Method for improving interlayer mechanical property of two-dimensional fiber cloth reinforced ceramic-based composite material

A composite material layer and composite material technology, which is applied in the field of ceramic matrix composite material preparation, can solve the problems of material damage tolerance decrease, interlayer shear strength increase, and interlayer shear strength low, so as to improve the shear strength and toughness, the method is simple and effective, and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An Improved Quartz Fiber Cloth Reinforced SiO 2f -SiO 2 The method for the interlaminar mechanical properties of composite materials, the specific steps are as follows:

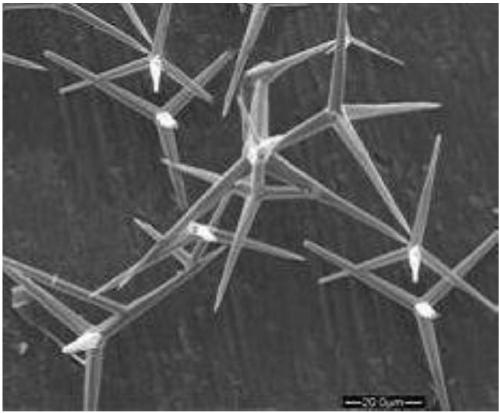

[0027] 1) Add 30wt% tetraacicular zinc oxide whiskers (for its shape, see figure 1 ), at 90°C, use a temperature-controlled magnetic stirrer with a rotation speed of 60 rpm for 30 minutes, and make the viscosity reach 25mpa·s for later use;

[0028] 2) Apply the mixture obtained in step 1) evenly on the quartz fiber cloth with a thickness of 300 μm; use the same method and standard to paint 15 layers of quartz fiber cloth, and stack the 15 layers of quartz fiber cloth in sequence ;

[0029] 3) The obtained laminated quartz fiber cloth is hot-pressed to form a prefabricated body, wherein the hot-pressing temperature is 120° C., the pressure is 80 MPa, and the holding time is 60 minutes;

[0030] 4) The preform obtained in step 3) is impregnated with silica sol in a vacuum environment, and dried at 9...

Embodiment 2

[0048] Use the same method to improve Nextel720-Al 2 o 3 Composite interlaminar mechanical properties; specific steps are as follows:

[0049] 1) Add 10wt% tetraacicular zinc oxide whiskers to the nano-alumina slurry, heat-treat it with a temperature-controlled magnetic stirrer with a rotation speed of 90 rpm at 80°C for 10 minutes, and make the viscosity reach 15mpa·s for later use ;

[0050] 2) Apply the mixture obtained in step 1) evenly on the Nextel720 fiber cloth with a thickness of 100 μm; use the same method and standard to paint 25 layers of Nextel720 fiber cloth, and stack the 25 layers of Nextel720 fiber cloth in turn ;

[0051] 3) The obtained laminated Nextel720 fiber cloth is hot-pressed to form a prefabricated body, wherein the hot-pressing temperature is 200°C, the pressure is 60MPa, and the holding time is 30min;

[0052] 4) The preform obtained in step 3) is impregnated with nano-alumina slurry in a vacuum environment, and dried at 90°C; then deesterified...

Embodiment 3

[0056] Use the same method to improve Nextel610-Al 2 o 3 Composite interlaminar mechanical properties; specific steps are as follows:

[0057] 1) Add 20wt% tetrapod-shaped zinc oxide whiskers to the nano-alumina slurry, heat-treat at 70°C using a temperature-controlled magnetic stirrer with a rotation speed of 75 rpm for 15 minutes, and make the viscosity reach 20mpa·s for later use ;

[0058] 2) Apply the mixture obtained in step 1) evenly on the Nextel610 fiber cloth with a thickness of 200 μm; use the same method and standard to paint 20 layers of Nextel610 fiber cloth, and stack the 20 layers of Nextel610 fiber cloth in turn ;

[0059] 3) The obtained laminated Nextel610 fiber cloth is hot-pressed to form a prefabricated body, wherein the hot-pressing temperature is 160°C, the pressure is 70MPa, and the holding time is 40min;

[0060] 4) The preform obtained in step 3) is impregnated with nano-alumina slurry in a vacuum environment, and dried at 85°C; then deesterified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com