Method for forming foaming layer on surface of container or container semi-finished product

A semi-finished product and foam layer technology, which is applied to hollow objects, other household appliances, household appliances, etc., can solve the problems of weakening the convenience of paper cups, unable to form three-dimensional patterns, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical features and expected effects of the present invention will be described below through preferred embodiments, but they are not intended to limit the protection scope of the present invention, and will be described first.

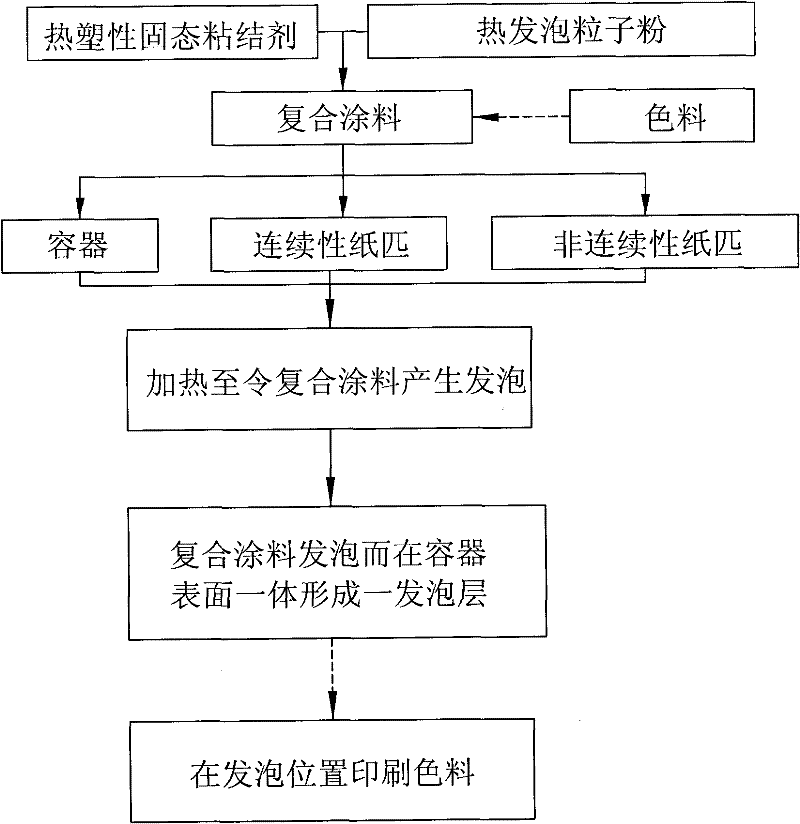

[0044] Please refer to figure 1 . A method for forming a foam layer on the surface of a container or a semi-finished container comprises the following steps:

[0045] a) Stir or knead the thermoplastic solid binder with a plurality of solid expanded particles until the thermoplastic solid binder forms a jelly, and the solid expanded particles are uniformly dispersed in the jelly binder to form a composite Coating, wherein each of the expanded particles is formed by coating a low-boiling point solvent in a thermoplastic polymer, and the above-mentioned heating temperature is lower than the boiling point of the low-boiling point solvent, and the preferred mixing of the thermoplastic solid binder and the solid expanded particles The ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com