Polyester composite double-insulating enamelled wire for transformer

A double insulation and transformer technology, applied in the direction of transformer/inductor coil/winding/connection, insulated cable, insulated conductor, etc., can solve the problems of reduced performance and service life, reduced insulation performance of enameled wire, damage to enameled wire of transformer coil, etc. Achieve the effects of improving insulation resistance and short circuit resistance, improving performance and service life, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

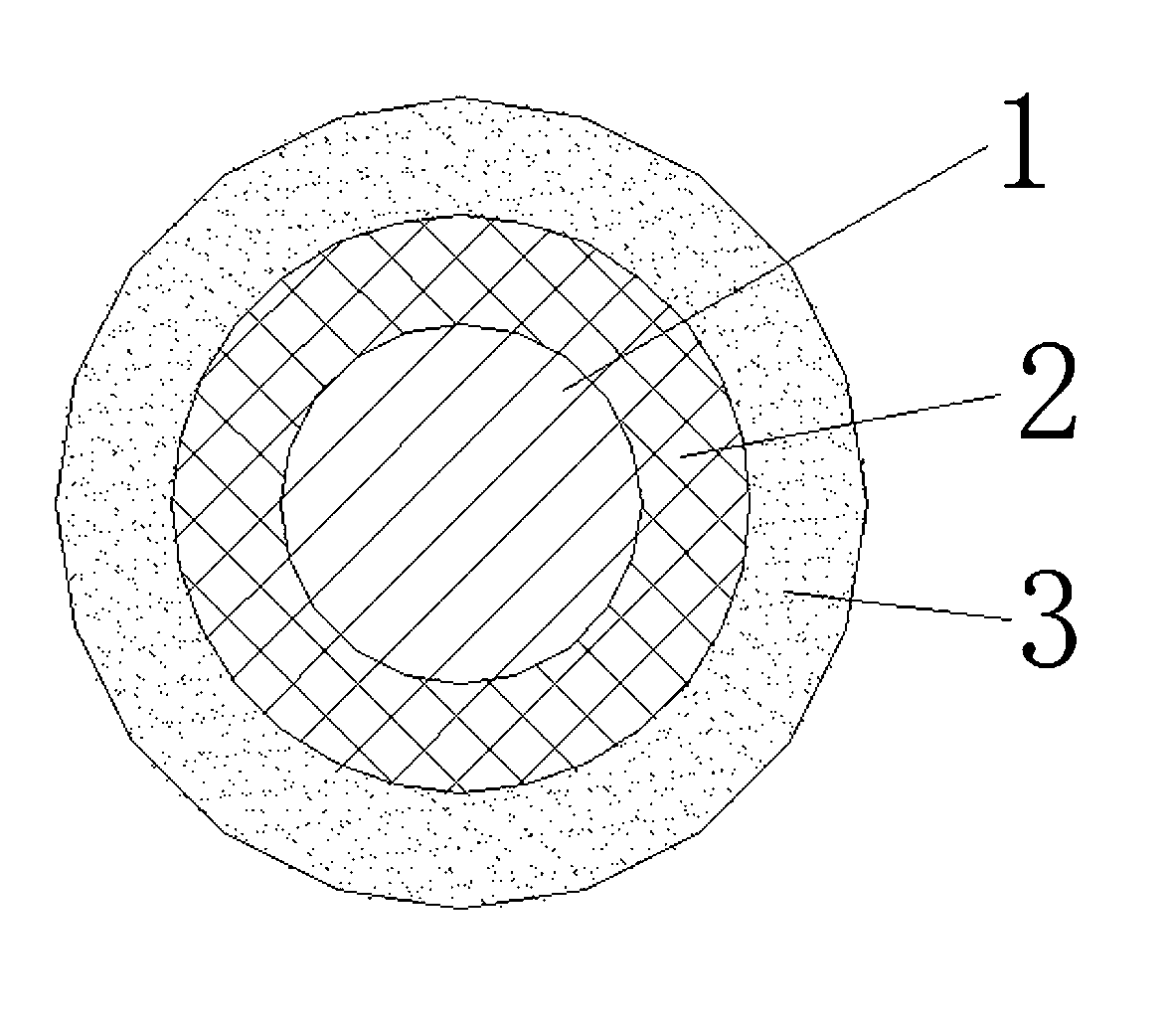

[0009] Such as figure 1 As shown, the polyester composite double-insulated enameled wire for a transformer includes a copper wire conductor 1, the outside of the copper wire conductor 1 is coated with a layer of insulating varnish 2, and the outside of the insulating varnish 2 is provided with a PET polyester film 3; wherein, The thickness of the PET polyester film 3 is 0.03-1mm. In this embodiment, the copper wire conductor coated with insulating varnish is covered by PET polyester film. Since PET polyester film has high temperature resistance, good voltage resistance and insulation performance, and is thinner, it can make the short circuit resistance of enameled wire Strong ability, effectively improve the service life of the product. The transformer made of polyester composite double-insulated enameled wire has effectively solved the technical problem of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com