Patents

Literature

30 results about "Yankee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term "Yankee" and its contracted form "Yank" have several interrelated meanings, all referring to people from the United States; its various senses depend on the context. Outside the United States, "Yank" is used informally to refer to any American, including Southerners. Within the Southern United States, "Yankee" is a derisive term which refers to all Northerners, or specifically to those from the region of New England. According to the Oxford English Dictionary, it is "a nickname for a native or inhabitant of New England, or, more widely, of the northern States generally"; during the American Civil War, it was "applied by the Confederates to the soldiers of the Federal army".

Method Of Controlling Adhesive Build-Up On A Yankee Dryer

ActiveUS20070204966A1Reducing steady-state tensionReduce tensionNon-fibrous pulp additionNatural cellulose pulp/paperAdhesiveEngineering

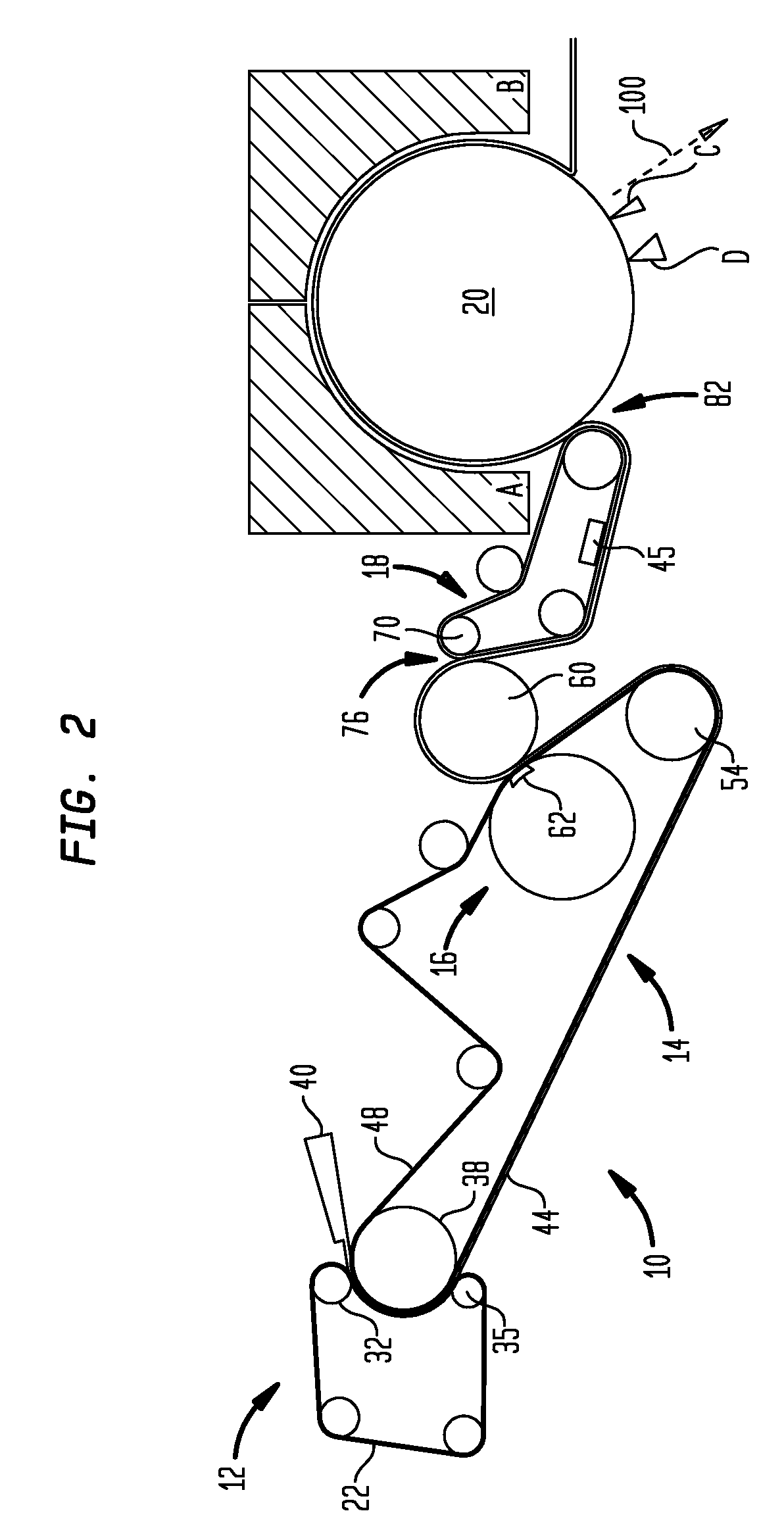

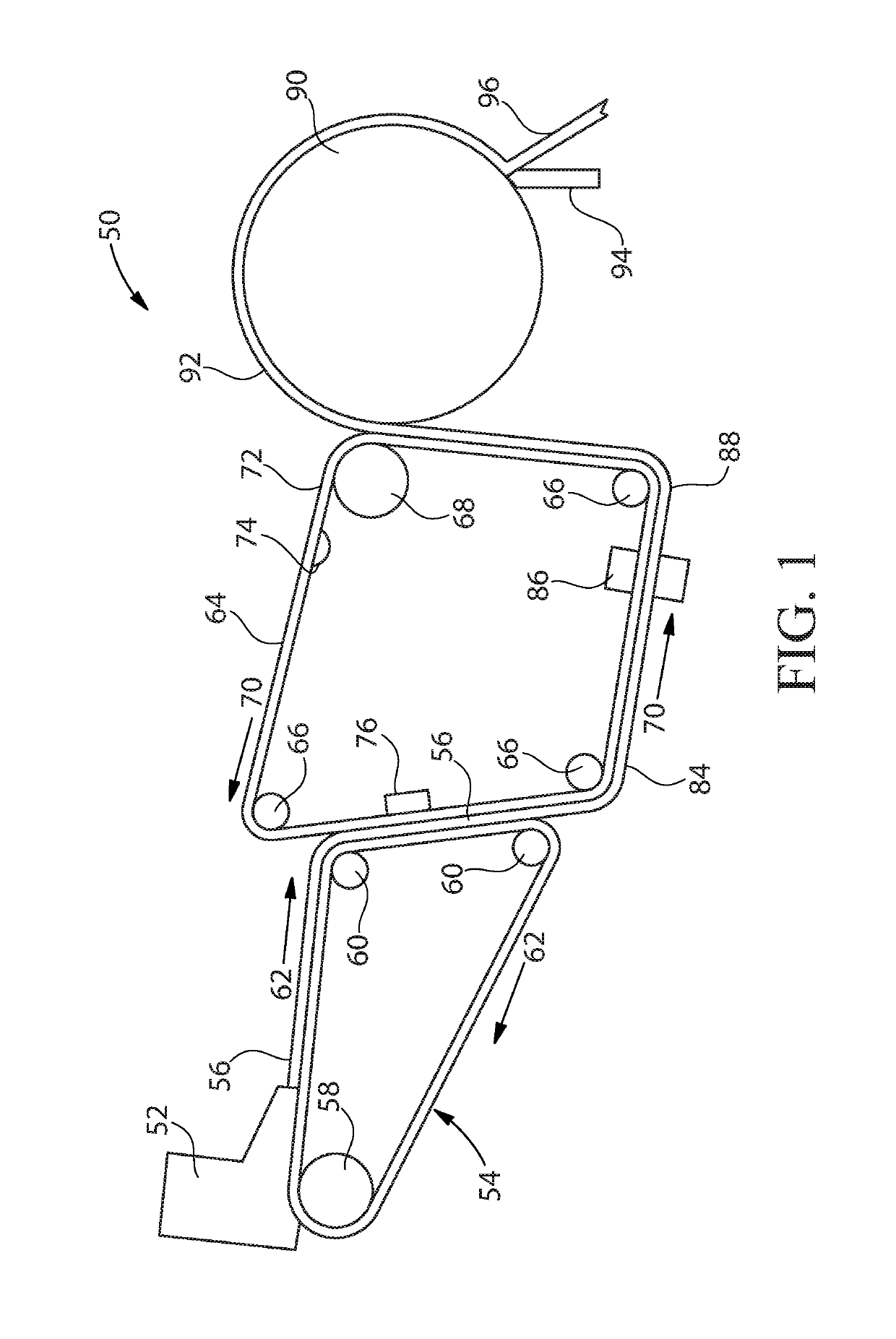

An improved method of controlling build-up of adhesive coating on a Yankee drying cylinder preferably includes intermittently: (a) increasing the add-on rate of resinous adhesive to the drying cylinder substantially above the steady-state add-on rate; (b) segregating the absorbent sheet product produced while the add-on rate of resinous adhesive to the drying cylinder is elevated above the steady-state add-on rate from absorbent sheet product accumulated during steady-state operation; and (c) while the add-on rate of resinous adhesive to the drying cylinder is increased above the steady-state add-on rate, stripping at least a portion of the adhesive coating from the drying cylinder with a cleaning doctor.

Owner:GPCP IP HLDG LLC

Method of controlling adhesive build-up on a yankee dryer

ActiveUS7850823B2Increase ratingsReduce the temperatureNon-fibrous pulp additionNatural cellulose pulp/paperAdhesiveEngineering

Owner:GPCP IP HLDG LLC

Modifying agent for yankee coatings

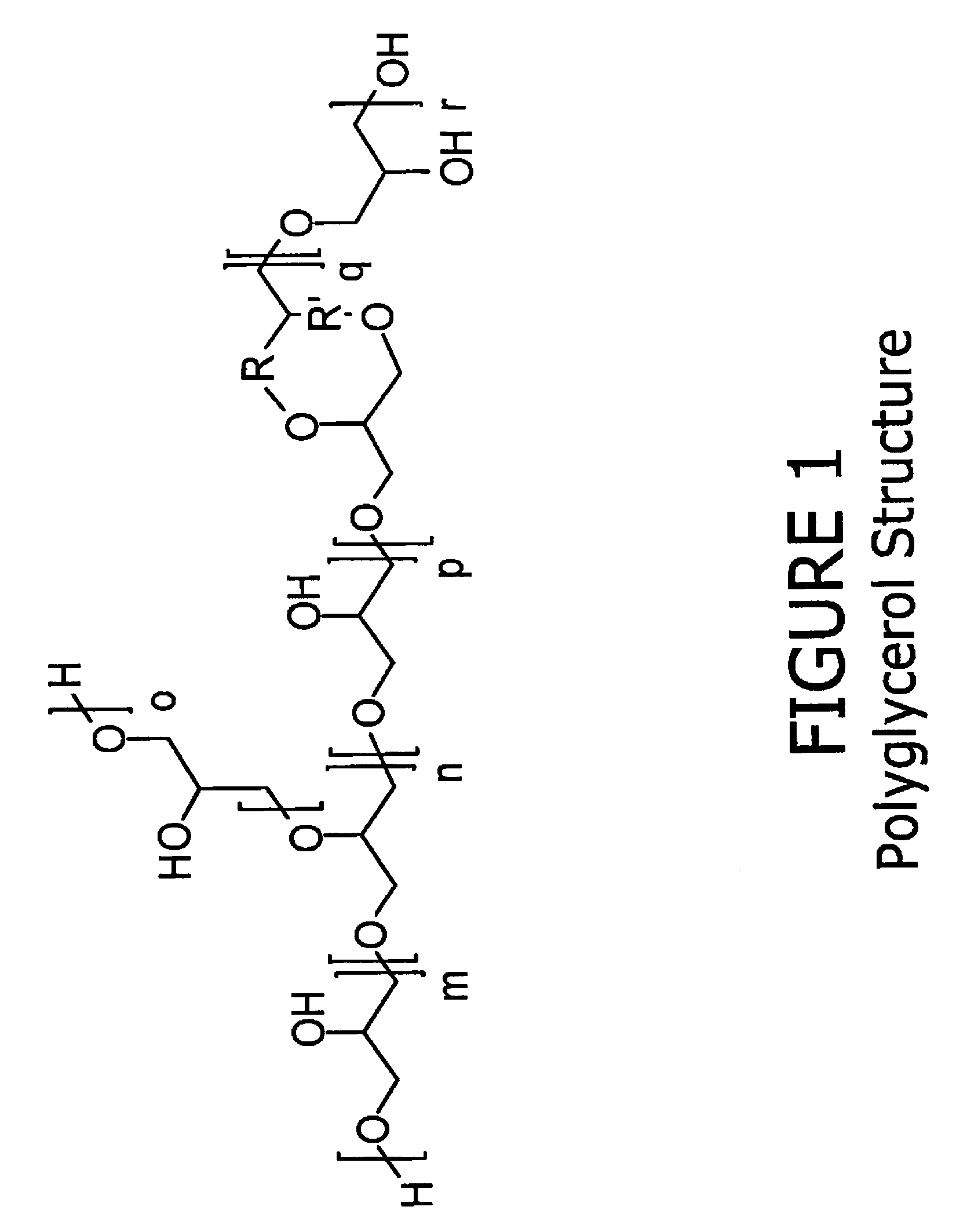

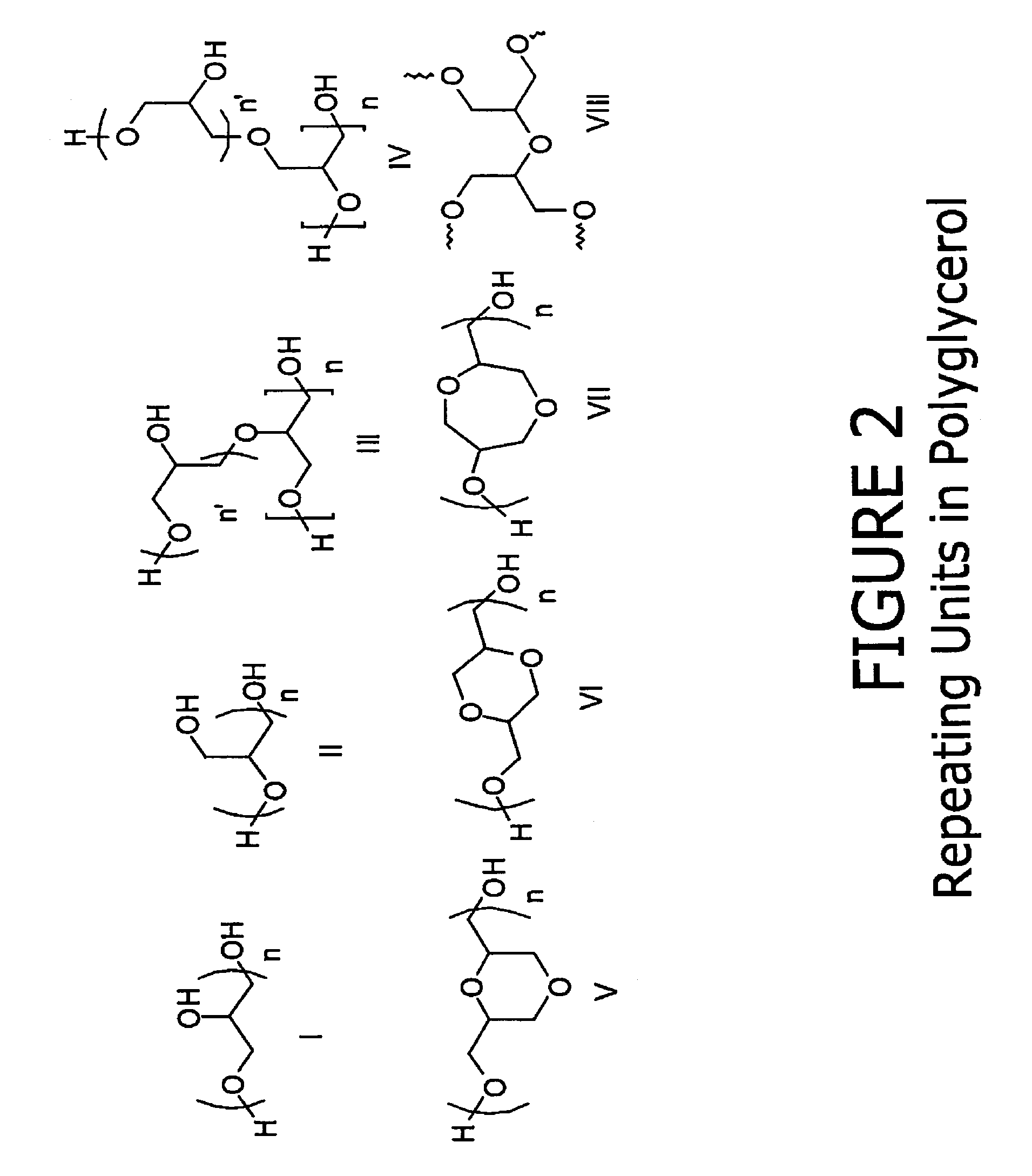

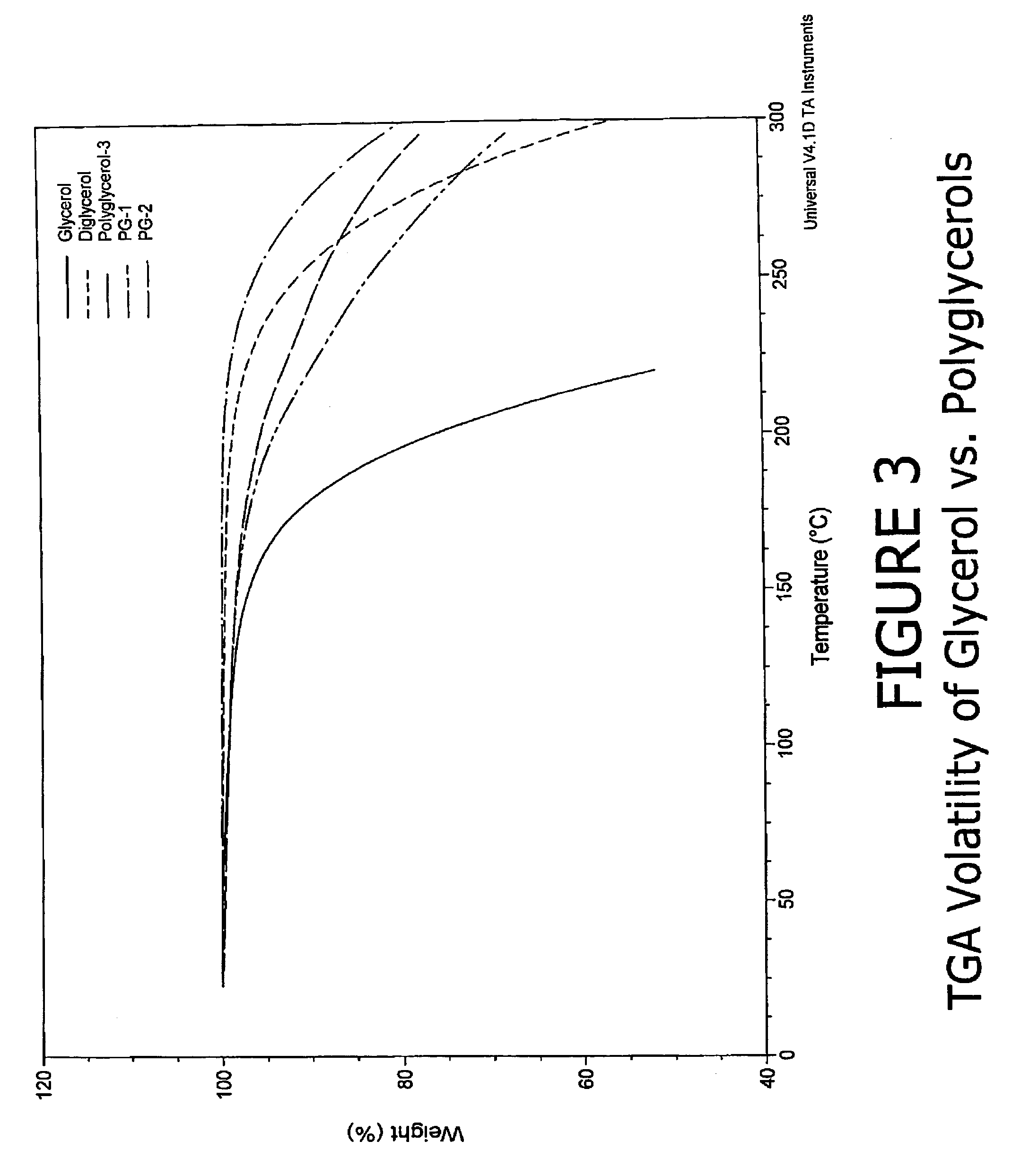

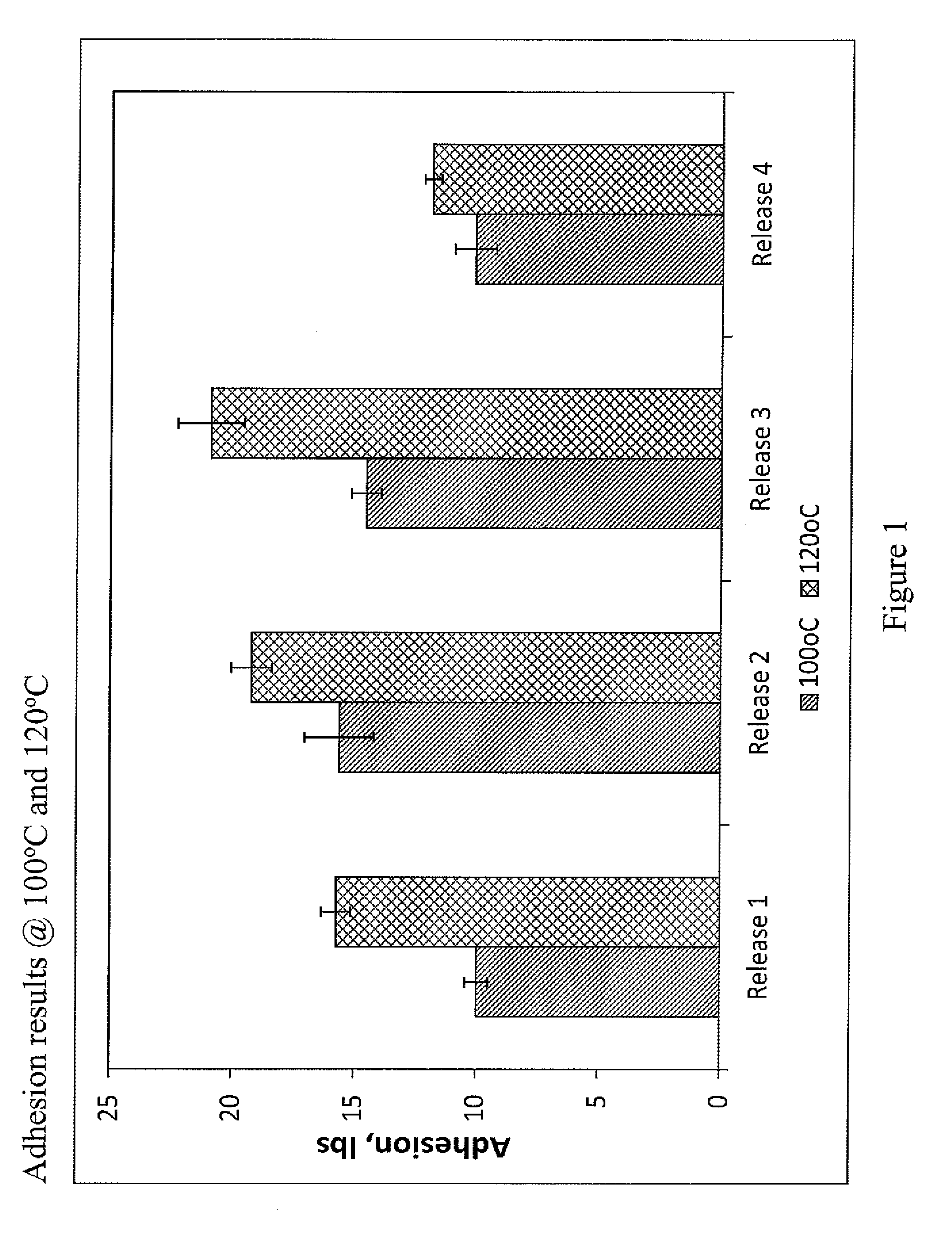

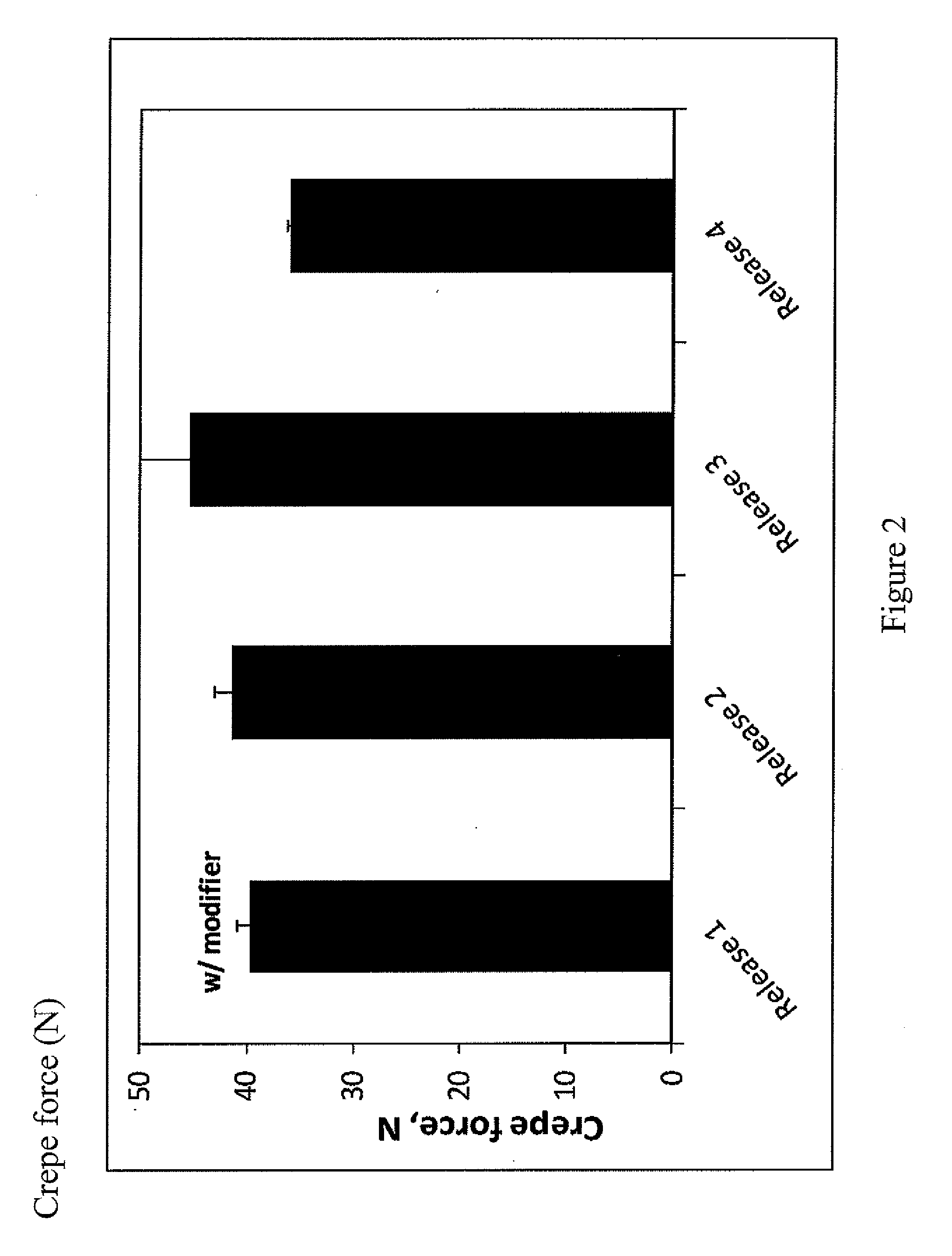

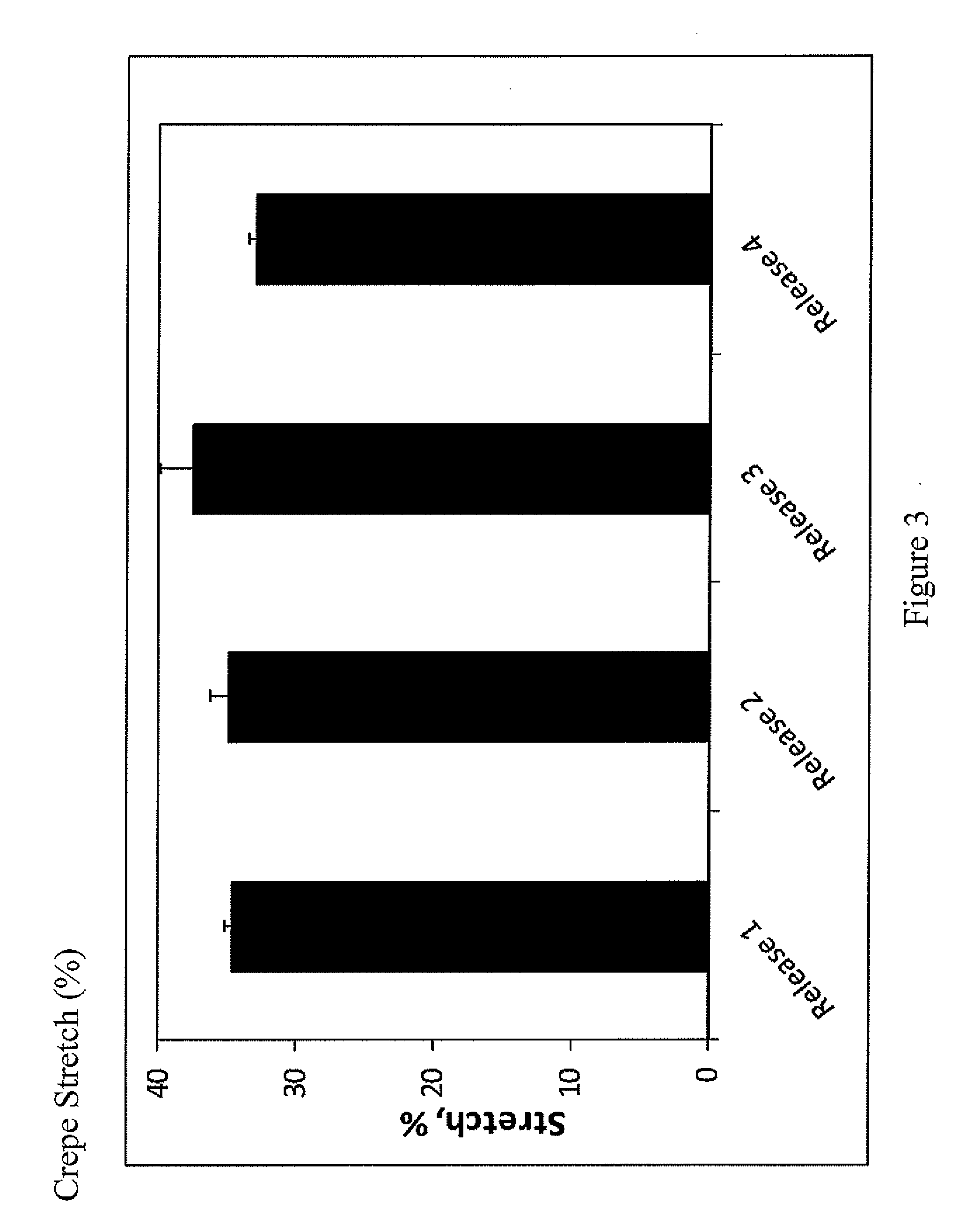

ActiveUS8101045B2Superior dry tack adhesionIncreased the dry tack adhesionNatural cellulose pulp/paperMechanical working/deformationPolyolGlycerol

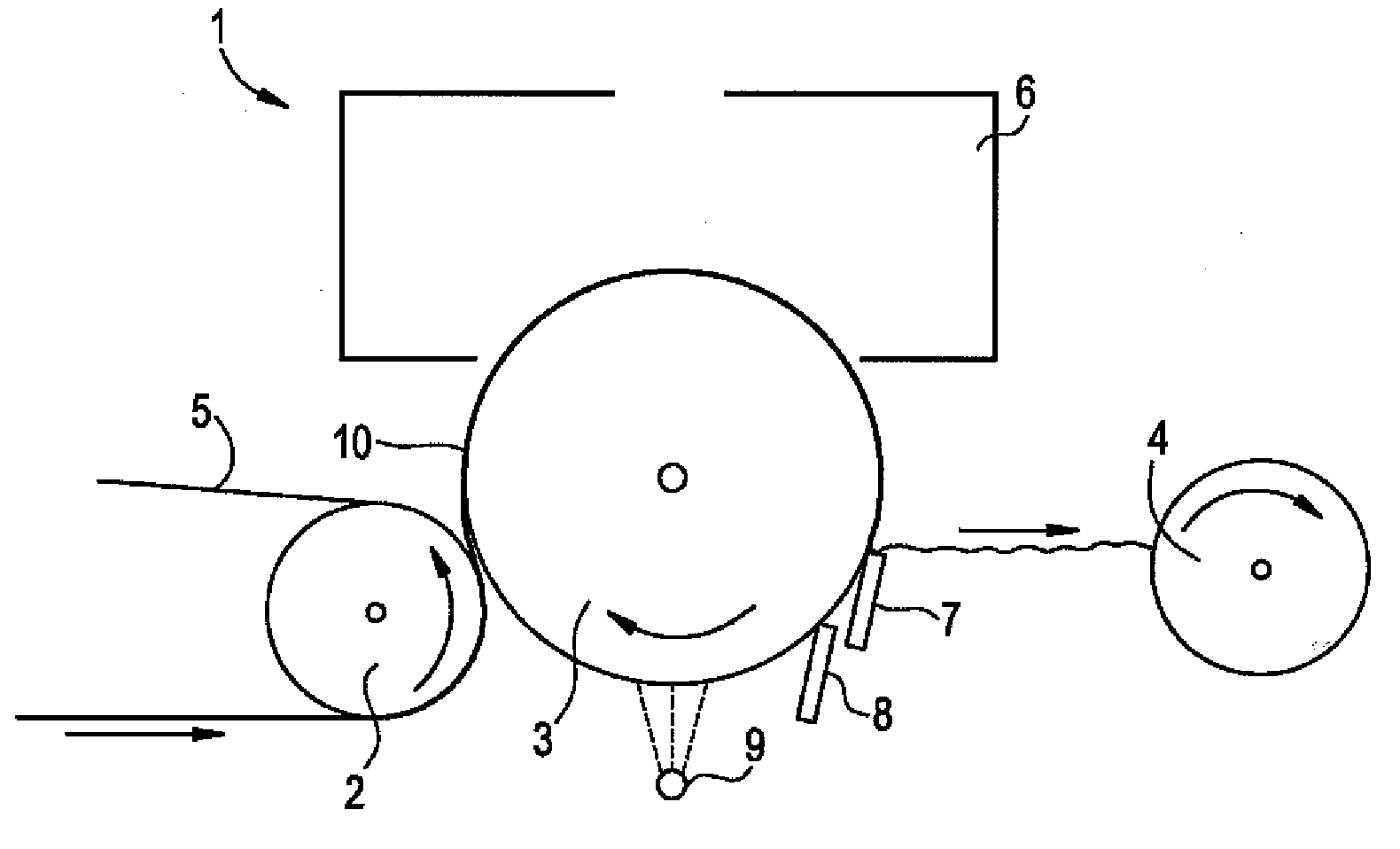

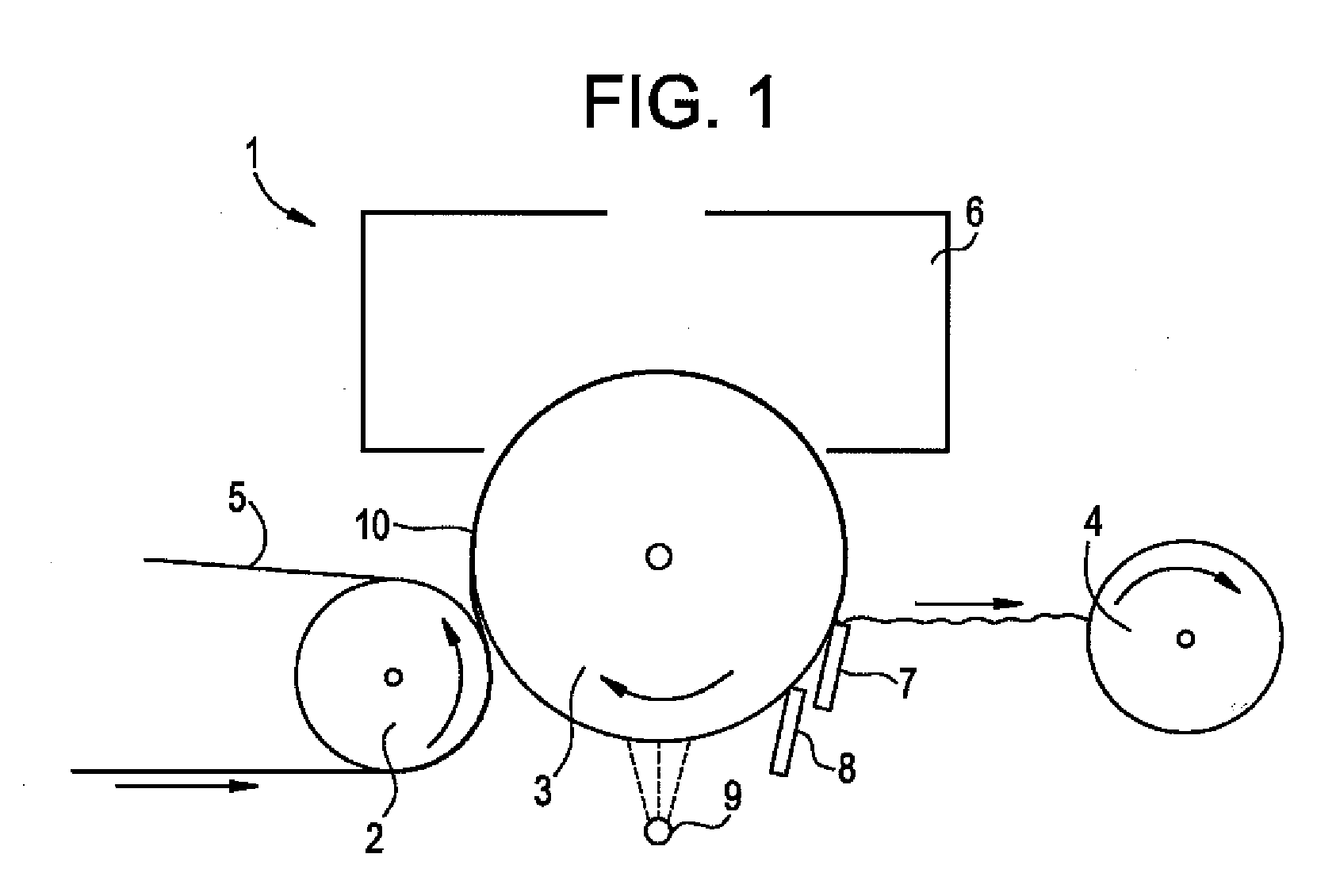

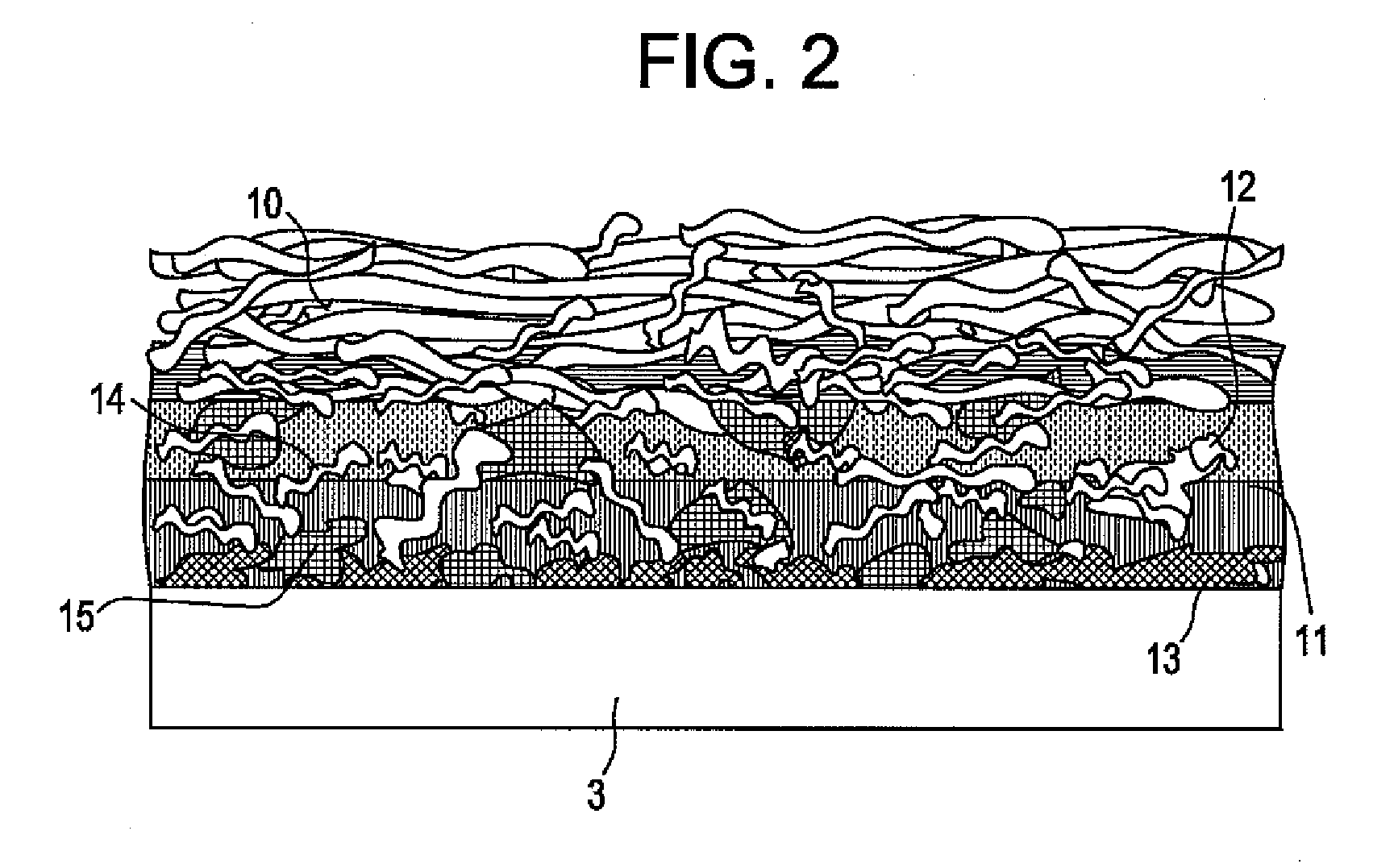

The invention provides a composition of matter useful for producing very soft high grades of tissue paper. The composition of matter comprises an adhesive composition that includes a glycerol-based polyol. The glycerol-based polyol prevents the composition from becoming brittle and is non-volatile. This allows the composition to become rewetted after creping and allows for strong levels of adhesion even at high temperatures.

Owner:NALCO CO

Creping adhesives with improved film properties

The invention provides a composition of matter used to produce very soft high grades of tissue paper. The composition of matter comprises a PAE resin acidified with a multifunctional acid. The multifunctional acid includes but is not limited to carboxyl and sulfonyl. The acid has a functional group selected from carboxyl and sulfonyl and a functional group selected from carboxyl, sulfonyl, hydroxyl, lactone, phenol, amine and heterocycle. The PAE resin facilitates the use of an adhesive in a Yankee Dryer apparatus that is durable when the adhesive is wet but remains soft when the adhesive becomes dry. These properties allow the adhesive to be strong and remain engaged to the dryer apparatus when wet but be easily removed by the creping blade when dry.

Owner:ECOLAB USA INC

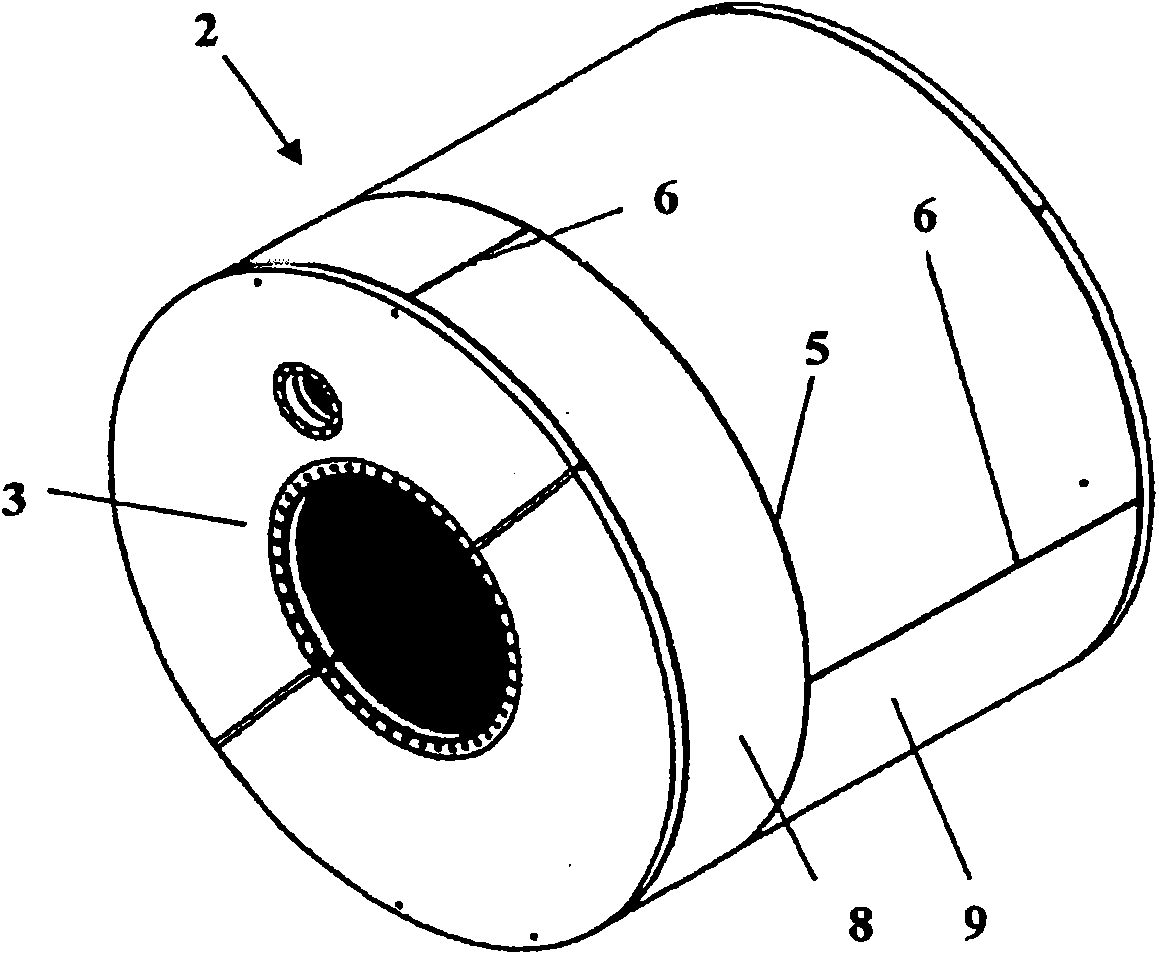

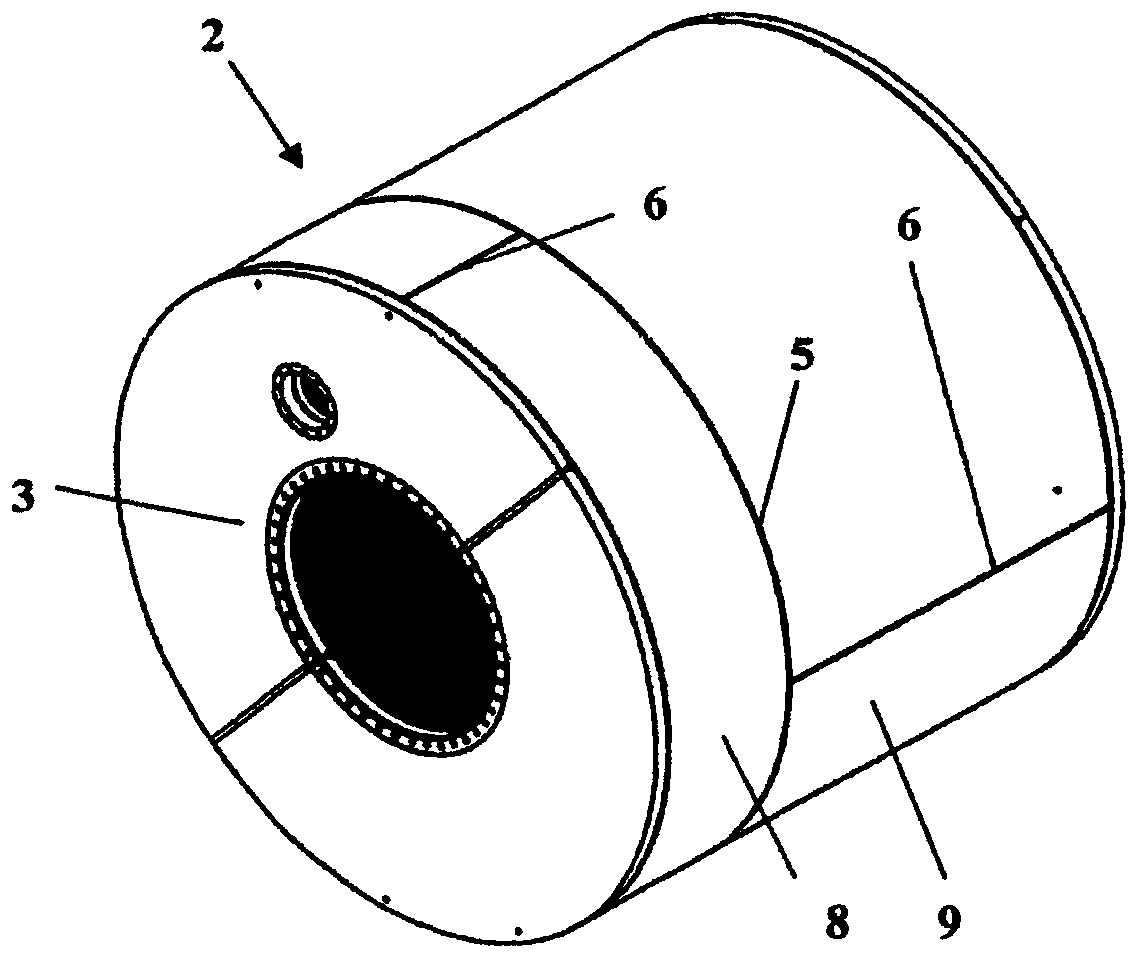

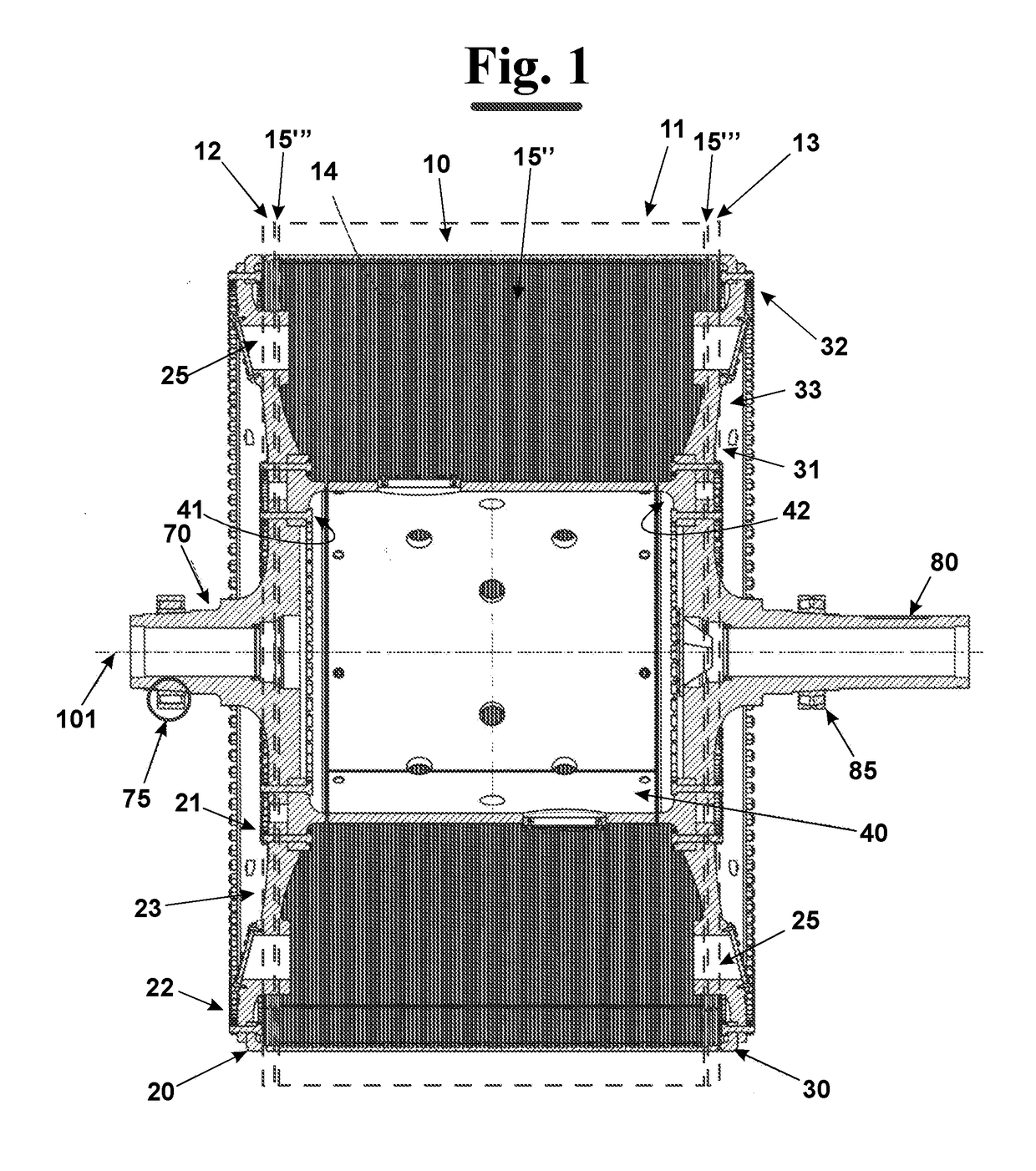

Yankee cylinder for paper producing machine

ActiveUS20100132903A1Simple and safe construction systemImprove integrityDryer sectionSynthetic resin layered productsEngineeringYankee

Owner:TOSCOTEC

Method for producing a yankee cylinder

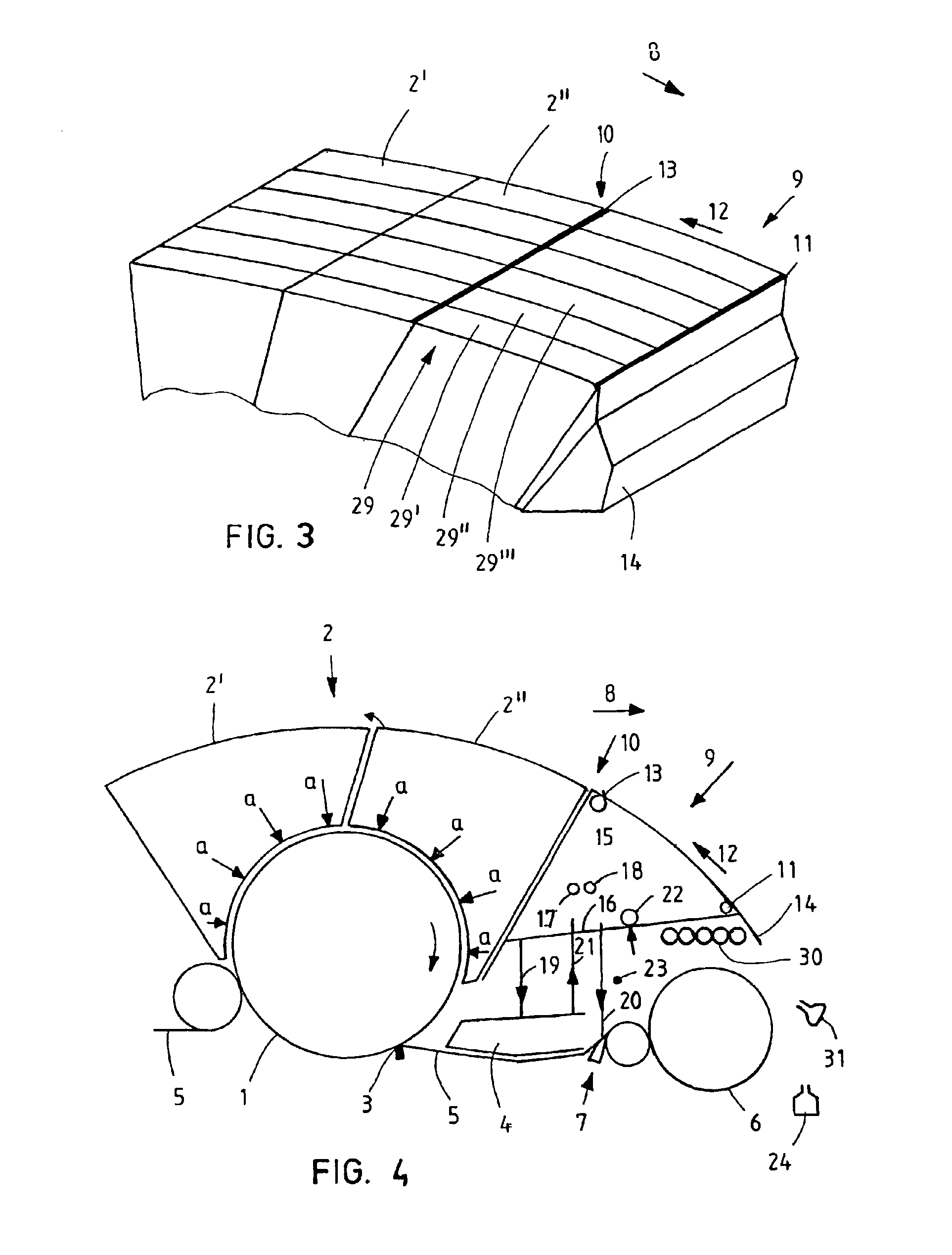

The method involves cutting and rolling of coated plates. The welding of shell plates to several cylinder sections (8,9) is performed. The mechanical preprocessing of individual cylinder sections on the inner and outer sides, and at the end faces is performed. The welding of individual cylinder sections to a finished cylindrical surface (2) of Yankee cylinder is performed.

Owner:ANDRITZ AG

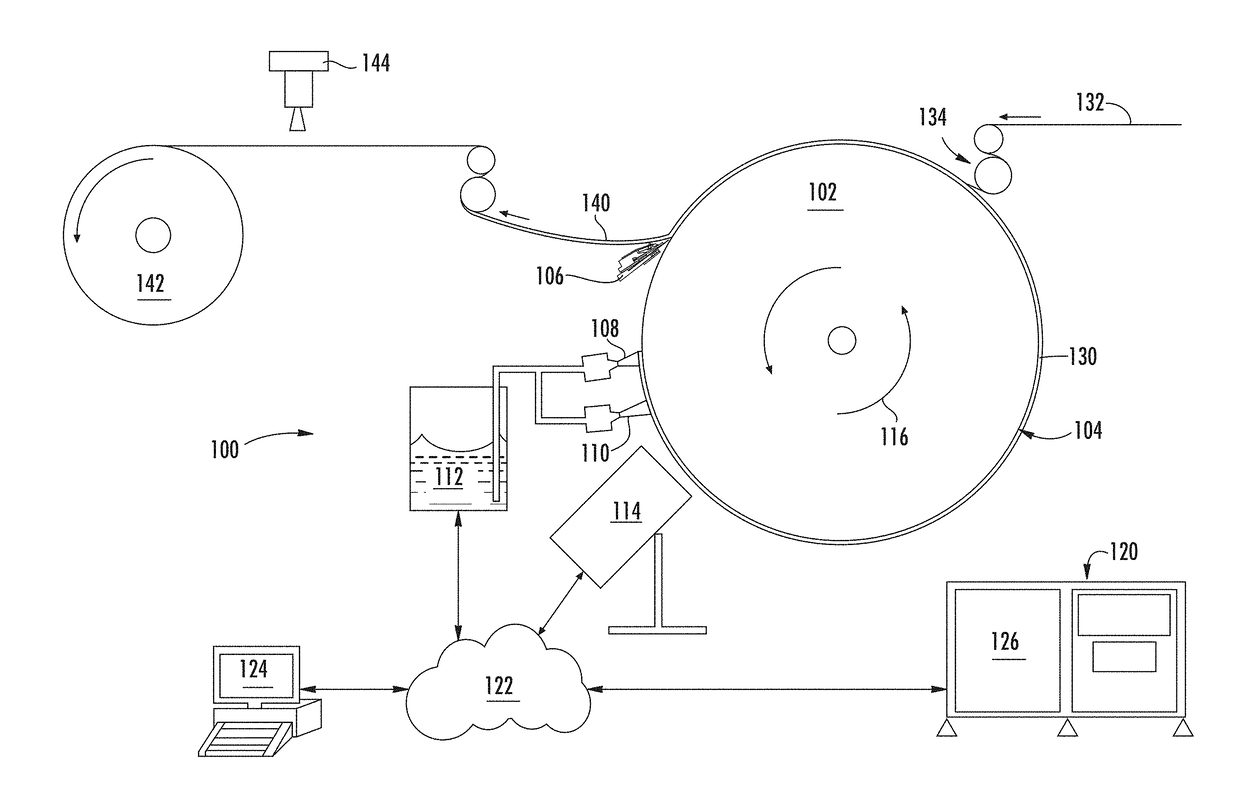

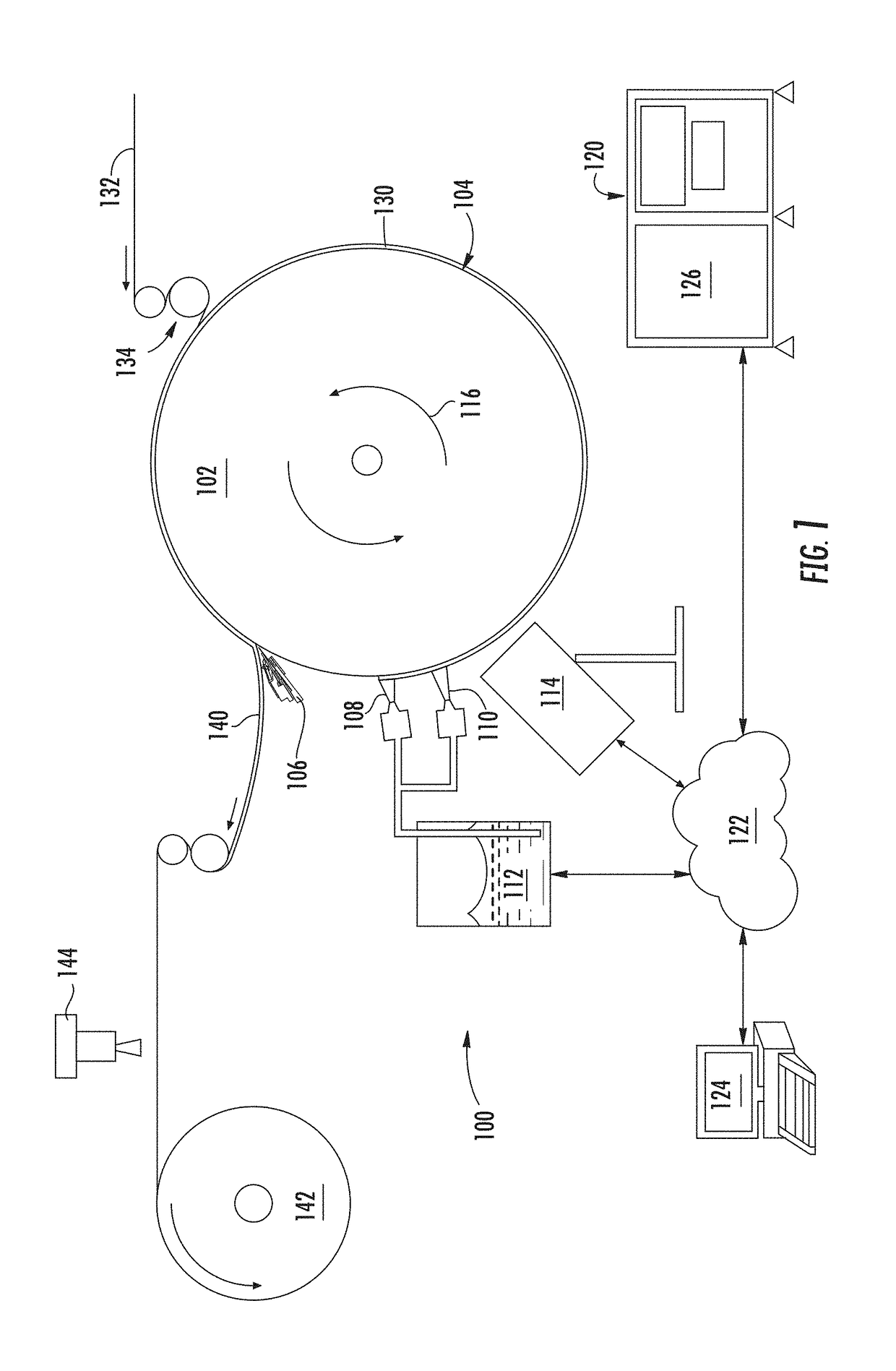

Yankee dryer profiler and control

ActiveUS20180119359A1Influence qualityQuality improvementMechanical working/deformationCoated paper substrateCrêpe paperYankee

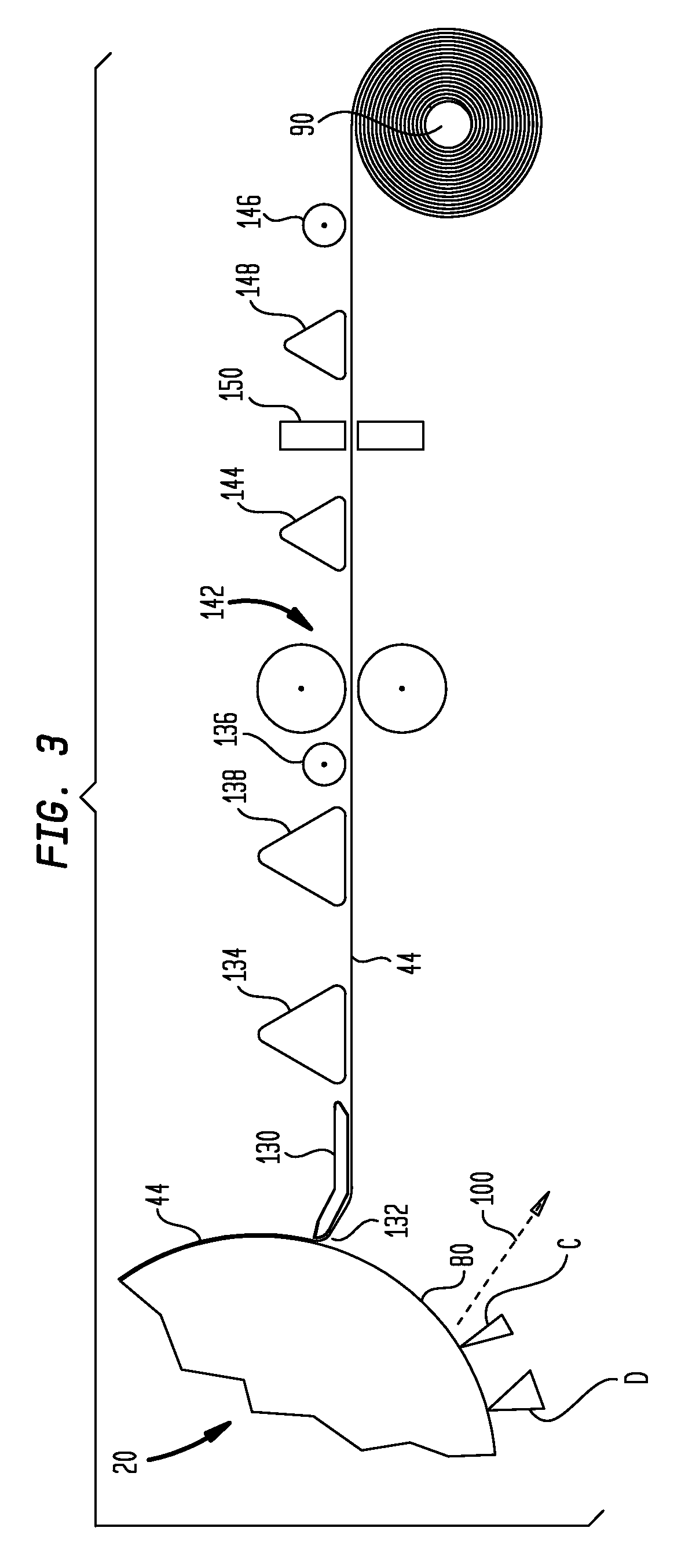

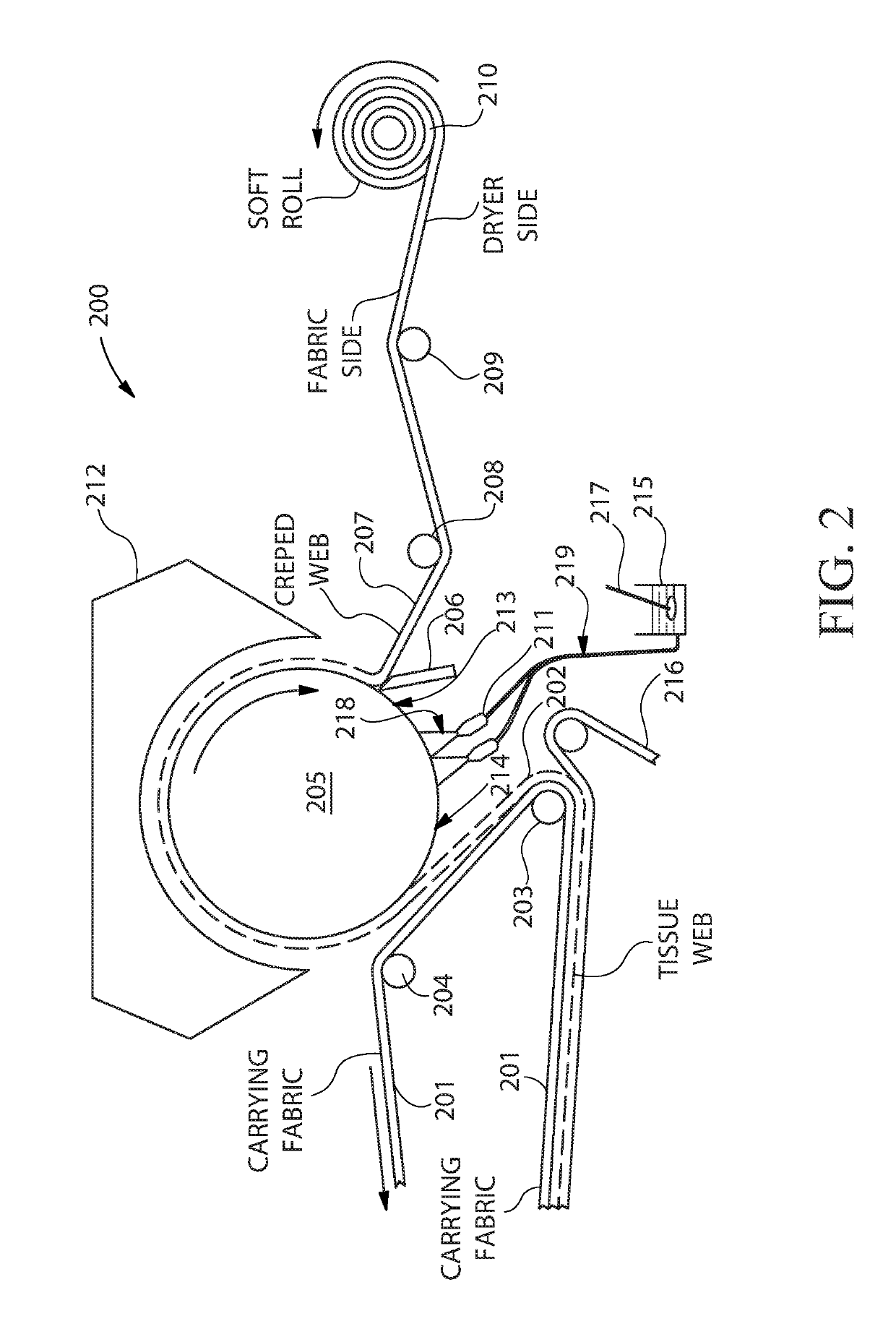

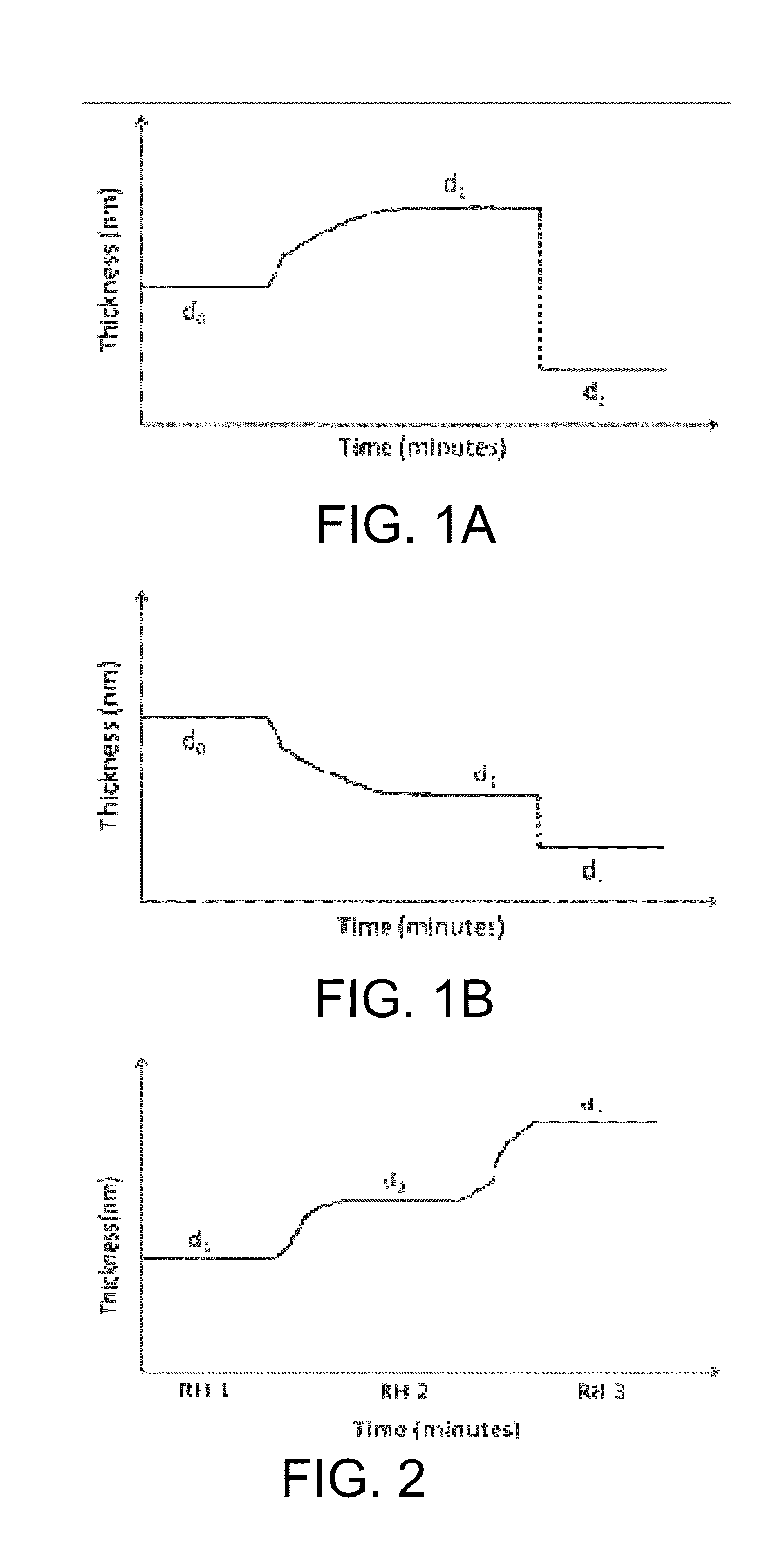

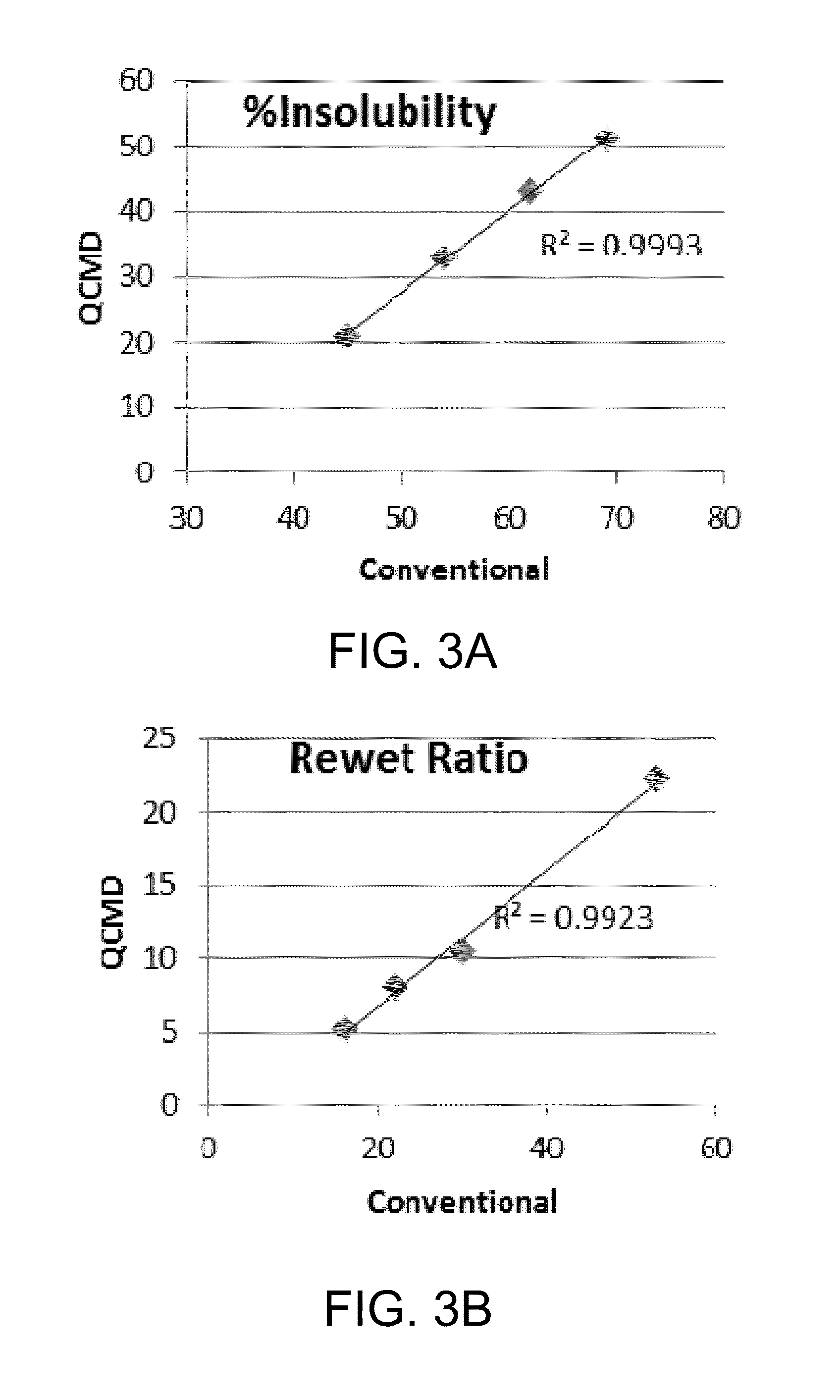

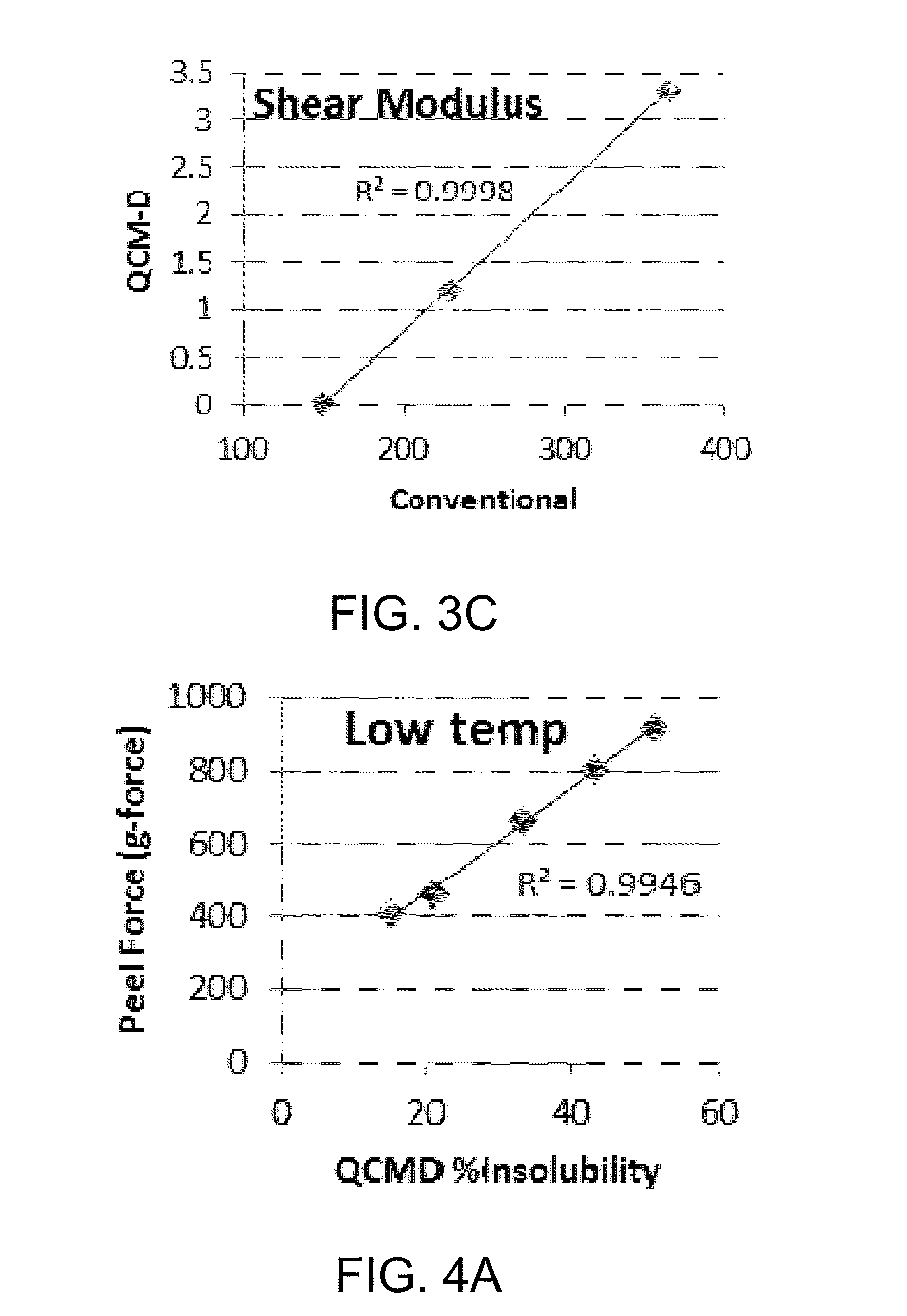

A method for creping paper includes applying an adhesive composition to an outer surface of a creping cylinder (Yankee cylinder) to form an adhesive coating, contacting paper with the adhesive coating, removing the paper and adhesive coating from the creping cylinder, and determining a quality of the adhesive coating. Determining the quality of the adhesive coating may include measuring a degree of cross-linking of the adhesive polymer, a concentration of the adhesive polymer in the adhesive coating, a water content of the adhesive coating, an ash content of the adhesive coating, or combinations thereof. Determining the quality of the adhesive coating may also include determining a thickness of the adhesive coating by measuring light absorbed by the coating and calculating the thickness using Beer's Law. Systems and apparatuses for determining the quality of the adhesive coating and for creping paper are also disclosed.

Owner:GORDEN MICHAEL

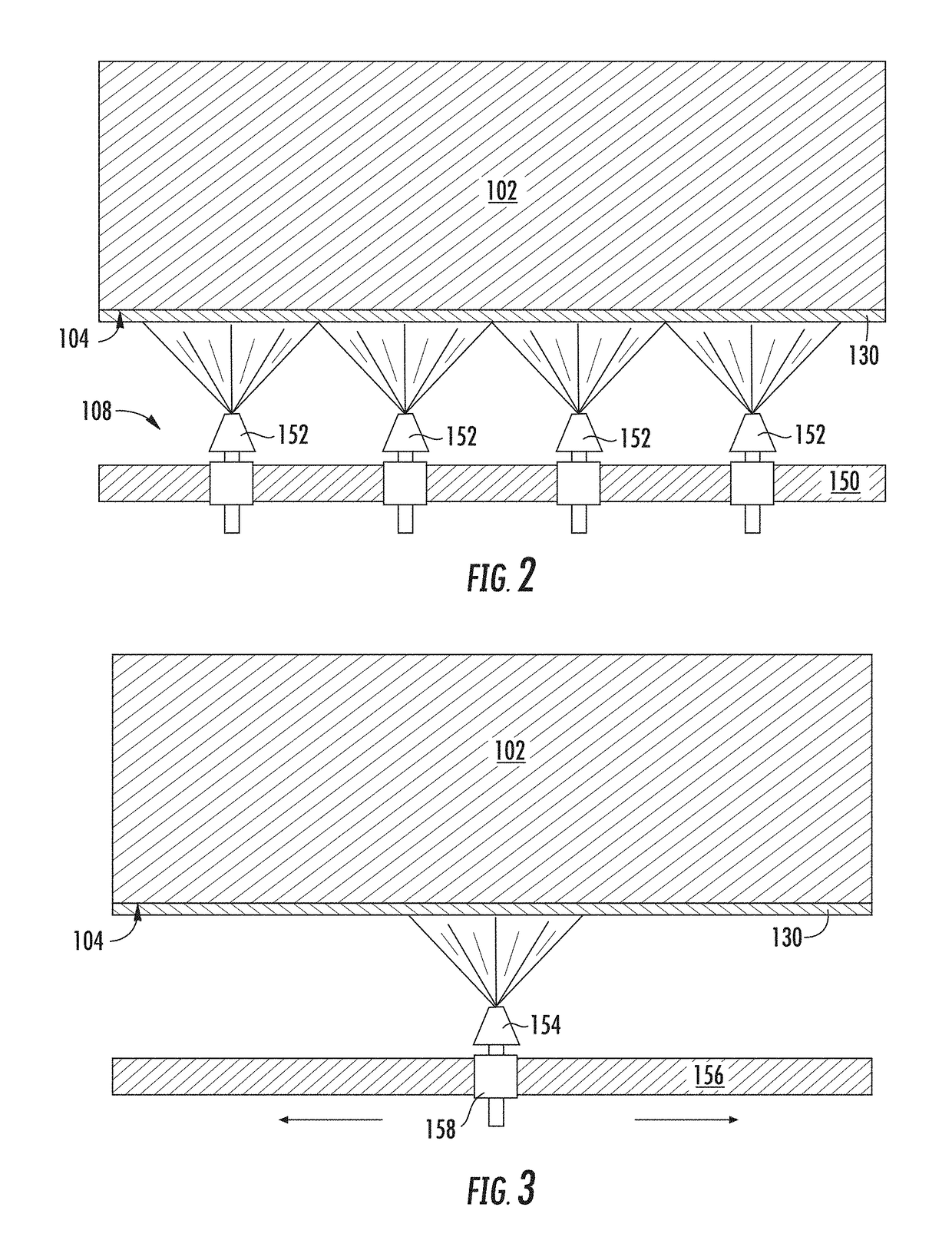

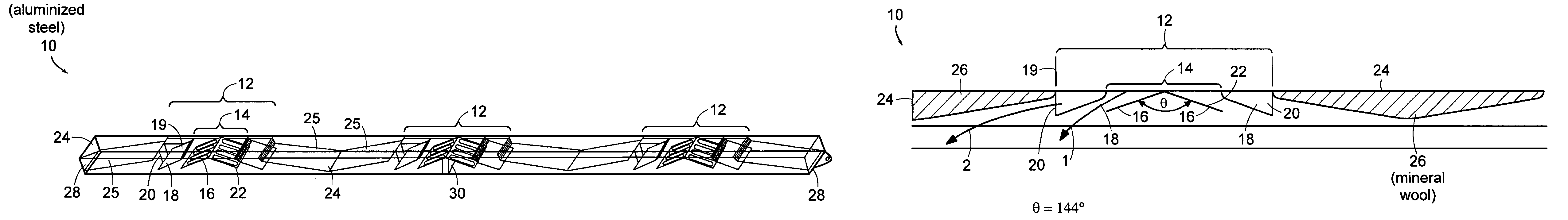

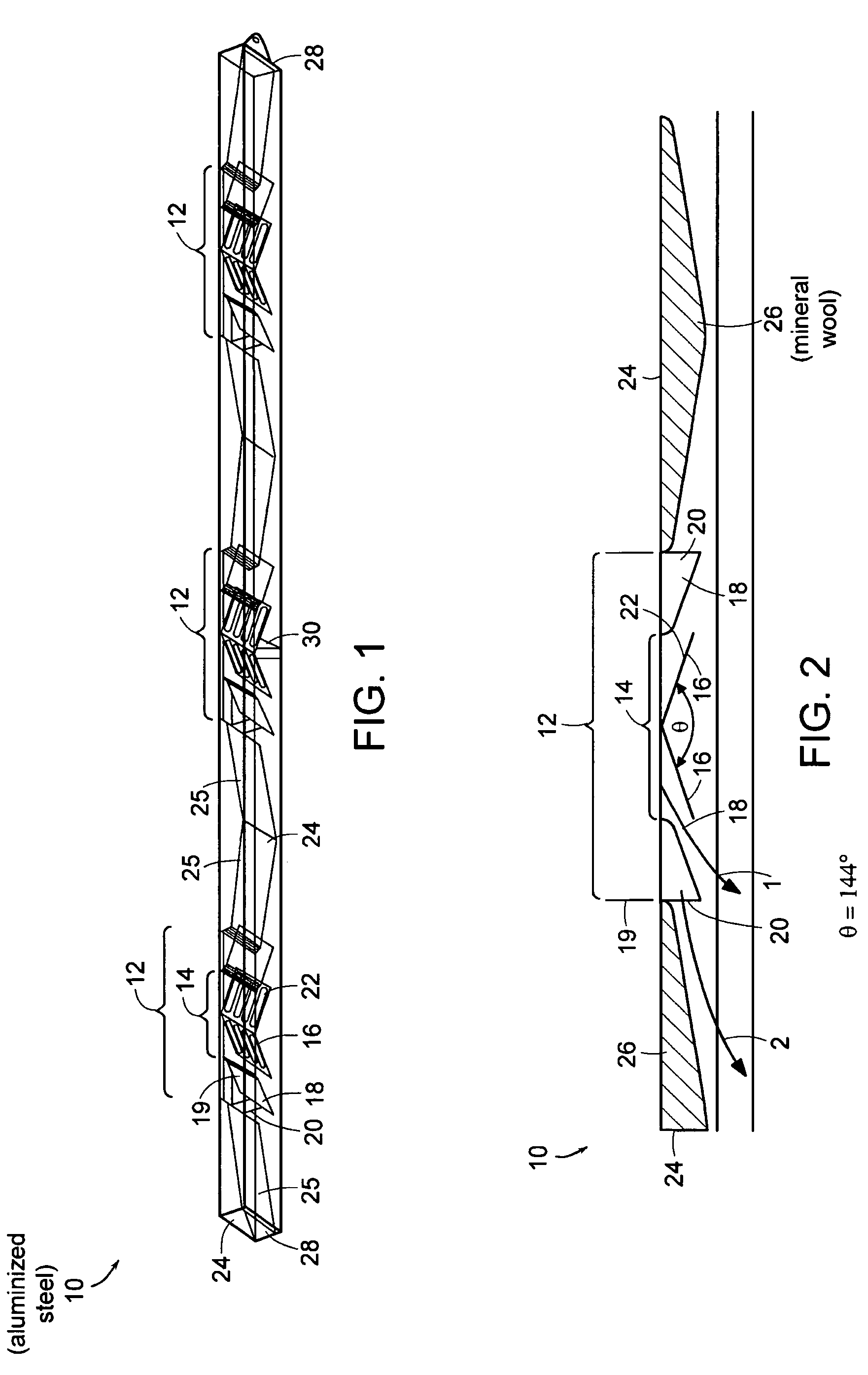

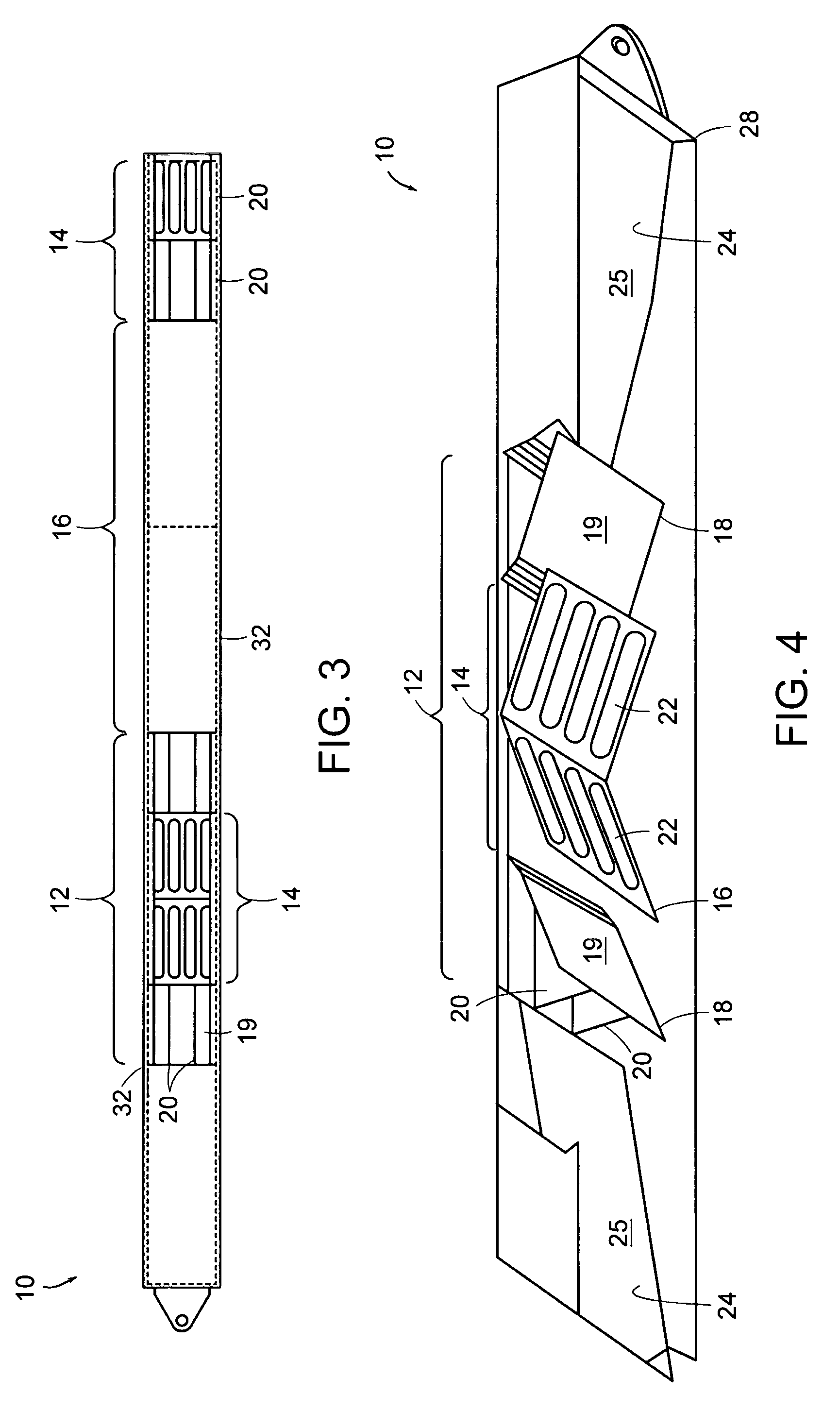

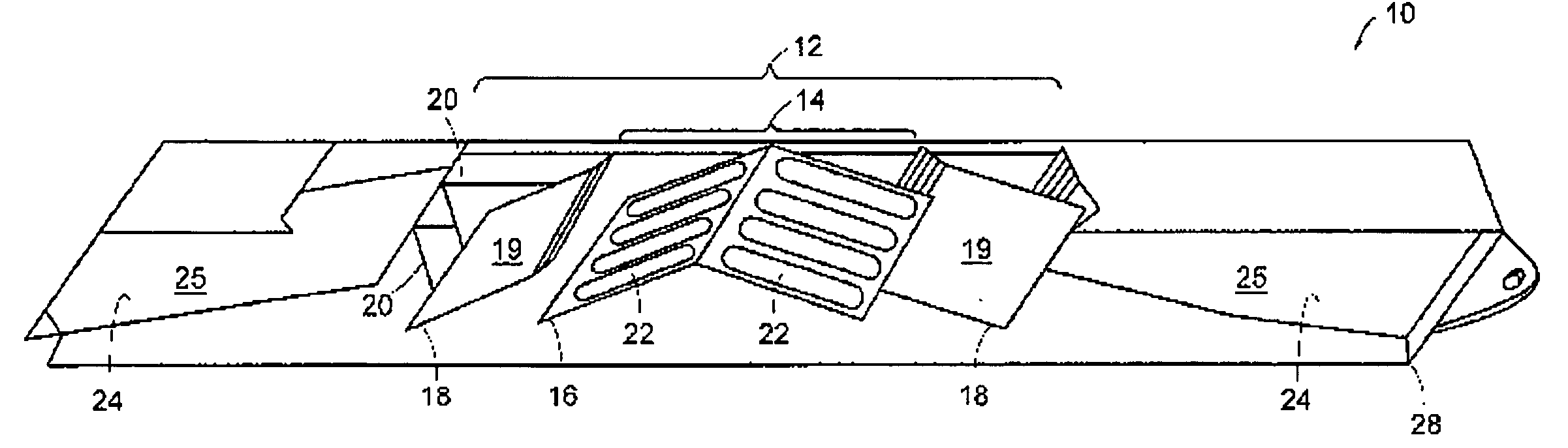

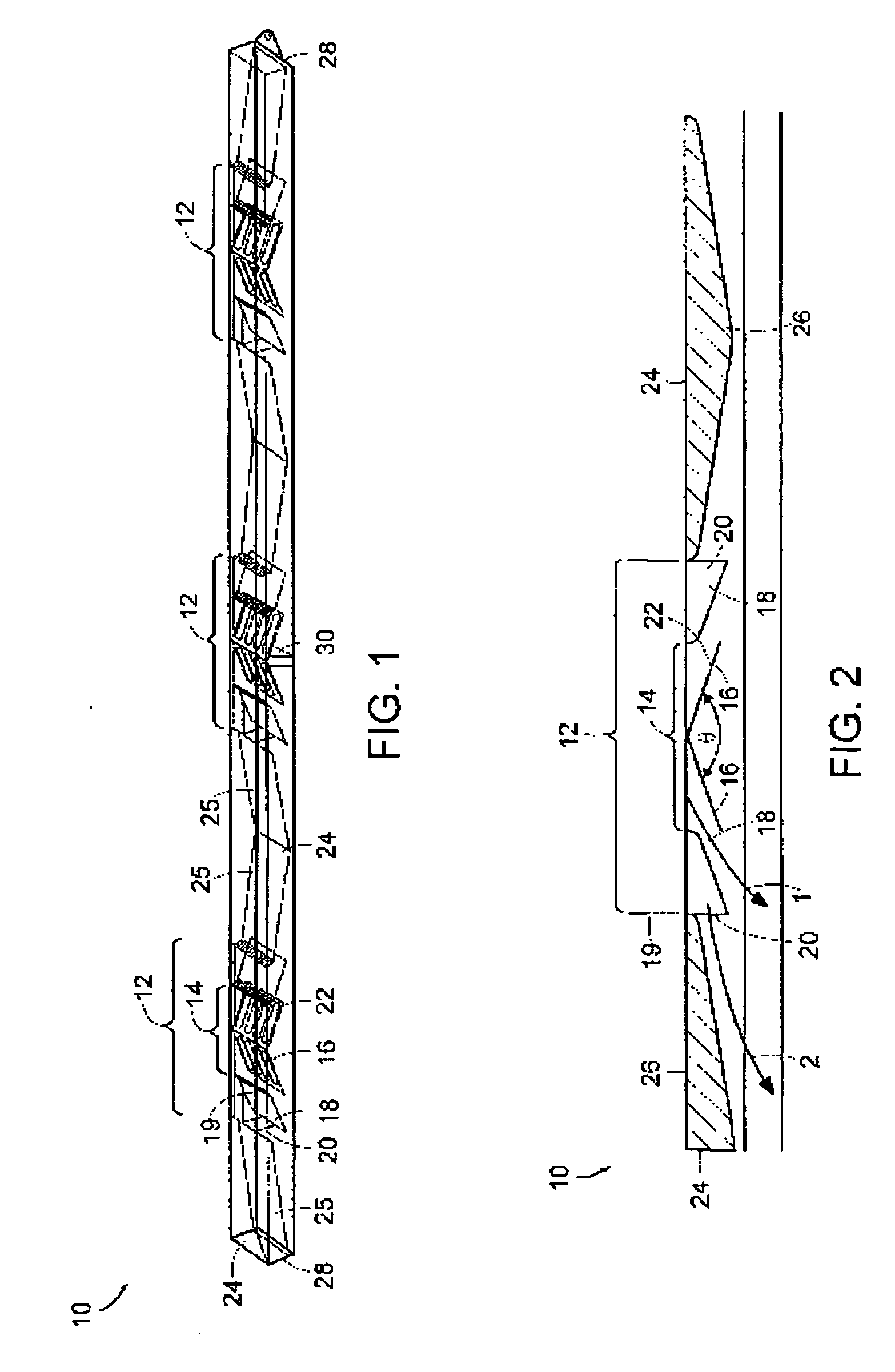

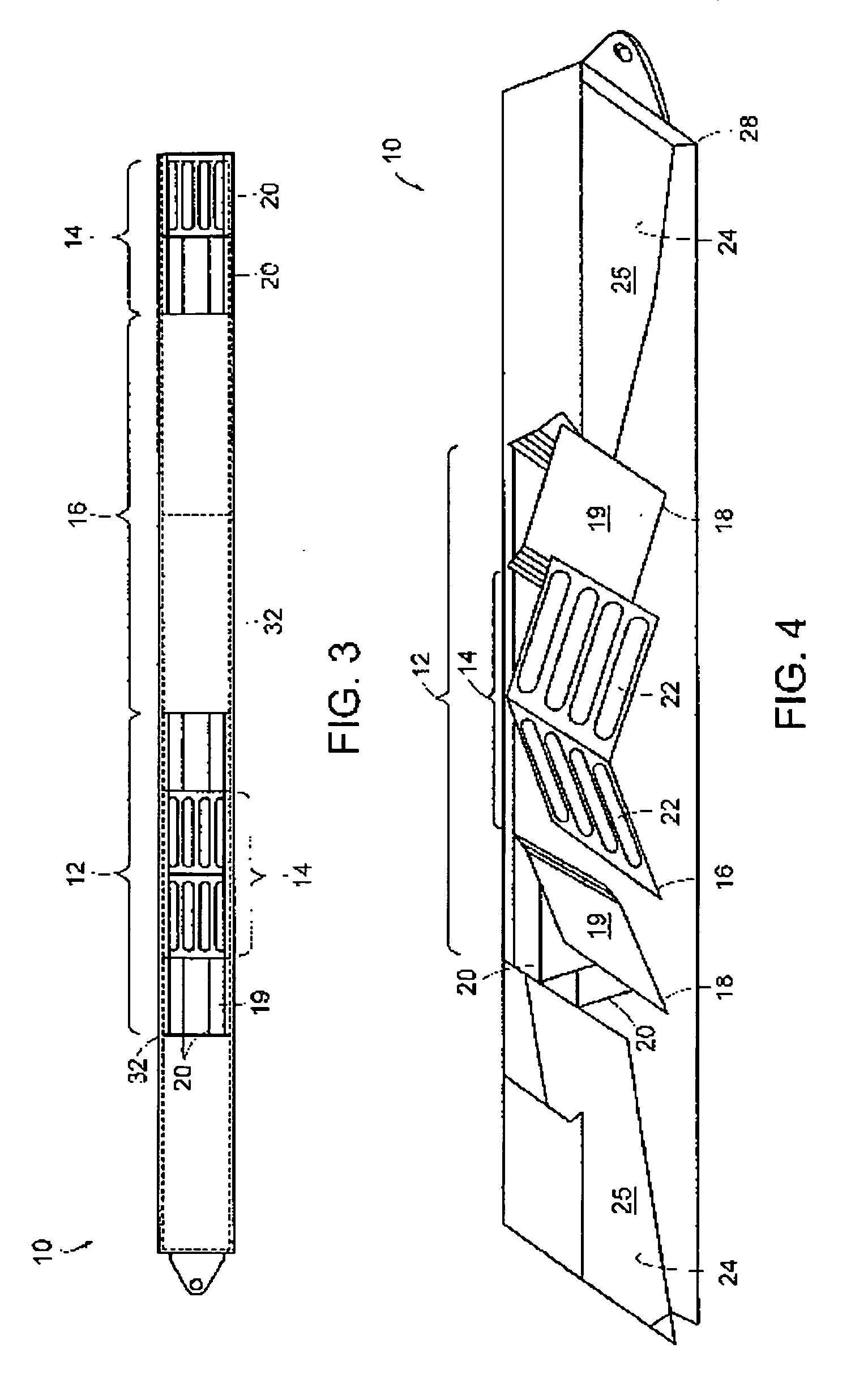

Nozzle insert for a Yankee impingement hood

ActiveUS20060107549A1Uniform temperatureGuaranteed uniform velocityDryer sectionDrying gas arrangementsHeat lossesYankee

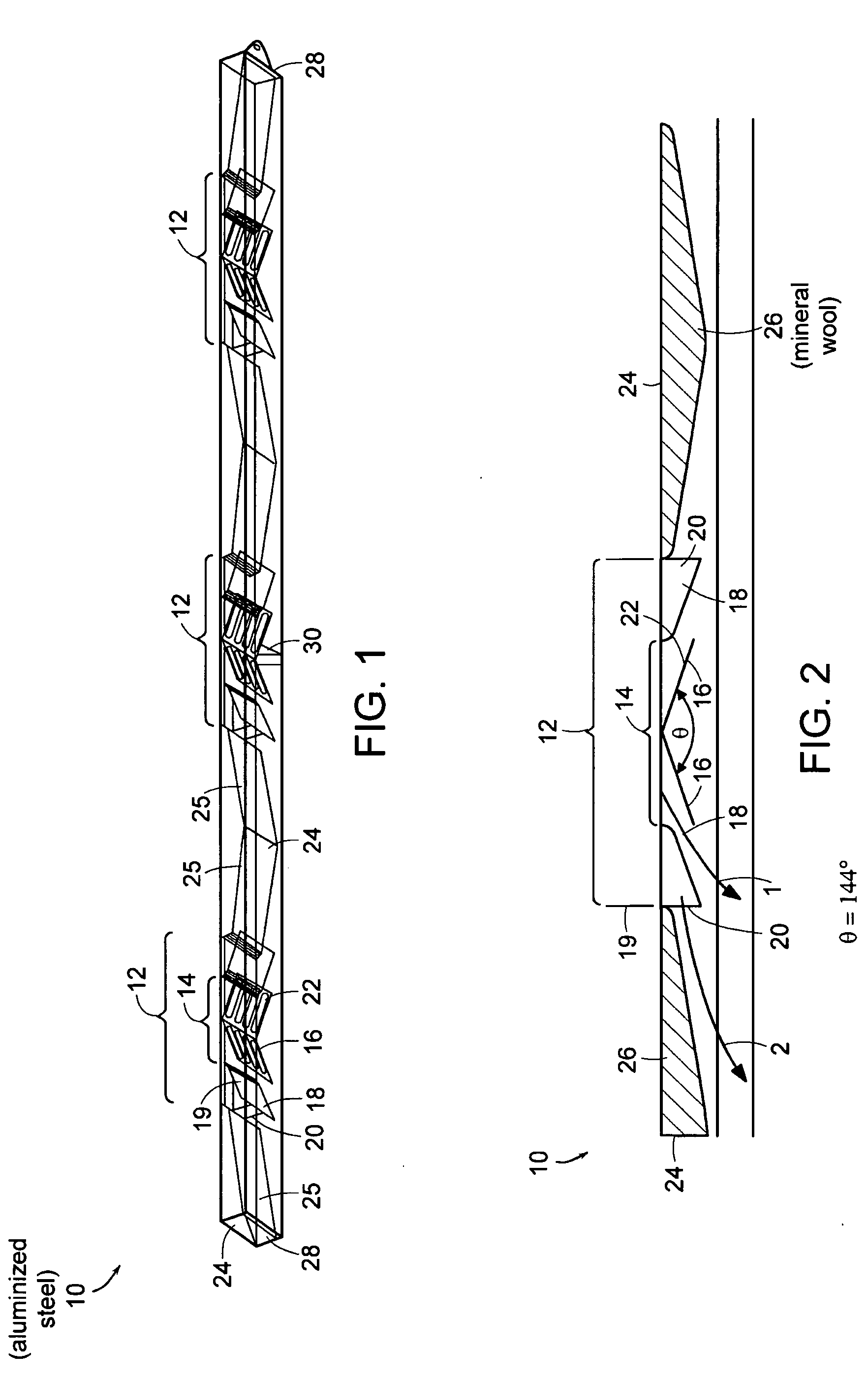

The present invention includes a nozzle insert for use in a drying machine of the type used in paper web drying. The nozzle insert of the present invention includes at least one intake having a central portion, wherein a pair of center vanes is disposed for directing airflow. The central portion is bounded by at least one turning vane adapted for directing airflow in a lateral direction. For each turning vane, there is at least one straightening vane adapted for curtailing swirling of the airflow. The vanes are oriented at optimal angles for directing the flow of the nozzle in a lateral direction, while permitting some air to penetrate the central portion through a series of ports. The intakes are bounded by a series of insulated bulkheads, which serve to direct airflow and contain heat-loss through thermal emission.

Owner:VALMET OY

Method of producing a creping paper and the creping paper thereof

ActiveUS20160168798A1Improve performanceImprove efficiencyNatural cellulose pulp/paperMechanical working/deformationFiberCrêpe paper

The present invention provides for a method of producing a creped paper and the crepe paper products made using this method. The method includes treating the surface of a crepe fiber web and / or surface of a Yankee drum dryer or cylinder with compositions containing a combination of hydrophobes and surfactants and wherein these compositions have been subjected to physical treatments to reduce the mean particle size to about 1 micron (μm) or less.

Owner:SOLENIS TECH CAYMAN

Method for producing a yankee dryer

Owner:ANDRITZ AG

Nozzle insert for a Yankee impingement hood

ActiveUS7448147B2Uniform temperatureGuaranteed uniform velocityDryer sectionDrying gas arrangementsHeat lossesYankee

The present invention includes a nozzle insert for use in a drying machine of the type used in paper web drying. The nozzle insert of the present invention includes at least one intake having a central portion, wherein a pair of center vanes is disposed for directing airflow. The central portion is bounded by at least one turning vane adapted for directing airflow in a lateral direction. For each turning vane, there is at least one straightening vane adapted for curtailing swirling of the airflow. The vanes are oriented at optimal angles for directing the flow of the nozzle in a lateral direction, while permitting some air to penetrate the central portion through a series of ports. The intakes are bounded by a series of insulated bulkheads, which serve to direct airflow and contain heat-loss through thermal emission.

Owner:VALMET OY

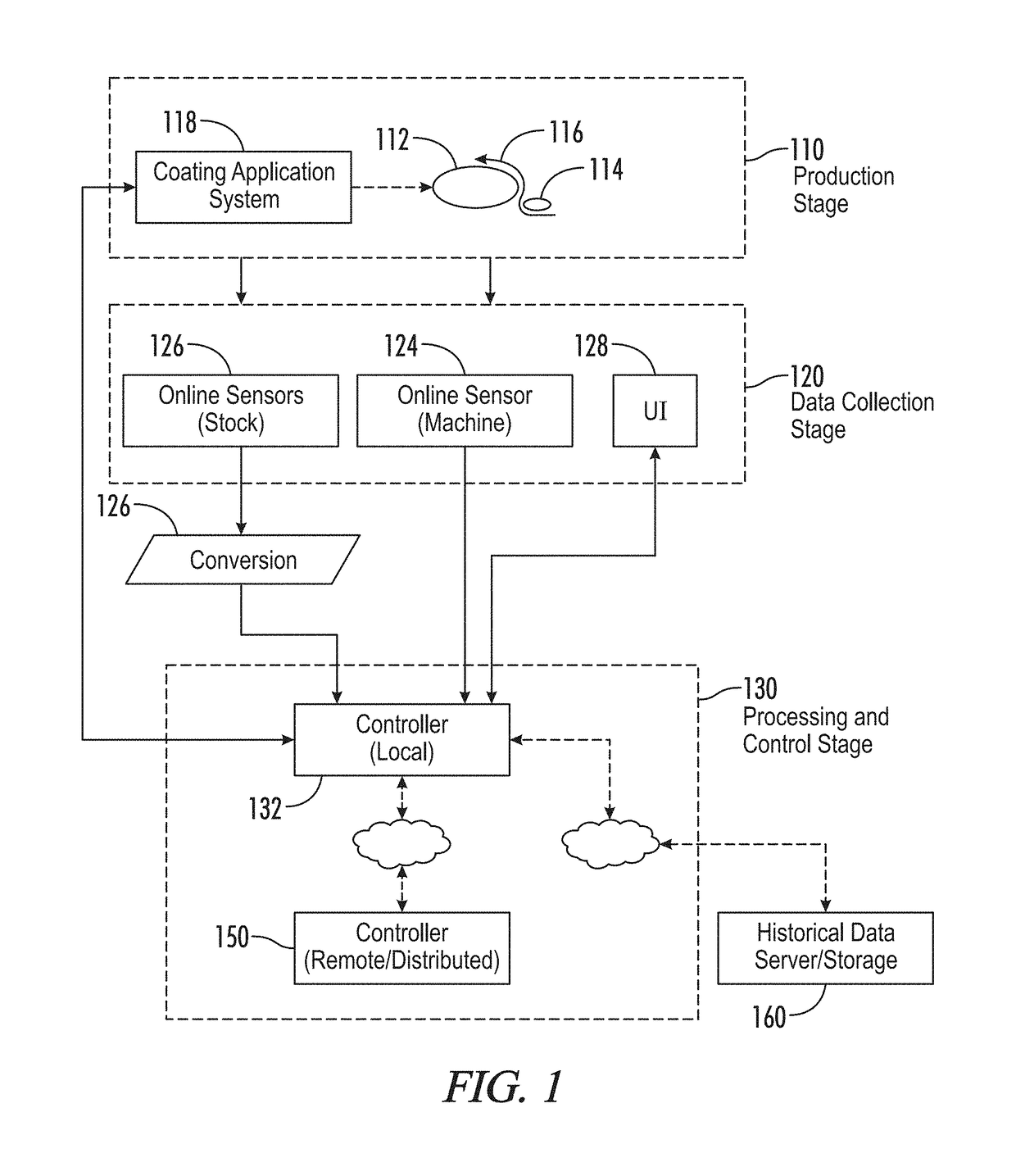

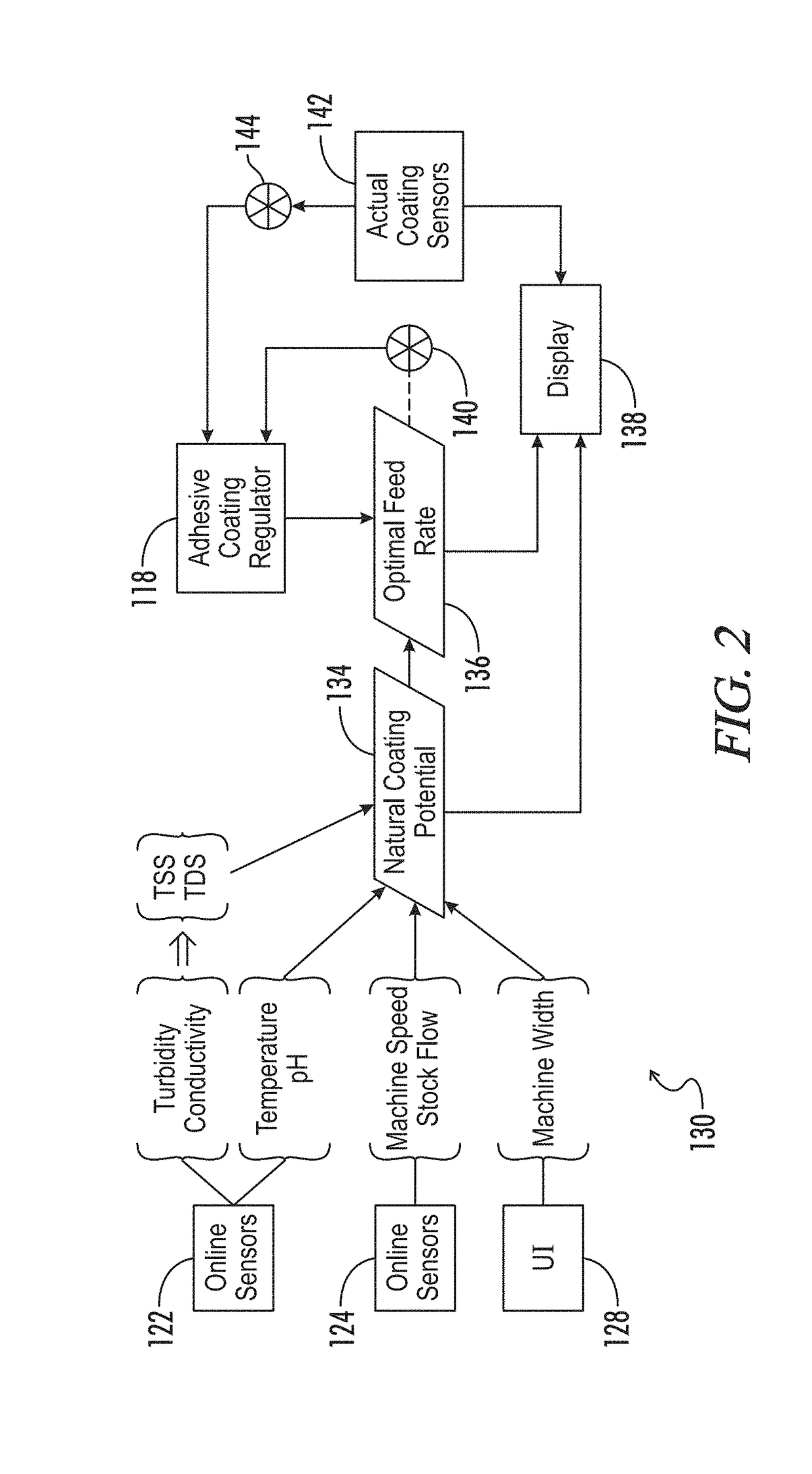

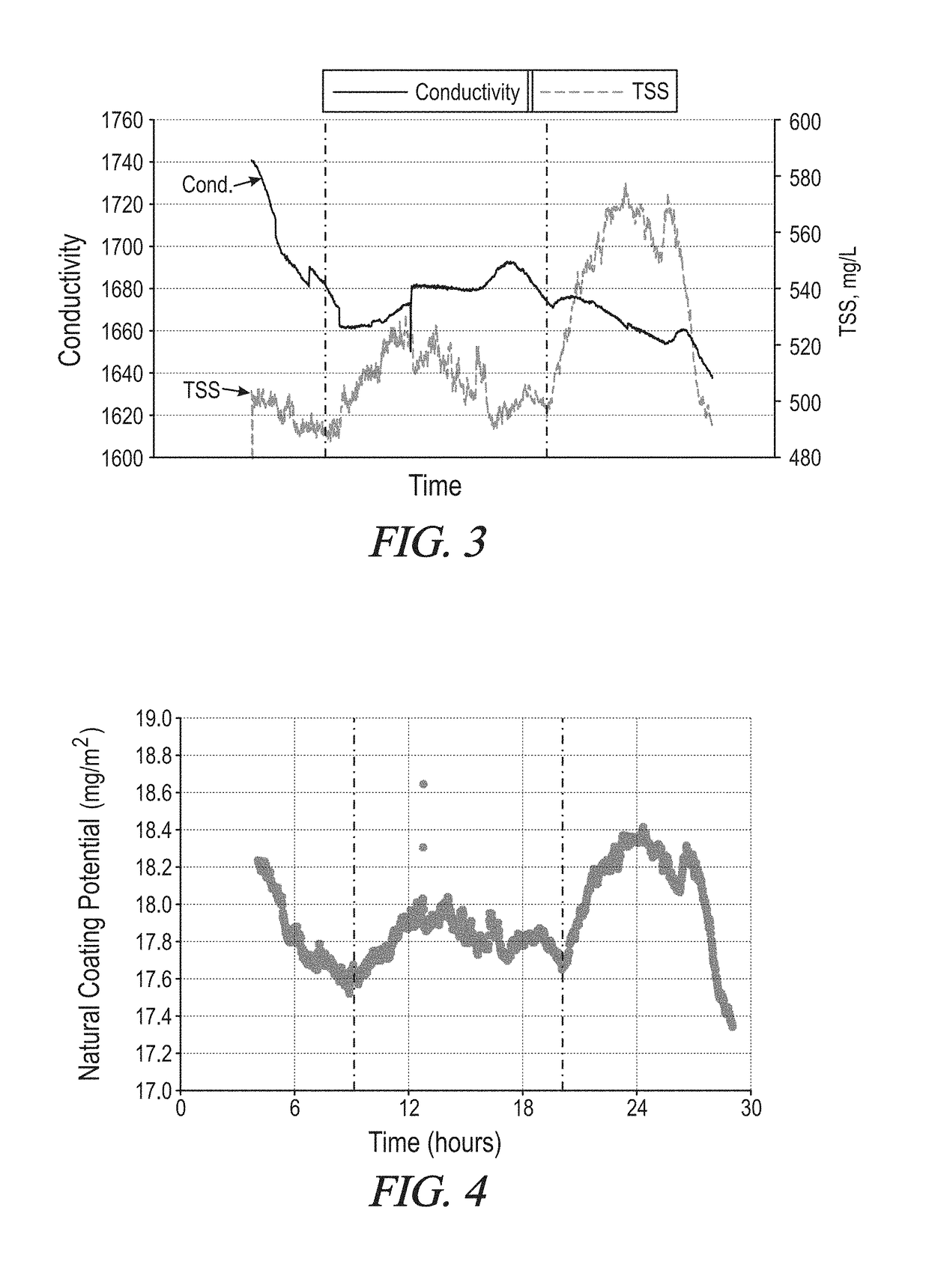

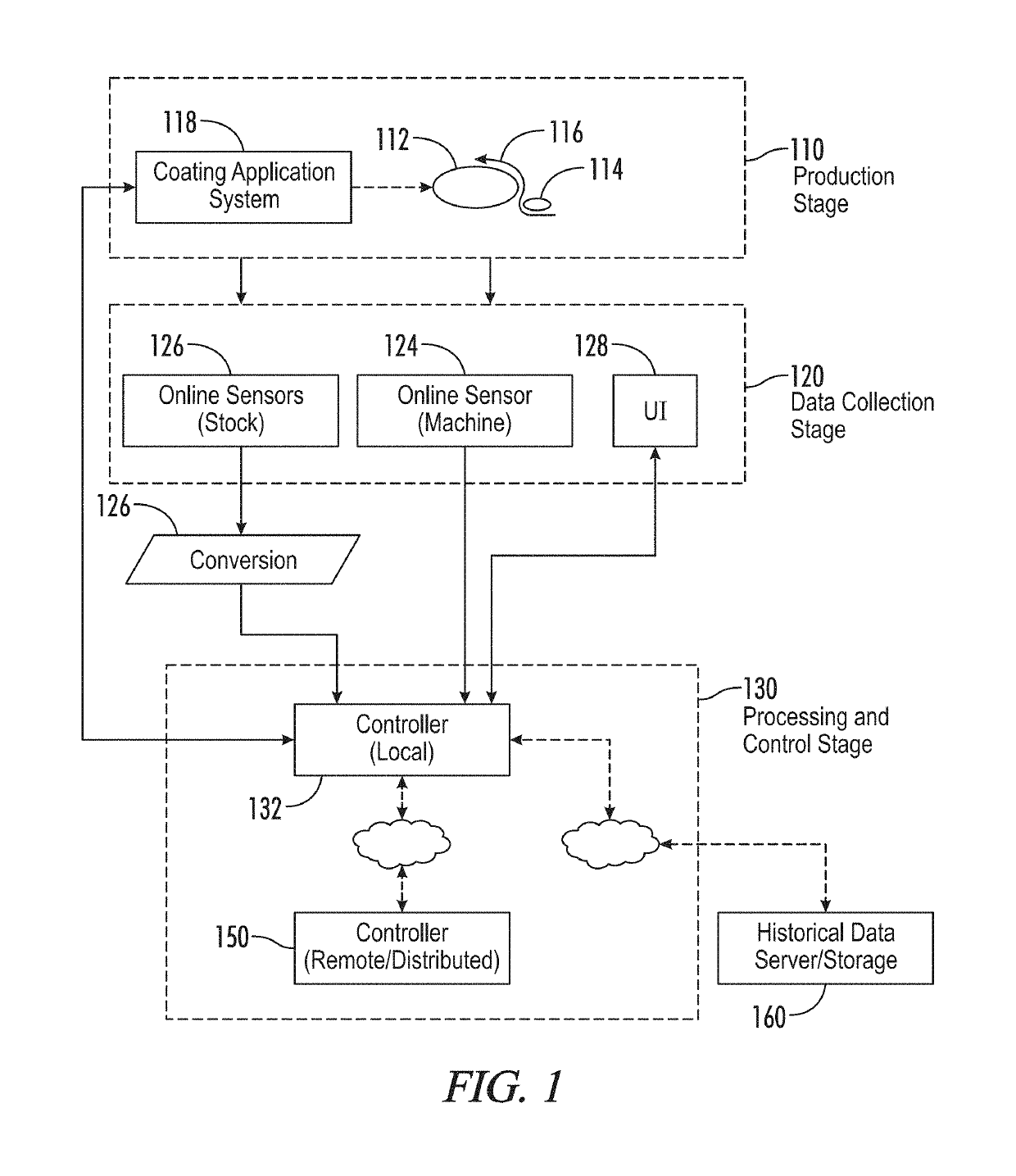

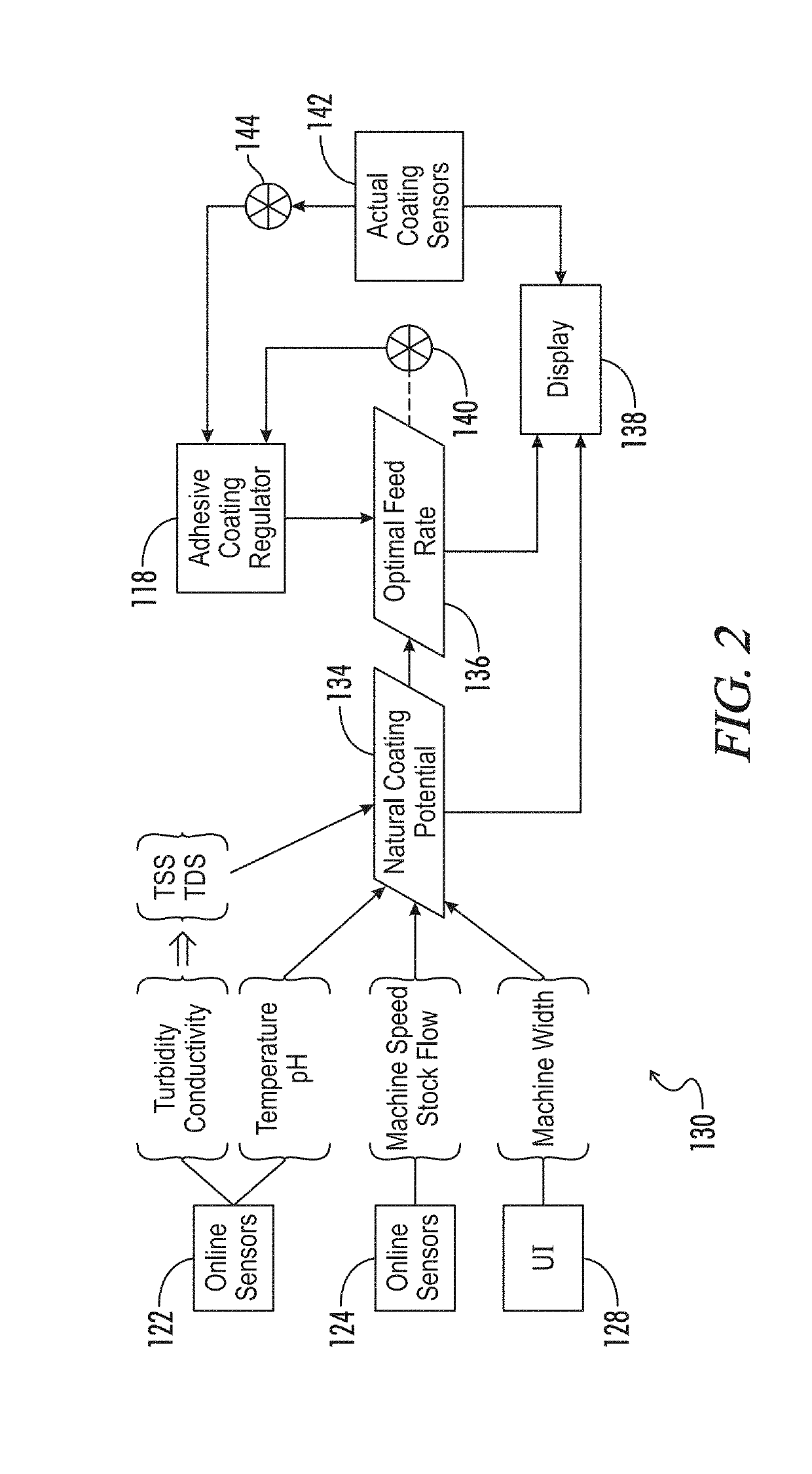

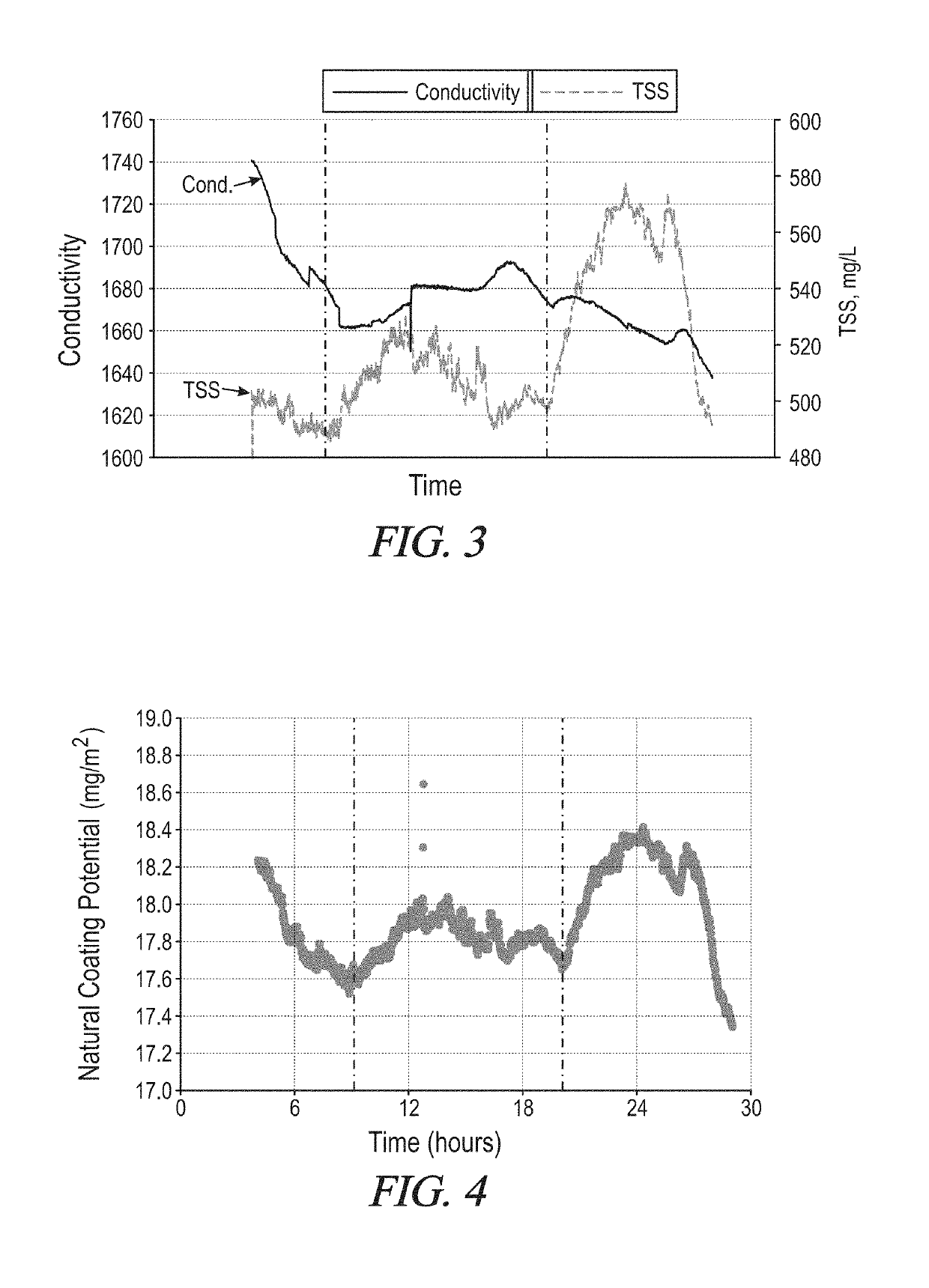

Real time regulation of yankee dryer coating based on predicted natural coating transfer

ActiveUS20190024316A1Increase valueLiquid surface applicatorsMechanical working/deformationLine sensorProcess engineering

A method is provided for decision support in regulating an adhesive coating applied to Yankee dryers. Online sensors are configured to continuously measure stock characteristics, and additional sensors provide actual stock flow rate and machine speed. A controller predicts potential natural coating application from a fibrous sheet generated from the stock to the Yankee dryer surface, substantially in real time, based on the measured characteristics and sensed actual machine values. An output signal may be provided to a display unit, wherein an optimal adhesive coating feed rate may be determined and displayed for operator decision support. The controller may in an automatic mode be configured to regulate the adhesive coating feed rate based on a comparison of one or more determined optimal values associated with respective actual values. The method may include identifying fiber source changes in real time, and predicting a natural coating potential based partly on predetermined correlations.

Owner:BUCKMAN LAB INT INC

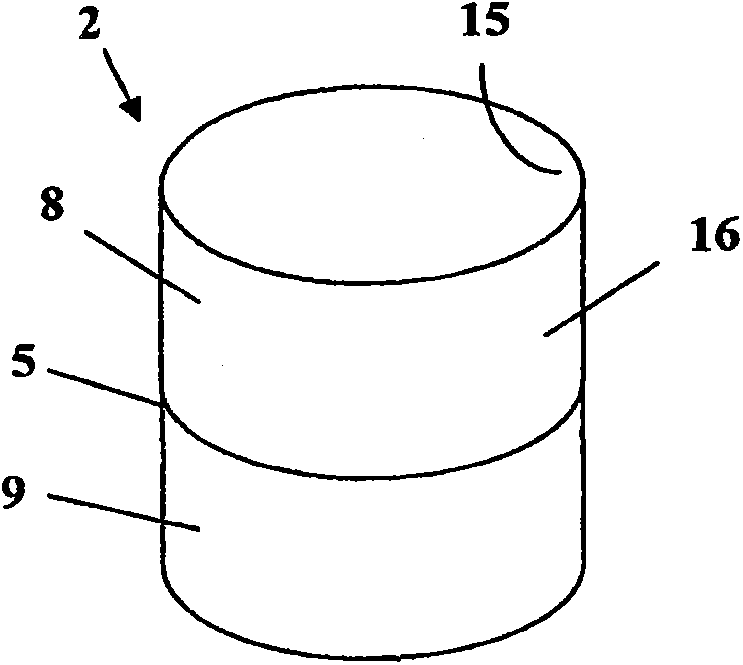

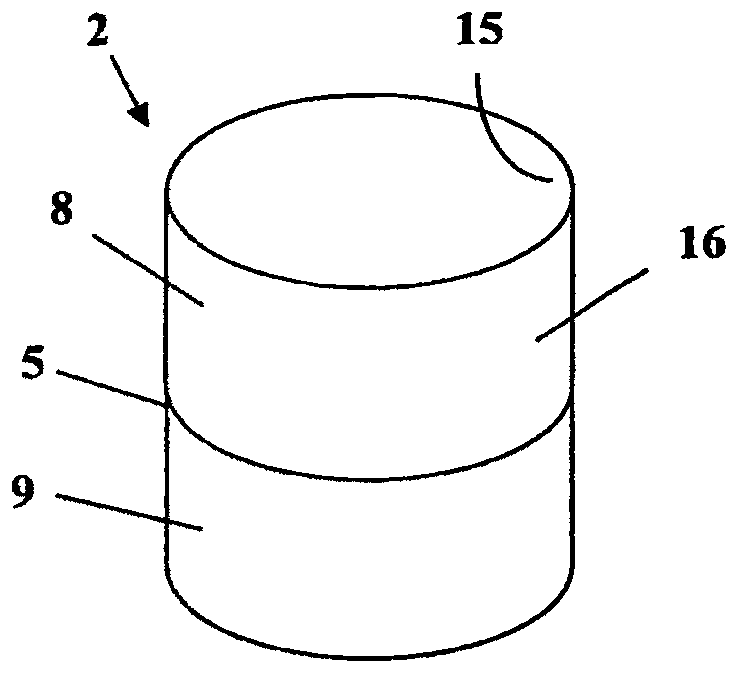

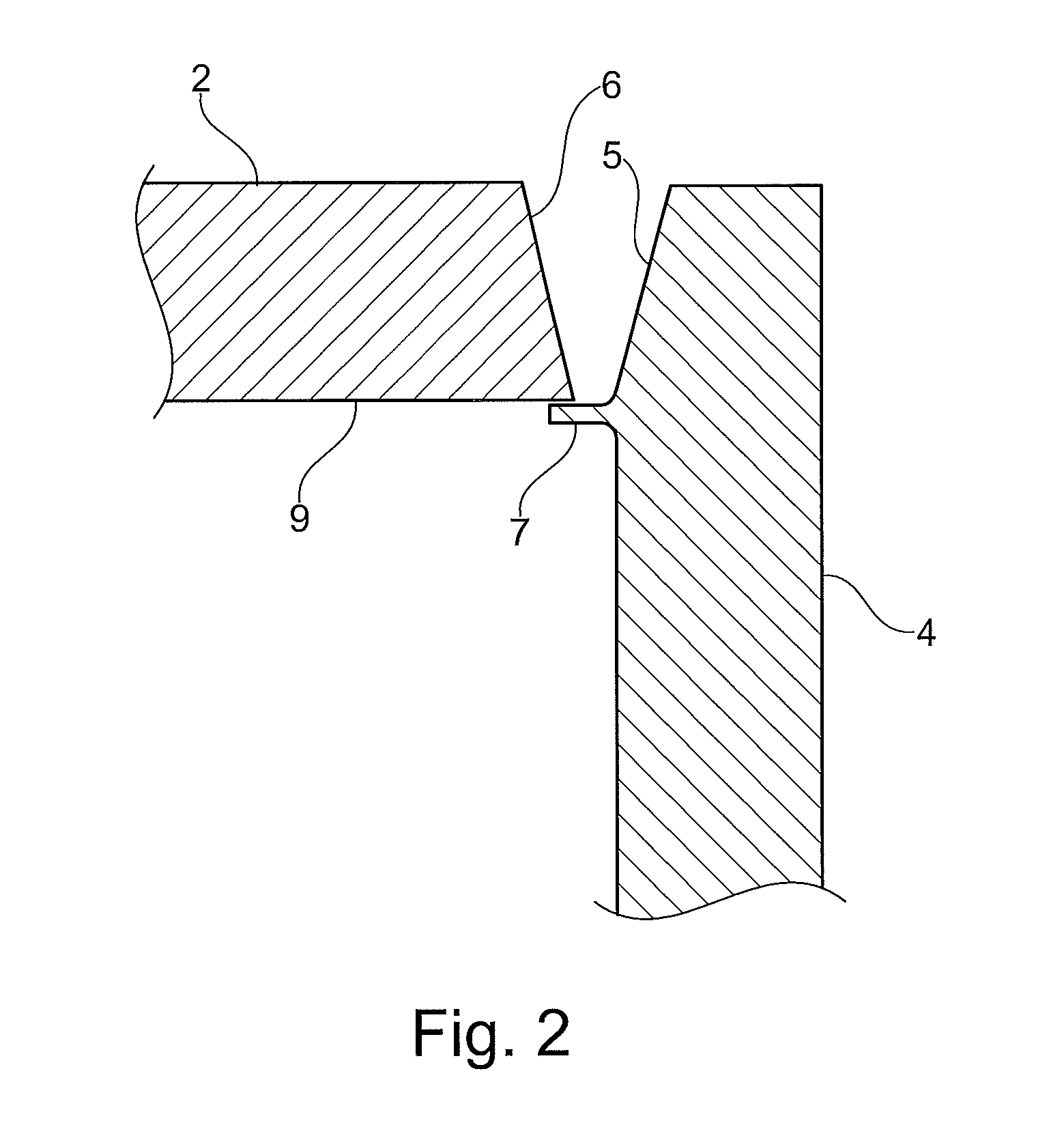

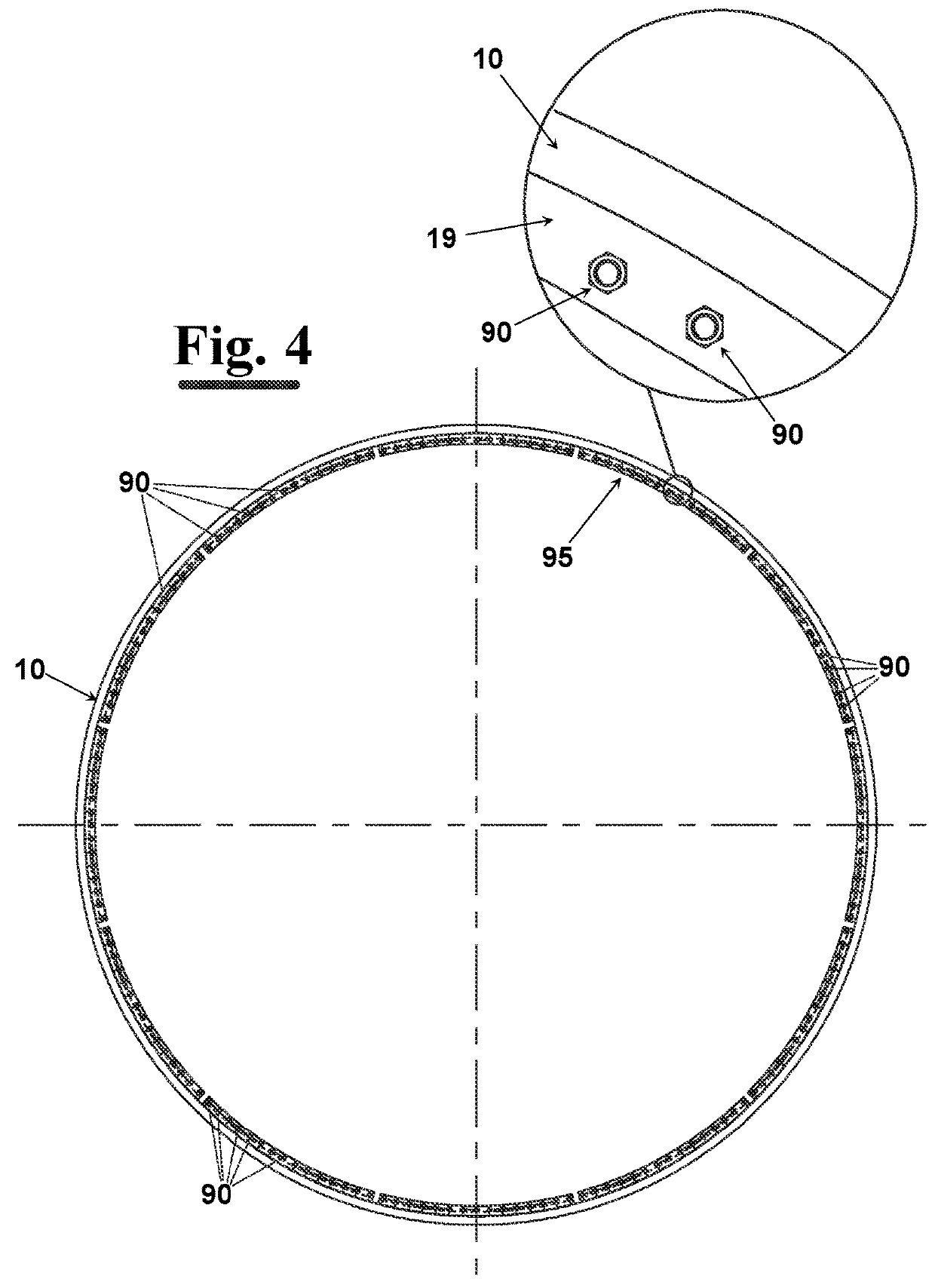

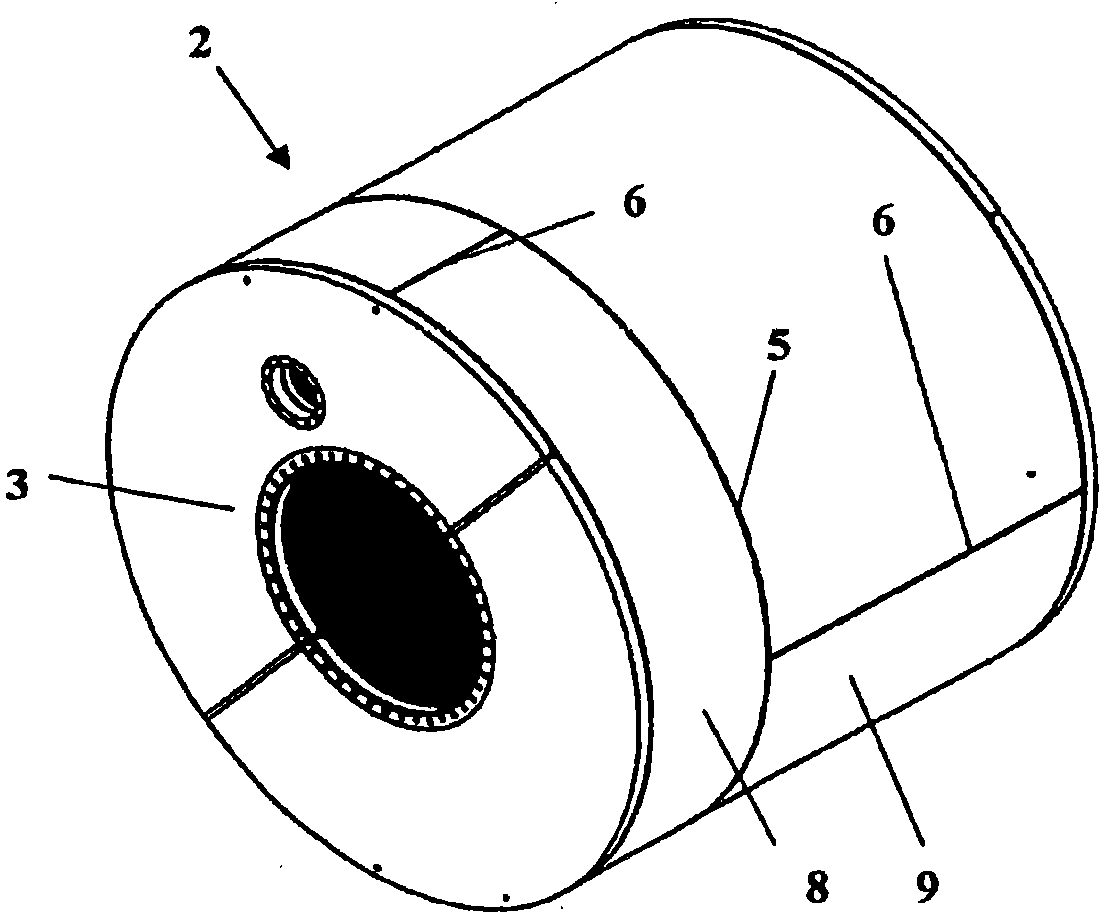

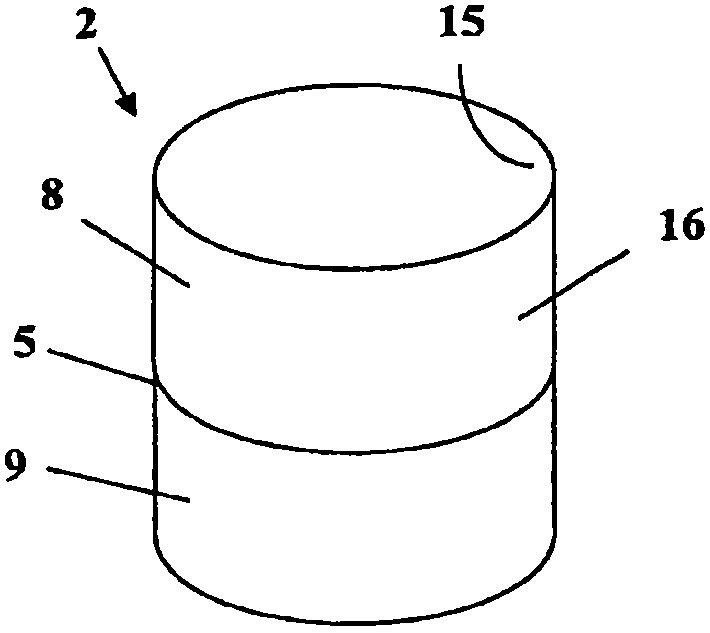

A method of making a steel yankee cylinder

The invention relates to a method of making a steel Yankee cylinder 1 by welding a cylindrical shell 2 to two end walls 3, 4 such that the cylindrical shell 2 and the end walls 3,4 together form the Yankee cylinder 1. The welding operation is carried out exclusively from the outside of the Yankee cylinder 1 and in the welding operation is carried out as a butt welding operation in which a backing material 7 is used on the inside of the Yankee cylinder 1 such that, between each end wall 3, 4 and the cylindrical shell 1, a single weld bead 8 is formed which extends all the way between the opposing surfaces 5, 6 and completely fuses the opposing surfaces 5, 6 of each end wall 3, 4 and the cylindrical shell 2 respectively.

Owner:VALMET AB

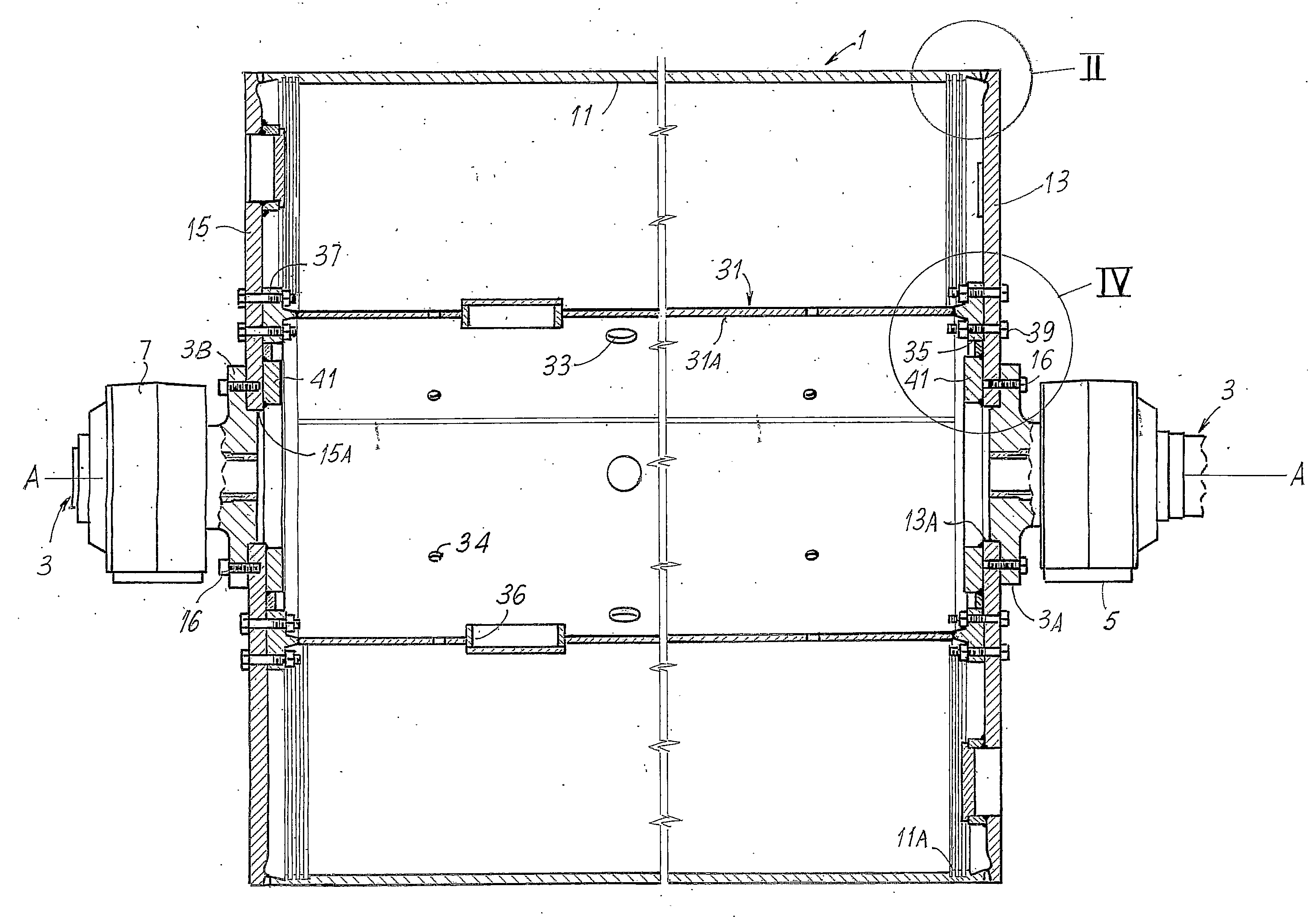

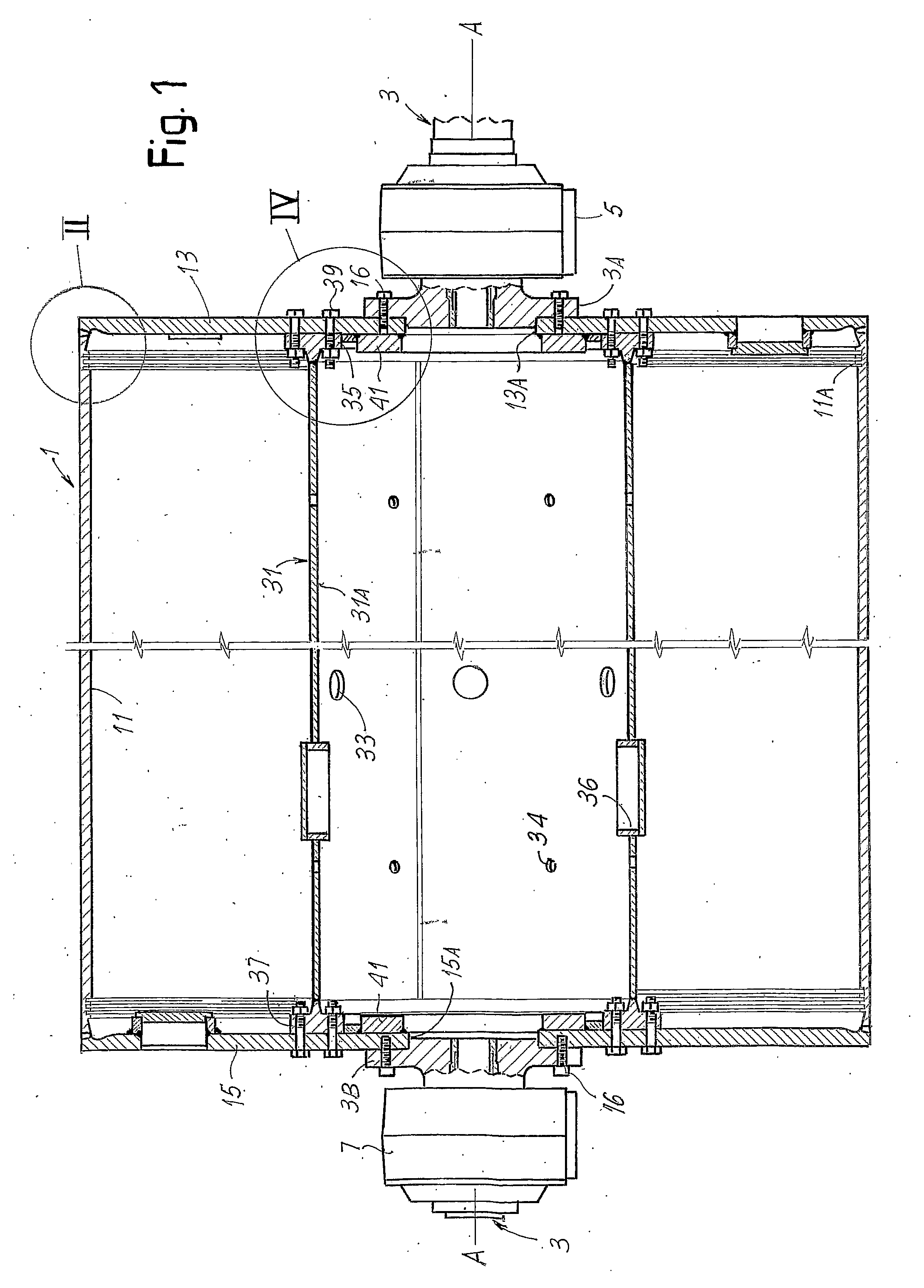

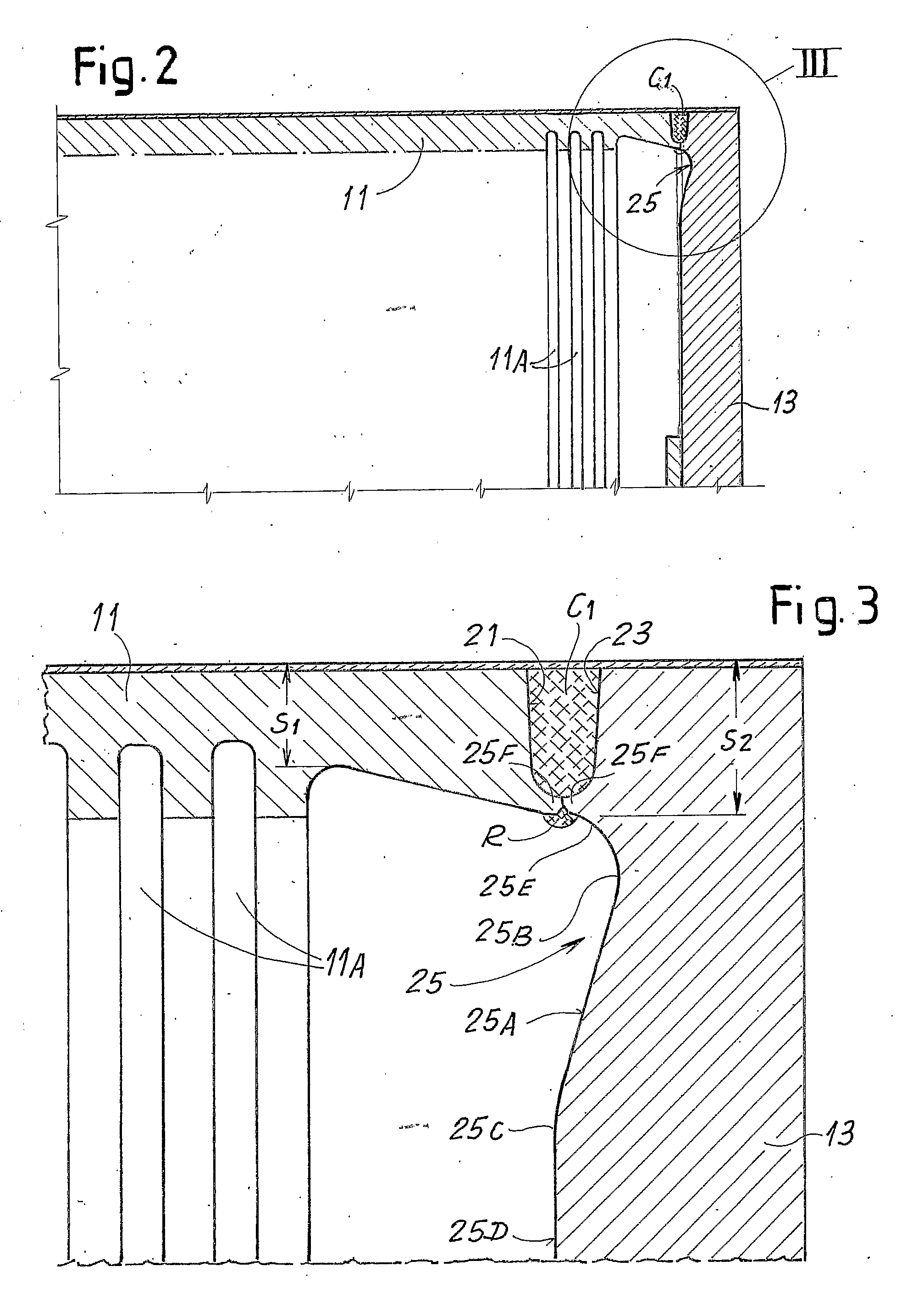

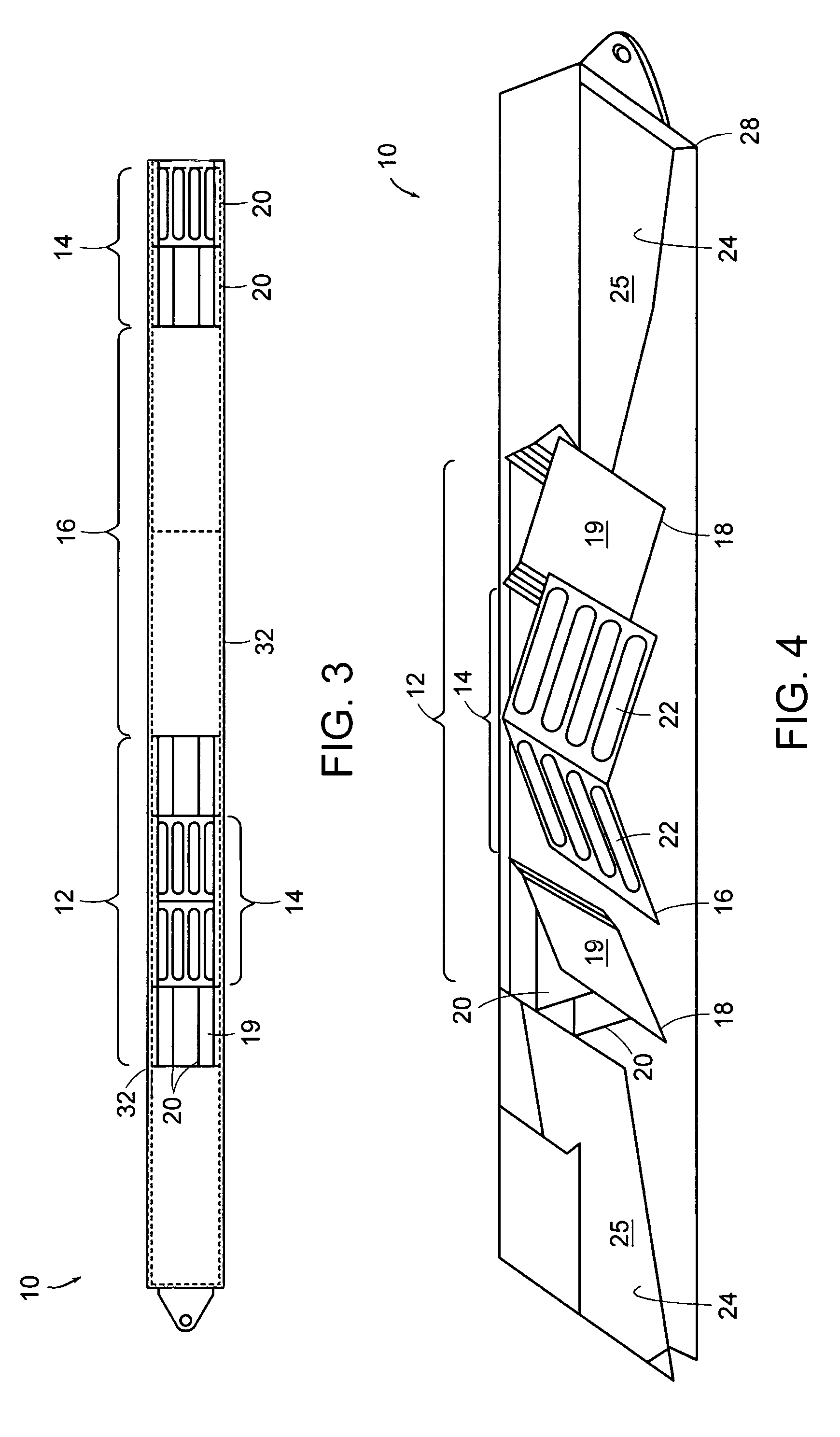

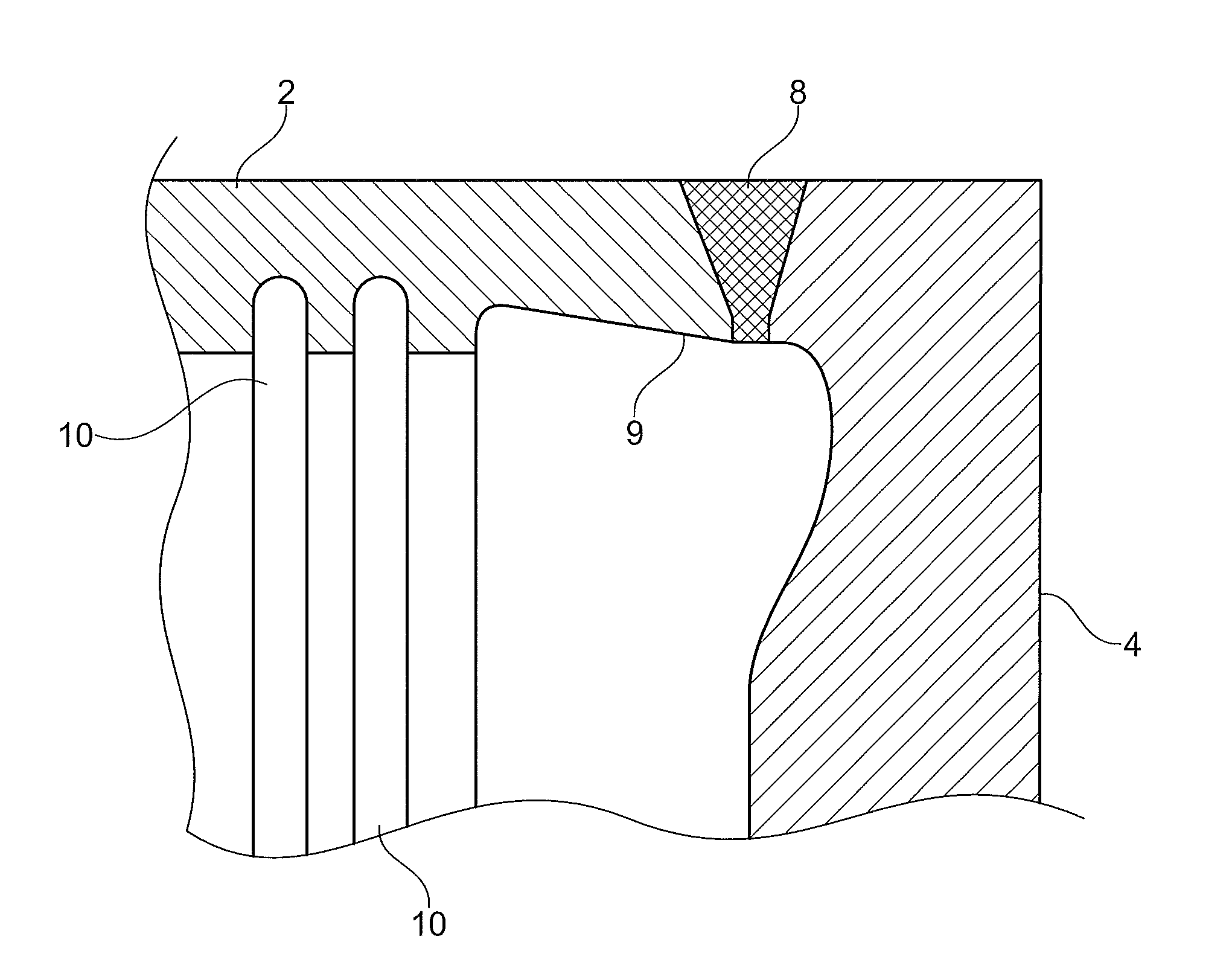

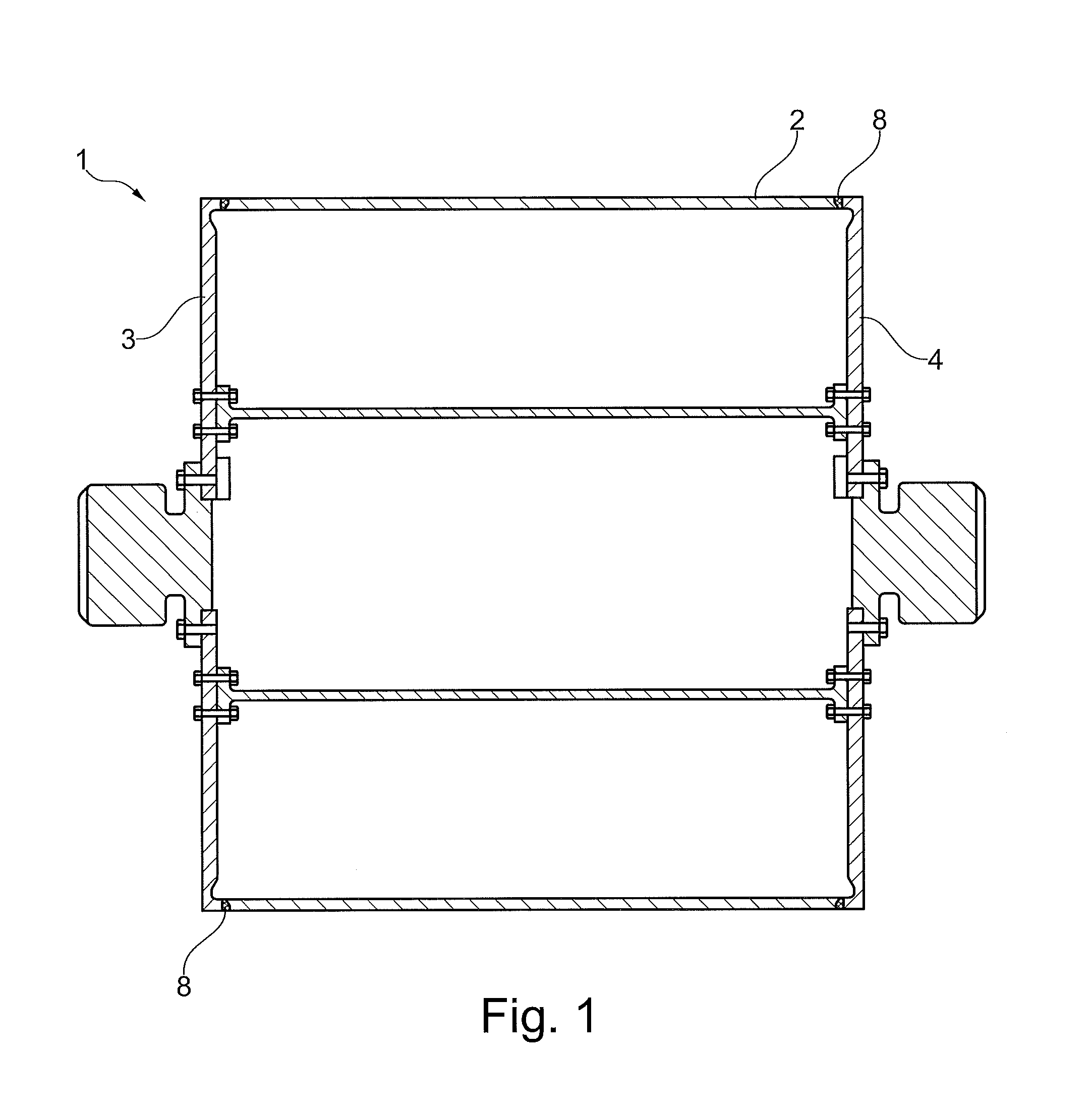

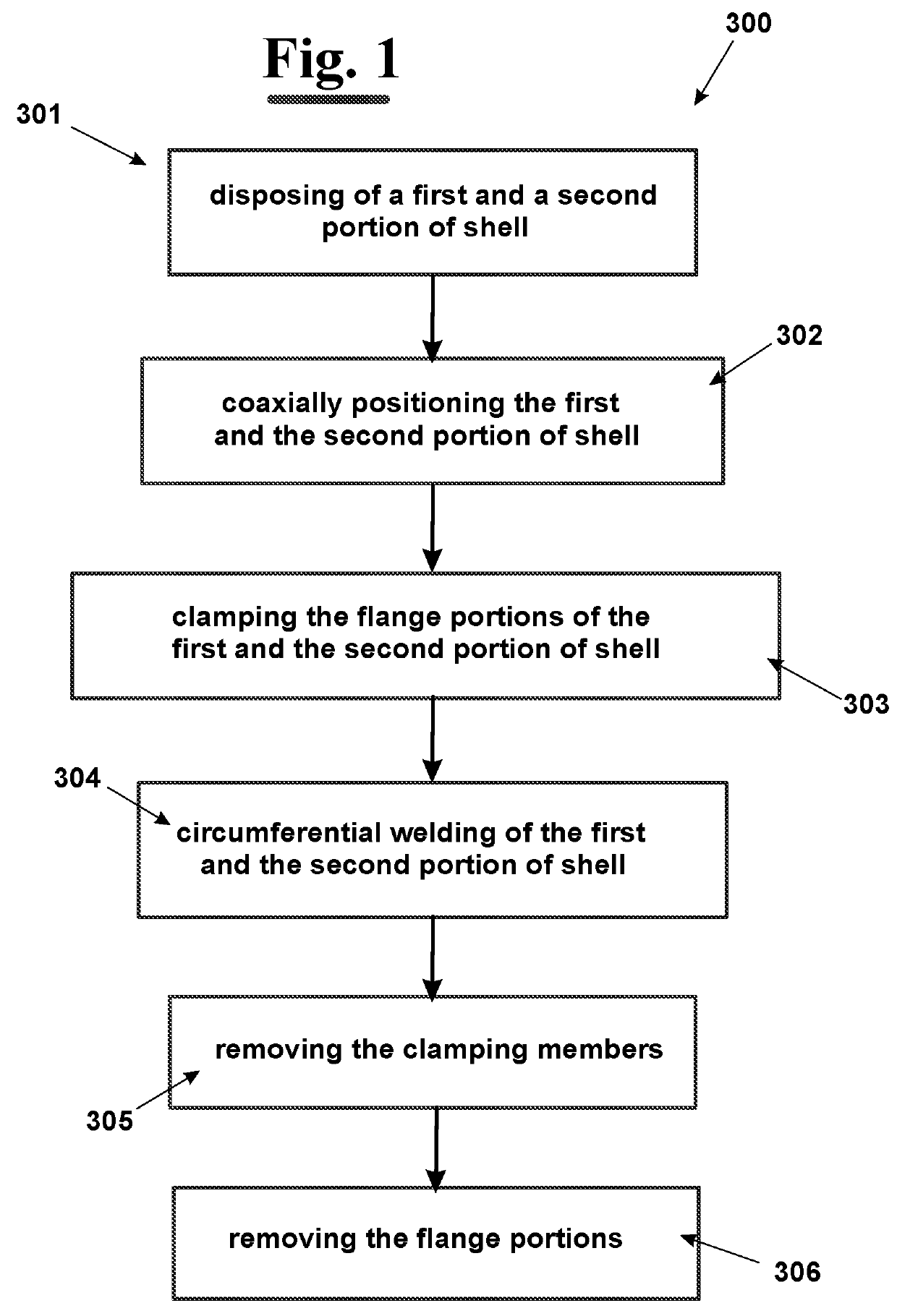

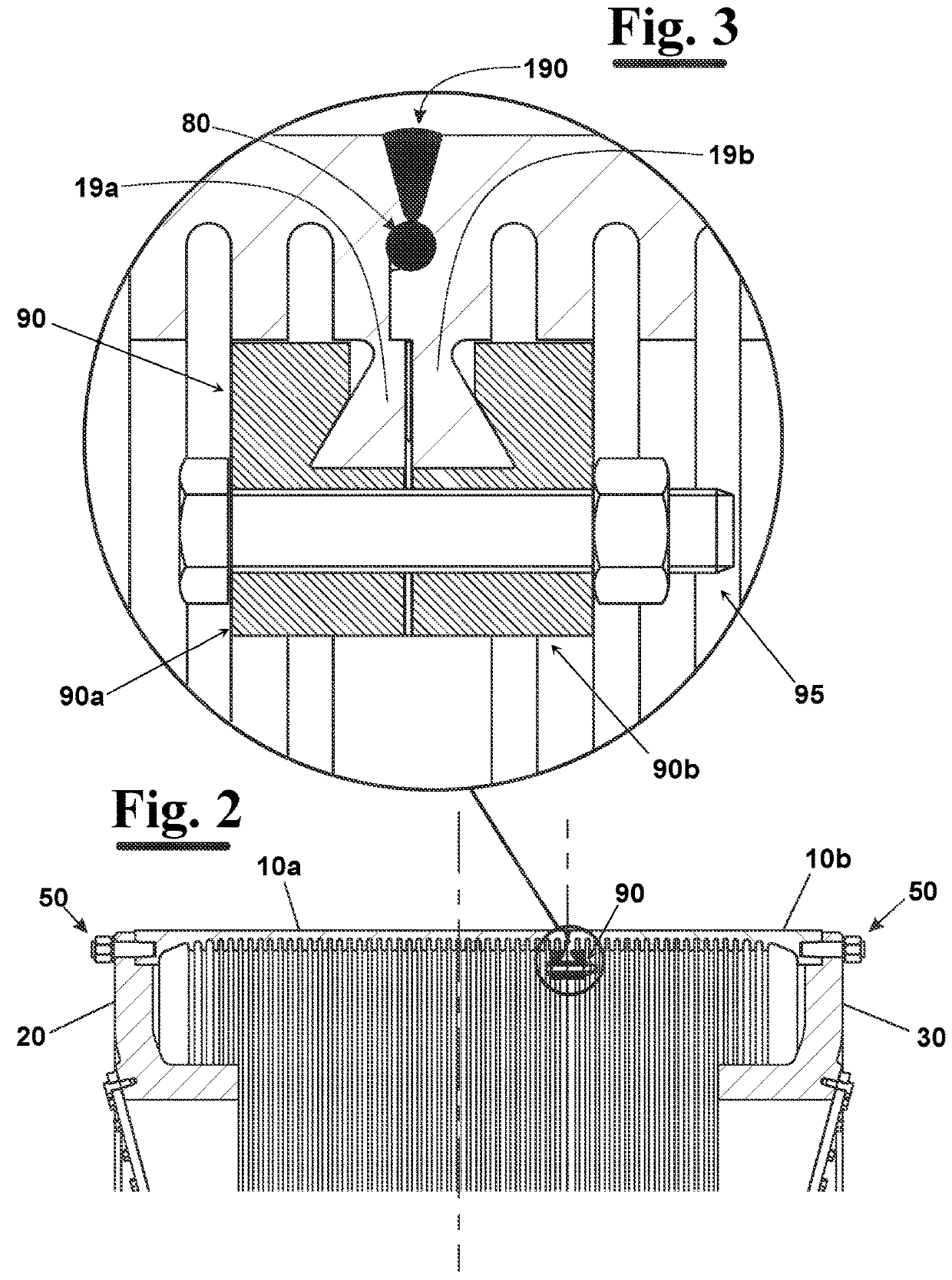

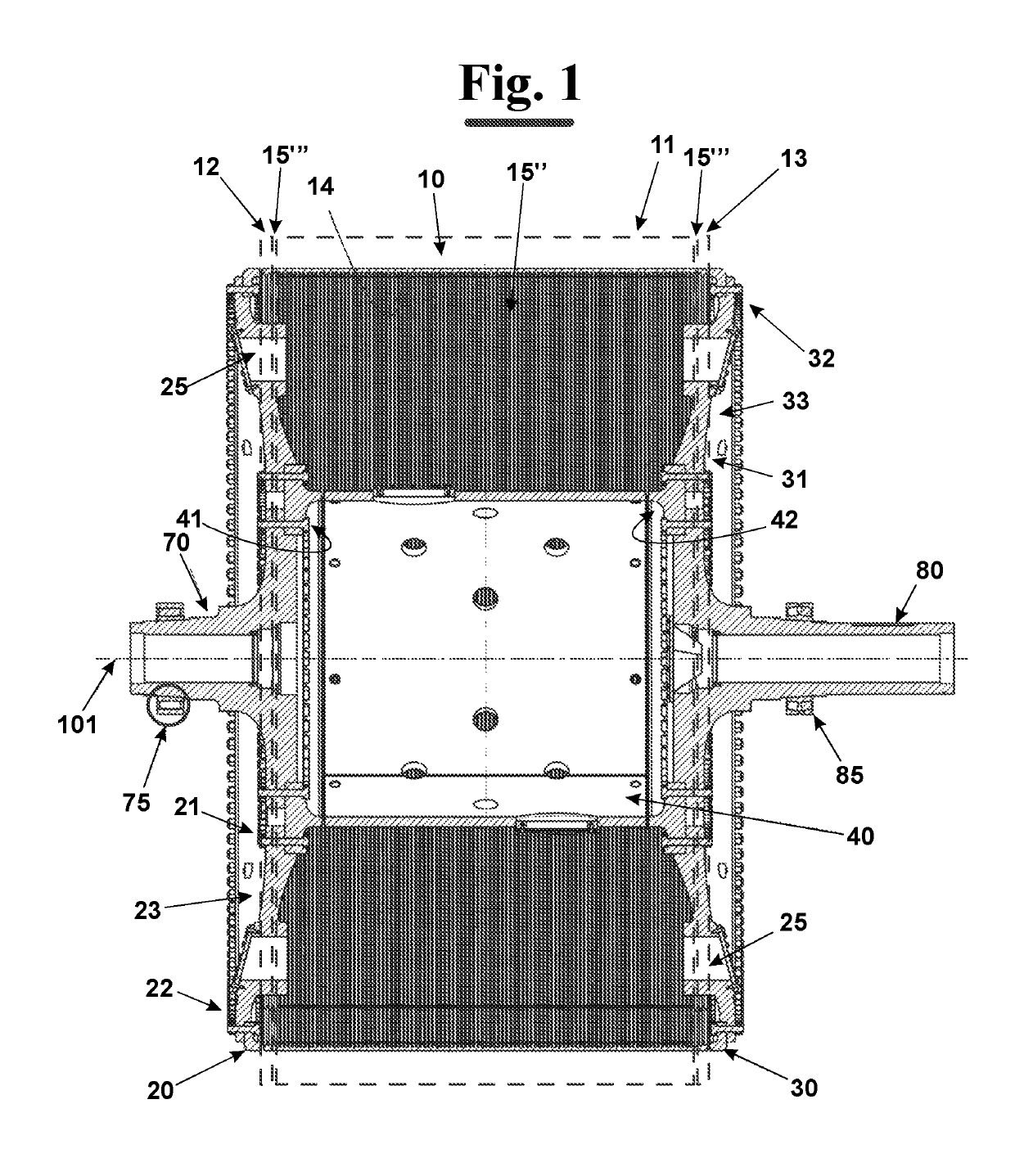

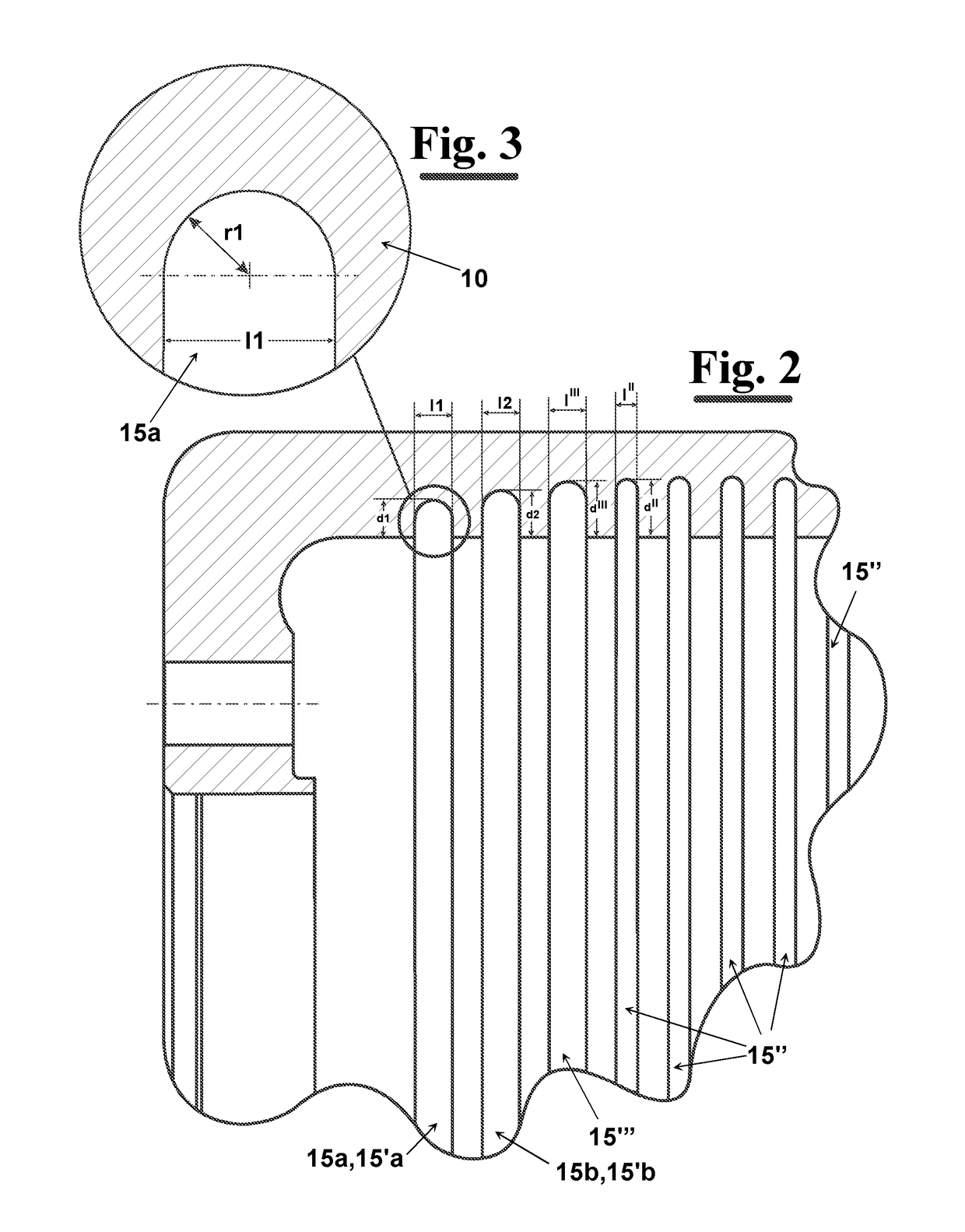

Method for assembling an improved yankee cylinder

A method for producing a Yankee dryer cylinder, or Yankee cylinder, comprises the steps of disposing of a first and of at least a second cylindrical portion of shell. These are made of steel, have the same diameter and are provided with a plurality of grooves at an internal surface. In particular, the portions of shell, at a respective end, are provided of respective flange portions. The method provides to coaxially position the portions of shell up to arrange respective coupling surfaces of the flange portions adjacent one to the other. Then the engagement of the portions of shell is provided by means of a plurality of clamping members, each of which arranged to clamp the adjacent flange portions. Then, it is provided the circumferential welding of the cylindrical portion of the shell that are opposite to the flange portions, and the removal of the clamping members and of the flange portions.

Owner:A CELLI PAPER

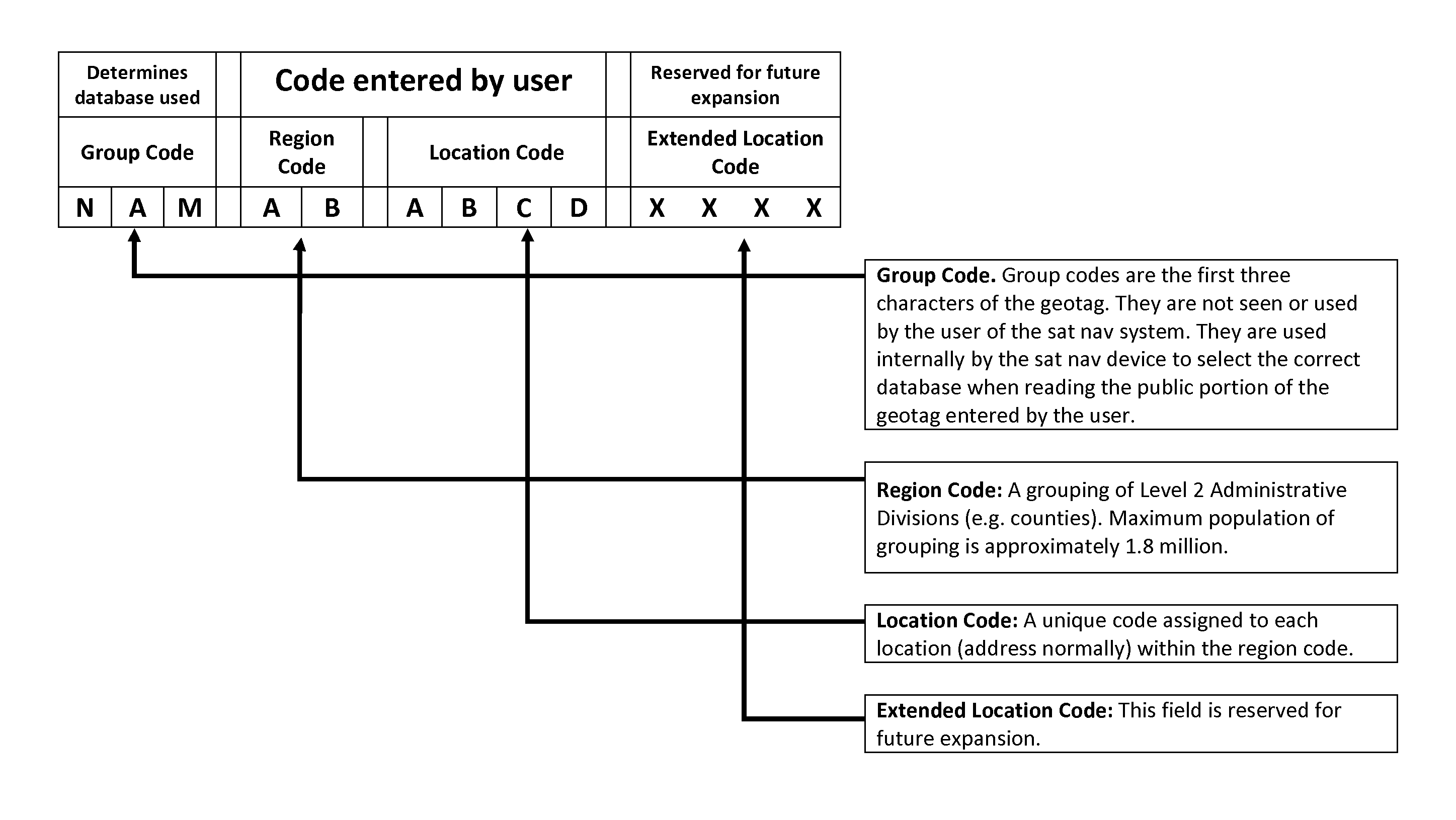

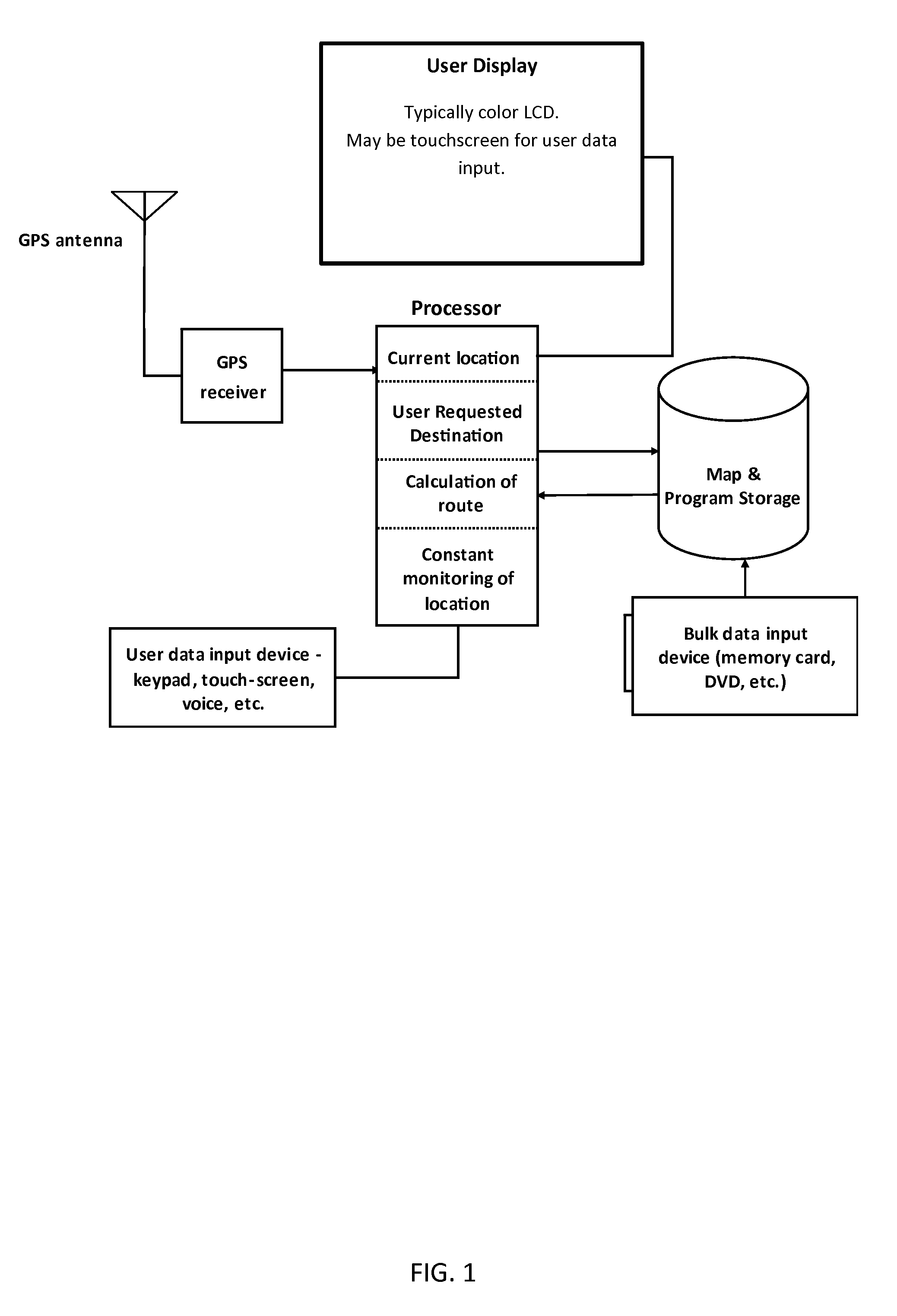

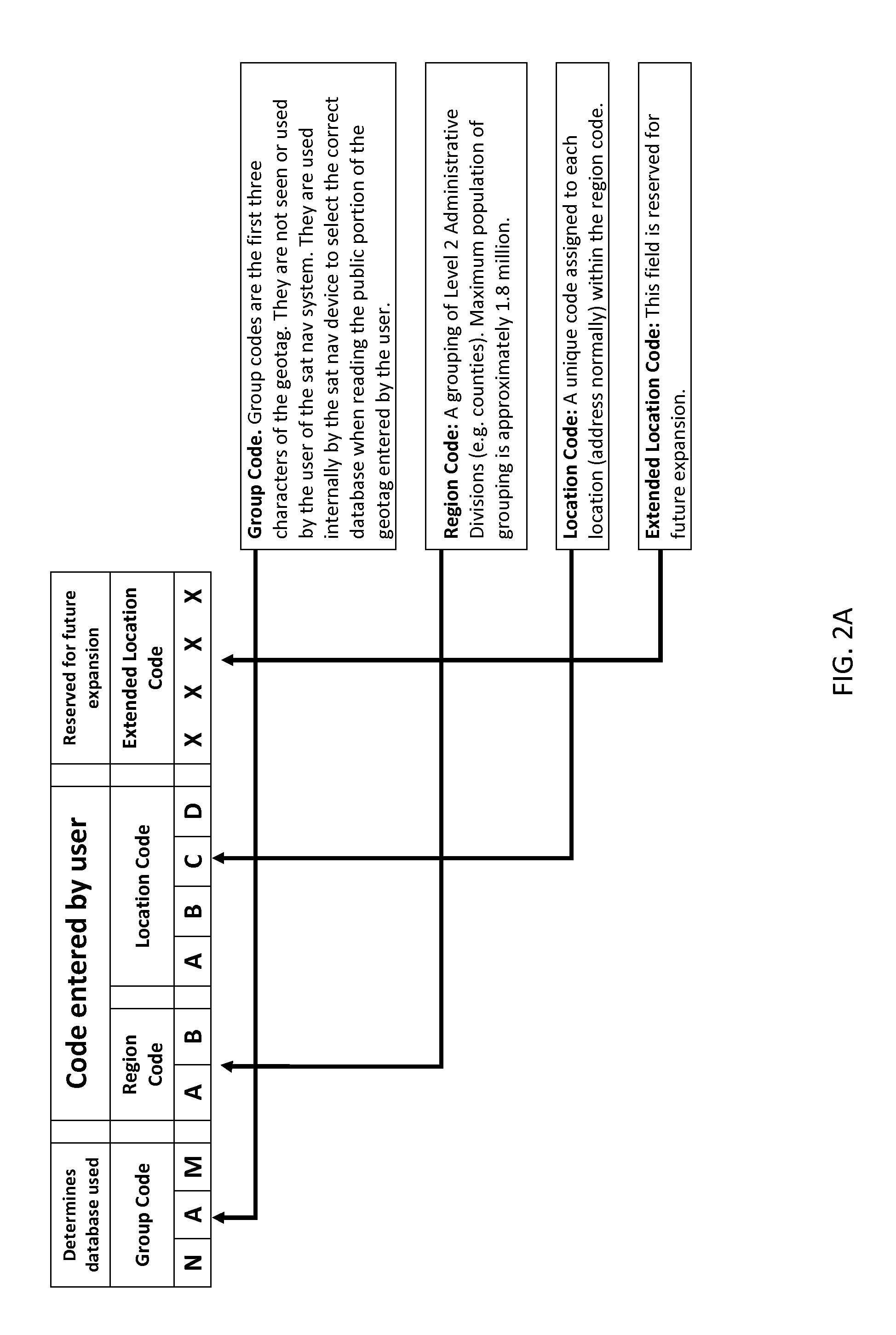

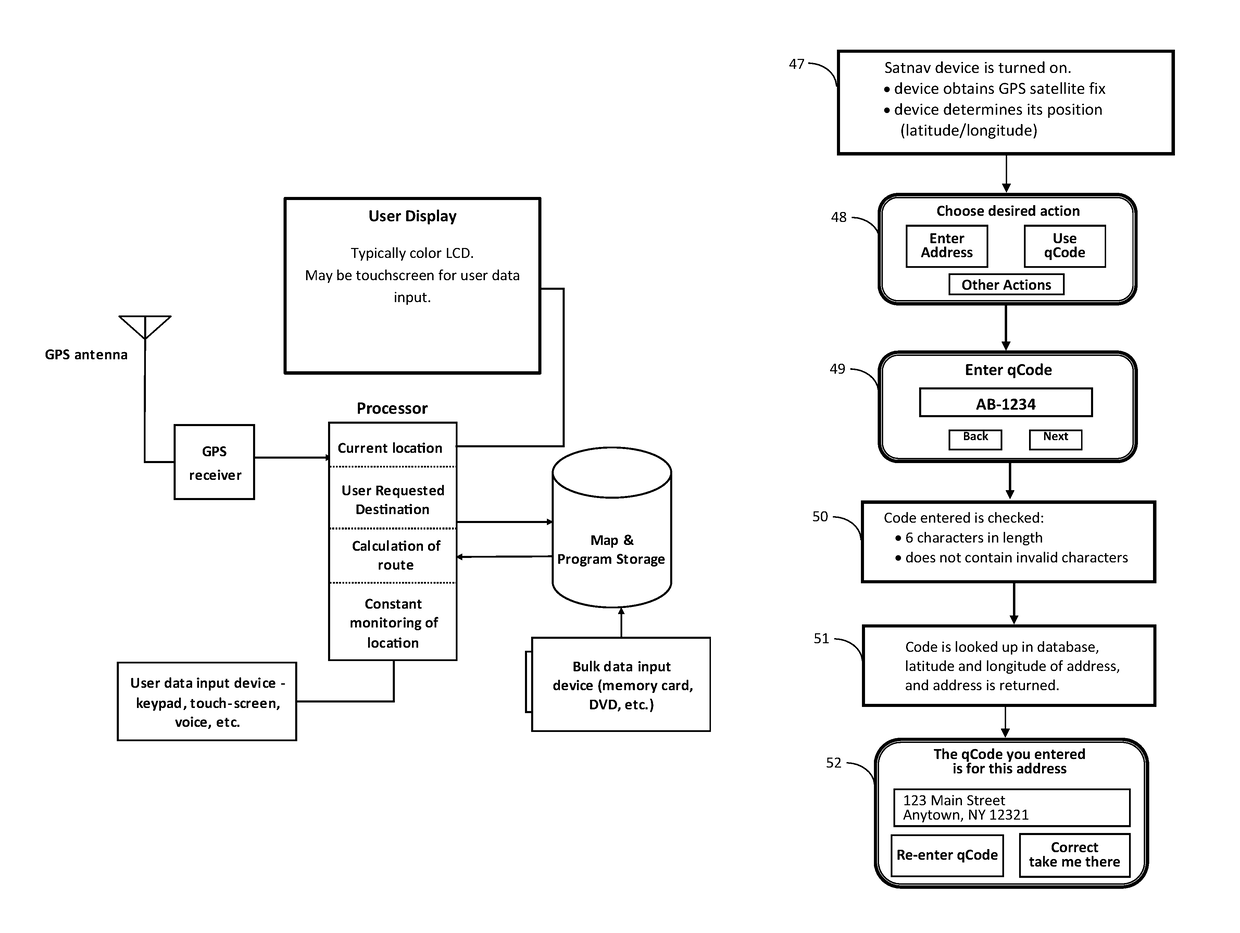

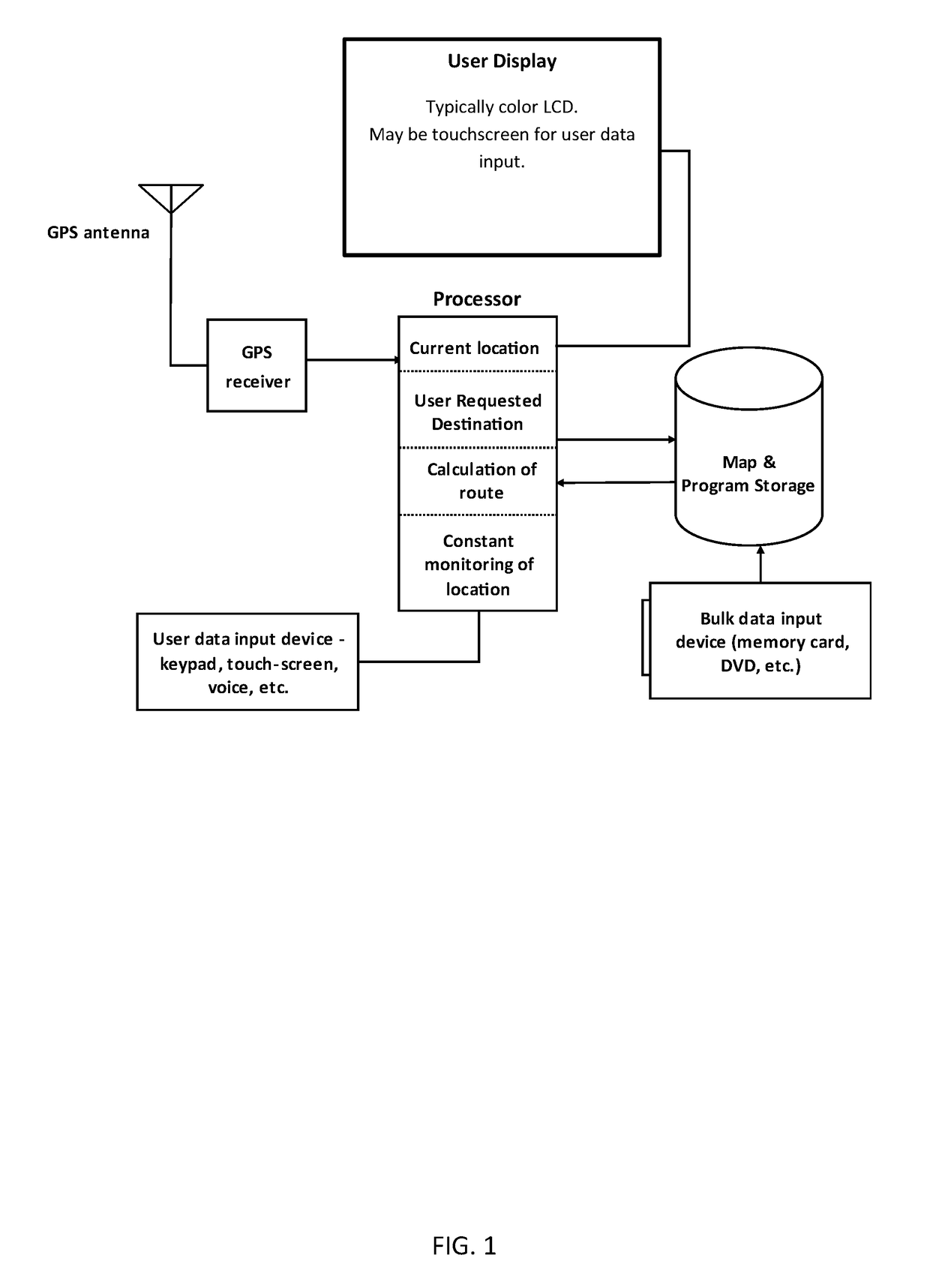

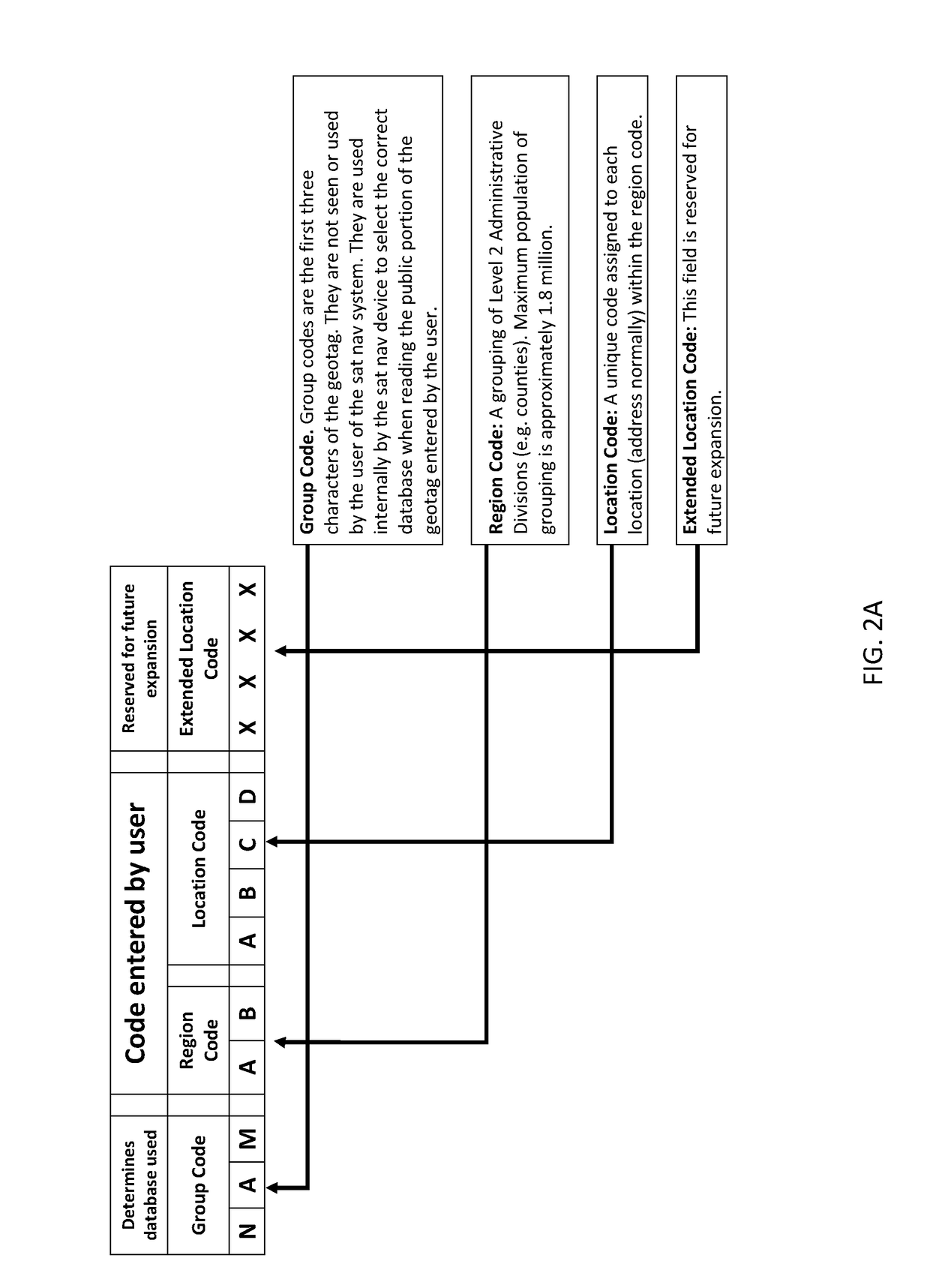

Coding system for satellite navigation system

ActiveUS20150308840A1High degreeConvenient and accurateInstruments for road network navigationRoad vehicles traffic controlParking areaYankee

The present invention provides a method, the QCODE method, of geotagging all postal addresses and other points of interest that one might want to navigate to and which allows the user to identify these addresses and other points of interest with a code consisting of 6 alphanumeric characters or less. A point of interest may or may not have a street address, for example, “the main entrance to the Jefferson Building at the USPTO complex in Alexandria Va.” or “the entrance to the VIP parking area at Yankee Stadium”. The disclosure teaches embodiments that are naturally upgraded to integrate changing spatial information due to addition of countries, better data, political changes, and other similar changes in geographical data. A single geocoding engine is capable of handling the various address formats in use in different countries and jurisdictions.

Owner:HALE MERTON G

Process for manufacturing an improved web material by the in-situ measurement and adjustment of ion concentration

A process having the steps of producing the web material with the papermaking machine; measuring a molar amount of a monovalent inorganic ionizable cation species (MIICS) in the web material; measuring a molar amount of a divalent inorganic ionizable cation species (DIICS) in the web material; calculating a molar ratio of the measured molar amount of the MIICS to the measured molar amount of the DIICS in the web material; determining if the molar ratio of MIICS to DIICS is about less than or equal to 10; and, if the molar ratio of MIICS to DIICS is greater than about 10, adding an amount of DIICS to the papermaking machine to adjust the molar ratio of MIICS to DIICS so the web material adhering to the Yankee drum drying system has a molar ratio of MIICS to DIICS of about less than or equal to 10, is disclosed.

Owner:ELDORADO BRASIL CELULOSE SA

Real time regulation of yankee dryer coating based on predicted natural coating transfer

ActiveUS10329715B2Increase valueLiquid surface applicatorsMechanical working/deformationProcess engineeringYankee

A method is provided for decision support in regulating an adhesive coating applied to Yankee dryers. Online sensors are configured to continuously measure stock characteristics, and additional sensors provide actual stock flow rate and machine speed. A controller predicts potential natural coating application from a fibrous sheet generated from the stock to the Yankee dryer surface, substantially in real time, based on the measured characteristics and sensed actual machine values. An output signal may be provided to a display unit, wherein an optimal adhesive coating feed rate may be determined and displayed for operator decision support. The controller may in an automatic mode be configured to regulate the adhesive coating feed rate based on a comparison of one or more determined optimal values associated with respective actual values. The method may include identifying fiber source changes in real time, and predicting a natural coating potential based partly on predetermined correlations.

Owner:BUCKMAN LAB INT INC

Nozzle insert for a yankee impingement hood

ActiveUS20090007454A1Uniform temperatureGuaranteed uniform velocityDryer sectionDrying gas arrangementsHeat lossesThermal radiation

The present invention includes a nozzle insert for use in a drying machine of the type used in paper web drying. The nozzle insert of the present invention includes at least one intake having a central portion, wherein a pair of center vanes is disposed for directing airflow. The central portion is bounded by at least one turning vane adapted for directing airflow in a lateral direction. For each turning vane, there is at least one straightening vane adapted for curtailing swirling of the airflow. The vanes are oriented at optimal angles for directing the flow of the nozzle in a lateral direction, while permitting some air to penetrate the central portion through a series of ports. The intakes are bounded by a series of insulated bulkheads, which serve to direct airflow and contain heat-loss through thermal emission.

Owner:VALMET OY

Method for producing a yankee cylinder

The method involves cutting and rolling of coated plates. The welding of shell plates to several cylinder sections (8,9) is performed. The mechanical preprocessing of individual cylinder sections on the inner and outer sides, and at the end faces is performed. The welding of individual cylinder sections to a finished cylindrical surface (2) of Yankee cylinder is performed.

Owner:ANDRITZ AG

Methods of measuring a characteristic of a creping adhesive film and methods of modifying the creping adhesive film

ActiveUS9182271B2Analysing fluids using sonic/ultrasonic/infrasonic wavesResonant frequencyQuartz crystal microbalancePredicting performance

Owner:KEMIRA OY

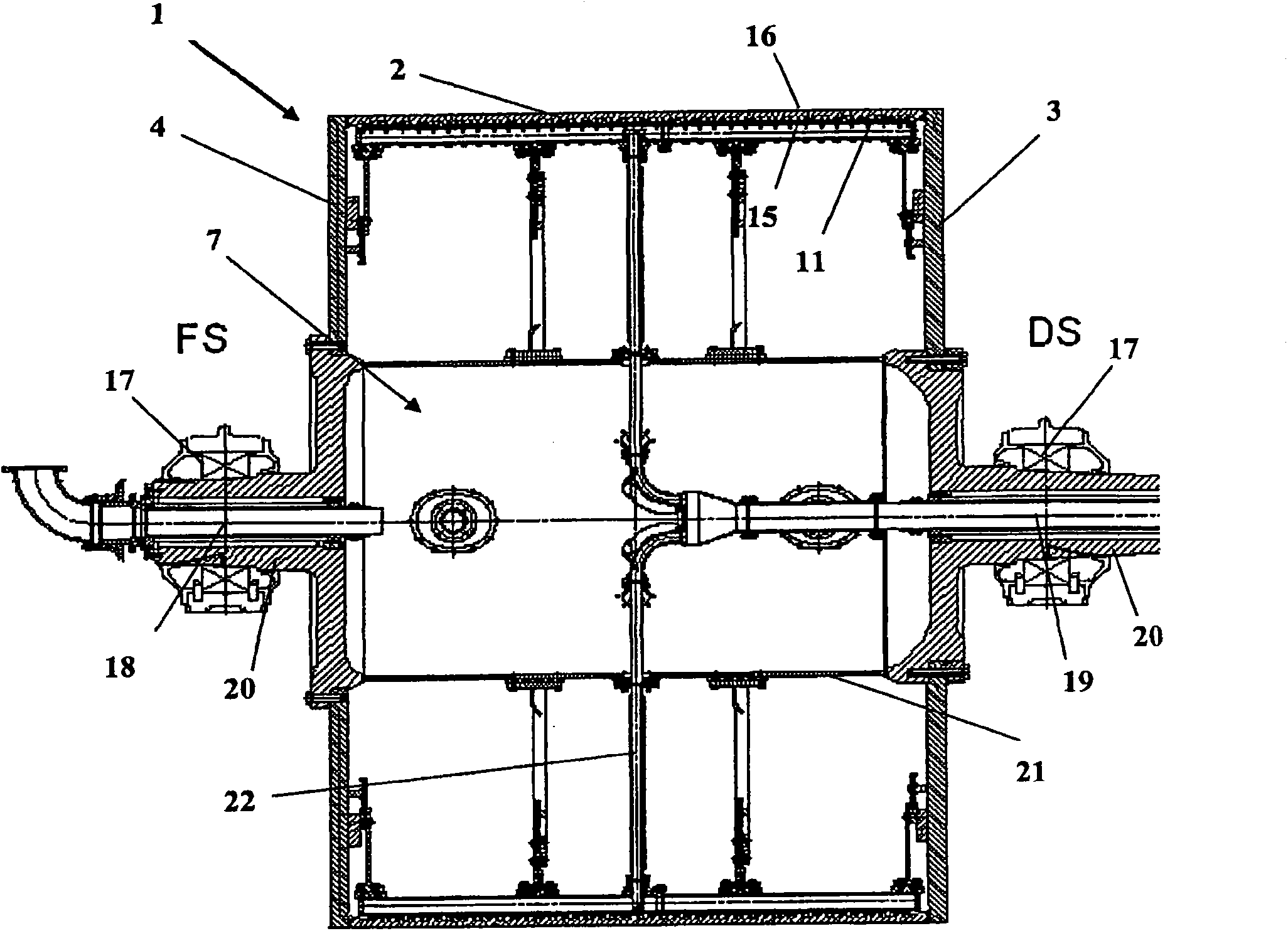

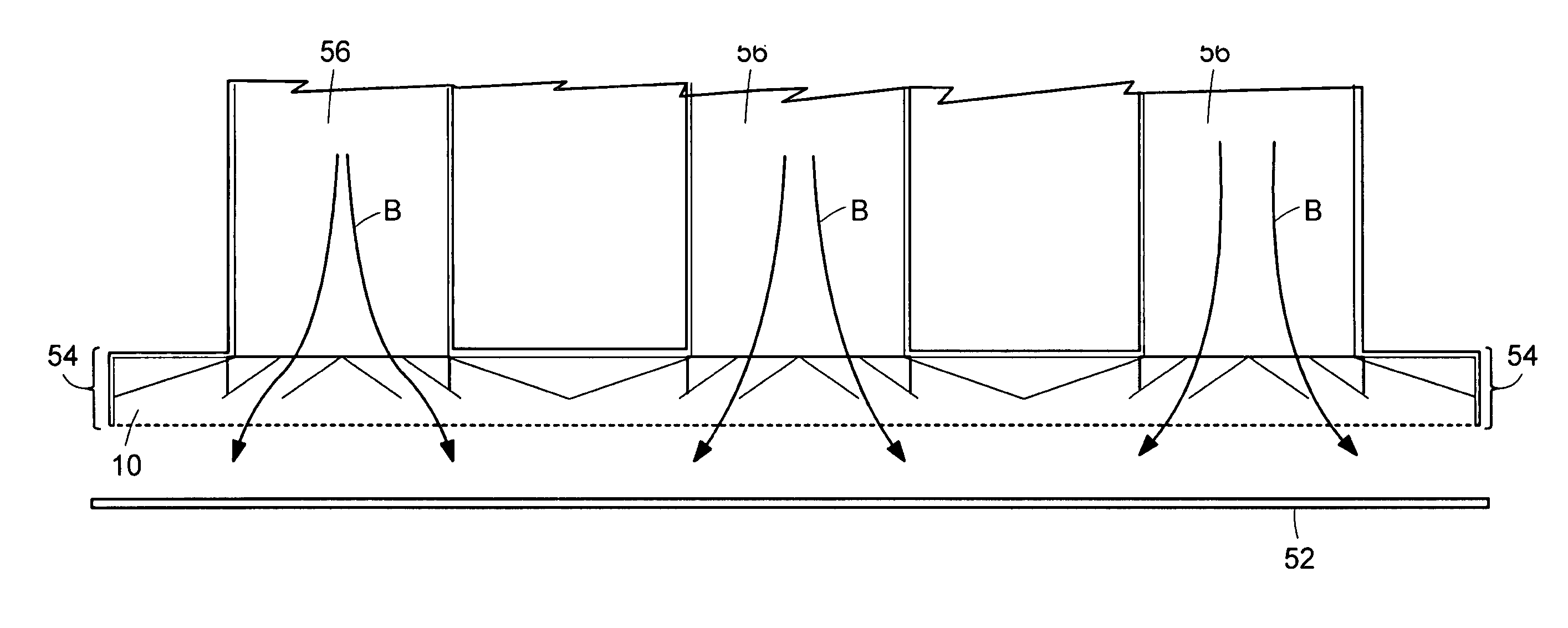

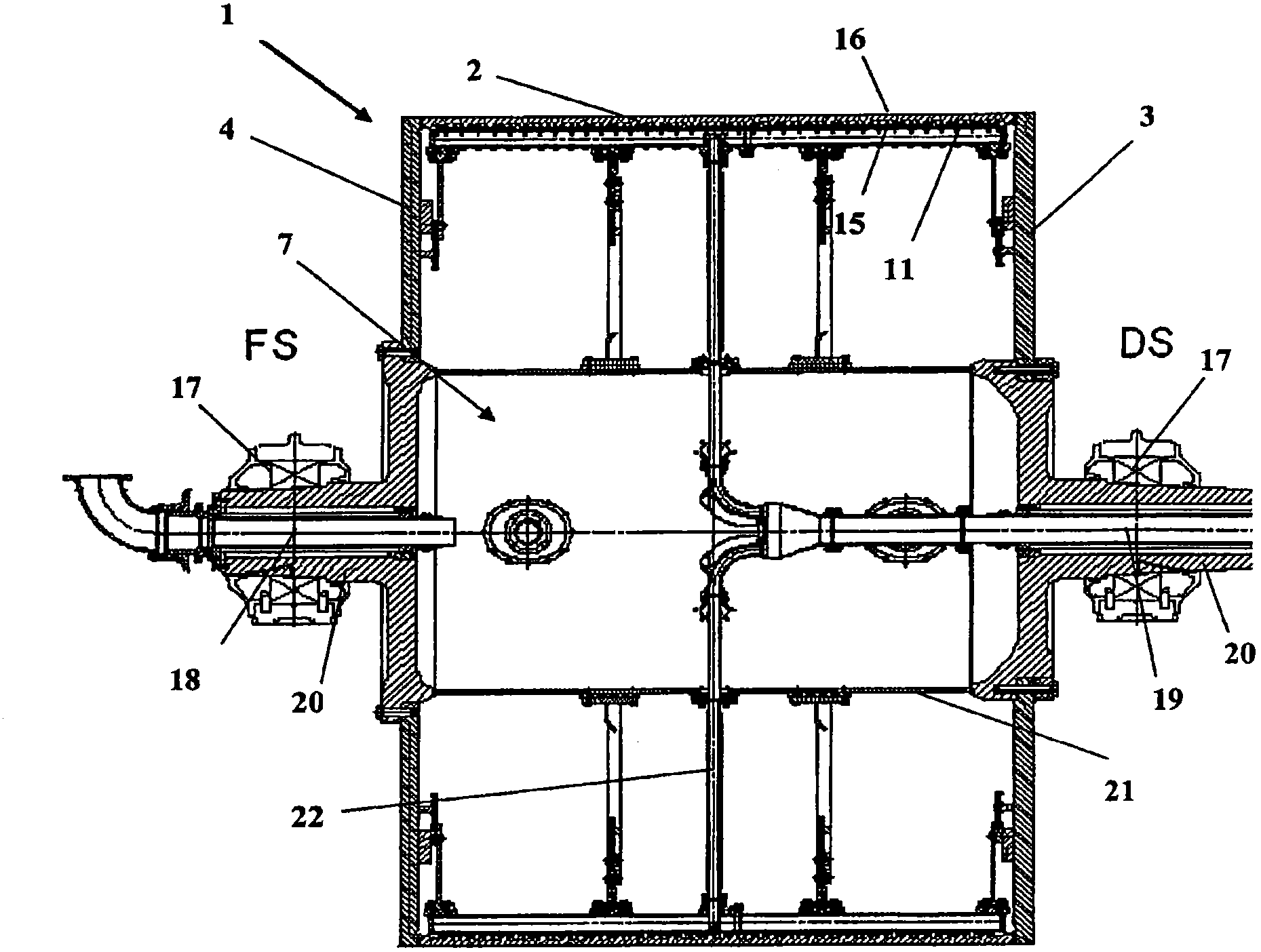

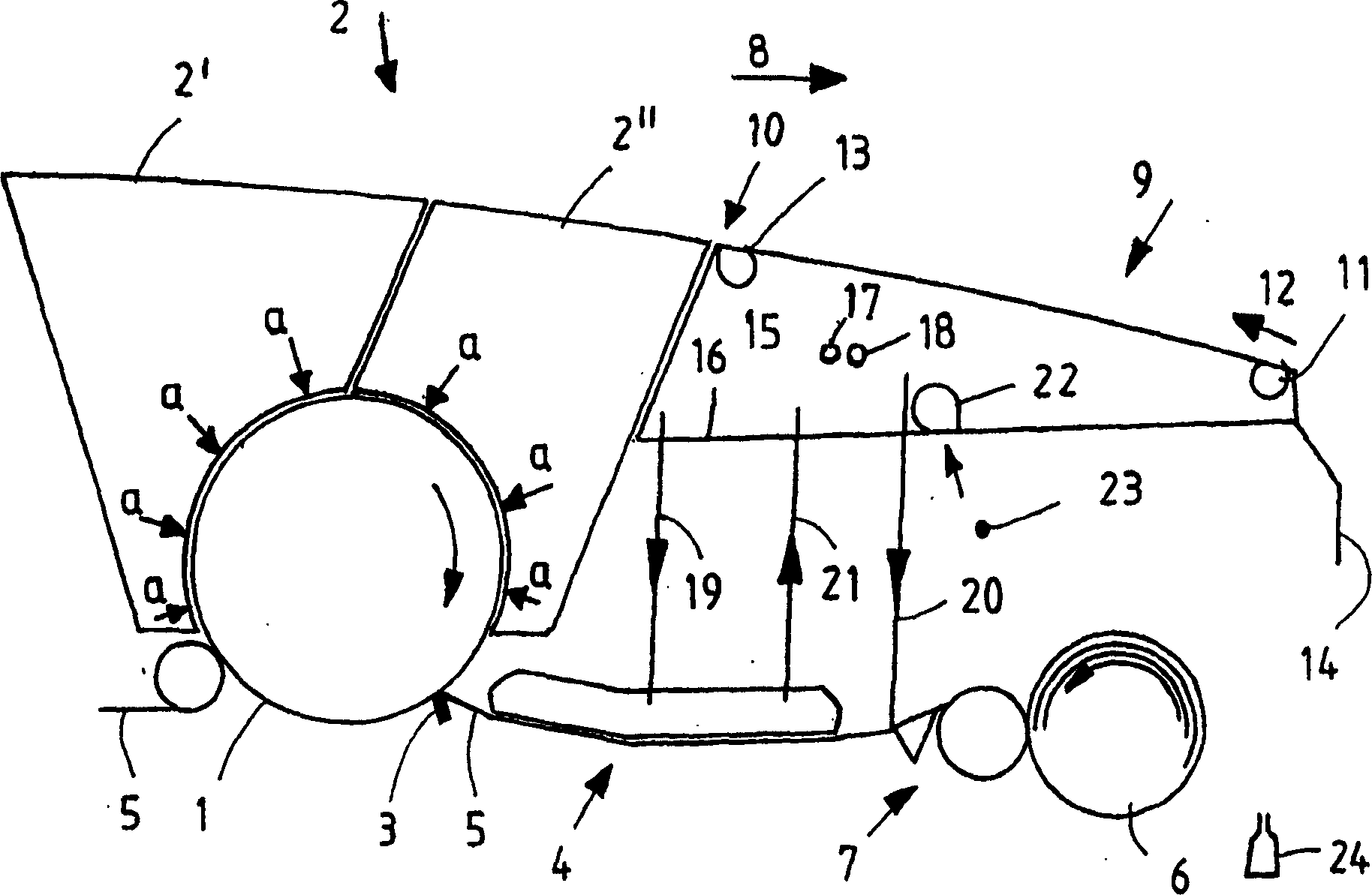

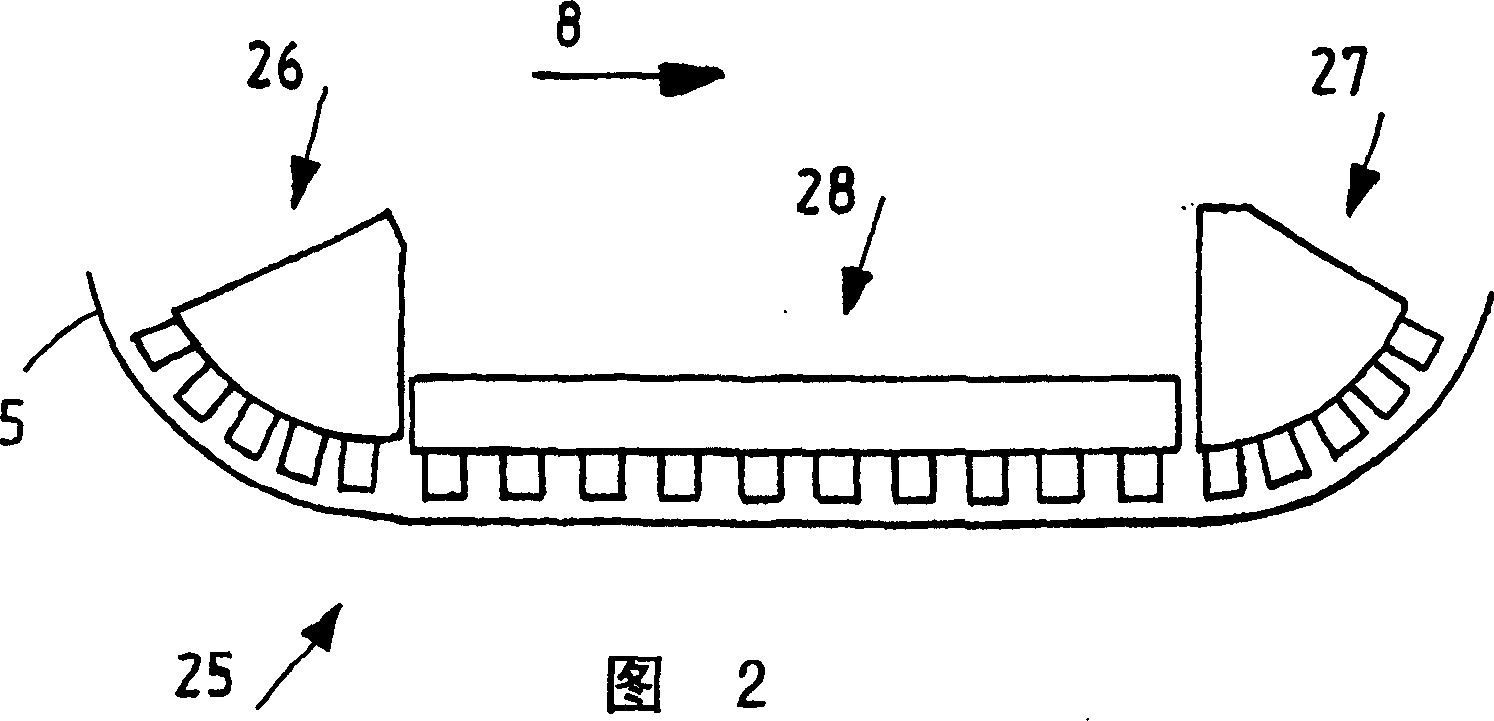

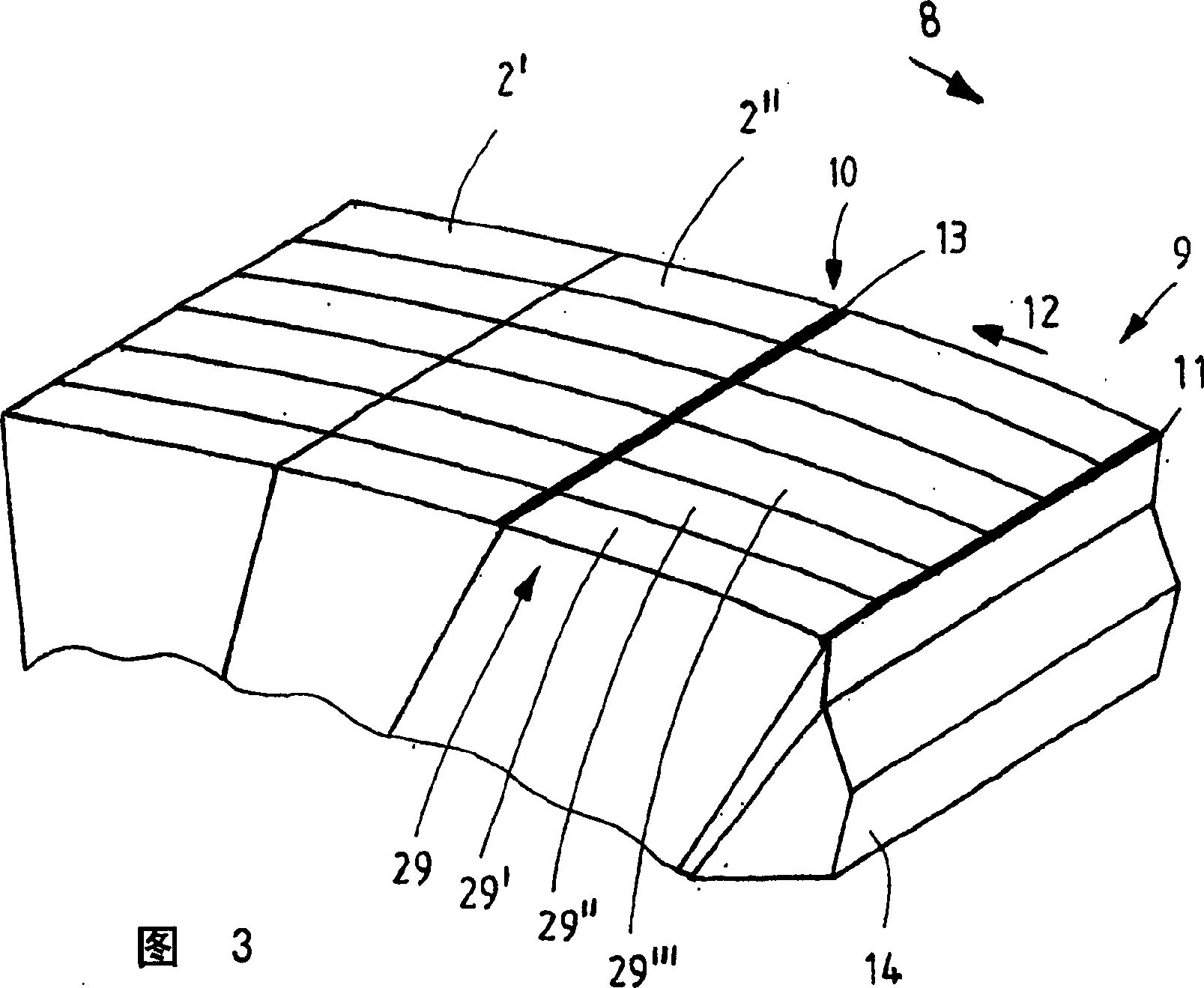

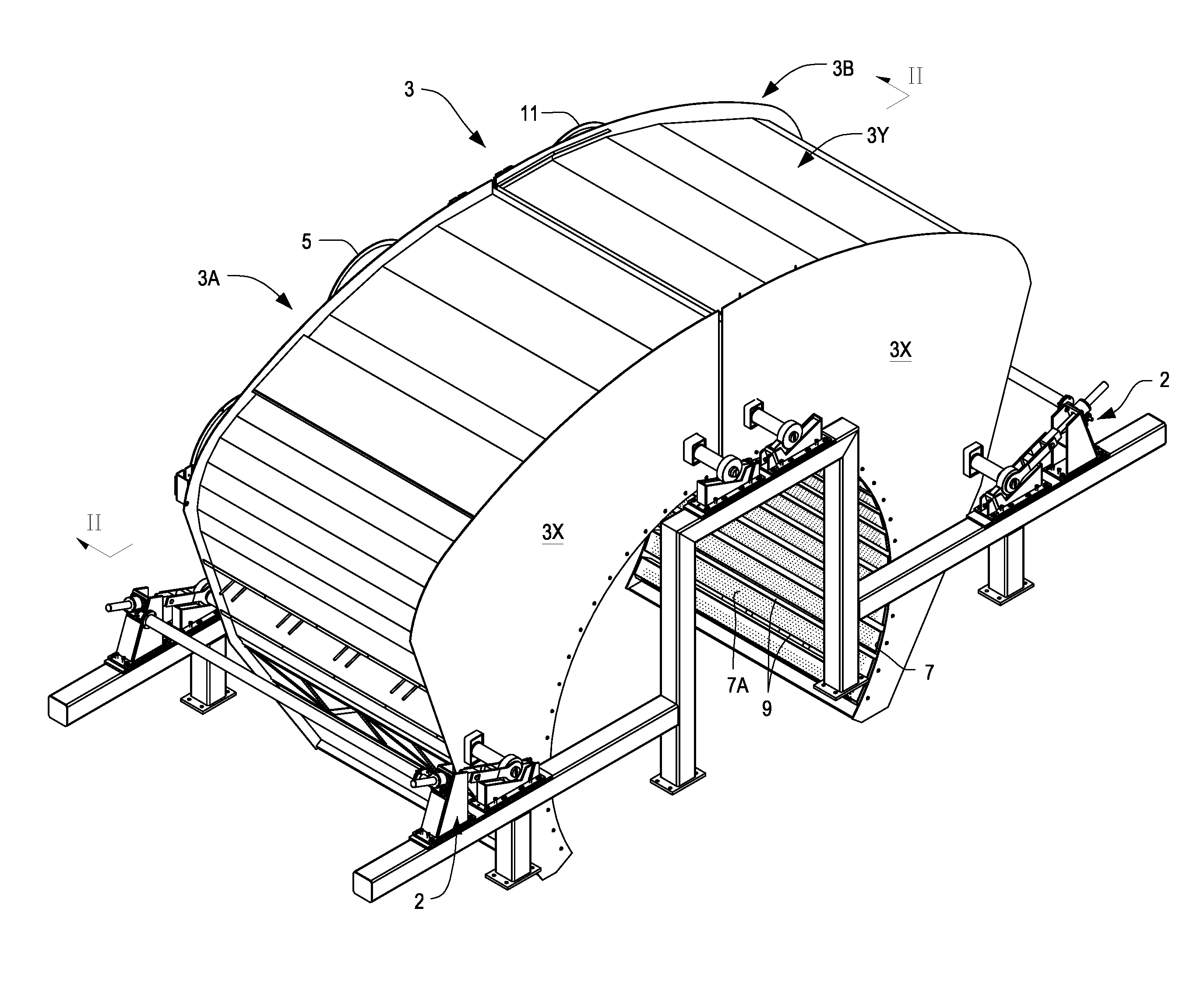

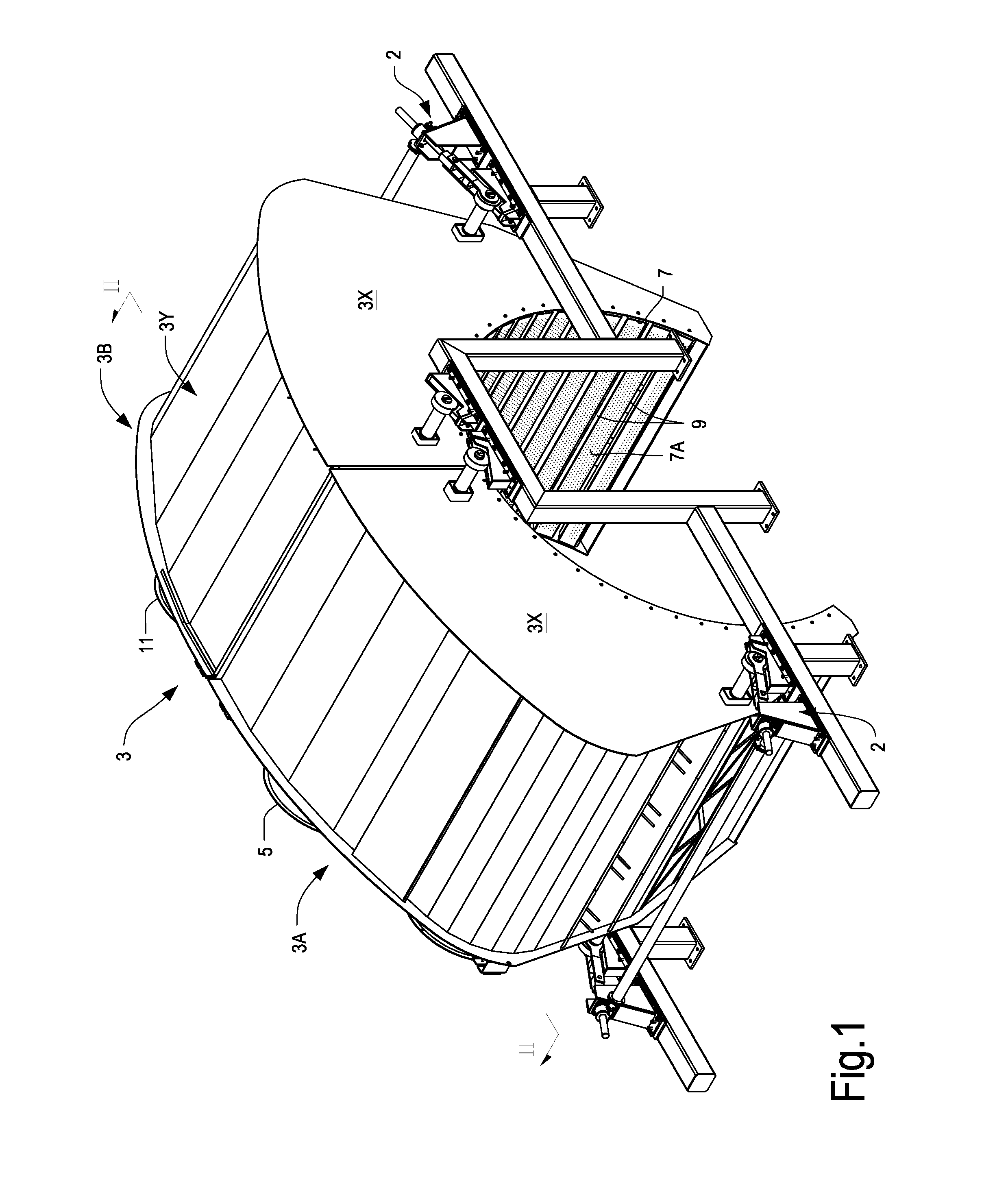

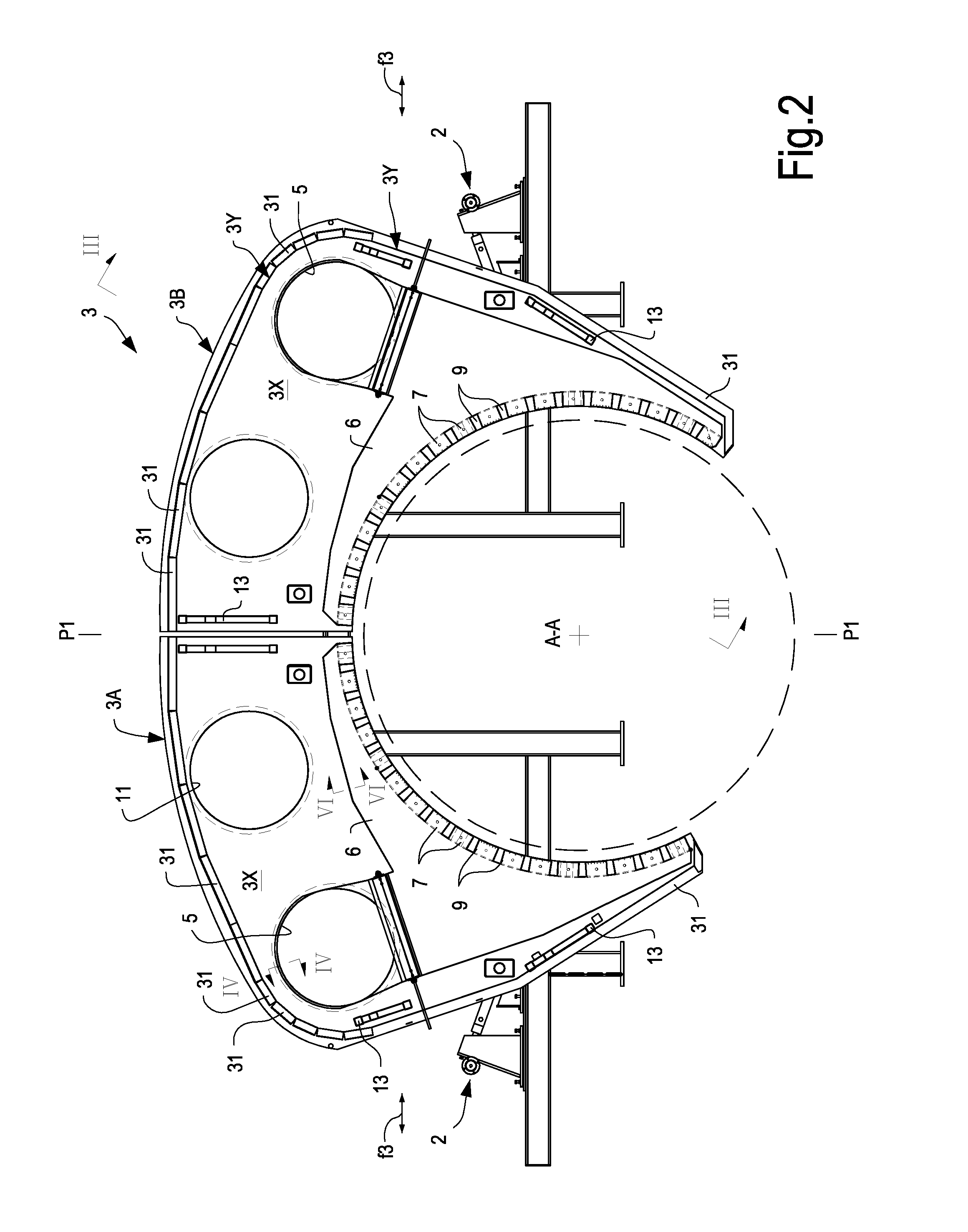

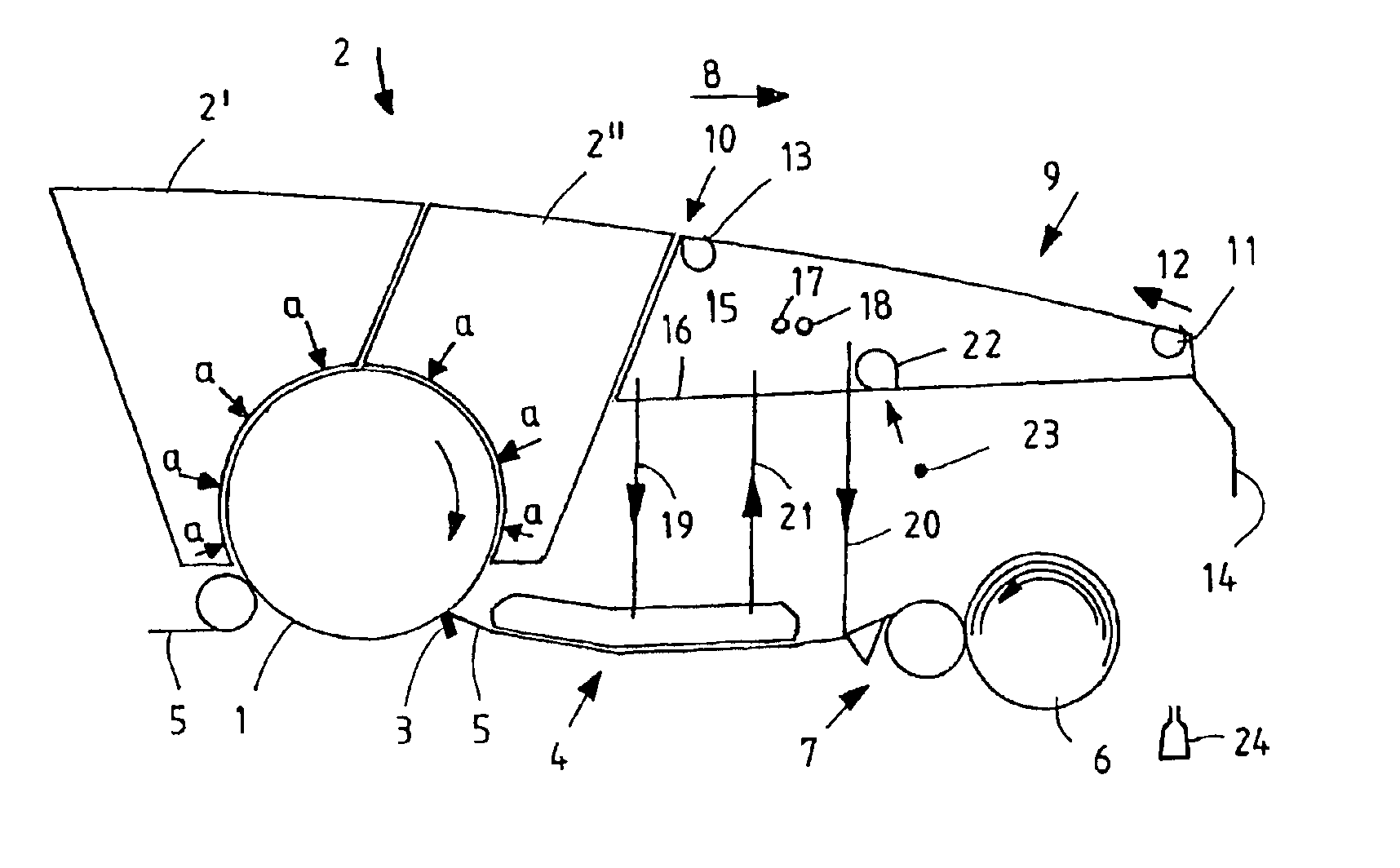

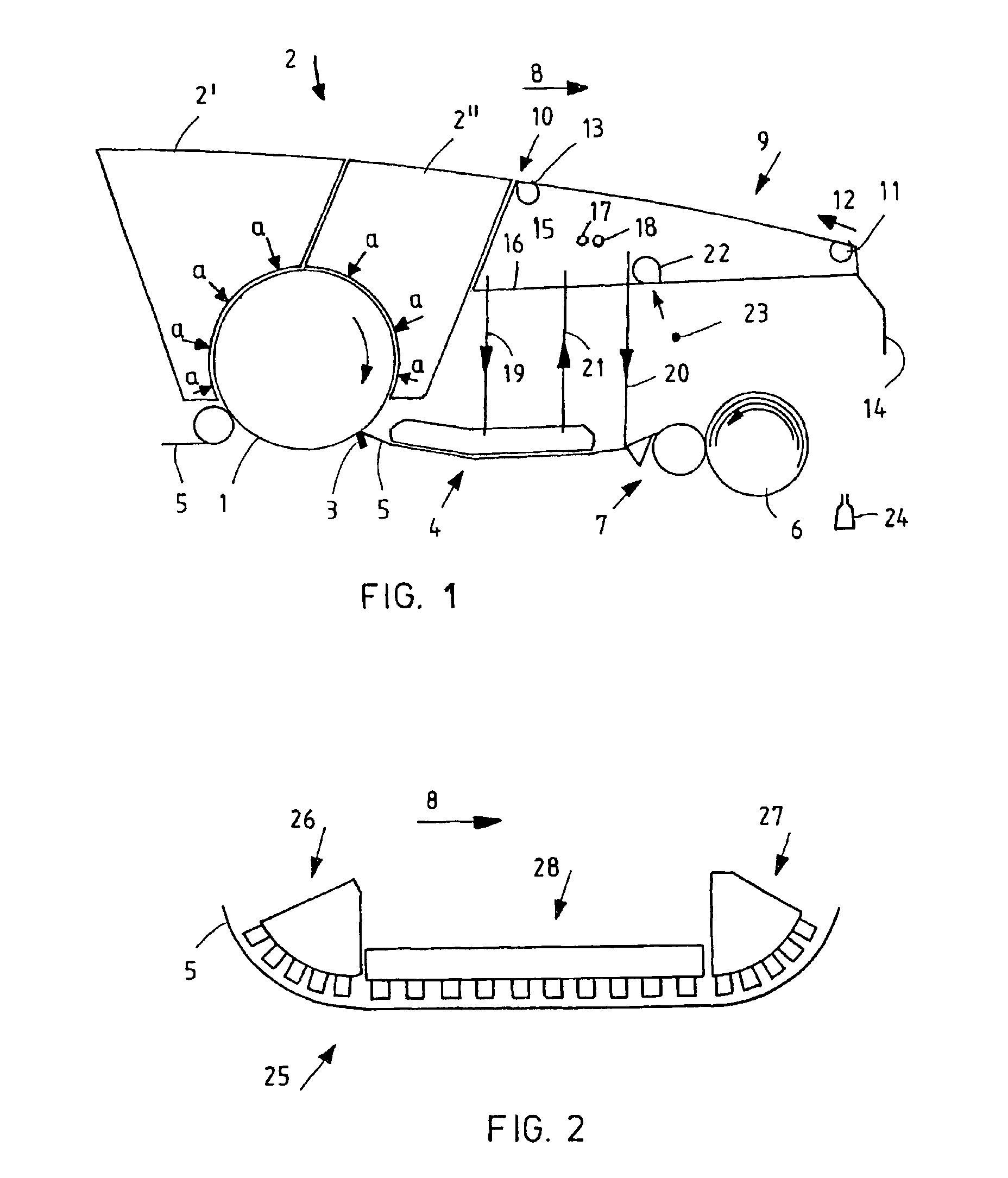

A yankee drying hood arrangement, a yankee drying cylinder fitted with a yankee drying hood arrangement and a method of drying a fibrous web

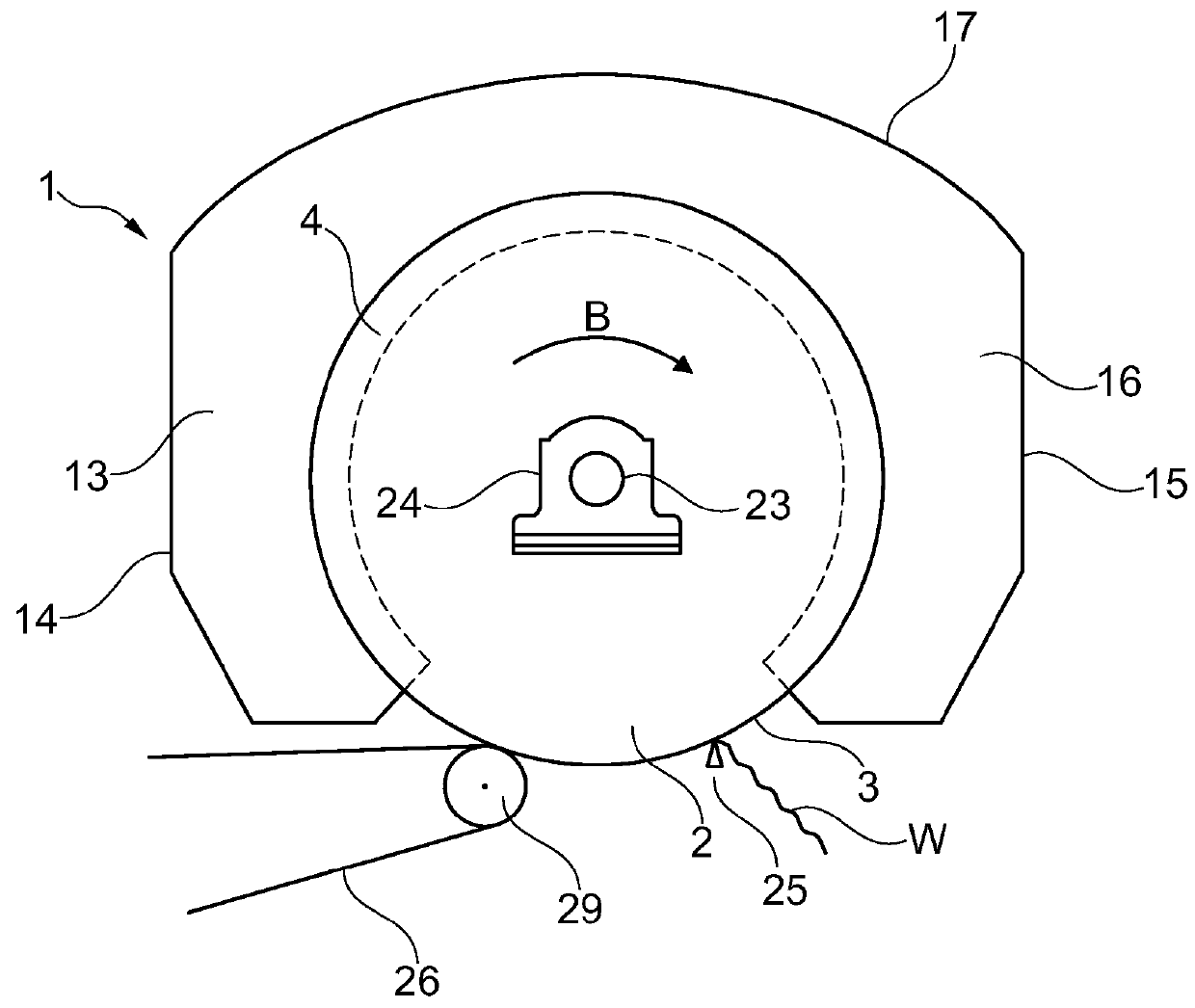

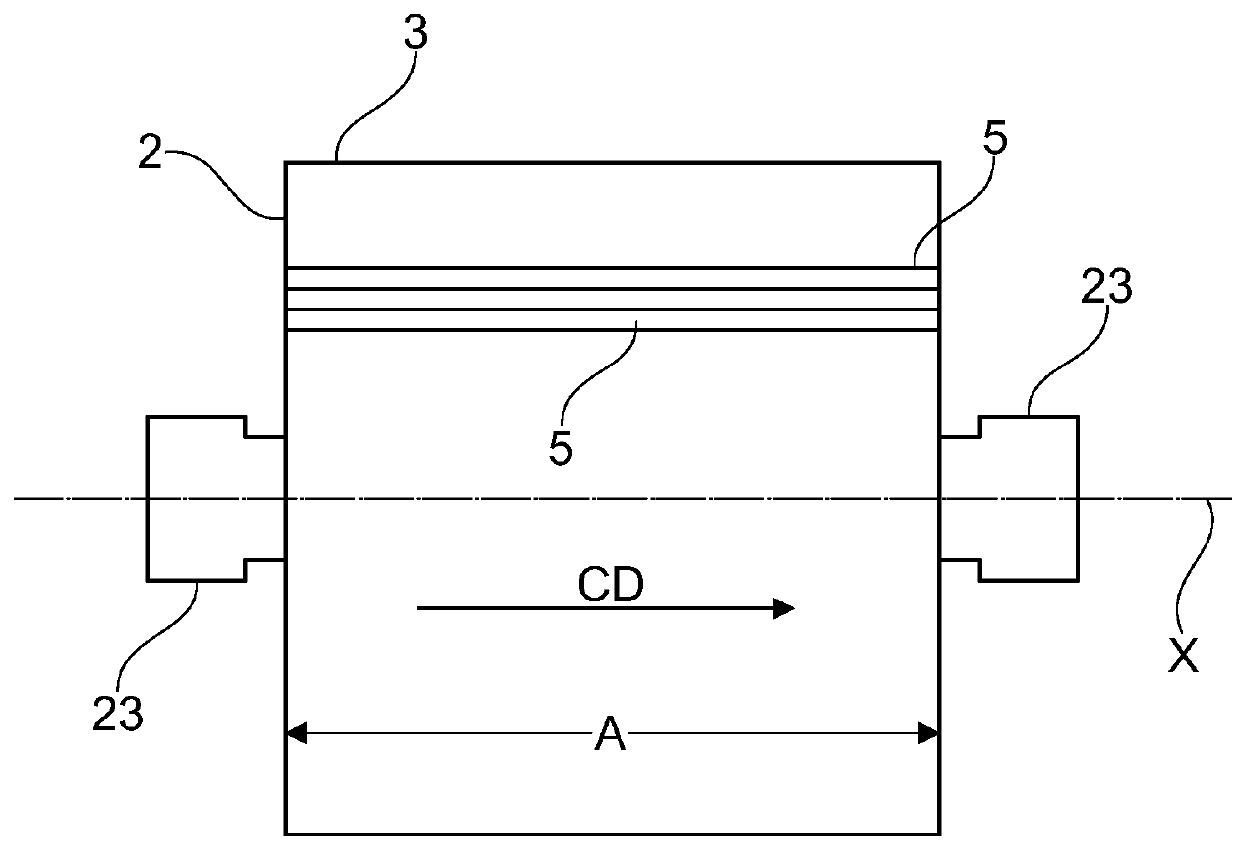

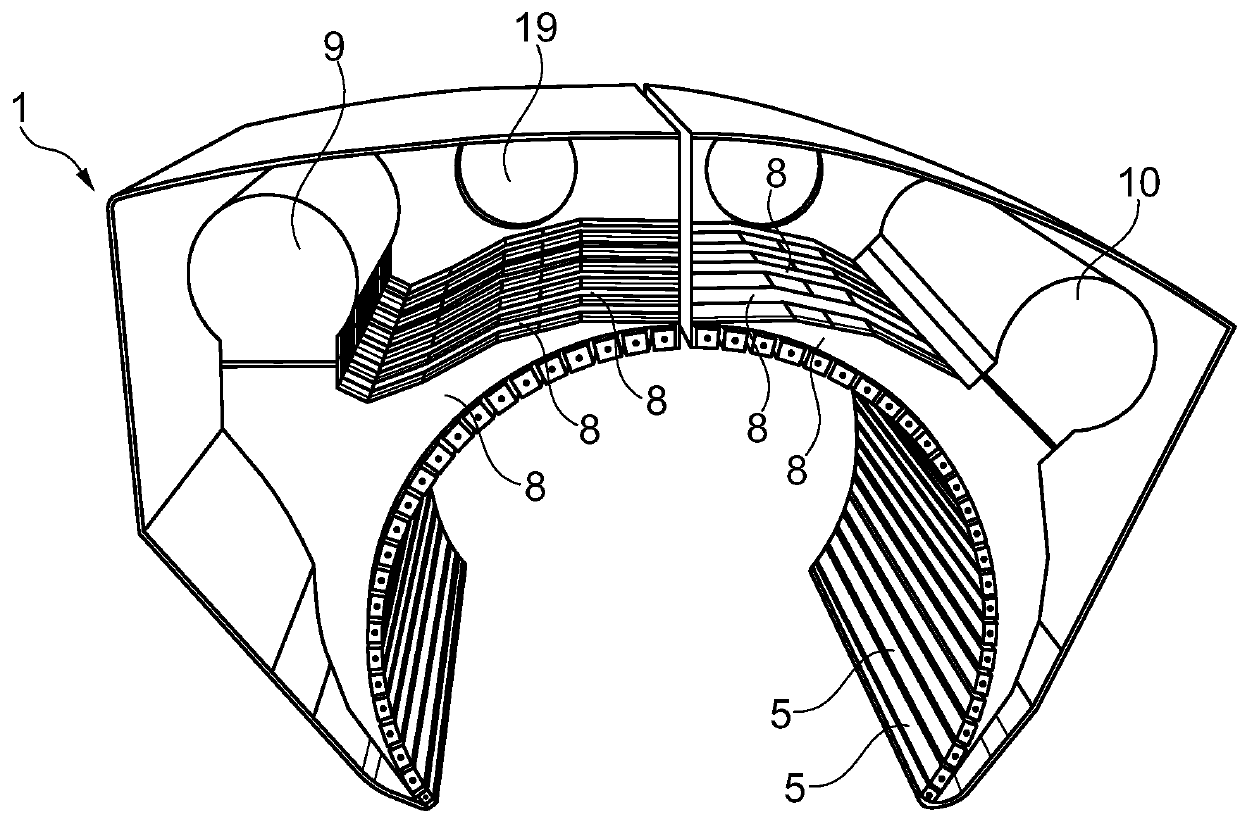

The invention relates to a Yankee drying hood arrangement (1) which is shaped to be fitted over a Yankee drying cylinder (2) such that the drying hood arrangement (1) can cover a part (4) of the circular cylindrical surface (3) of a Yankee drying cylinder (2). The Yankee drying hood arrangement (1) comprises a plurality of nozzle boxes (5) distributed equidistantly around an imaginary axis (X) such that, when the Yankee drying hood arrangement (1) is fitted over a Yankee drying cylinder (2), the nozzle boxes (5) are spaced from the circular cylindrical surface (3) of the Yankee drying cylinder (2) but form a curved structure (6) that follows the outer contour of the circular cylindrical surface (3) of the Yankee drying cylinder (2). Each nozzle box (5) has a longitudinal extension in a direction parallel to the axial extension of the Yankee drying cylinder (2) and each nozzle box (5) has openings (7) distributed along the longitudinal extension of the nozzle box (5) through which openings (7) a fluid such as hot air can exit the nozzle boxes (5) and stream towards the circular cylindrical surface (3) of the Yankee drying cylinder (2) at different points at different points along the axial extension of the Yankee drying cylinder (2). The Yankee drying arrangement further comprises a plurality of distributor conduits (8) for a fluid such as hot air and the distributor conduits (8) extend in the circumferential direction around the curved structure (6) formed by the nozzle boxes (5). Each distributor conduit (8) is in communication with several nozzle boxes (5) such that a fluid such as hot air can stream from each distributor conduit (8) to several different nozzle boxes (5). At least one main supply conduit (9, 10) for a fluid such as hot air is in communication with the distributor conduits (8) such that a fluid such as hot air can stream to the distributor conduits (8). The distributor conduits (8) are oriented around the curved structure (6) of the nozzle boxes (5) in such a pattern that, when one and the same distributor conduit (8) communicates with different nozzle boxes (5), it does so at different points along the longitudinal extension of the different nozzle boxes (5). The invention also relates to a Yankee drying cylinder fitted with the inventive Yankee drying hood arrangement and to a method of drying a fibrous web.

Owner:VALMET S P A IT

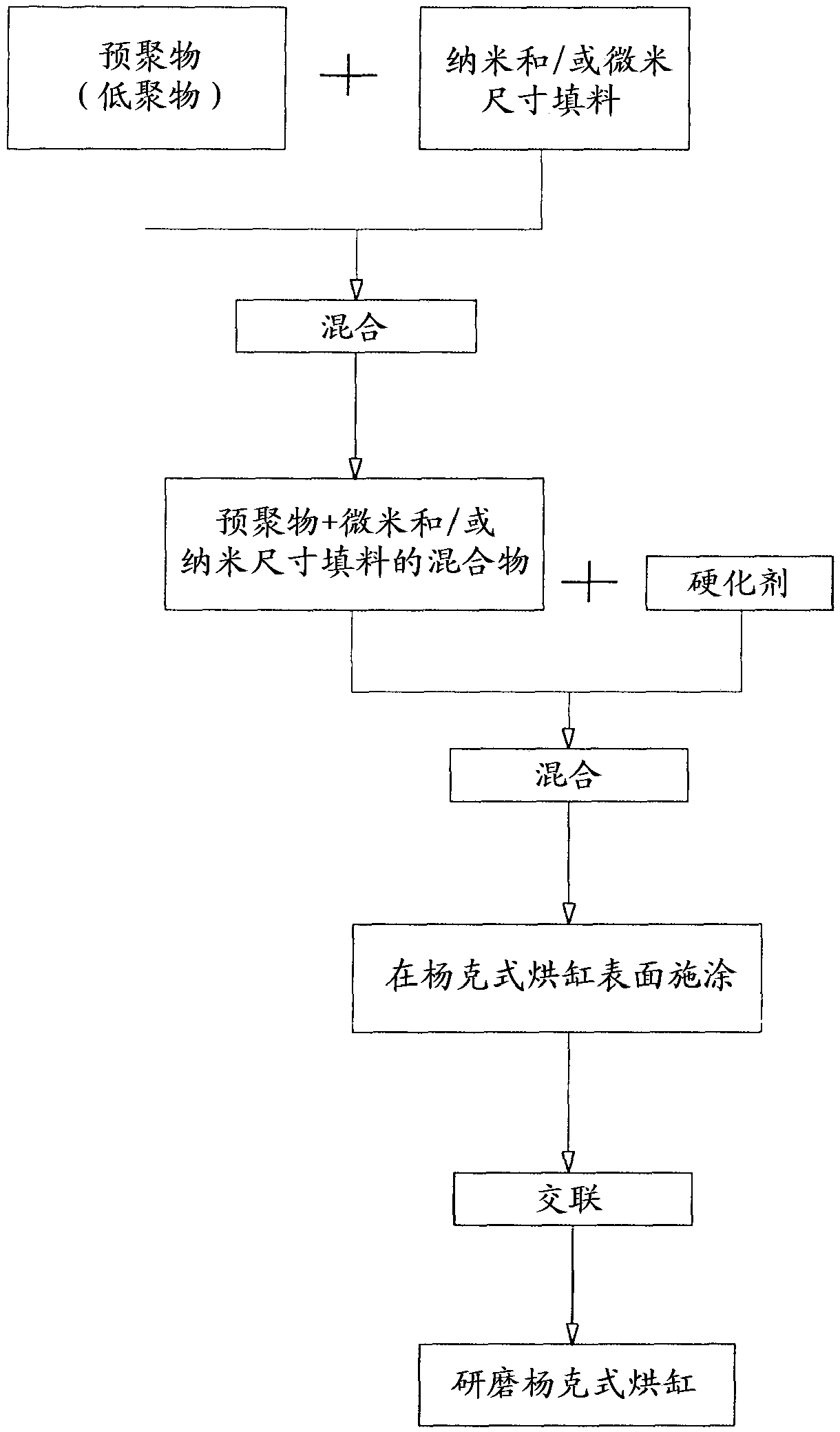

Method for coating paper mill cylinders and cylinders thus obtained

Owner:A CELLI PAPER

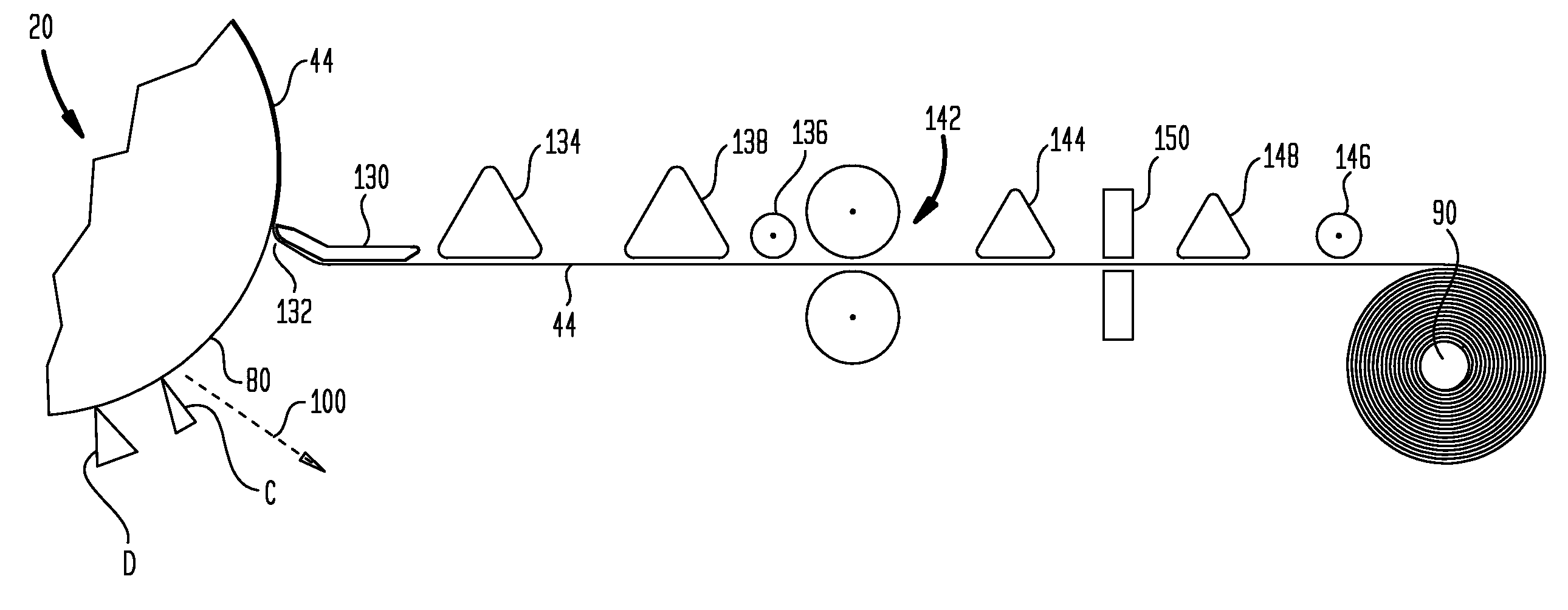

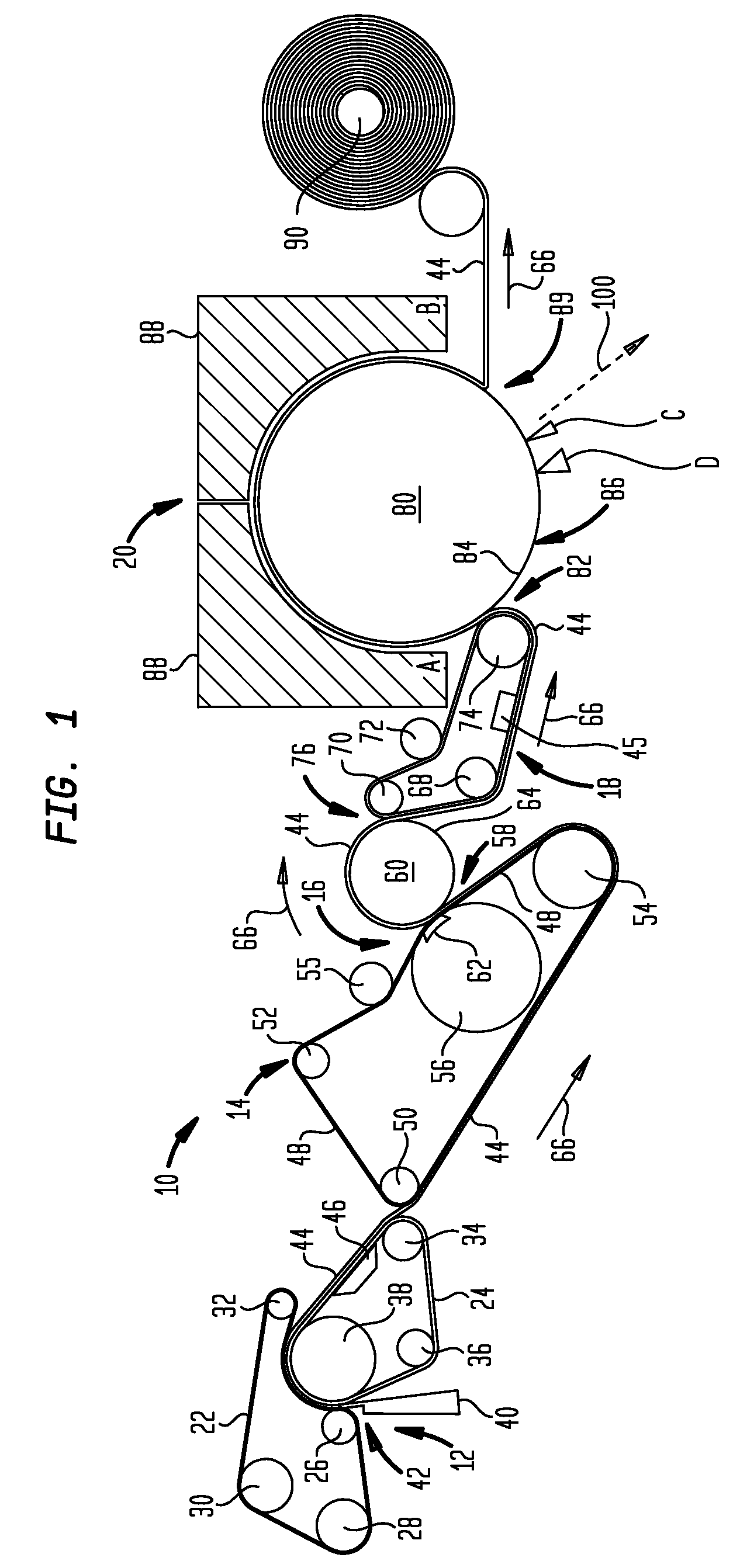

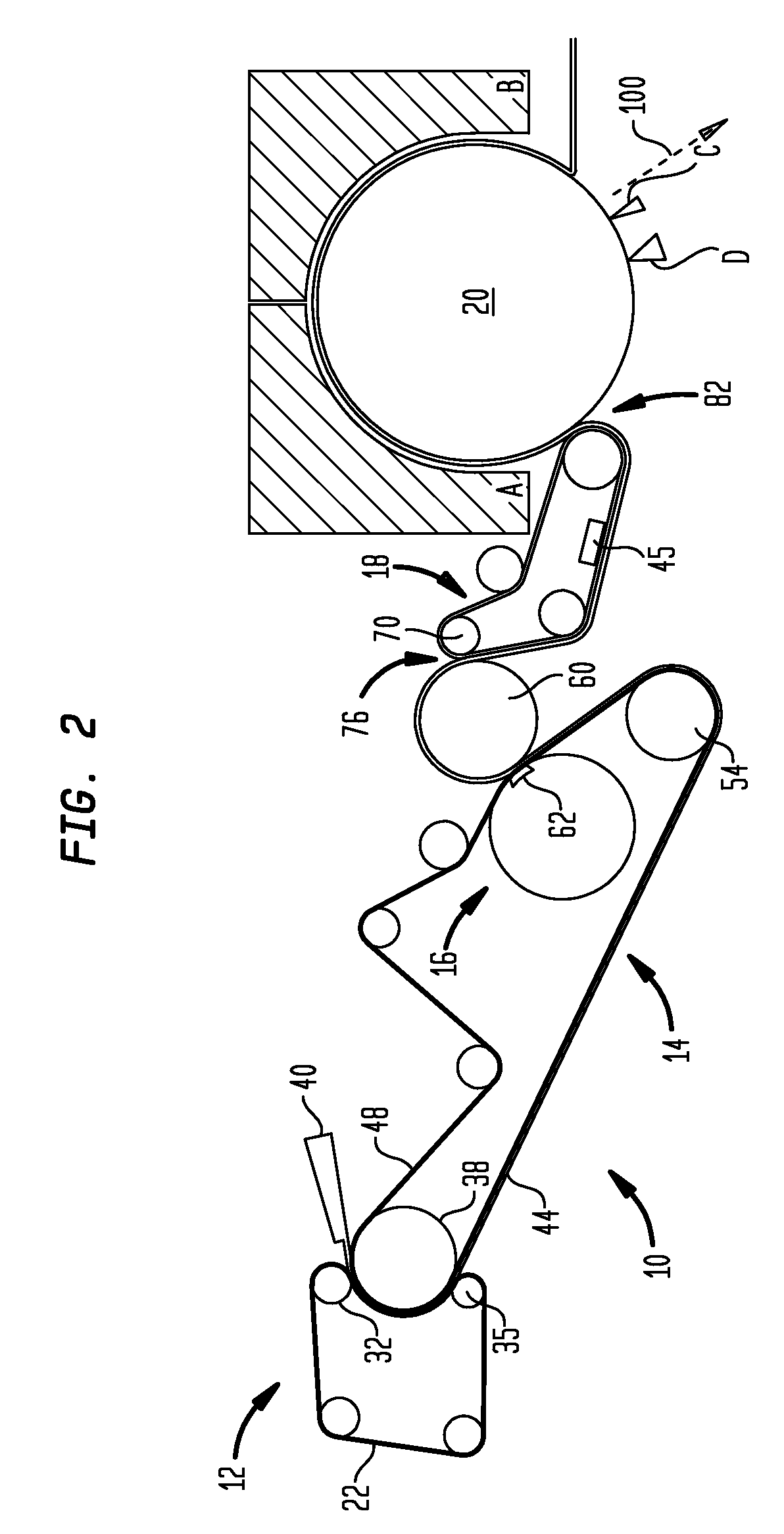

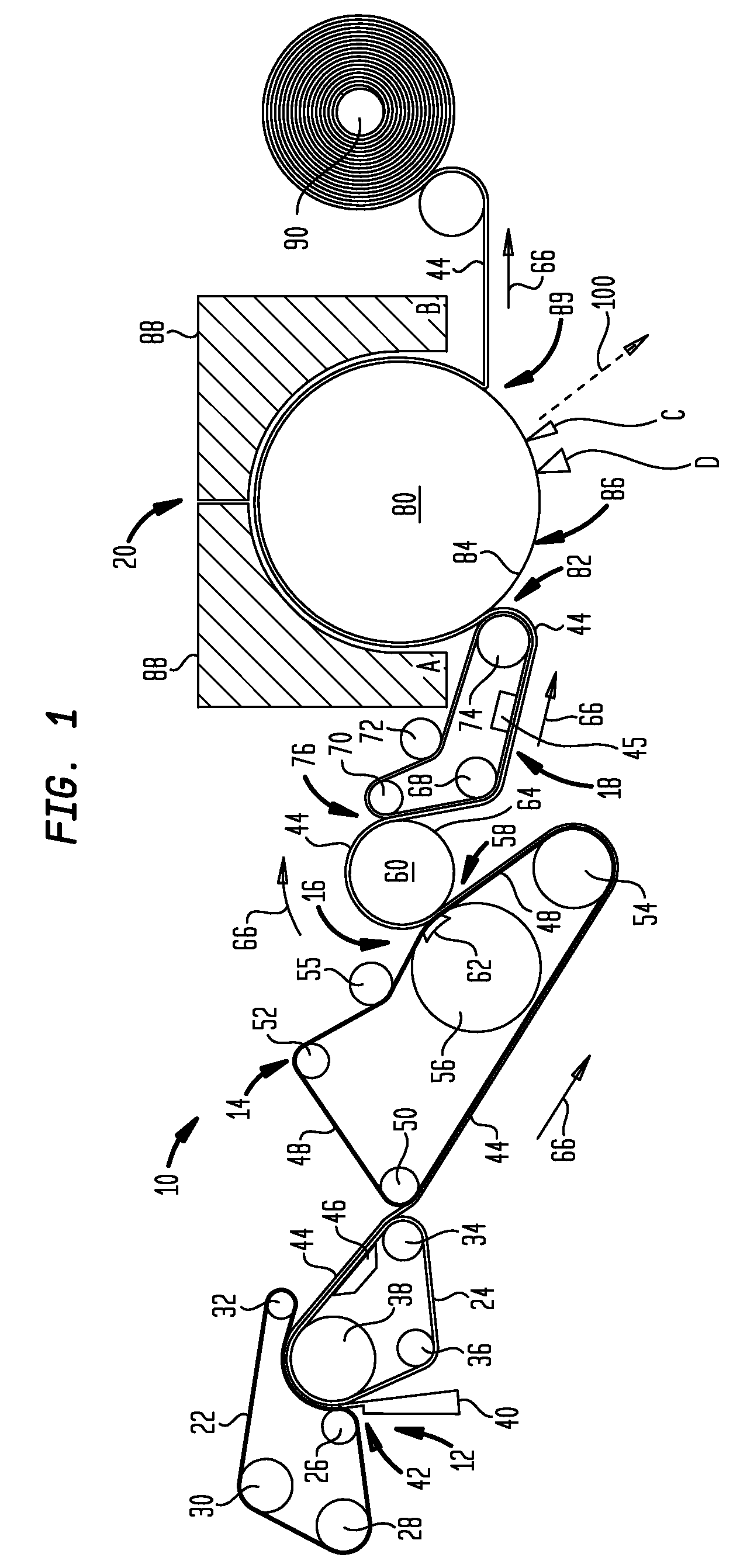

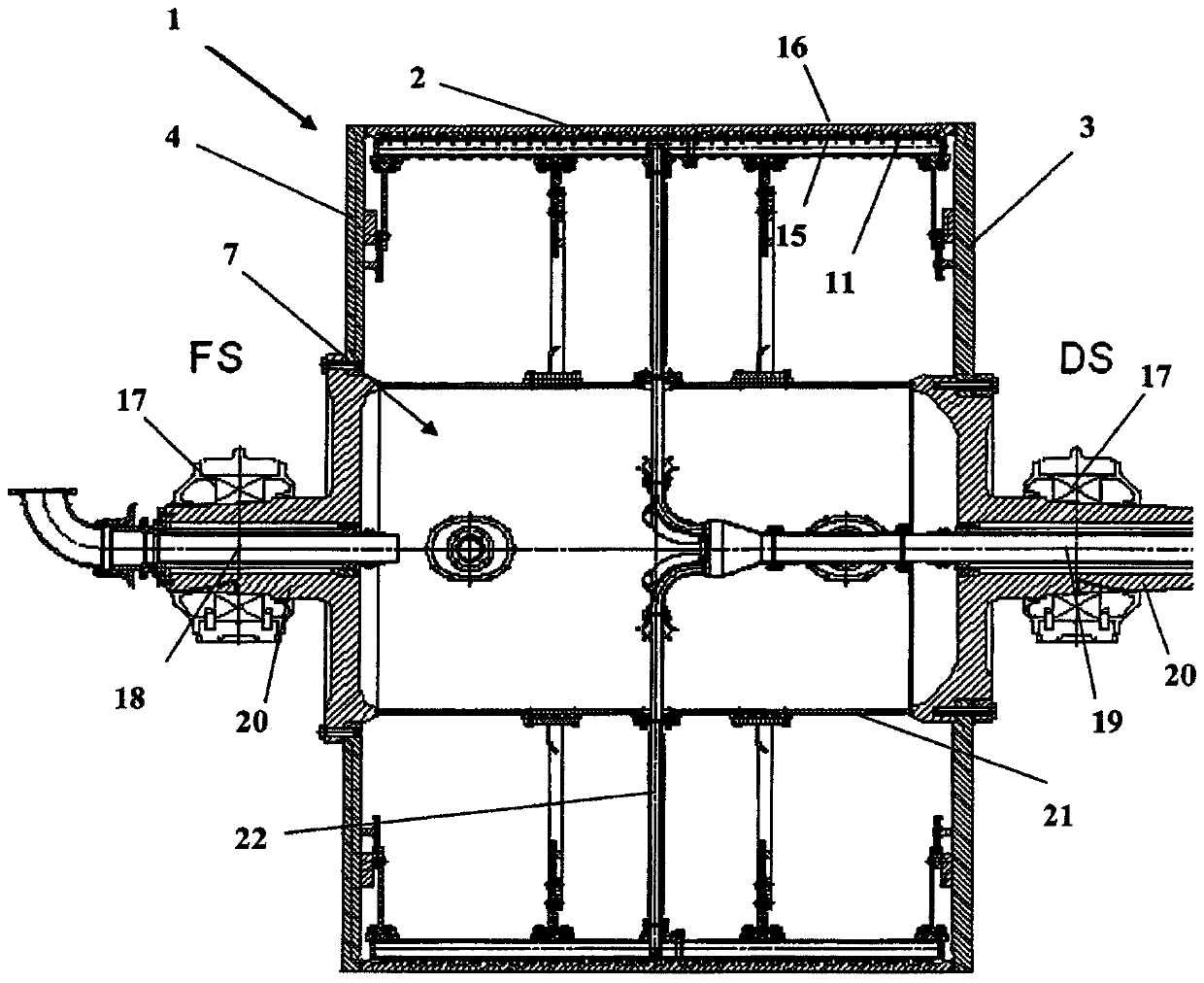

Arrangement within yankee cylinder or like roller of paper machine

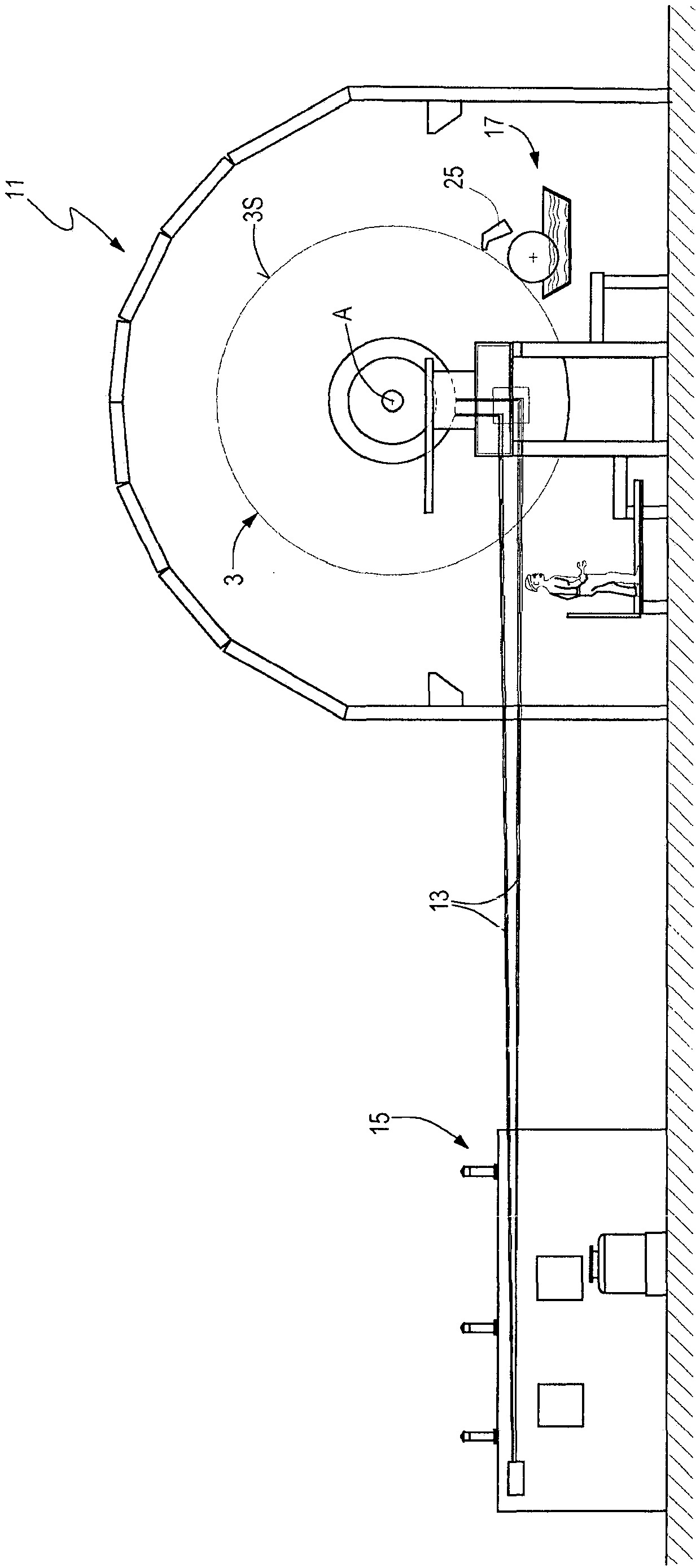

The invention relates to an arrangement within a Yankee cylinder or the like at the dry end of a paper machine, which arrangement comprises at least a drying cylinder, a hood covering the drying cylinder, web guiding means, and a roller. After the drying cylinder at the dry end of the machine, seen in the machine direction, a covered area which above and on the sides is at least mainly covered extends at least to the area of the roller.

Owner:METSO PAPER INC

Coding system for satellite navigation system

ActiveUS9952052B2Instruments for road network navigationGeographical information databasesParking areaYankee

The present invention provides a method, the QCODE method, of geotagging all postal addresses and other points of interest that one might want to navigate to and which allows the user to identify these addresses and other points of interest with a code consisting of 6 alphanumeric characters or less. A point of interest may or may not have a street address, for example, “the main entrance to the Jefferson Building at the USPTO complex in Alexandria Virginia” or “the entrance to the VIP parking area at Yankee Stadium”. The disclosure teaches embodiments that are naturally upgraded to integrate changing spatial information due to addition of countries, better data, political changes, and other similar changes in geographical data. A single geocoding engine is capable of handling the various address formats in use in different countries and jurisdictions.

Owner:HALE MERTON G

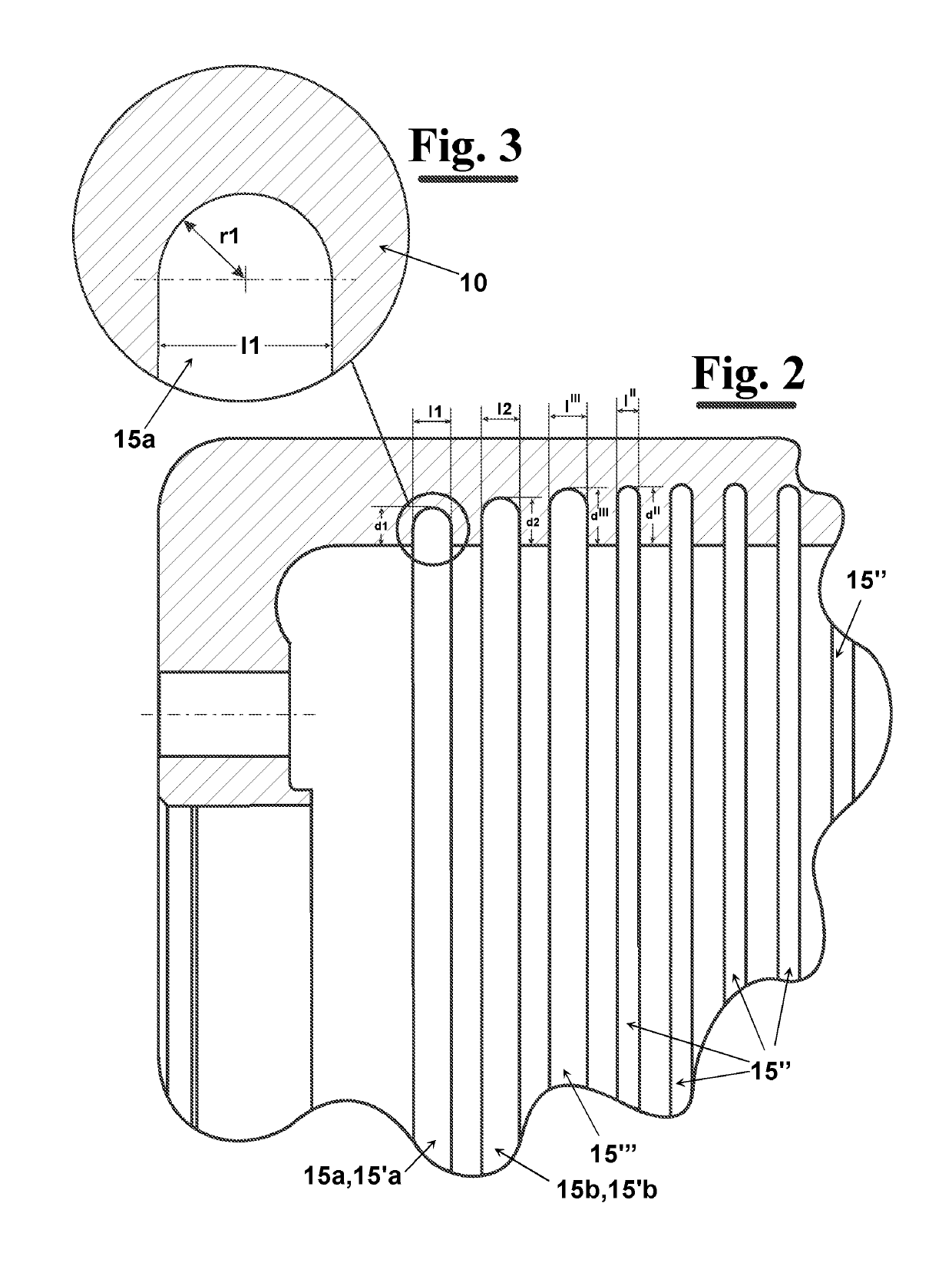

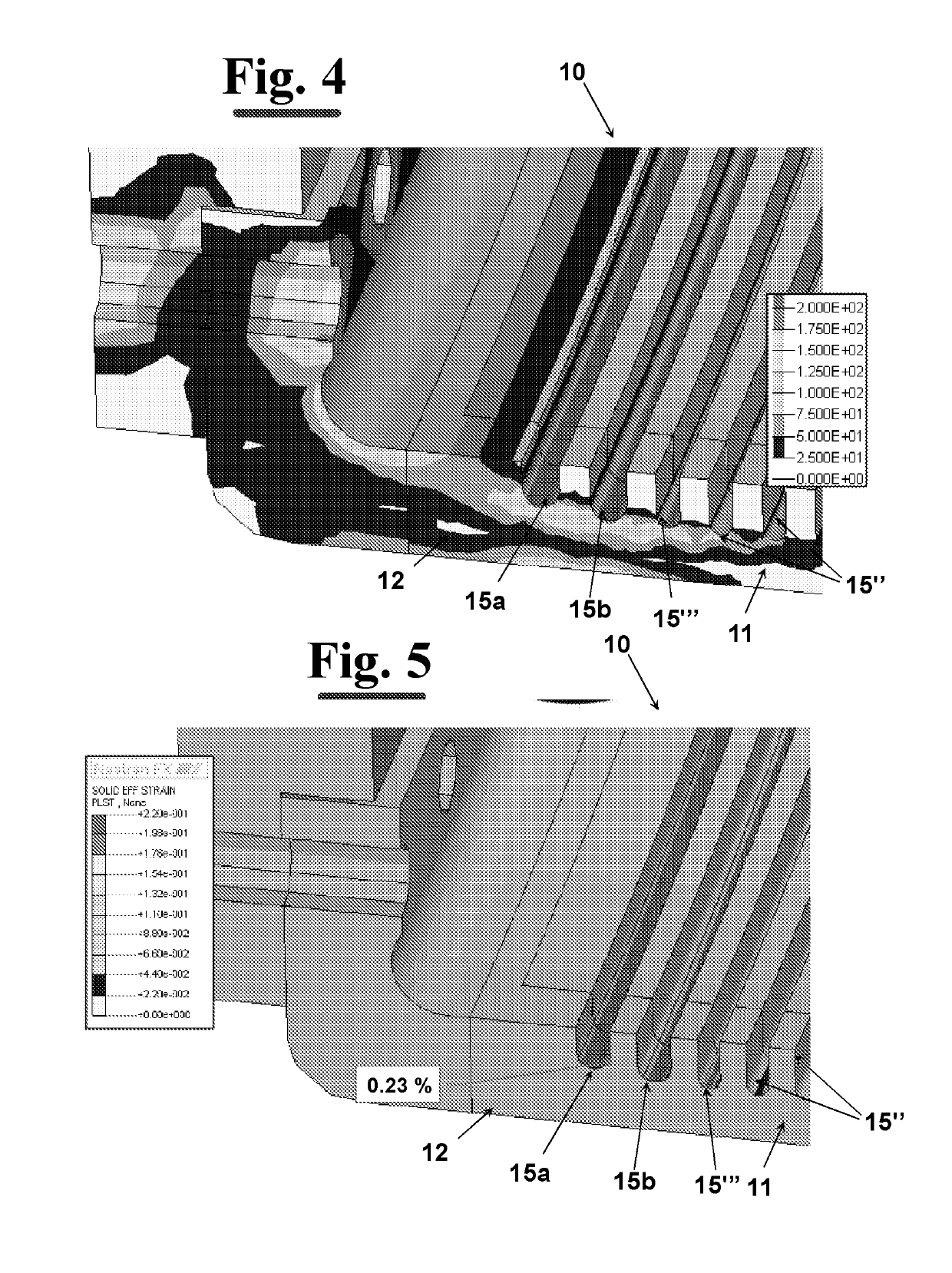

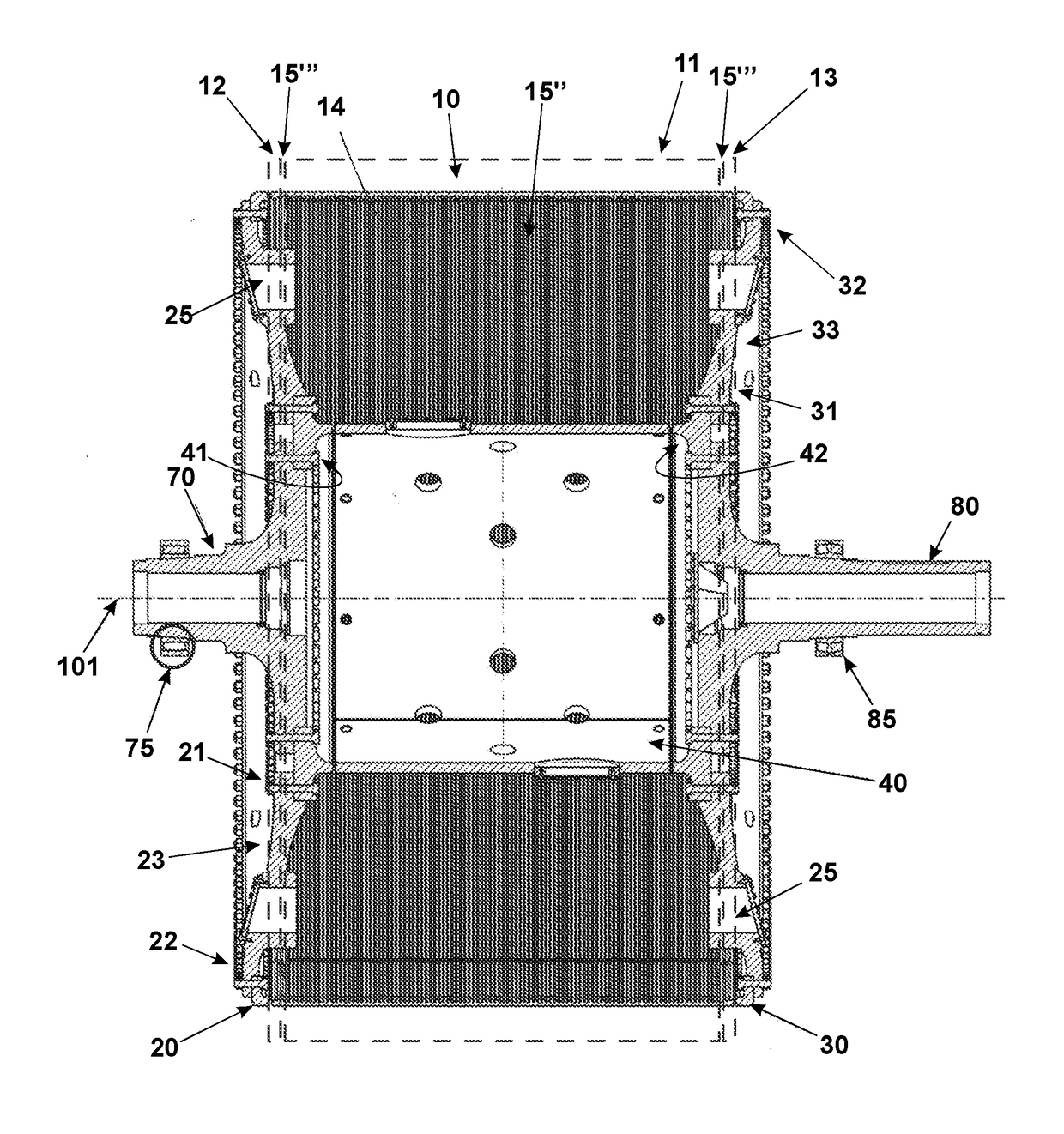

Yankee dryer cylinder with improved internal geometry

ActiveUS10519600B2Improve performance and service lifeEvenly distributedDryer sectionDrying machines with non-progressive movementsEngineeringYankee

Owner:A CELLI PAPER

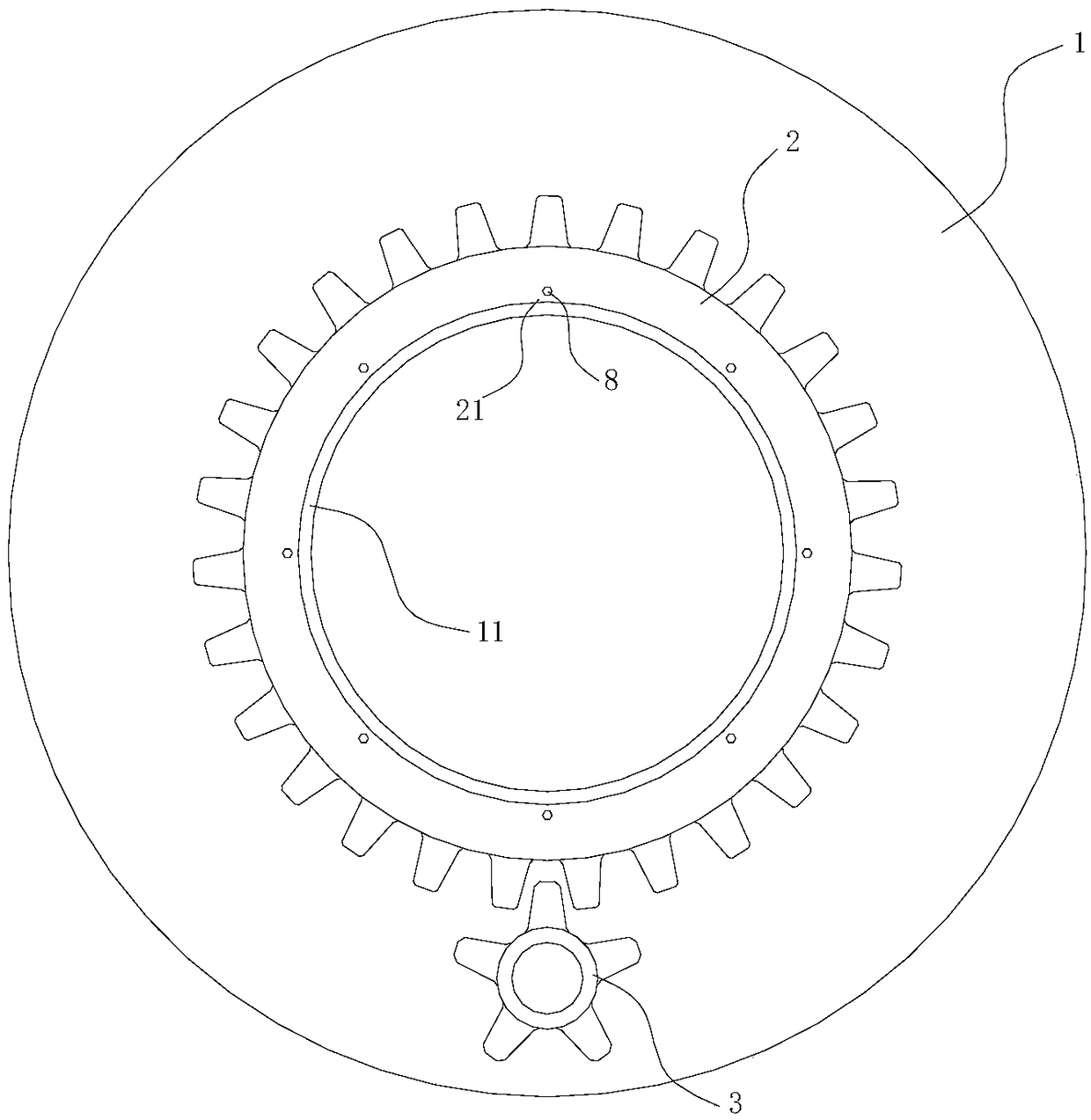

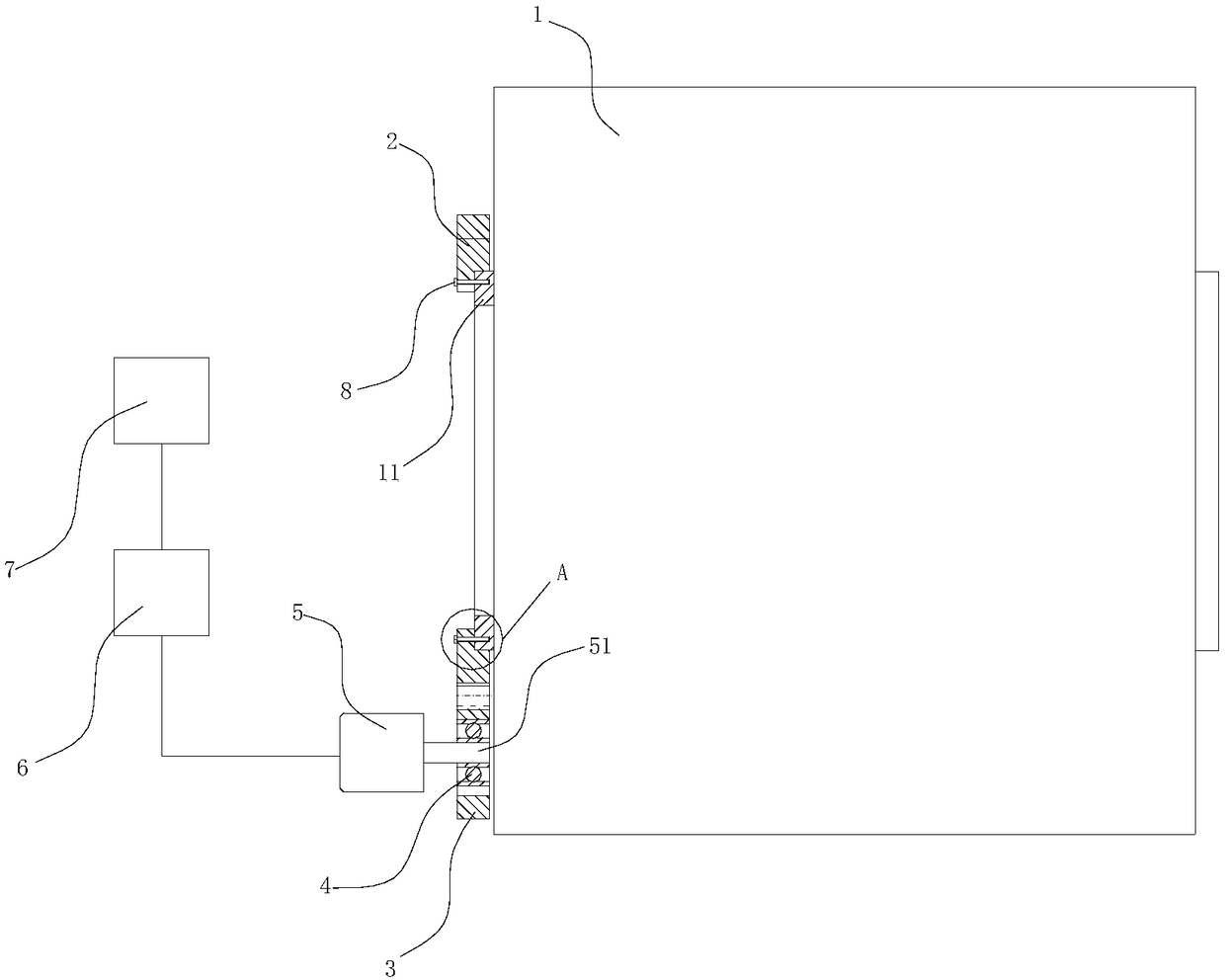

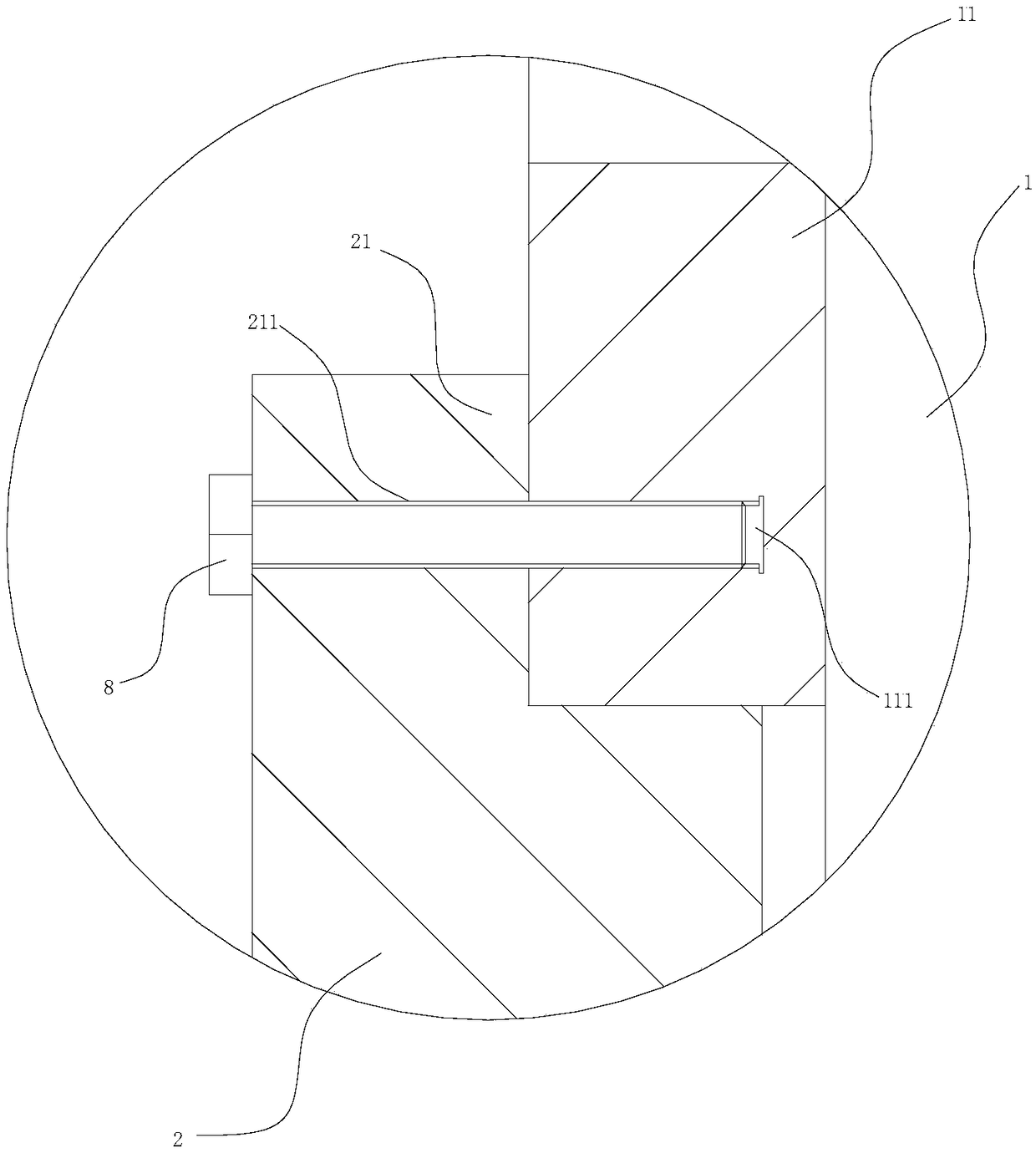

Automatic winching device for Yankee dryer

PendingCN108789024AEasy to assemble and disassembleEasy to replaceDryer sectionSeat surface grinding machinesEngineeringYankee

The invention discloses an automatic winching device for a Yankee dryer. The automatic winching device for the Yankee dryer comprises the Yankee dryer with a main drive system, wherein a steel supportring coaxial with the Yankee dryer is arranged at the two axial sides of the Yankee dryer separately. The automatic winching device for the Yankee dryer further comprises a gear ring, a gear matchedwith the gear ring, a one-way clutch, a speed reduction motor, a frequency converter and a controller, wherein the gear ring sleeves the circumferential outer side of the steel support ring; the speedreduction motor is installed aside the Yankee dryer; the axis of an output shaft of the speed reduction motor is parallel to the axis of the Yankee dryer; the one-way clutch is arranged in a gear shaft hole; an outer ring of the one-way clutch is connected with the gear; the output shaft of the speed reduction motor is connected with an inner ring of the one-way clutch; the gear, the one-way clutch and the output shaft of the speed reduction motor are coaxial; the gear is engaged with the gear ring; the frequency converter is connected with the speed reduction motor; the frequency converter and the main drive system of the Yankee dryer are connected with the controller separately; and the speed reduction motor and the main drive system of the Yankee dryer form alternately-running controlinterlocking through the controller. The automatic winching device for the Yankee dryer is capable of automatically carrying out winching operation on the Yankee dryer in the case of halt of the maindrive system of the Yankee dryer.

Owner:CHINA TOBACCO ANHUI RECONSTITUTED TOBACCO SCI & TECH CO LTD

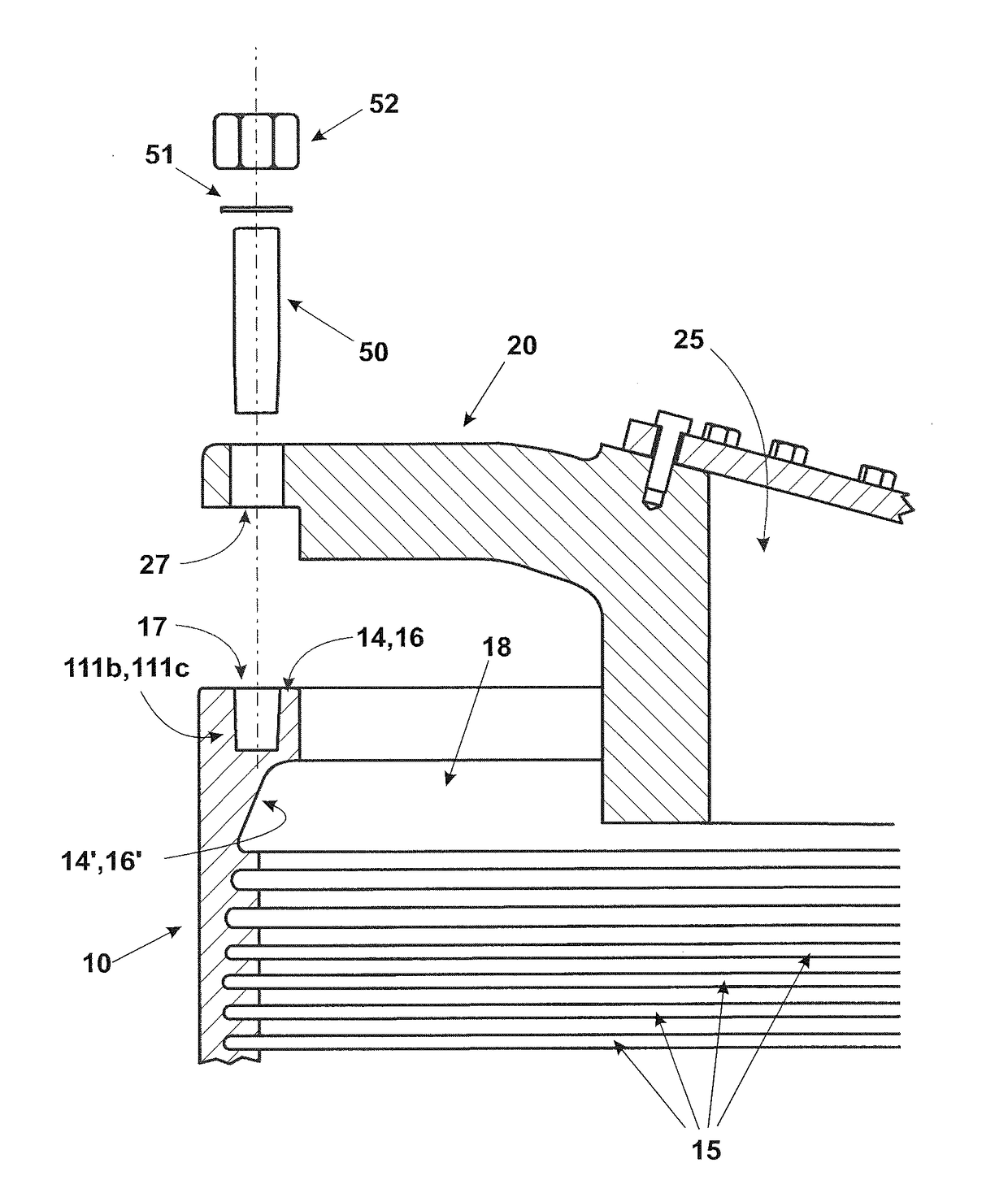

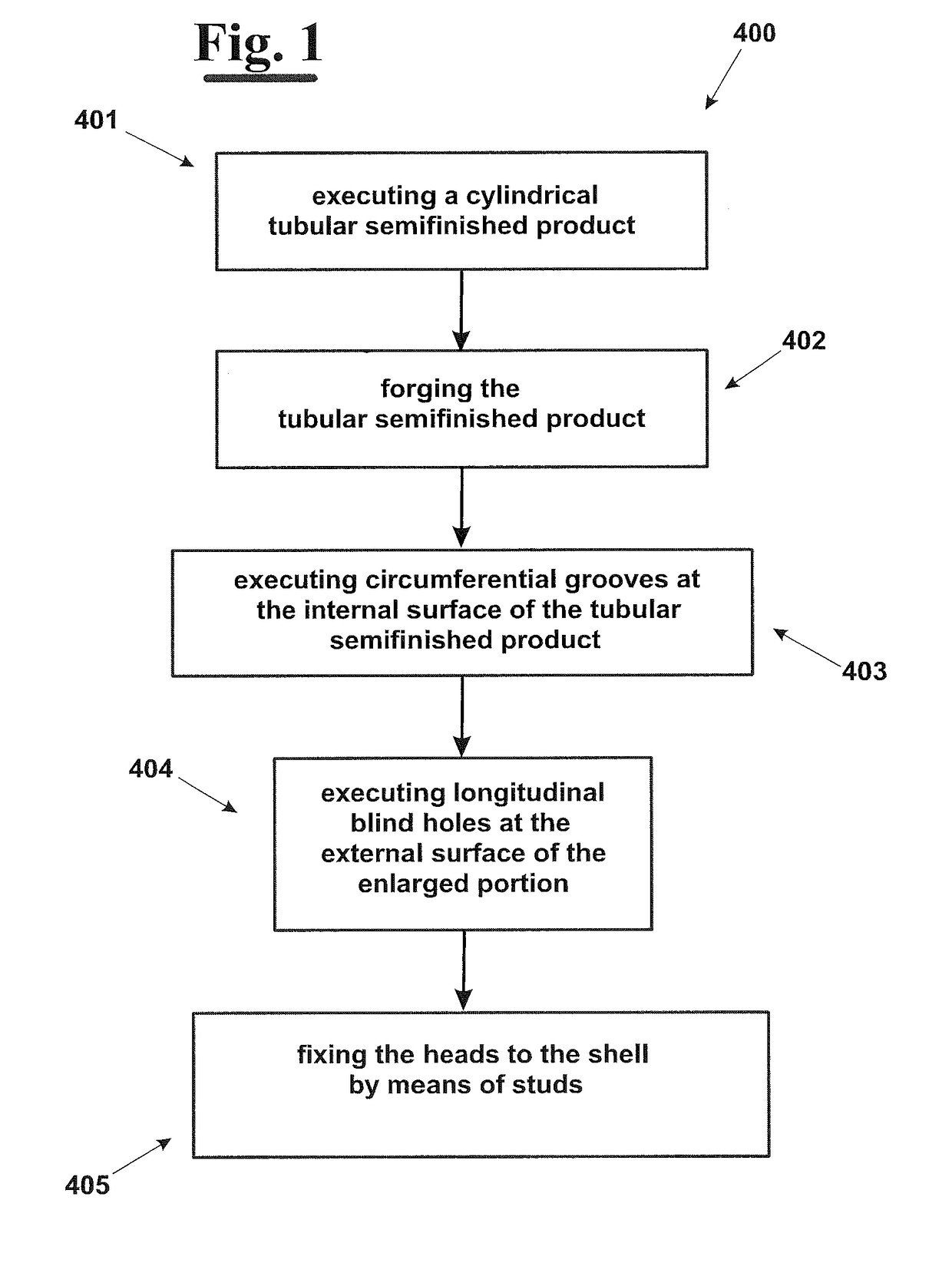

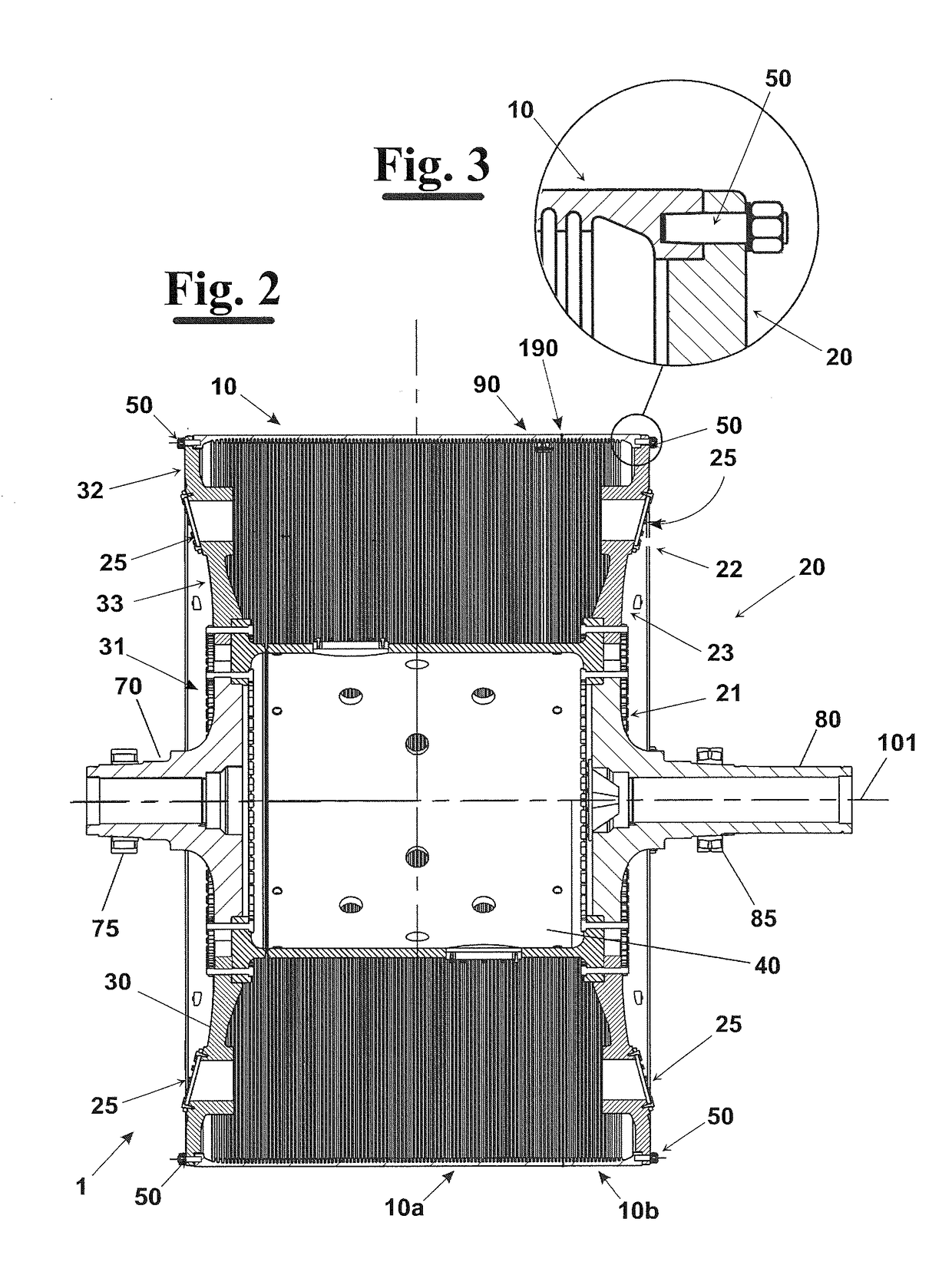

Method for producing an improved yankee cylinder

ActiveUS20180171556A1Improve performanceExtended service lifeDryer sectionDrying machines with progressive movementsWork in processYankee

A method for producing a Yankee dryer cylinder, or Yankee cylinder, includes the steps of executing a cylindrical tubular semifinished product made of steel and having a side wall provided with an internal surface and an external surface. A forging step of the cylindrical tubular semifinished product follows for obtaining predetermined thicknesses at the central portion and at the terminal portions of the side wall where the enlarged terminal portions are made. The cylindrical shell is completed executing a plurality of grooves at the internal surface of the cylindrical tubular semifinished product. Then a plurality of longitudinal blind holes are executed at the external surfaces of the enlarged terminal portions of the cylindrical shell. Then, the heads are positioned at each of enlarged terminal portion of the cylindrical shell to which they are fixed by means of studs that pass the blind holes of the shell and respective through holes of which the heads are provided.

Owner:A CELLI PAPER

Yankee dryer cylinder with improved internal geometry

ActiveUS20180051415A1Improve performance and service lifeEvenly distributedDryer sectionEngineeringYankee

Owner:A CELLI PAPER

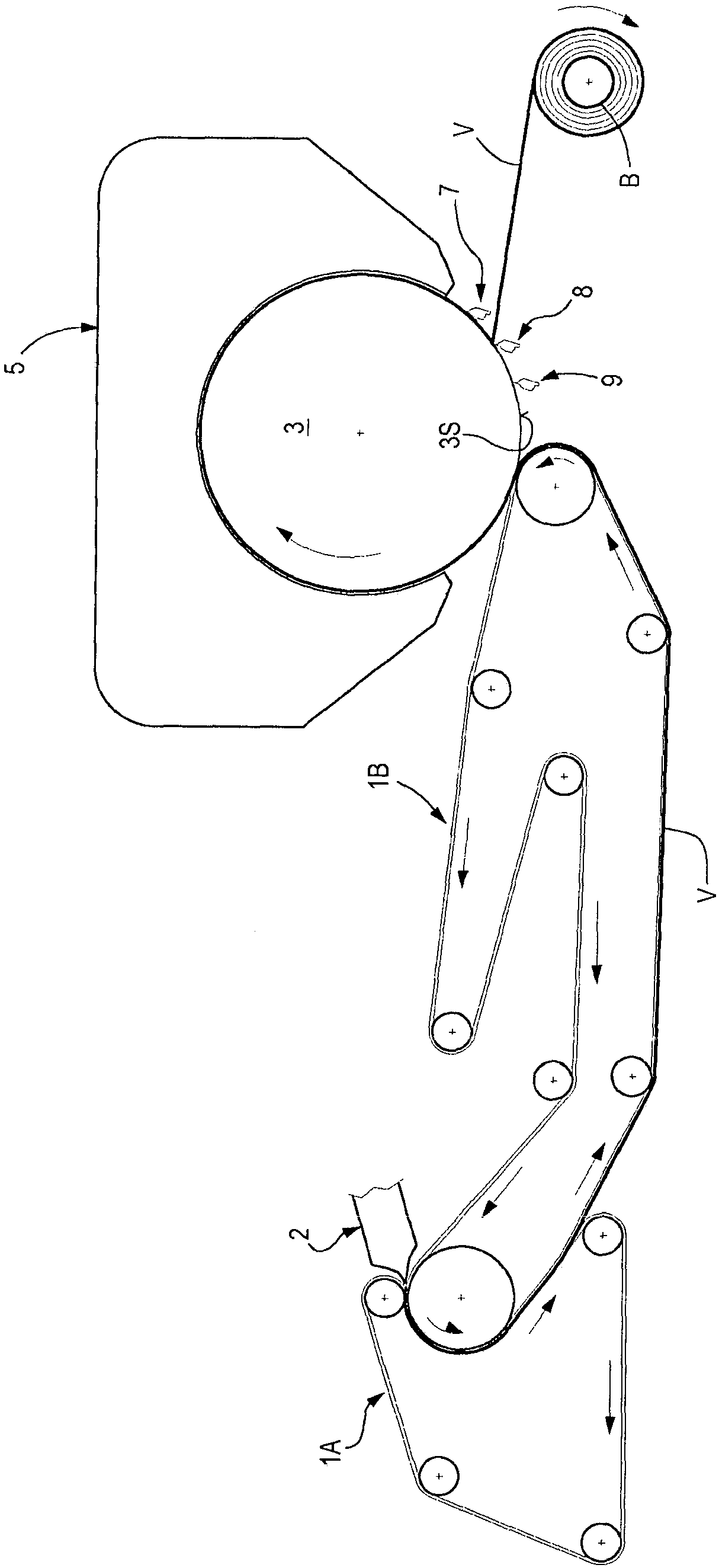

Arrangement within a yankee cylinder or the like and a roller of a paper machine

InactiveUS6896770B2Guaranteed uptimeImprove productivityAgriculture tools and machinesMechanical working/deformationYankeePaper machine

A Yankee cylinder or the like at the dry end of a paper machine has at least a drying cylinder, a hood covering the drying cylinder, a web guiding means, and a roller. After the drying cylinder at the dry end of the machine, seen in the machine direction, a covered area which above and on the sides is at least mainly covered extends at least to the area of the roller.

Owner:VALMET TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com