Preparation method of zirconium boride-silicon carbide/graphite layered superhigh temperature ceramic

A technology of ultra-high temperature ceramics and zirconium boride, which is applied in chemical instruments and methods, ceramic layered products, layered products, etc., can solve the problems of poor toughness of zirconium boride ultra-high temperature ceramics, and is beneficial to wire cutting processing, Strong machinability, increase the effect of expansion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

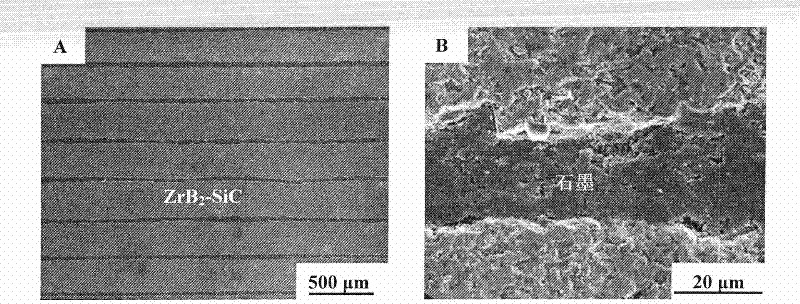

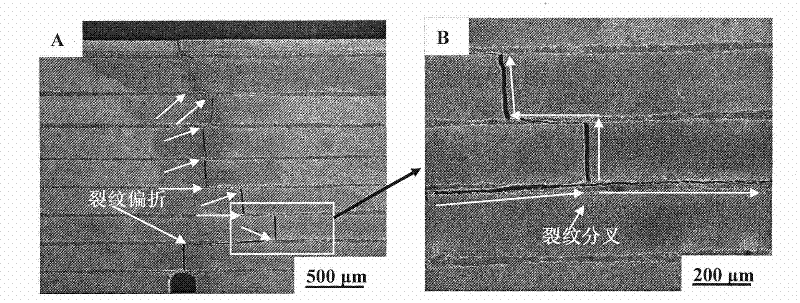

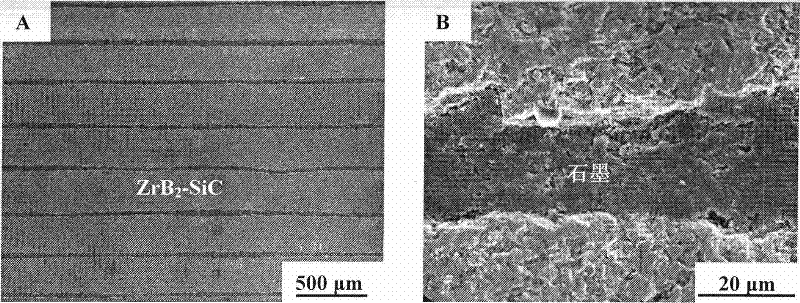

[0025] 1. Preparation of zirconium boride casting sheet and graphite casting sheet: (1) preparation of zirconium boride casting material, first weigh 2.61 grams of polyvinyl butyral, 2.61 grams of polyethylene glycol, 52.23 grams of ethanol, Stir evenly, then add 42.63 grams of 1 μm zirconium boride powder and 9.60 grams of 0.5 μm silicon carbide powder, stir evenly to form a zirconium boride casting material, wherein the zirconium boride powder and silicon carbide powder are according to 70%: 30% (2) Preparation of graphite cast material, first weigh 3.06 grams of polyvinyl butyral, 3.06 grams of polyethylene glycol, 152.9 ethanol, stir evenly, then add 18.40 grams of graphite powder and 12.18 grams of Zirconium boride powder, stir evenly, form graphite casting material, wherein graphite powder and zirconium boride powder are to take by volume percentage according to 80%: 20%; Casting with graphite casting material, drying at room temperature and demoulding to obtain 1000 μm ...

Embodiment 2

[0030] 1. Preparation of zirconium boride casting sheet and graphite casting sheet: (1) preparation of zirconium boride casting material, first weighing 5.51 grams of polyvinyl butyral, 5.51 grams of polyethylene glycol, and 82.68 grams of ethanol, Stir evenly, then add 48.72 grams of 2 μm zirconium boride powder and 6.40 grams of 1 μm silicon carbide powder, stir evenly to form a zirconium boride casting material, wherein the zirconium boride powder and silicon carbide powder are according to 80%: 20% Volume percentage is weighed; (2) preparation of graphite cast material, first weigh 4.02 grams of polyvinyl butyral, 4.02 grams of polyethylene glycol, 187.53 grams of ethanol, stir well, then add 20.70 grams of graphite powder and 6.09 grams Zirconium boride powder is stirred evenly to form graphite cast material, wherein graphite powder and zirconium boride powder are weighed according to the volume percentage of 90%: 10%; (3) casting molding, respectively making zirconium bor...

Embodiment 3

[0035] 1. Preparation of zirconium boride casting sheet and graphite casting sheet: (1) preparation of zirconium boride casting material, first weigh 8.70 grams of polyvinyl butyral, 8.70 grams of polyvinyl alcohol, 116.02 grams of ethanol, stir Evenly, add 54.81 grams of zirconium boride powder of 5 μm and 3.20 grams of silicon carbide powder of 2 μm, stir evenly, and form zirconium boride cast material, wherein zirconium boride powder and silicon carbide powder are according to the volume of 90%: 10% Percent weighing; (2) preparation of graphite casting material, first weigh 4.6 grams of polyvinyl butyral, 4.6 grams of polyvinyl alcohol, 230 grams of ethanol, stir evenly, then add 23 grams of graphite powder, stir evenly, and form Graphite casting material; (3) casting molding, casting zirconium boride casting material and graphite casting material respectively, drying and demoulding at room temperature to obtain 200 μm thick zirconium boride casting sheet and 20 μm thick gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com