furnace, evacuate to -0.095Mpa, pass Ar as the protective gas, and raise the furnace temperature to 1100°C at a heating rate of 5°C / min. When the temperature reaches the deposition temperature, dilute Ar and react H 2 , and then open the carrier gas H 2 Methyltrichlorosilane (MTS) is brought into the reaction zone for deposition, and the gas flow control range during this process is: dilute Ar: 300 sccm, react H 2 : 0.5L / min, carrier gas H 2 : 10sccm; the deposition time is 4h, after the deposition, stop feeding the reaction gas, turn off the heating power supply to ...

Embodiment 3

[0038] 1) The density is 1.7g / cm 3 The two-dimensional C / C composite material is used as the matrix, and a sample with a size of 10mm×10mm×10mm is cut from the C / C composite material, polished with 400 mesh SiC sandpaper, then ultrasonically cleaned with ethanol, and placed in a temperature of 70 Dry in an oven at ℃ for 4 h.

[0039] 2) Hang the C / C substrate in the deposition area of the vertical resistance furnace, evacuate to -0.095Mpa, pass Ar as the protective gas, and raise the furnace temperature to 1200°C at a heating rate of 5°C / min. When the temperature reaches the deposition temperature, dilute Ar and react H 2 , and then open the carrier gas H 2 Methyltrichlorosilane (MTS) is brought into the reaction zone for deposition, and the gas flow control range during this process is: dilute Ar: 600 sccm, react H 2 : 1.5L / min, carrier gas H 2 : 20sccm; deposition time is 2h. After the deposition, stop feeding the reaction gas, turn off the heating power supply to coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com