Si3N4-based ceramic cutter material with added graphene and preparation method of material

A technology of ceramic cutting tools and graphene, which is applied in the field of Si3N4-based ceramic cutting tool materials with graphene added and its preparation, can solve the problems of easy generation of pores and defects, weak matrix bonding, and comprehensive performance to be improved, and achieves good comprehensive mechanics. Performance, morphology integrity, the effect of improving comprehensive mechanical properties and lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

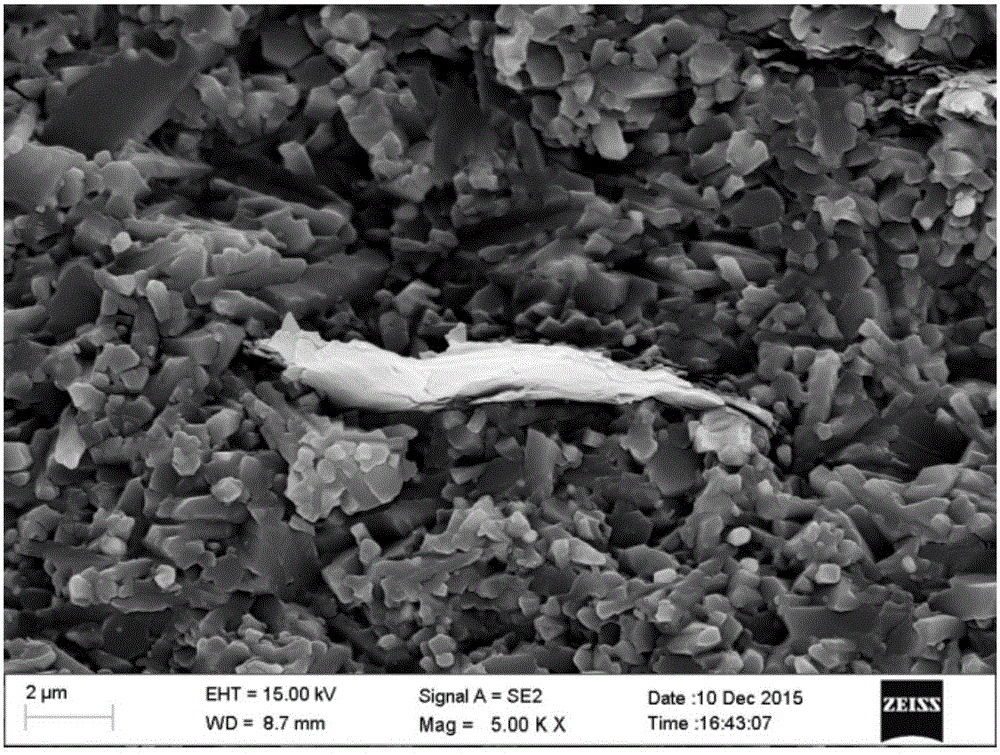

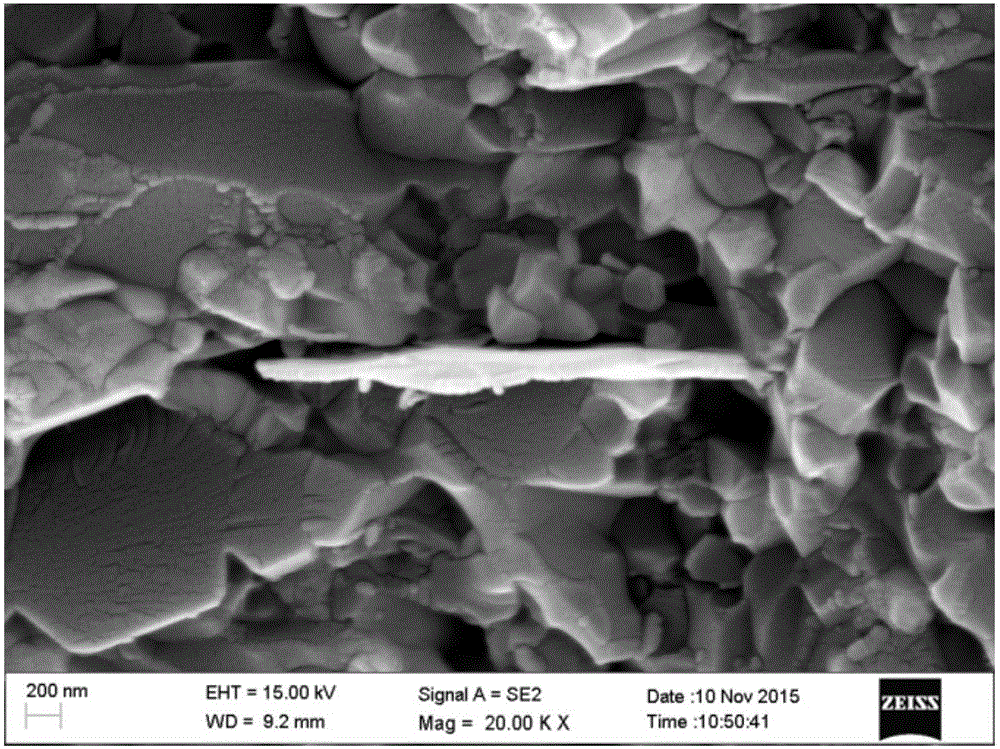

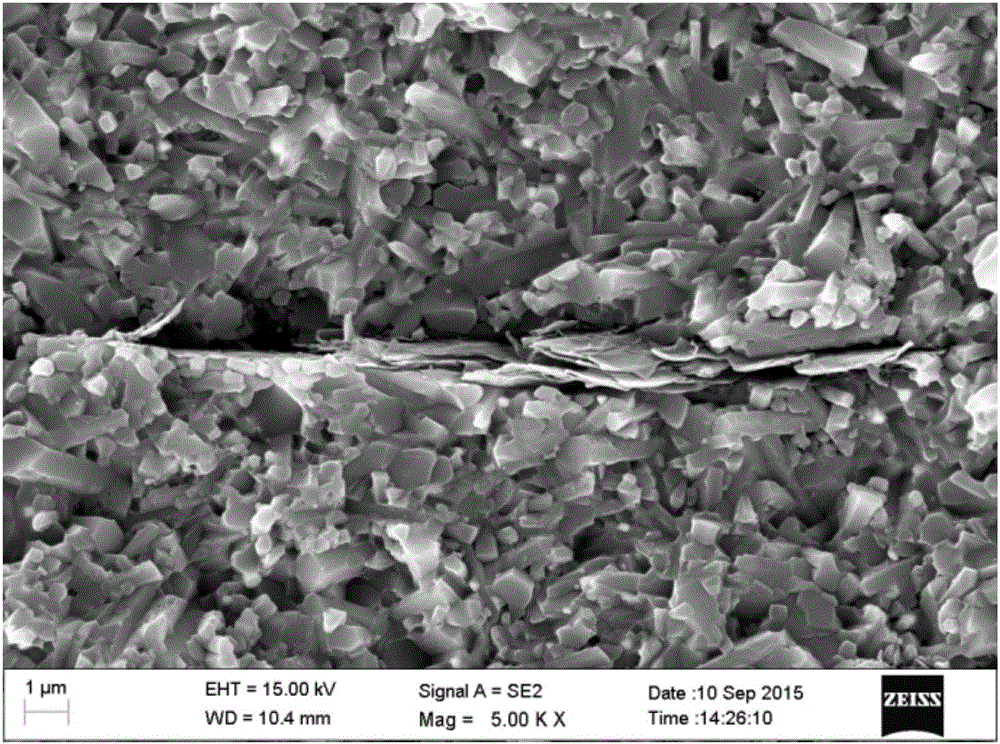

Image

Examples

Embodiment 1

[0056] Si 3 N 4 / Graphene composite ceramic tool material, the mass percentage of raw material composition is: graphene is 0.5%, A1 2 o 3 2%, Y 2 o 3 is 4%, MgO is 2%, and the rest is Si 3 N 4 .

[0057] The preparation steps are as follows:

[0058] According to Si 3 N 4 Weigh 0.5% of the mass of polyvinylpyrrolidone (PVP, K30) into 70mL isopropanol, ultrasonically disperse and mechanically stir for 10min, until it is completely dissolved; weigh Si 3 N 4 and added to the solution, ultrasonically dispersed and mechanically stirred for 30min to obtain Si 3 N 4 Dispersions.

[0059] According to A1 2 o 3 , Y 2 o 3 Weigh polyvinylpyrrolidone (PVP, K30) and add 0.5% of the total mass of MgO into 50mL isopropanol, ultrasonically disperse and mechanically stir for 10min, until it is completely dissolved; weigh A1 2 o 3 Add to the solution, ultrasonically disperse and mechanically stir for 10min, weigh Y 2 o 3 Add it into the solution, ultrasonically disperse and...

Embodiment 2

[0063] Si 3 N 4 / Graphene composite ceramic tool material, the mass percentage of raw material composition is: graphene is 1%, A1 2 o 3 2%, Y 2 o 3 is 4%, MgO is 2%, and the rest is Si 3 N 4 .

[0064] The preparation steps are as follows:

[0065] According to Si 3 N 4 Weigh 1% of the mass of polyvinylpyrrolidone (PVP, K30) into 70mL of isopropanol, ultrasonically disperse and mechanically stir for 20min, until it is completely dissolved; weigh Si 3 N 4 and added to the solution, ultrasonically dispersed and mechanically stirred for 20min to obtain Si 3 N 4 Dispersions.

[0066] According to A12 o 3 , Y 2 o 3 Add 1% of the total mass of MgO to polyvinylpyrrolidone (PVP, K30) and add it to 50mL of isopropanol, ultrasonically disperse and mechanically stir for 20min, until it is completely dissolved; weigh A1 2 o 3 Add to the solution, ultrasonically disperse and mechanically stir for 20min, weigh Y 2 o 3 Add it into the solution, ultrasonically disperse and...

Embodiment 3

[0070] Si 3 N 4 / Graphene composite ceramic tool material, the mass ratio of raw material composition is: graphene is 2%, A1 2 o 3 2%, Y 2 o 3 is 4%, MgO is 2%, and the rest is Si 3 N 4 .

[0071] The preparation method steps are as follows:

[0072] According to Si 3 N 4 Weigh 2% of the mass of polyvinylpyrrolidone (PVP, K30) into 70mL of isopropanol, ultrasonically disperse and mechanically stir for 30min, until it is completely dissolved; weigh Si 3 N 4 and added to the solution, ultrasonically dispersed and mechanically stirred for 10 min to obtain Si 3 N 4 Dispersions.

[0073] According to A1 2 o 3 , Y 2 o 3 Weigh polyvinylpyrrolidone (PVP, K30) and add 2% of the total mass of MgO into 50mL isopropanol, ultrasonically disperse and mechanically stir for 30min, until it is completely dissolved; weigh A1 2 o 3 Add to the solution, ultrasonically disperse and mechanically stir for 10min, weigh Y 2 o 3 Add it into the solution, ultrasonically disperse and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com