Anti-deformation jointing die for board book

An anti-deformation and book jamming technology, applied in book binding, adhesives for bookbinding, printing, etc., can solve the problems that affect the aesthetics and durability of jammed books, have not been effectively solved, and the amount of glue is not easy to control. , to achieve the effect of improving service life and performance, good force range, increasing elasticity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

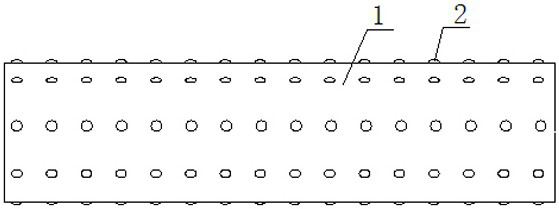

[0019] Attached below figure 1 A further detailed description of the anti-deformation bonding mold for the card book according to the present invention:

[0020] The anti-deformation bonding mold for card book of the present invention comprises a cylindrical metal carrier, and a layer of rubber 1 is covered on the outer surface of the cylindrical metal carrier. The rubber 1 serves as a gluing working surface, on which protrusions 2 with a circular outer contour are evenly distributed. In this example, the shape of the protrusion 2 is spherical, and the diameter of the circular outer contour of the protrusion 2 is 4 cm. The surface of the spherical protrusion 2 is relatively smooth, which can avoid frictional damage while applying glue, and improve the durability of the protrusion 2 . In order to ensure that the gluing process is carried out reliably, the height of the protrusion 2 is 5 mm. According to the requirement of the amount of glue applied and the moisture content r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com