Method for coating paper mill cylinders and cylinders thus obtained

A technology of coating and coating film, which is applied in the direction of papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems of increased noise, irregular coating, uneven coating, etc., achieve effective heat exchange and wear resistance , good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

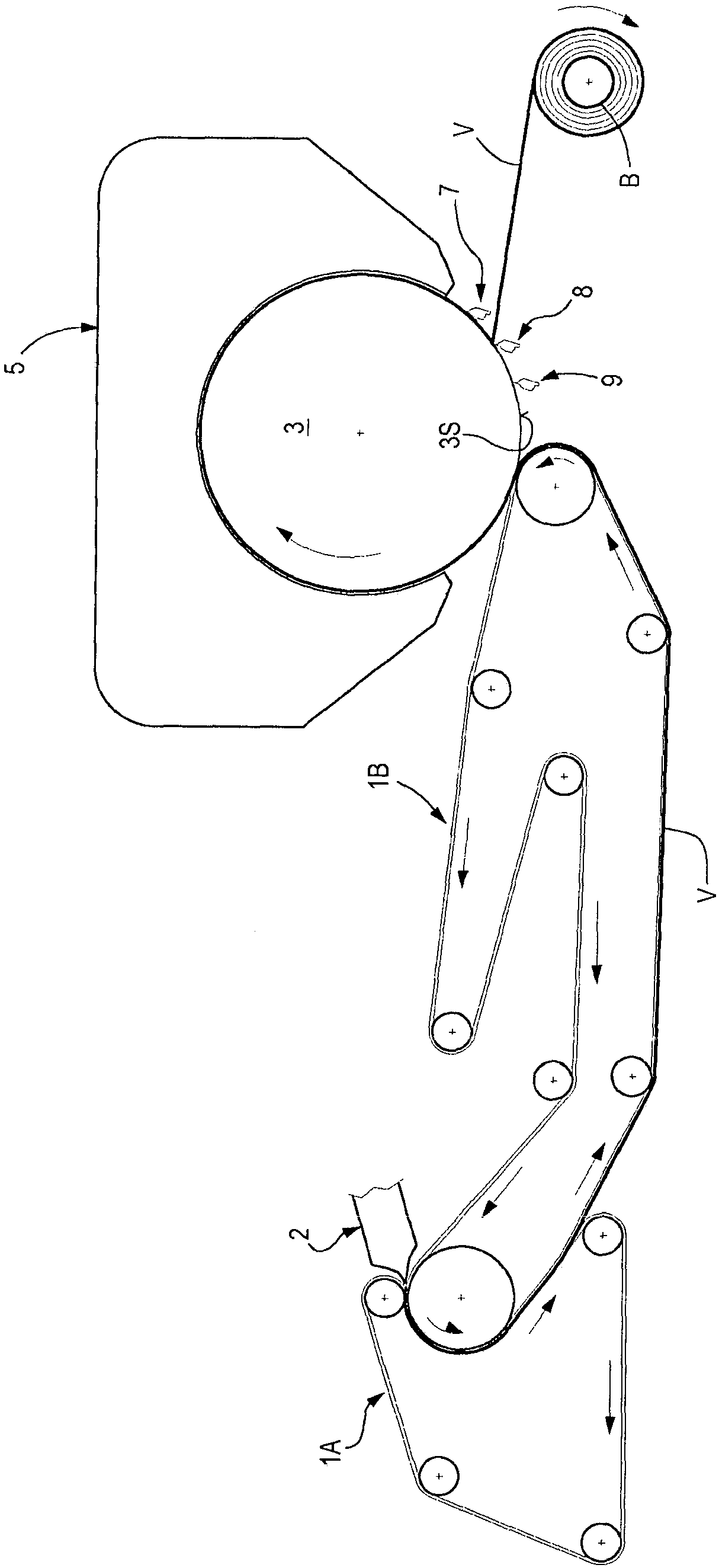

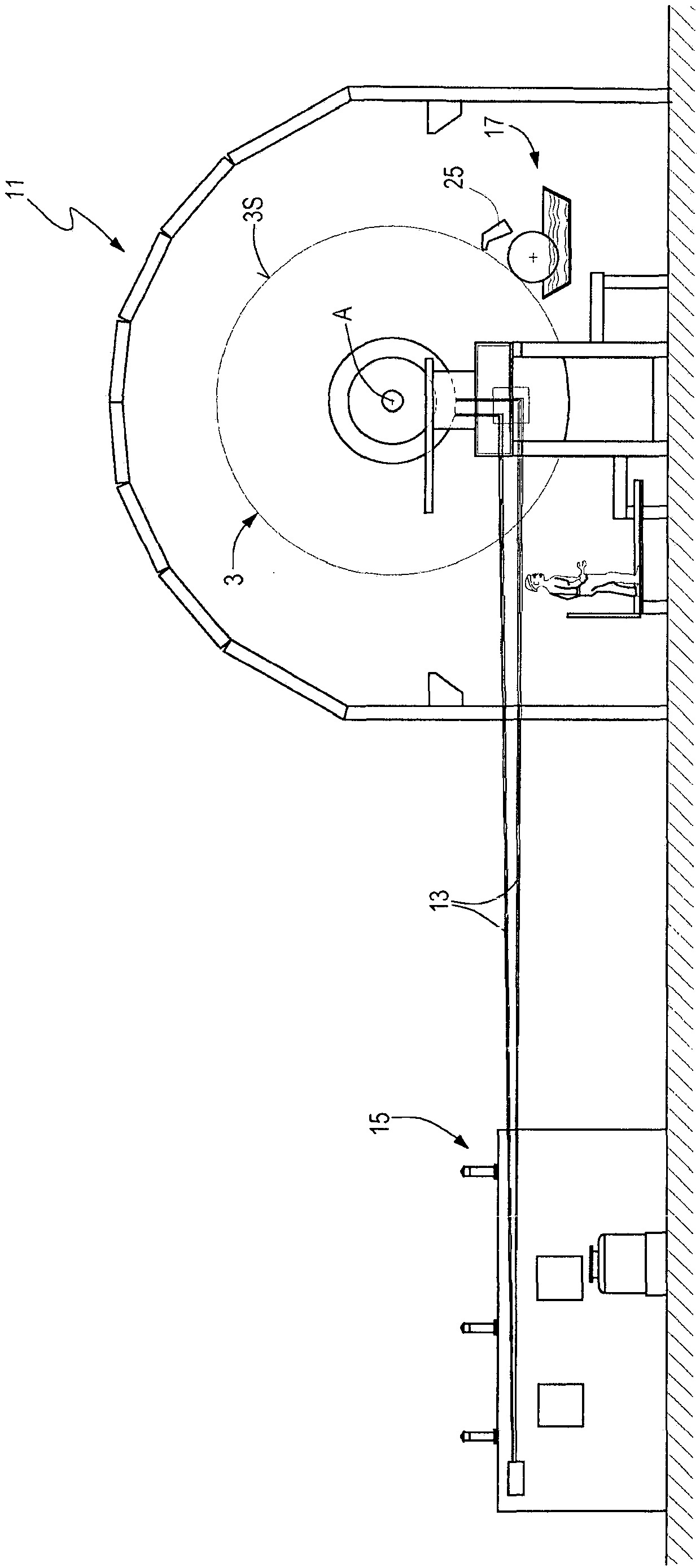

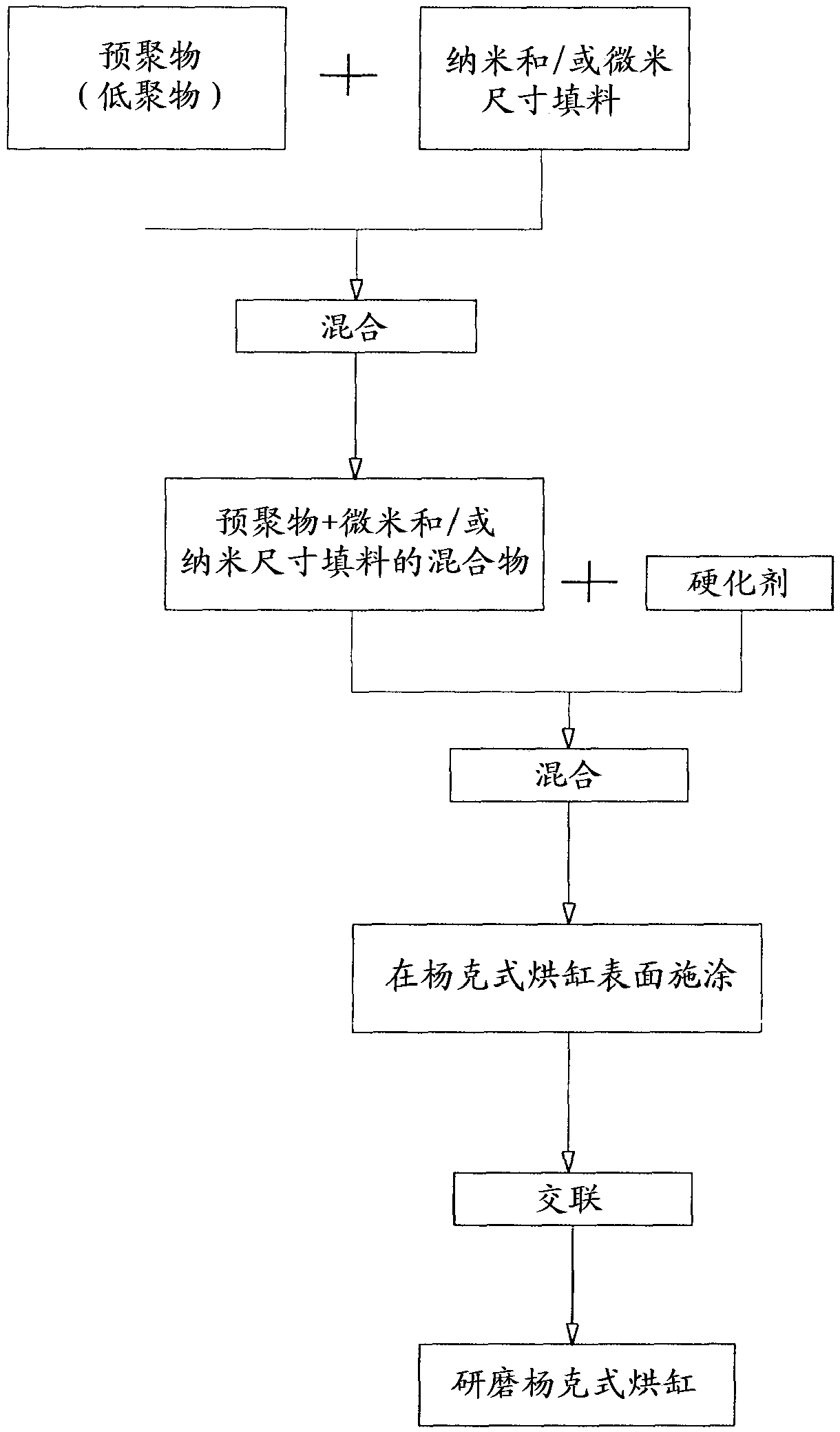

Method used

Image

Examples

Embodiment 1

[0090] Nanocomposite R1-A : 0.045g (1.5% by weight relative to the uncrosslinked epoxy resin) sodium montmorillonite (sold by Laviosa Chimica Mineraria SpA, Italy) and 1ml solvent (acetone) were added to 3g epoxy resin EPOSIR 7120 (supplied by SIR Industriale SpA, Italy). Then, 0.531 g of hardener (diethylenetriamine) was added to the above filled epoxy resin. The samples were kept at room temperature for 2 hours, then at 50°C for 2 hours, then at 70°C for 2 hours. The Rockwell hardness of the sample after crosslinking is equal to 62.1HRC.

Embodiment 2

[0092] Sample R1-B : 0.09 g (3% by weight relative to the uncrosslinked epoxy resin) of sodium montmorillonite (MMT, Laviosa) and 1 ml of solvent were added to 3 g of epoxy resin EPOSIR 7120. Then, 0.531 g of hardener (diethylenetriamine) was added to the above filled epoxy resin. The samples were kept at room temperature for 2 hours, then at 50°C for 2 hours, then at 70°C for 2 hours. After cross-linking, the sample had a Rockwell hardness of 62.1 HRC; the sample had been deposited on a spatula to a thickness of 1 mm.

Embodiment 3

[0094] Nanocomposite R1-C : 0.045 g (1.5% by weight relative to the epoxy resin) of multi-walled carbon nanotubes (MWCNT) Baytubes C150P (sold by BAYER MATERIAL-SCIENCE AG, Germany) and 1 ml of solvent were added to 3 g of epoxy resin EPOSIR 7120. Then, 0.531 g of hardener (diethylenetriamine) was added to the above filled epoxy resin. The samples were kept at room temperature for 2 hours, then at 50°C for 2 hours, then at 70°C for 2 hours. After crosslinking, the Rockwell hardness of the sample was 60.3HRC.

[0095] In addition to the three examples listed in the table, the following samples were also prepared:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com