Method for preparing carbon fiber composite material interface layer

A composite material and carbon fiber technology, applied in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of carbon fiber performance impact and complexity, and achieve the effects of reducing impact, adjustable thickness, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, a surface layer is prepared on the surface of the carbon fiber material, as follows:

[0037] (1) Mix acidified carbon nanotubes, PFNH-200 phenolic resin, curing agent hexamethylenetetramine, and DMF, stir evenly, and then ultrasonicate in a water bath for 30 minutes, then crush and ultrasonicate at 600w for 90 minutes to obtain a sizing agent, in which the concentration of acidified carbon nanotubes The concentration of PFNH-200 phenolic resin is 5mg / ml, and the concentration of curing agent hexamethylenetetramine is 0.5mg / ml.

[0038] (2) Sizing the carbon fiber surface with the sizing agent in step (1), and the sizing time is 30s; then drying and curing the sized carbon fiber.

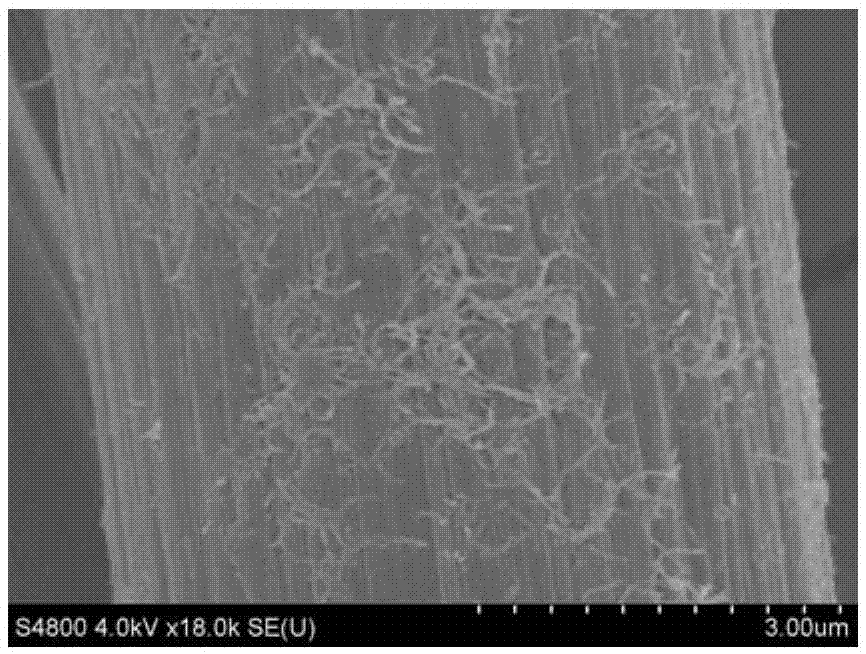

[0039] The scanning electron microscope picture of the carbon fiber after the above treatment is as follows figure 1 As shown, it can be seen that carbon nanotubes are evenly distributed on the surface of the carbon fiber matrix, and there are traces of resin on the surfa...

Embodiment 2

[0041] In this example, the carbon fiber material is exactly the same as that in Example 1, and the surface layer is prepared on the surface of the carbon fiber. The preparation method is basically the same as that of Example 1, except that ethanol is used instead of DMF as the solvent in the sizing agent.

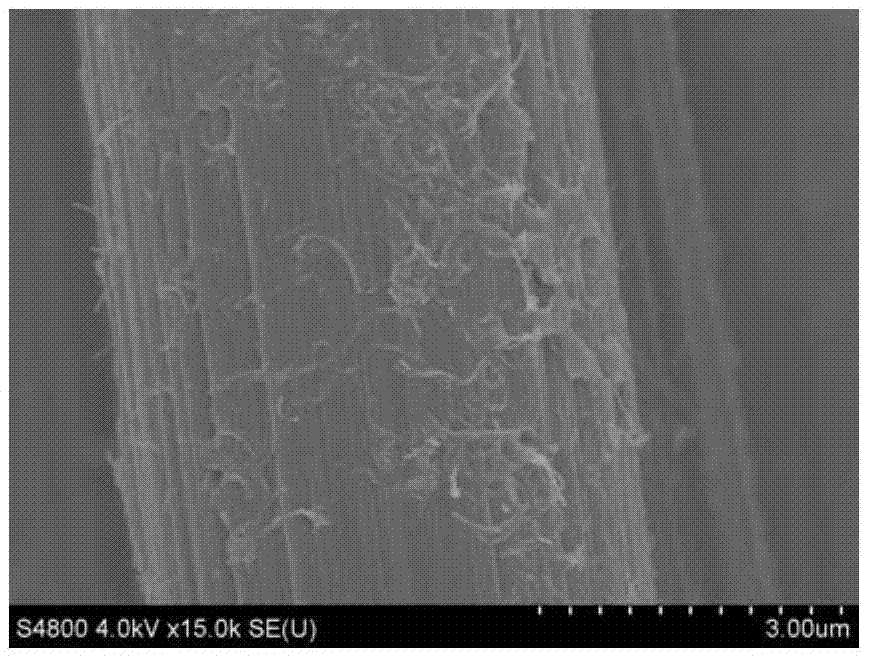

[0042] The scanning electron microscope image of the treated carbon fiber is as follows: figure 2 As shown, it can be seen that carbon nanotubes are evenly distributed on the surface of the carbon fiber matrix, and resin is obviously attached to the surface.

Embodiment 3

[0044] In this embodiment, the carbon fiber material is exactly the same as that in Example 1, and the surface layer is prepared on the surface of the carbon fiber. The preparation method is basically the same as in Example 1, except that the concentration of the phenolic resin in the sizing agent is 10mg / ml, The concentration of curing agent was 1 mg / ml.

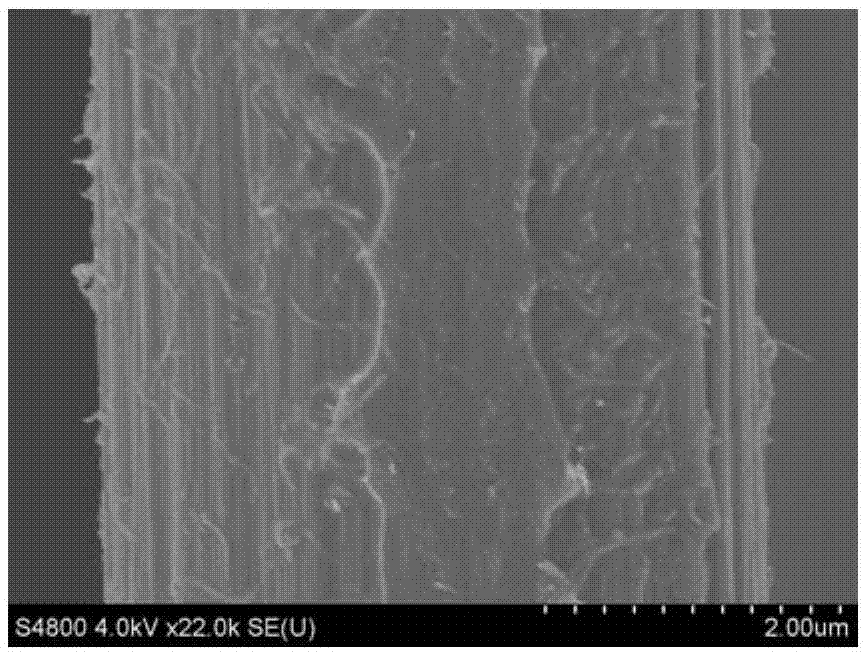

[0045] The scanning electron microscope image of the treated carbon fiber is as follows: image 3 As shown, it can be seen that carbon nanotubes are evenly adsorbed on the surface of carbon fibers, and a layer of resin is attached to the entire surface of carbon fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com