Method for regulating and controlling overall performance of hypereutectic aluminum-silicon alloy casting

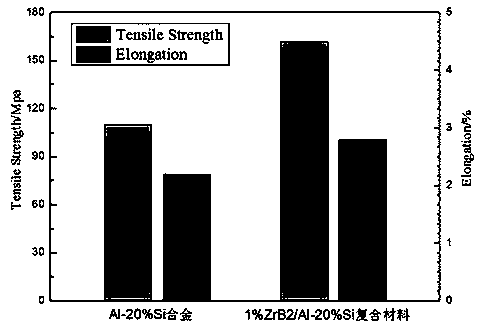

An aluminum-silicon alloy and hypereutectic technology, which is applied in the field of particle-reinforced aluminum-matrix composite material forming, can solve the problems of low strength and toughness, uneven distribution of microstructure, and achieve improved yield strength, improved performance and service life, increased The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

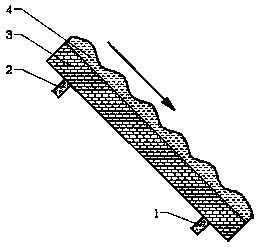

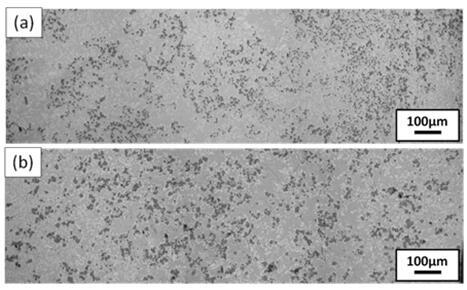

[0024] Embodiment 1: ZrB prepared in this embodiment 2 Reinforced hypereutectic Al-Si alloy composite with 1% in situ self-generated ZrB 2 Particles (500nm~3μm), the matrix is Al~20%Si, the liquidus temperature is 706°C, the specific steps are as follows;

[0025] 1. According to the molar ratio of 1:2, K with a purity of 99.9% 2 ZrF 6 And purity 99.9% for KBF 4 Mix well, and then dehydrate at 200°C;

[0026] 2. According to the mass ratio of 4:1, put industrially pure Al with a purity of 99.7% and metallurgical silicon with a purity of 98% in a resistance furnace to melt, and when the melt temperature reaches and remains at 850°C, put the fluorine The salt is sent into the molten pool by blowing powder from the bottom of the molten pool with an inert gas, the amount of fluorine salt added is 2% of the mass of the melt, and the particle-reinforced hypereutectic aluminum-silicon alloy composite material is prepared under vigorous mechanical stirring at 500r / min for 50min;...

Embodiment 2

[0030] Embodiment 2: the TiB that this embodiment makes 2 The composition of the reinforced hypereutectic aluminum-silicon alloy composite material is 6% in-situ self-generated TiB2 particles (80nm~1μm), the matrix is Al-17%Si-4Cu-0.4Mg alloy (A390 alloy), and the liquidus temperature is 700°C;

[0031] 1. According to the molar ratio of 1:2, K with a purity of 99.9% 2 TiF 6 And purity 99.9% for KBF 4 Mix well, and then dehydrate at 200°C;

[0032] 2. Melt the A390 alloy in a resistance furnace. When the melt temperature reaches and maintains at 850°C, the fluorine salt in step 1 is sent into the molten pool by blowing powder from the bottom of the molten pool through an inert gas. The amount of fluorine salt added It is 11% of the mass of the melt, and the particle reinforced hypereutectic aluminum-silicon alloy composite material is prepared under vigorous mechanical stirring at 500r / min for 50min;

[0033] 3. Add C to the composite material 2 Cl 6 Carry out slag and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com