Method for producing a yankee dryer

A cylinder shell and site technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, paper making, etc., can solve the problems of no way to transport parts to customers, consume too much effort and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

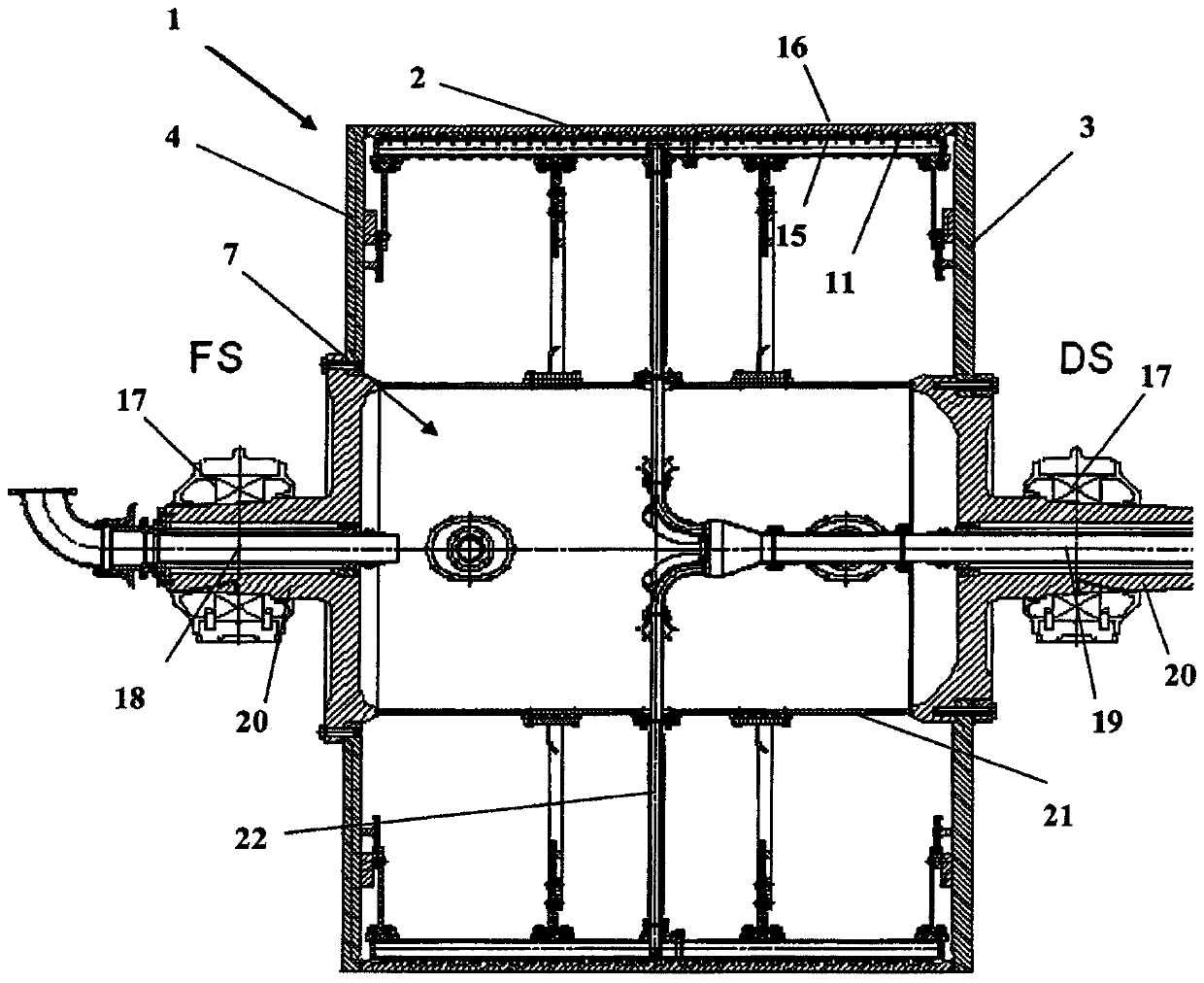

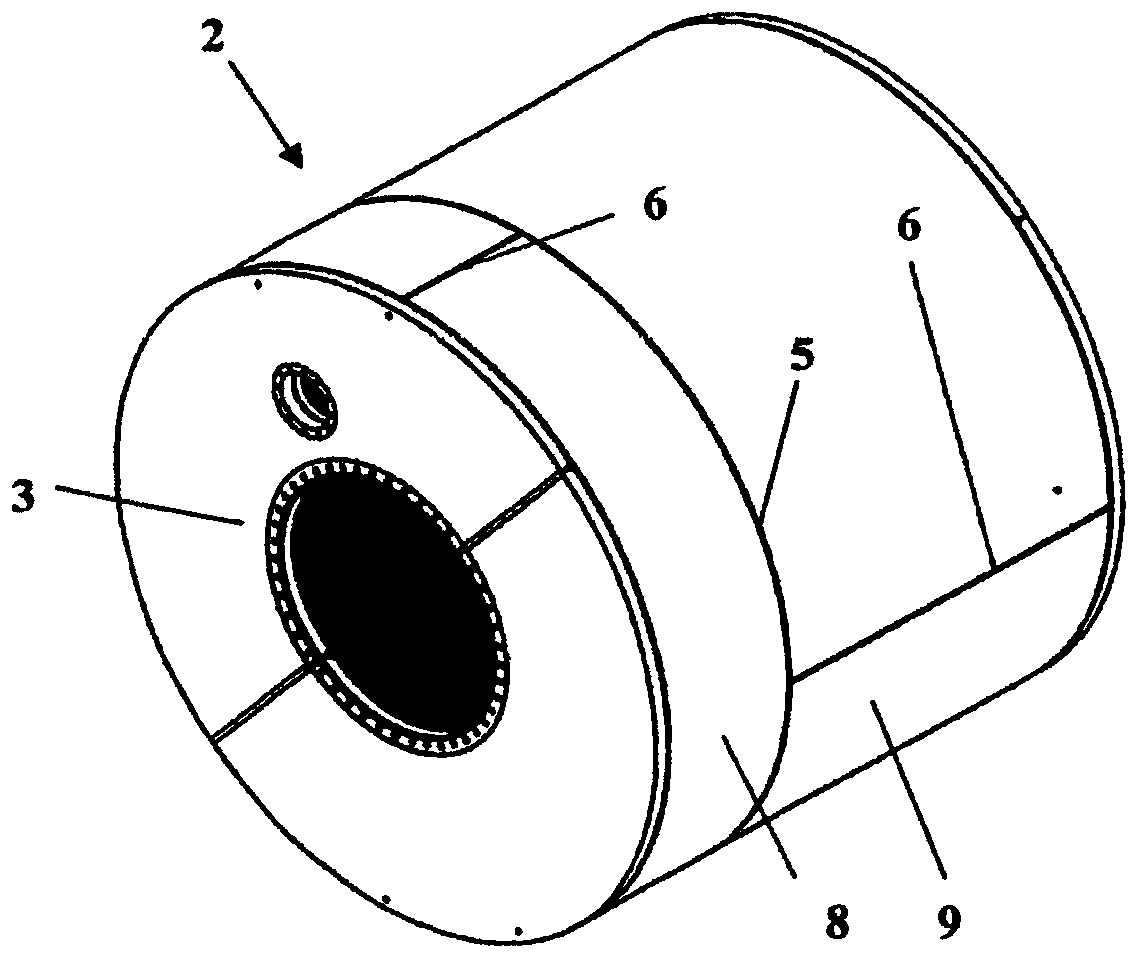

[0049] figure 1 The Yankee cylinder 1 is shown. The Yankee cylinder 1 includes a cylindrical steel casing 2 which is welded or bolted to two end covers 3 and 4.

[0050] Inside the Yankee cylinder 1, there are a central shaft 7 having a central portion 21 and two bearing shafts 20, and the two bearing shafts 20 rotate in the bearings 17.

[0051] During operation, steam is supplied to the Yankee cylinder 1 through the steam feed 18. Waste steam and condensed water are discharged from the Yankee cylinder through condensate pipes 22 and 19, respectively.

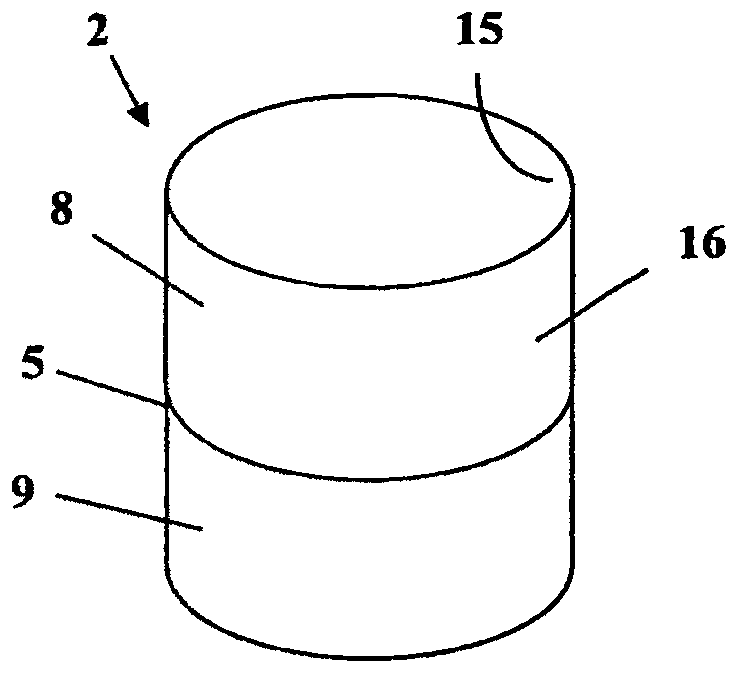

[0052] There are a large number of grooves 11 on the inside 15 of the cylinder barrel, and the grooves 11 extend in the circumferential direction of the Yankee cylinder 1. Through the groove 11, the heat transfer to the outside 16 of the cylinder barrel is enhanced, and the removal of condensed water is facilitated.

[0053] In the manufacturing methods used in the prior art so far, individual shell plates are cut, crimped and welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com