Nano metal oxide-containing solvent-based vehicle thermal insulation coating

A nano-metal and thermal insulation coating technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of time-consuming, high cost, brittleness, etc., and achieve the effect of overcoming easy aggregation, taking into account anti-corrosion, and reducing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 prepares the acrylic resin A containing nanometer metal oxide

[0019] Concrete preparation steps are as follows:

[0020] ①Preparation of nano metal oxide sol

[0021] First use ultrasonic or high-speed dispersion to disperse 100g of nano-metal oxide CuO with a particle size of 7nm in 250g of solvent butyl acetate to form a sol, then add it to a reaction vessel equipped with a condenser, a stirrer, and a thermometer, stir and After the temperature was raised to 60°C, 50g of silane coupling agent vinyltrimethoxysilane was added dropwise, and the reaction was kept under stirring for 4h to obtain the nano-metal oxide CuO sol. In the total weight of the nano-metal oxide sol, the nano-metal oxide CuO accounted for 25wt%, silane coupling agent vinyltrimethoxysilane accounts for 12.5wt%;

[0022] ②Preparation of acrylic resin A containing nano-metal oxides

[0023] Add 100 g of nano-metal oxide CuO sol and 100 g of solvent xylene prepared in step ① into a reac...

Embodiment 2

[0025] Embodiment 2 prepares the acrylic resin B containing nanometer metal oxide

[0026] Concrete preparation steps are as follows:

[0027] ①Preparation of nano metal oxide sol

[0028] It is basically the same as Example 1, the difference is: the nanometer metal oxide MnO with a particle diameter of 15nm 2 Substituting the nanometer metal oxide CuO with a particle size of 7nm; the prepared nanometer metal oxide MnO 2 In the total weight of the sol, the nanometer metal oxide MnO 2 Accounting for 25wt%, the silane coupling agent vinyltrimethoxysilane accounts for 12.5wt%;

[0029] ②Preparation of acrylic resin B containing nano-metal oxides

[0030] Add the nanometer metal oxide MnO prepared in step ① into a reaction vessel equipped with a condenser, a stirrer, a thermometer and a dropping funnel 2 Sol 100g and solvent xylene 332g, stir evenly, heat up to 140°C, add dropwise 90g styrene, 180g methyl methacrylate, 6g acrylic acid, 144g butyl methacrylate, 36g isooctyl ac...

Embodiment 3

[0032] Embodiment 3 prepares transparent solvent-based vehicle thermal insulation coating containing nanometer metal oxide

[0033] ① Coating formula

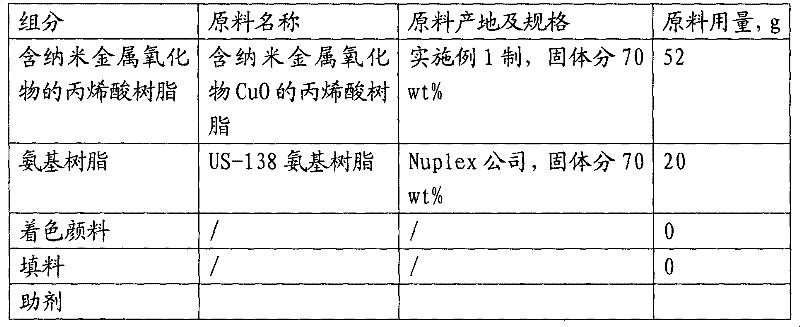

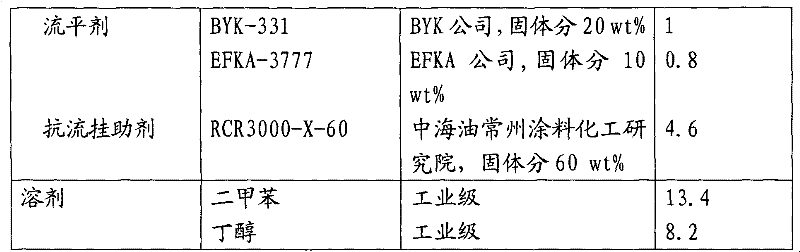

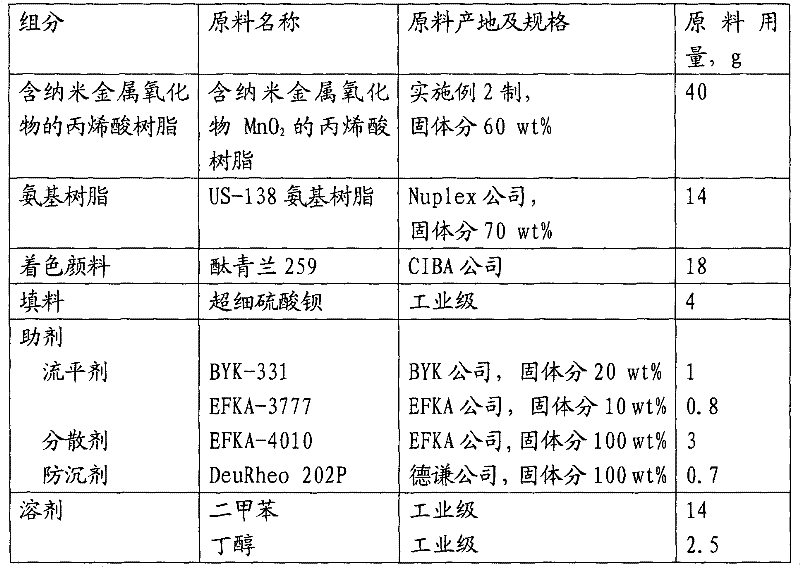

[0034] It is composed of the following components. Except for solvent, the content of each component is as follows in terms of solids: acrylic resin containing nanometer metal oxide accounts for 36.4wt%, amino resin accounts for 14wt%, coloring pigment accounts for 0wt%, and filler accounts for 0wt%. The solvent accounts for 3.04wt%, and the solvent accounts for 46.56wt% (including the solvent contained in the remaining components). The sum of the above components is 100%. The raw material consumption of each component is shown in Table 1.

[0035] Table 1

[0036]

[0037]

[0038] ②Preparation process

[0039] The transparent solvent-based vehicle heat-insulating coating containing nanometer metal oxide is prepared according to the existing technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com